Development and Performance Evaluation of Weak Acid Plugging Removal Agent for Chlorite

-

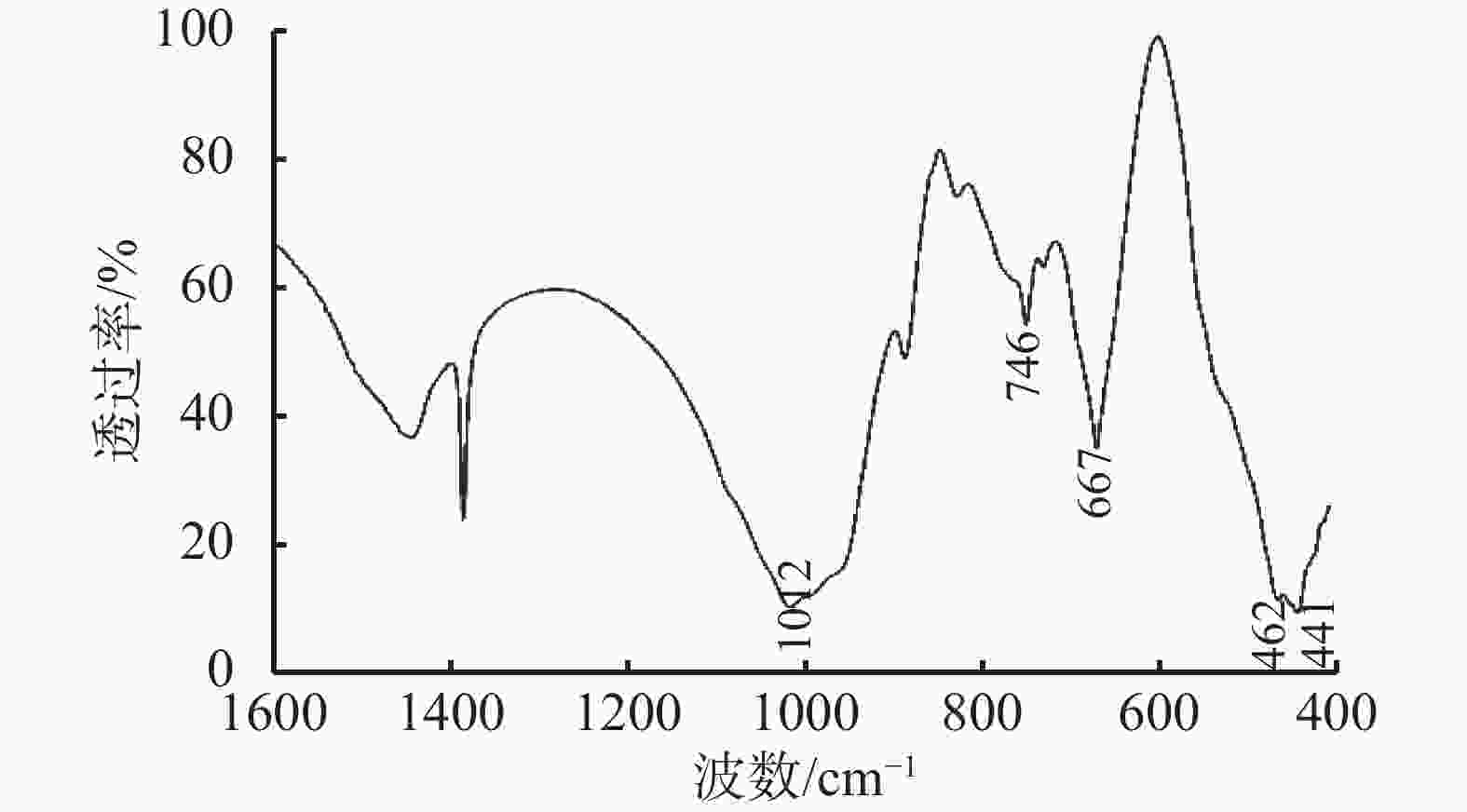

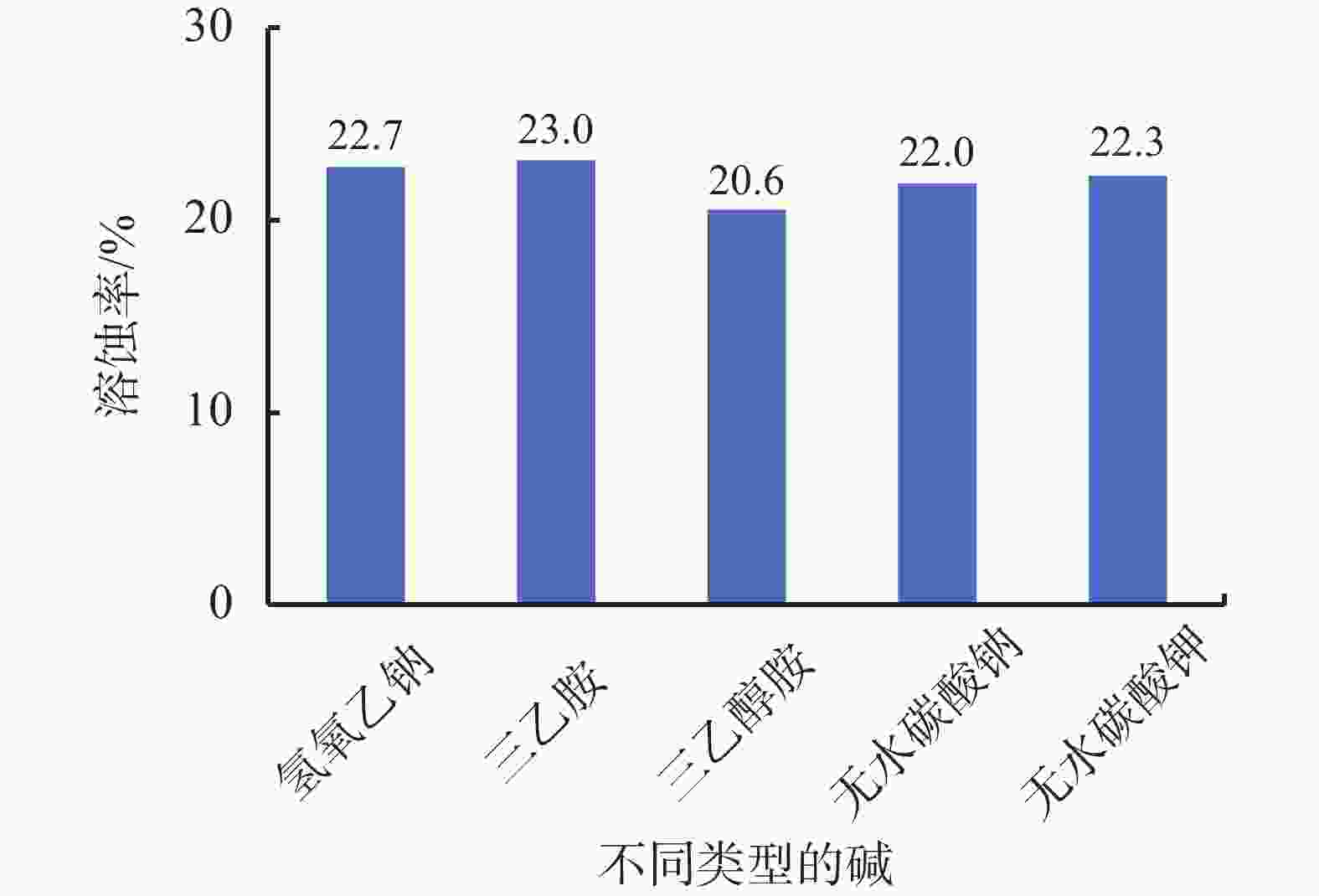

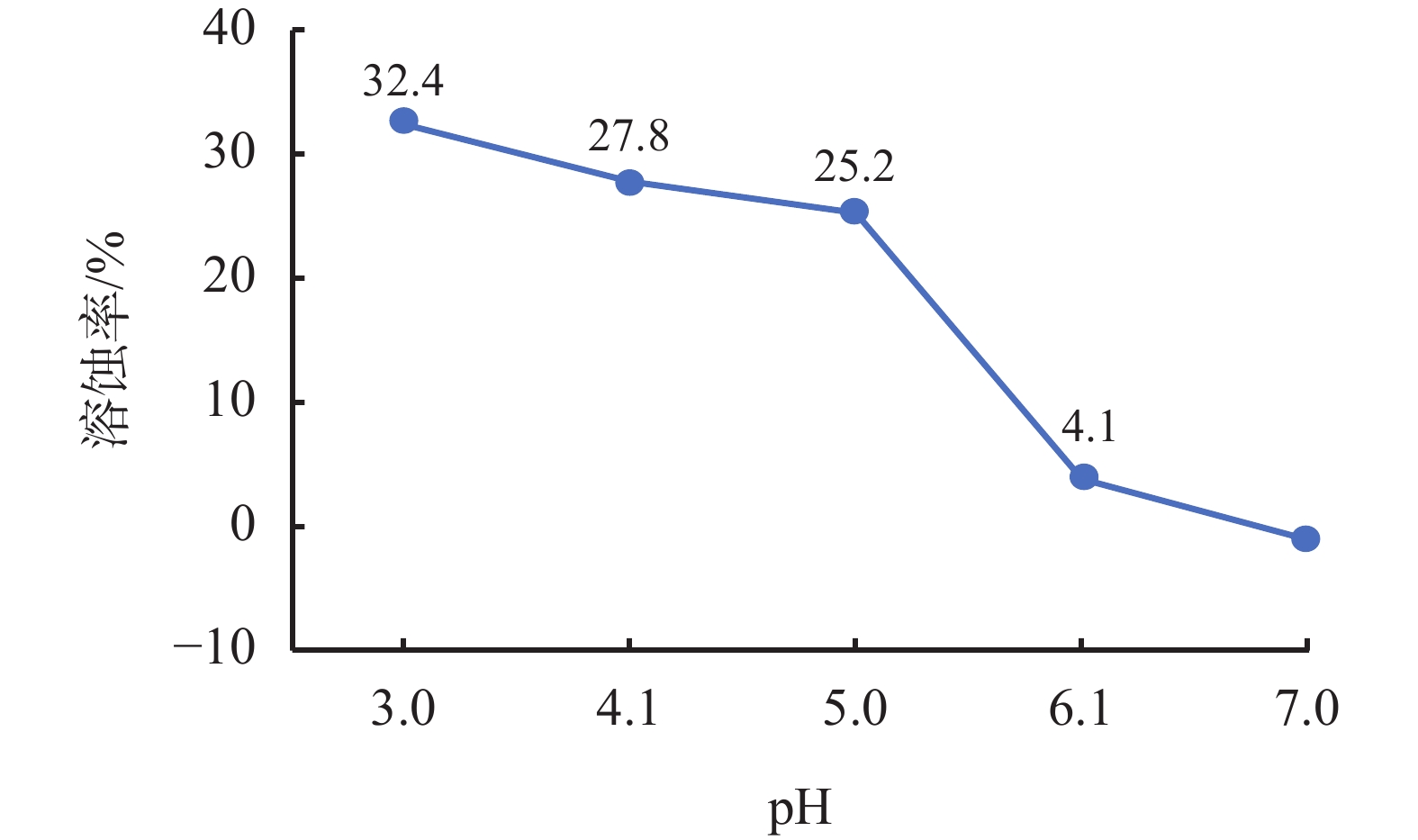

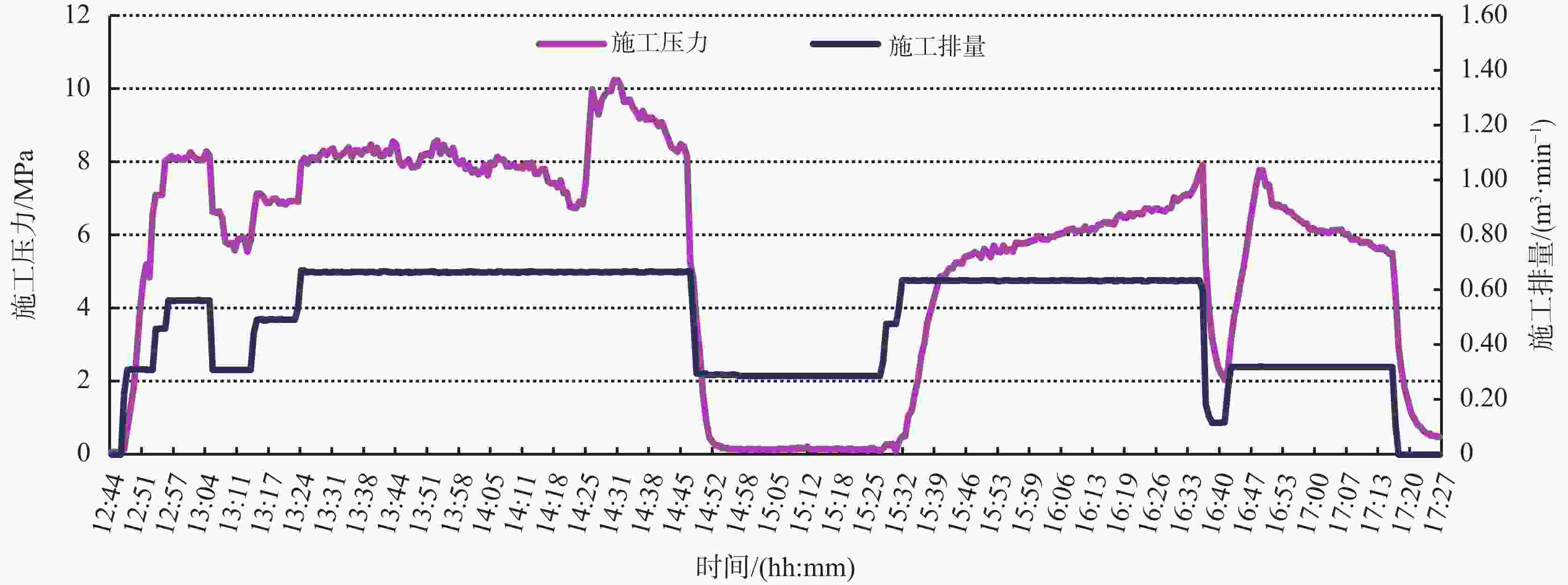

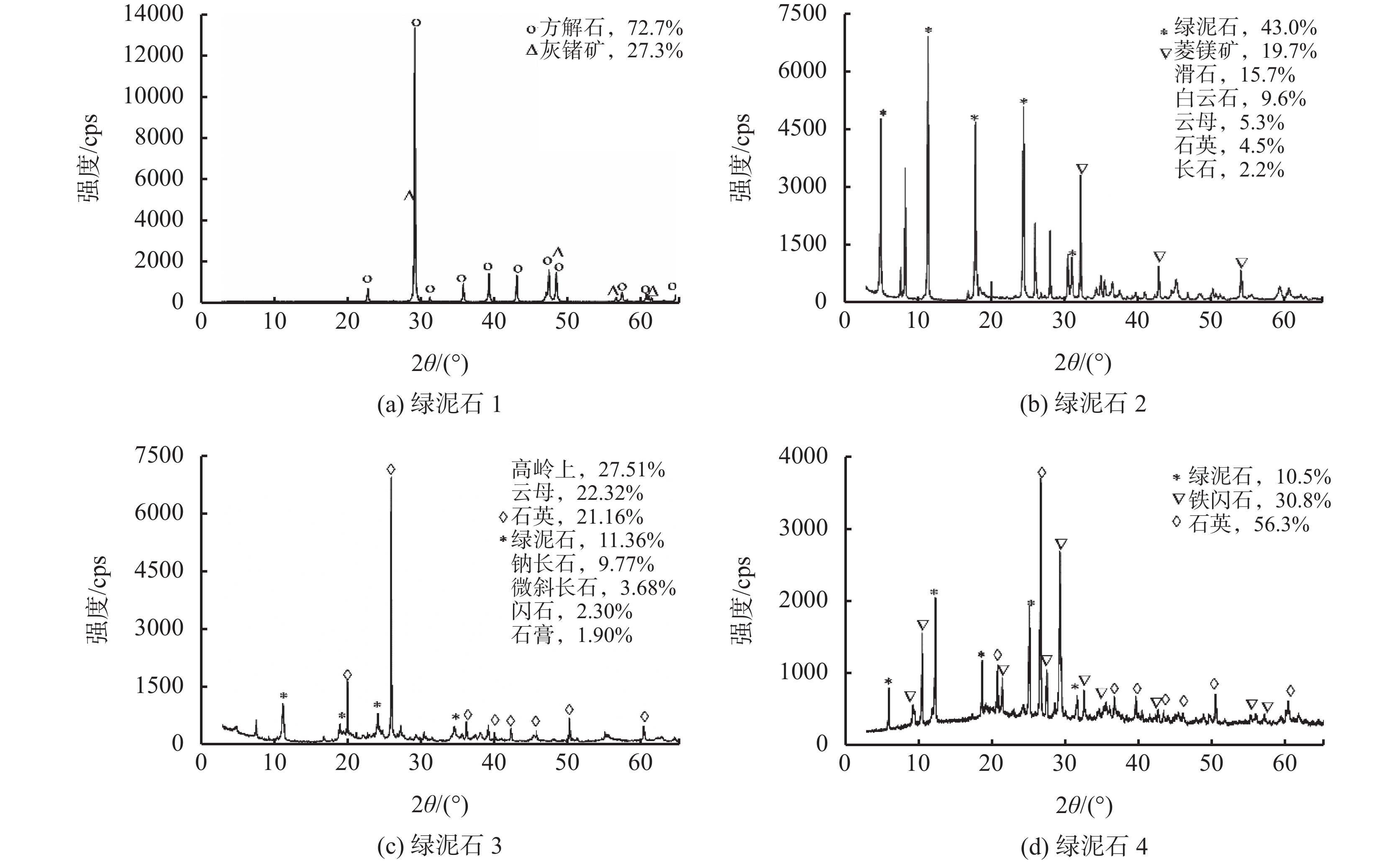

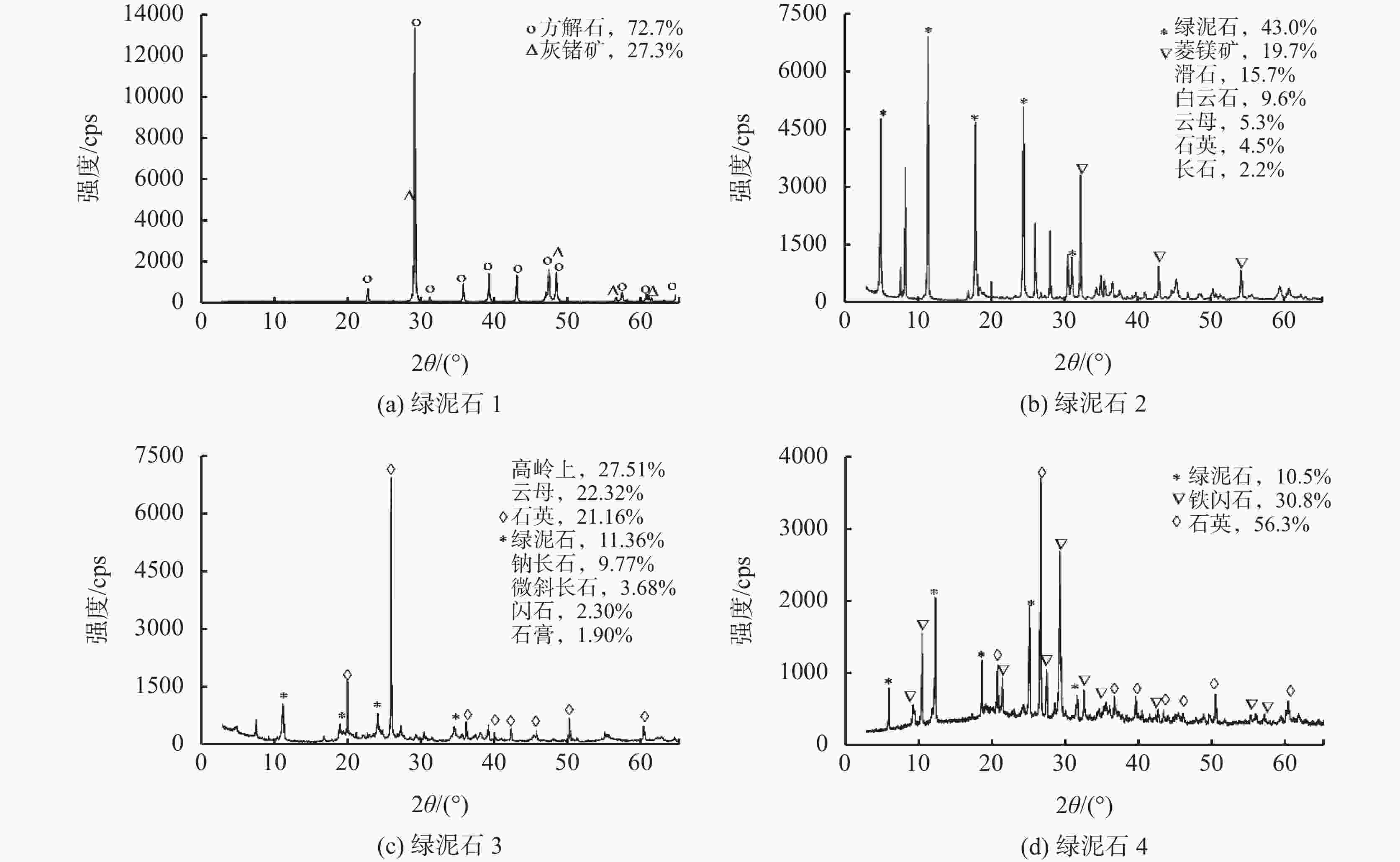

摘要: 黏土矿物常对油田储层造成污染和堵塞,绿泥石矿物是黏土矿物的主要组成部分之一。目前现场常采用的强酸性解堵剂腐蚀性大,作用时间短,当体系质子消耗到一定量时,体系解堵效率大大降低。为了解决以上问题,对各产地绿泥石物性分析比较,引入缓冲概念,针对性地复配了一种螯合能力强、具有缓冲能力的弱酸性解堵剂。通过室内实验研究发现:在解堵主剂质量浓度4%、pH值为5条件下,解堵剂对绿泥石24 h溶蚀率达25%,说明该解堵剂具有溶蚀率高、解堵效果好、腐蚀性弱以及配伍性好的优点。机理研究表明,解堵剂和缓冲体系有效组合,持续稳定提供一定浓度质子的特点是该弱酸性绿泥石解堵剂高效解堵的关键。WZ-X井在开发开采过程中,由于钻完井液侵入地层造成黏土膨胀与运移伤害,使用绿泥石解堵剂进行解除污染,作业后该井产液量由55.5 m3/d提升至98.0 m3/d。该技术的成功应用为油田解堵提供了新的方向。的方向。Abstract: Clay minerals often pollute and block oil reservoirs. Chlorite is one of the main components of clay minerals. The strong acid as plugging remover in feature of high corrosivity and high efficiency was commonly used in the oilfields. When the protons are consumed, the efficiency of the plugging remover system is greatly reduced. To solve the problem of oilfield blockage material, this paper compares the physical properties of chlorite from various producing areas, and purposefully develops a weak acid plugging remover with a strong chelating ability to metal in clay minerals and buffering ability. The experimental research displays that under the conditions of 4% mass concentration of main plugging removal agent and pH = 5, the dissolution rate of chlorite reaches 25% under 24 h, indicating that the plugging remover has the advantages of high dissolution rate, good plugging removal effect, weak corrosion, and good compatibility. The mechanism study shows that the effective combination of plugging remover and buffer system to continuously and stably provide a certain concentration of protons is the key to the efficient plugging removal of chlorite under weak acidic conditions. During the exploitation of well WZ-X, clay swelling and migration damage were caused by drilling and completion fluid immersion into the formation. Chlorite plugging agent was used to remove pollution. After the operation, the fluid production of the well increased from 55.5 m3/d to 98 m3/d. The successful application of this technology provides a new direction for oilfield plugging removal.

-

Key words:

- Plugging remover /

- Weak acidic condition /

- Buffer system /

- Chlorite /

- Dissolution rate

-

表 1 植酸和柠檬酸+草酸体系对 绿泥石的溶蚀结果(90 ℃)

体系 反应

pH值反应时

间/h溶蚀

率/%1%植酸 6.2 4 1.7 2%植酸 6.2 2.9 3%植酸 6.1 0.5 4%植酸 6.3 -1.4 5%植酸 6.1 1.3 2.5%草酸+5%柠檬酸 1.0 11.6 2.5%草酸+5%柠檬酸+1%HEDP 0.9 19.9 表 2 浓度为5%的不同解堵剂对 绿泥石的溶蚀结果(90 ℃)

体系 反应

pH值反应时

间/h溶蚀

率/%三(羟甲基)氨基甲烷+HCl 4.1 4 3.7 谷氨酸二乙酸四钠+HCl 4.0 5.6 草酸钠(饱和)+HCl 4.1 4.7 5-磺基水杨酸 0.8 9.7 单宁酸 1.8 9.4 葡萄糖酸钠+HCl 4.0 7.5 解堵剂A 1.4 26.8 表 3 4%解堵剂A与磷酸氢二钠-柠檬酸缓冲体系的pH梯度实验(24 h)

体系配方 缓冲体系pH 反应体系pH 溶蚀率/% 4%解堵剂A

+

磷酸氢二钠/柠檬酸缓冲体系4.5 2.3 43.1 4.7 2.4 41.4 5.5 2.4 42.1 5.9 2.5 42.0 7.1 2.7 39.7 表 4 解堵剂A对现场岩屑的溶蚀测试

黏土样品 主要成分/% 溶蚀率/% 石英 云母 钠长石 高岭土 现场岩屑1# 60.64 23.01 7.59 6.16 现场岩屑2# 27.81 15.21 37.26 5.30 19.72 现场岩屑3# 71.80 10.03 6.60 3.45 现场岩屑4# 22.90 36.18 14.89 12.71 23.09 注:溶液pH值为3,反应时间为24 h,反应温度为90 ℃ 表 5 解堵剂A对N80钢片的腐蚀性为测试

配方 溶液pH t/h T/

℃m1/

gm2/

g腐蚀速率/g/(m2·h) 平均腐蚀速

率/g/(m2·h)4%解堵

剂A+

NaOH3.01 4 90 11.318 11.316 0.423 0.441 11.288 11.286 0.460 24 11.318 11.315 0.089 0.084 11.288 11.286 0.080 3.02 168 120 11.285 11.263 0.097 0.095 10.807 10.786 0.094 表 6 不同配方的滤液ICP表征结果

配方 反应前pH t/h 溶蚀率/% 元素含量/(mg·L−1) Al Mg Si 2%植酸 6.2 4 2.8 0.3 43.7 12.9 2.5%草酸+5%柠檬酸 0.8 11.6 323.9 1206.0 345.8 2.5%草酸+5%柠檬酸+1%HEDP 0.9 19.9 349.5 1925.0 402.1 4%解堵剂A 1.5 30.2 84.8 1655.0 99.32 4%解堵剂A+NaOH 3.0 22.7 91.5 1636.0 135.2 24 33.0 101.7 1580.0 171.5 4%解堵剂A+0.2 mol/L磷酸氢二钠+0.1mol/L柠檬酸 2.3 43.1 284.0 2052.0 337.1 2.7 39.7 199.6 1430 234.8 -

[1] 王荣庆. 石油集输系统节能技术的应用[J]. 内江科技, 2004(5): 68-69.WANG Rongqing. Application of energy-saving technology in oil gathering system [J]. Neijiang Science and Technology, 2004(5): 68-69. [2] 傅诚德. “八五”石油科技要览[M]. 北京: 石油工业出版社, 2002.FU Chengde. Overview of Petroleum Science and Technology in the "Eighth Five-Year Plan" [M]. Beijing: Petroleum Industry Press, 2002. [3] 张炘,梁金国,李自力. 原油集输系统效益潜能研究[J]. 内蒙古石油化工,2007(8):60-62. doi: 10.3969/j.issn.1006-7981.2007.08.026ZHANG Xin, LIANG Jinguo, LI Zili. Study on the benefit potential of crude oil gathering and transmission system[J]. Inner Mongolia Petrochemical, 2007(8):60-62. doi: 10.3969/j.issn.1006-7981.2007.08.026 [4] 赵记臣. KKM 油田开发潜力综合分析[J]. 石化技术,2016(5):60-62. doi: 10.3969/j.issn.1006-0235.2016.05.043ZHAO Jichen. Comprehensive analysis of the development potential of KKM oil field[J]. Petrochemical Technology, 2016(5):60-62. doi: 10.3969/j.issn.1006-0235.2016.05.043 [5] 李晓光,刘钦甫,程宏飞,等. 磁绿泥石成分、结构及其形成环境研究进展[J]. 矿物岩石地球化学通报,2014(33):116-123.LI Xiaoguang, LIU Qinfu, CHENG Hongfei, et al. Progress in the study of magnetic chlorite composition, structure and its formation environment[J]. Mineral and Rock Geochemistry Bulletin, 2014(33):116-123. [6] 兰叶芳,黄思静,吕杰. 储层砂岩中自生绿泥石对孔隙结构的影响——来自鄂尔多斯盆地上三叠统延长组的研究结果[J]. 地质通报,2011(30):134-140.LAN Yefang, HUANG Sijing, LYU Jie. Influence of authigenic chlorite in reservoir sandstone on pore structure-Results from the Upper Triassic Yanchang Formation, Ordos Basin[J]. Geological Bulletin, 2011(30):134-140. [7] 周晓峰, 王建国, 兰朝利, 等. 鄂尔多斯盆地延长组绿泥石膜的形成机制[J], 中国石油大学学报(自然科学版). 2016(40): 20-28.ZHOU Xiaofeng, WANG Jianguo, LAN Chaoli, et al. Mechanism of chlorite film formation in the Yanchang Formation, Ordos Basin[J], Journal of China University of Petroleum (Natural Science Edition). 2016(40): 20-28. [8] 石永红, 王娟, 聂峰, 等. 宿松变质杂岩中石榴石-蓝晶石-硬绿泥石片岩形成条件及时限研究[J]岩石学报, 2016 (32): 493-504.SHI Yonghong, WANG Juan, NIE Feng, et al. Time-bound study on the formation conditions of garnet-blueschist-hard chlorite schist in Susong metamorphic heterogeneous rocks[J].Acta Petrologica Sinica, 2016 (32): 493-504. [9] 梁树能,甘甫平,闫柏琨,等. 绿泥石矿物成分与光谱特征关系研究[J]. 光谱学与光谱分析,2014(34):1763-1768.LIANG Shouneng, GAN Fuping, YAN Bakun, et al. Study on the relationship between mineral composition and spectral characteristics of chlorite[J]. Spectroscopy and Spectral Analysis, 2014(34):1763-1768. [10] 杨斌,印万忠,付亚峰,等. 柠檬酸对微细粒绿泥石夹带行为的影响[J]. 东北大学学报(自然科学版),2019(40):569-573,584.YANG Bin, YIN Wanzhong, FU Yafeng, et al. Effect of citric acid on the entrapment behavior of microfine grained chlorite[J]. Journal of Northeastern University (Natural Science Edition) , 2019(40):569-573,584. -

下载:

下载: