Development and Performance Evaluation of High Temperature Salt Resistant Drilling Lubricant

-

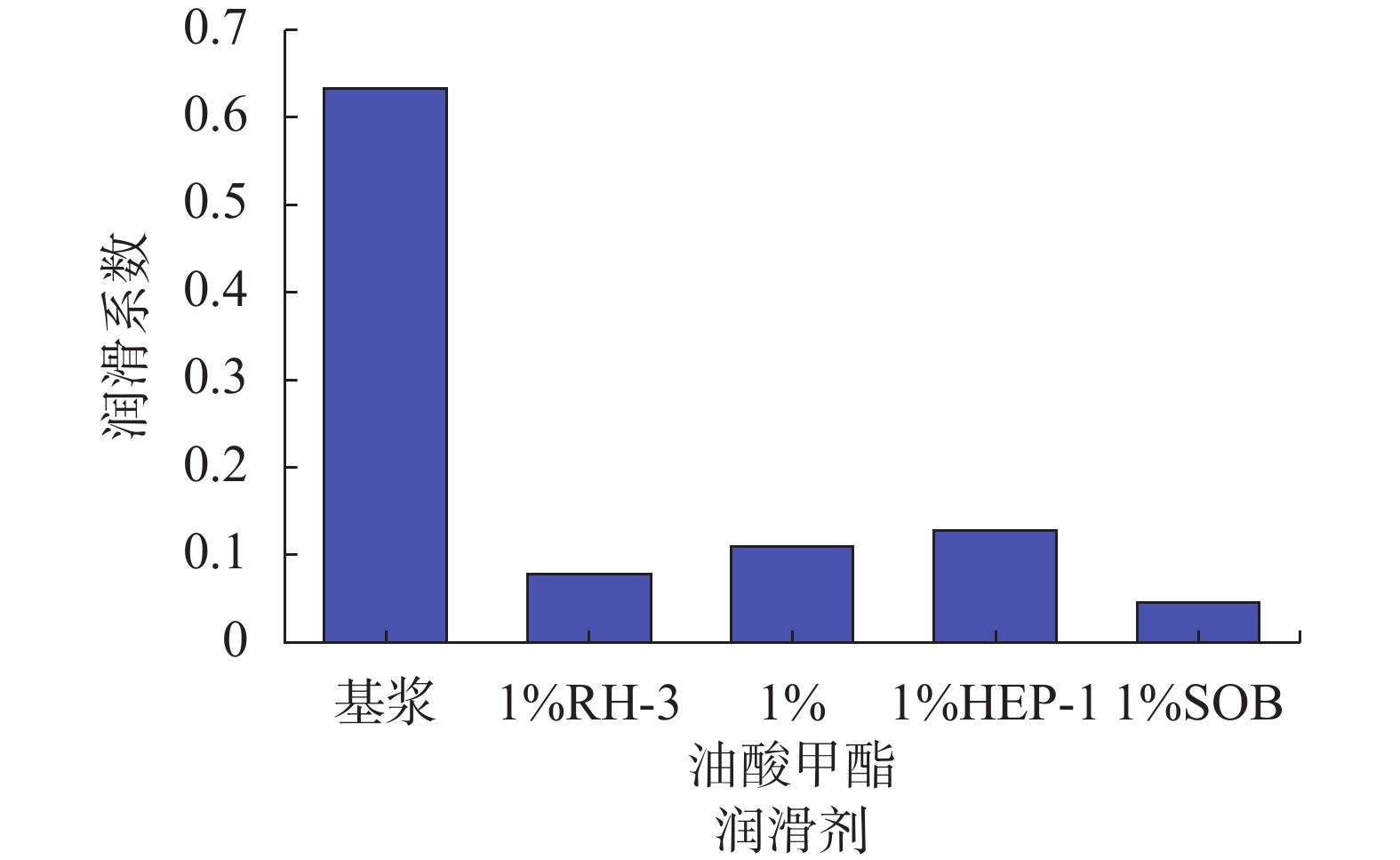

摘要: 针对深井超深井钻井过程中高扭矩和高摩阻等难题,利用硼酸、多元醇和长链脂肪酸等原料,合成出一种耐高温高盐钻井液润滑剂SOB,该润滑剂在高温高盐条件下具有良好的润滑性能。在5%基浆中加入1%润滑剂SOB后,润滑系数降低率为92.7%,泥饼的黏附系数降低至0.0405,极压润滑持效性强;210 ℃下润滑系数降低率保持在90.2%,210 ℃、35%NaCl条件下润滑系数降低率保持在81.3%。高温高盐条件下SOB在高密度钻井液中配伍性良好,200 ℃老化后对钻井液的流变性无影响,能够降低钻井液滤失量,润滑系数降低率为45.09%,相比常规润滑剂性能优越,这是由于润滑剂能够在钻具表面有效吸附,形成一层疏水性较强的膜,使钻具与井壁的直接接触变成了润滑膜之间的接触,从而降低摩擦。Abstract: Using boric acid, polyols and long-chain fatty acids, a high temperature salt resistant drilling lubricant SOB has been developed to deal with high torque high friction encountered in deep and ultra-deep well drilling. SOB has good lubricity at high temperatures and high salinities. A 5% base mud treated with 1% SOB has its friction coefficient reduced by 92.7%, and the adhesion coefficient of the mud cake produced by that mud is reduced to 0.0405, meaning that SOB has a sustainable lubricity under extreme pressure condition. Percent reduction of friction coefficient at 210 ℃ is generally 90.2%, percent reduction of friction coefficient of a mud containing 35%NaCl at 210 ℃ is generally 81.3%. At high temperature and high salinity conditions, SOB has good compatibility with other components of a high density drilling fluid. After aging at 200 ℃, the rheology of the drilling fluid was not affected, the mud filtration rate can be reduced, and the coefficient of friction of the mud was reduced by 45.09%, meaning that SOB has better lubricity than conventional drilling lubricants. The reason for this phenomenon is that SOB can be effectively adsorbed on the surfaces of the drill strings, forming a layer of film with strong hydrophobicity. The existence of this film changes the direct contact between the drill strings and the borehole wall to a contact between two films of the lubricant, thereby effectively reducing the friction therebetween.

-

Key words:

- Water based drilling fluid /

- Lubricant /

- Borate /

- High temperature resistant /

- Salt resistant

-

表 1 SOB对基浆极压摩擦不同时间的润滑系数的影响

SOB/

%不同时间(min)的润滑系数Kf 滑块发热

情况5 10 20 25 30 0 0.631 0.645 0.655 0.664 0.672 发热 1 0.046 0.045 0.043 0.042 0.043 不发热 表 2 润滑剂SOB对基浆性能的影响

SOB/

%T老化/

℃AV/

mPa·sPV/

mPa·sYP/

PaFLAPI /

mL0 室温 7.0 6.0 1.0 23.2 1 室温 8.5 6.0 2.5 18.4 0 150 7.5 5.5 2.0 29.6 1 150 8.5 7.0 1.5 24.8 0 180 5.0 4.5 0.5 32.4 1 180 6.0 5.0 1.0 28.2 0 210 4.0 4.0 0 36.0 1 210 4.5 4.0 0.5 34.4 表 3 高温高盐条件下润滑剂对高密度钻井液性能的影响

润滑剂 实验条件 AV/

mPa·sPV/

mPa·sYP/

PaFLAPI /

mLKf ΔKf/

%0 老化前 84.5 65 19.5 1.6 0.172 200 ℃、16 h 65.0 50 15.0 2.8 0.151 1%SOB 老化前 85.5 68 17.5 1.2 0.095 44.77 200 ℃、16 h 67.5 51 16.5 2.4 0.083 45.09 1%RH-3 老化前 83.0 66 17.0 1.4 0.130 24.42 200 ℃、16 h 64.0 51 13.0 2.4 0.112 25.83 1%

油酸甲酯老化前 82.5 64 18.5 1.2 0.142 17.44 200 ℃、16 h 63.5 49 14.5 2.6 0.123 18.54 1%HEP-1 老化前 85.0 67 18.0 1.4 0.110 12.21 200 ℃、16 h 66.5 49 17.5 2.4 0.128 15.23 -

[1] 刘清友,敬俊,祝效华. 长水平段水平井钻进摩阻控制[J]. 石油钻采工艺,2016,38(1):18-22. doi: 10.13639/j.odpt.2016.06.005LIU Qingyou, JING Jun, ZHU Xiaohua. Control of friction resistance in drilling of horizontal well with long horizontal section[J]. Oil Drilling & Production Technology, 2016, 38(1):18-22. doi: 10.13639/j.odpt.2016.06.005 [2] 樊好福,司西强,王中华. 水基钻井液用绿色润滑剂研究进展及发展趋势[J]. 应用化工,2019,48(5):1192-1196. doi: 10.3969/j.issn.1671-3206.2019.05.046FAN Haofu, SI Xiqiang, WANG Zhonghua. Research progress and development trend of green lubricants for water based drilling fluids[J]. Applied Chemical Industry, 2019, 48(5):1192-1196. doi: 10.3969/j.issn.1671-3206.2019.05.046 [3] 宣扬,钱晓琳,林永学,等. 水基钻井液润滑剂研究进展及发展趋势[J]. 油田化学,2017,34(4):721-726.XUAN Yang, QIAN Xiaolin, LIN Yongxue, et al. Research progress and development trend on environmental-friendly lubricant in water-based drilling fluid[J]. Oilfield Chemistry, 2017, 34(4):721-726. [4] 魏昱,王骁男,安玉秀,等. 钻井液润滑剂研究进展[J]. 油田化学,2017,34(4):727-733.WEI Yu, WANG Xiaonan, AN Yuxiu, et al. Research development of drilling fluid lubricant[J]. Oilfield Chemistry, 2017, 34(4):727-733. [5] PATEL A, ZHANG H J, KE M, et al. Lubricants and drag reducers for oilfield applications-chemistry, performance, and environmental impact[C]//SPE international symposium on oilfield chemistry. Society of Petroleum Engineers, 2013. [6] 艾贵成,田效山,兰祖权,等. 超高温超高密度有机盐钻井液技术研究[J]. 西部探矿工程,2010,22(9):47-49.AI Guicheng, TIAN Xiaoshan, LAN Zuquan, et al. Ultra-high temperature ultra-high density of organic salt drilling fluid technology[J]. West-China Exploration Engineering, 2010, 22(9):47-49. [7] 王琳,董晓强,杨小华,等. 高密度钻井液用润滑剂SMJH-1的研制及性能评价[J]. 钻井液与完井液,2016,33(1):28-32.WANG Lin, DONG Xiaoqiang, YANG Xiaohua, et al. Development and evaluation of a high density drilling fluid lubricant[J]. Drilling Fluid & Completion Fluid, 2016, 33(1):28-32. [8] ESPAGNE B J, LAMRANI-KERN S, ÉNE RODESCHINI H. Biodegradable lubricating composition and use thereof in a drilling fluid, in particular for very deep reservoirs: U. S. Patent 8, 846, 583[P]. 2014-9-30. [9] 杨芳. 纳米碳球耐高温钻井液润滑剂的研究[D]. 吉林大学, 2013.YANG Fang. Study of nanosize carbon spheres as high temperature drilling fluid lubricant[D]. Jilin University, 2013. [10] KNOTHE G, STEIDLEY K R. Lubricity of components of biodiesel and petrodiesel. The origin of biodiesel lubricity[J]. Energy & Fuels, 2005, 19(3):1192-1200. [11] 樊泽霞,王兆兴,邓志宇,等. 用废机油制备钻井液用极压润滑剂DRH-1的研究[J]. 中国石油大学胜利学院学报,2015,29(2):15-18. doi: 10.3969/j.issn.1673-5935.2015.02.006FAN Zexia, WANG Zhaoxing, DENG Zhiyu, et al. Study on the preparation of DRH-1 extreme pressure lubricant for drilling fluid with waste lubricating oil[J]. Journal of Shengli College China University of Petroleum, 2015, 29(2):15-18. doi: 10.3969/j.issn.1673-5935.2015.02.006 [12] 刘保双,唐代绪. 一种钻井液用白油润滑剂HML的研究[J]. 天然气工业,2002,22(4):48-49. doi: 10.3321/j.issn:1000-0976.2002.04.014LIU Baoshuang, TANG Daixu. Study on a new type drilling fluids with white oil lubricant HML-1[J]. Natural Gas Industry, 2002, 22(4):48-49. doi: 10.3321/j.issn:1000-0976.2002.04.014 [13] NGUYEN D, STEVENSON D, ROHR B. Lubricant additives for wellbore or subterranean drilling fluids or muds: U. S. Patent Application 14/614, 068[P]. 2015-8-6. [14] HALLIDAY W S, SCHWERTNER D. Olefin isomers as lubricants, rate of penetration enhancers, and spotting fluid additives for water-based drilling fluids: U. S. Patent 5, 605, 879[P]. 1997bkq-2-25. [15] BORUGADDA V B, GOUD V V. Improved thermo-oxidative stability of structurally modified waste cooking oil methyl esters for bio-lubricant application[J]. Journal of Cleaner Production, 2016, 112:4515-4524. doi: 10.1016/j.jclepro.2015.06.046 [16] 钱晓琳,宣扬,林永学,等. 钻井液环保润滑剂SMLUB-E的研制及应用[J]. 石油钻探技术,2020,48(1):34-39. doi: 10.11911/syztjs.2019113QIAN Xiaolin, XUAN Yang, LIN Yongxue, et al. Development and application of an environmental-friendly drilling fluid lubricant SMLUB-E[J]. Petroleum Drilling Techniques, 2020, 48(1):34-39. doi: 10.11911/syztjs.2019113 [17] MALCHOW Jr G A. Water-based drilling fluids containing phosphites as lubricating aids: U. S. Patent 5, 807, 811[P]. 1998-9-15. [18] PATEL A D, DAVIS E, YOUNG S, et al. Phospholipid lubricating agents in aqueous based drilling fluids: U. S. Patent 7, 094, 738[P]. 2006-8-22. [19] ALBRECHT M S, COWAN K M, MCNEIL III R I, et al. Silica-based drilling mud comprising glycoside lubricants with amino-linked alkyl chains: U. S. Patent 7, 320, 951[P]. 2008-1-22. [20] 李公让,王承俊. 极性吸附钻井液润滑剂的研究进展与发展趋势[J]. 钻井液与完井液,2020,37(5):541-549.LI Gongrang, WANG Chengjun. Research progress made and development trend of drilling fluid lubricants with polar adsorption ability[J]. Drilling Fluid & Completion Fluid, 2020, 37(5):541-549. [21] 李小瑞,张宇,景晓琴,等. 一种高性能环保型钻井液润滑剂的研究与应用[J]. 钻井液与完井液,2018,35(4):46-50. doi: 10.3969/j.issn.1001-5620.2018.04.008LI Xiaorui, ZHANG Yu, JING Xiaoqin, et al. Evaluation and application of the high performance environmentally friendly drilling fluid lubricant HPRH[J]. Drilling Fluid & Completion Fluid, 2018, 35(4):46-50. doi: 10.3969/j.issn.1001-5620.2018.04.008 [22] 侯铄,杨勇,寇天鑫,等. 润滑添加剂三乙醇胺硼酸酯的摩擦学特性研究[J]. 润滑与密封,2020,45(2):75-80. doi: 10.3969/j.issn.0254-0150.2020.02.014HOU Shuo, YANG Yong, KOU Tianxin, et al. Tribological properties of triethanolamine borate as lubricating additive[J]. Lubrication Engineering, 2020, 45(2):75-80. doi: 10.3969/j.issn.0254-0150.2020.02.014 [23] 孙令国. 极压抗磨剂的种类及作用机理[J]. 合成润滑材料,2016,43(3):29-34. doi: 10.3969/j.issn.1672-4364.2016.03.011SUN Lingguo. The kinds and mechanism of extreme pressure anti-wear additives[J]. Synthetic Lubricants, 2016, 43(3):29-34. doi: 10.3969/j.issn.1672-4364.2016.03.011 [24] 屈沅治,黄宏军,汪波,等. 新型水基钻井液用极压抗磨润滑剂的研制[J]. 钻井液与完井液, 2018, 35(1): 34-37.,2018,35(1):34-37.QU Yuanzhi, HUANG Hongjun, WANG Bo,et al. Development of extreme pressure anti-wear lubricant MPA for water base drilling fluids[J]. Drilling Fluid & Completion Fluid, 2018, 35(1):34-37. [25] 范丰奇,王将兵,周旭光. 不同极压抗磨剂的研究发展[J]. 润滑油,2018,33(4):30-35. doi: 10.19532/j.cnki.cn21-1265/tq.2018.04.007FAN Fengqi, WANG Jiangbing, ZHOU Xuguang. Research progress in different kinds of extreme pressure anti-wear additives[J]. Lubricating Oil, 2018, 33(4):30-35. doi: 10.19532/j.cnki.cn21-1265/tq.2018.04.007 [26] 刘云峰, 邱正松, 杨鹏, 等. 一种钻井液用高效抗磨润滑剂[J]. 钻井液与完井液, 2018, 35(5): 8-13.LIU Yunfeng, QIU Zhengsong, YANG Peng, et al. A high-performance drilling fluid anti-wear lubricant[J]. Drilling Fluid & Completion Fluid, 2018, 35(5): 8-13. [27] SAFFARI H R M, SOLTANI R, ALAEI M, et al. Tribological properties of water-based drilling fluids with borate nanoparticles as lubricant additives[J]. Journal of Petroleum Science and Engineering, 2018, 171:253-259. doi: 10.1016/j.petrol.2018.07.049 [28] 孙丙向,李文博. 氨解改性大豆卵磷脂钻井液润滑剂[J]. 钻井液与完井液,2022,39(2):164-170.SUN Bingxiang, LI Wenbo. Ammonolysis modified soybean lecithin as a drilling fluid lubricant[J]. Drilling Fluid & Completion Fluid, 2022, 39(2):164-170. [29] 王兰,吴琦,蒋官澄. 改性大豆卵磷脂在水基钻井液中的润滑性能[J]. 钻井液与完井液,2019,36(1):10-14.WANG Lan, WU Qi, JIANG Guancheng. Modified soybean lecithin used as water base drilling fluid lubricant[J]. Drilling Fluid & Completion Fluid, 2019, 36(1):10-14. -

下载:

下载: