The Development and Application of a New Environmentally Friendly Low Friction Non-Sulfonate Drilling Fluid

-

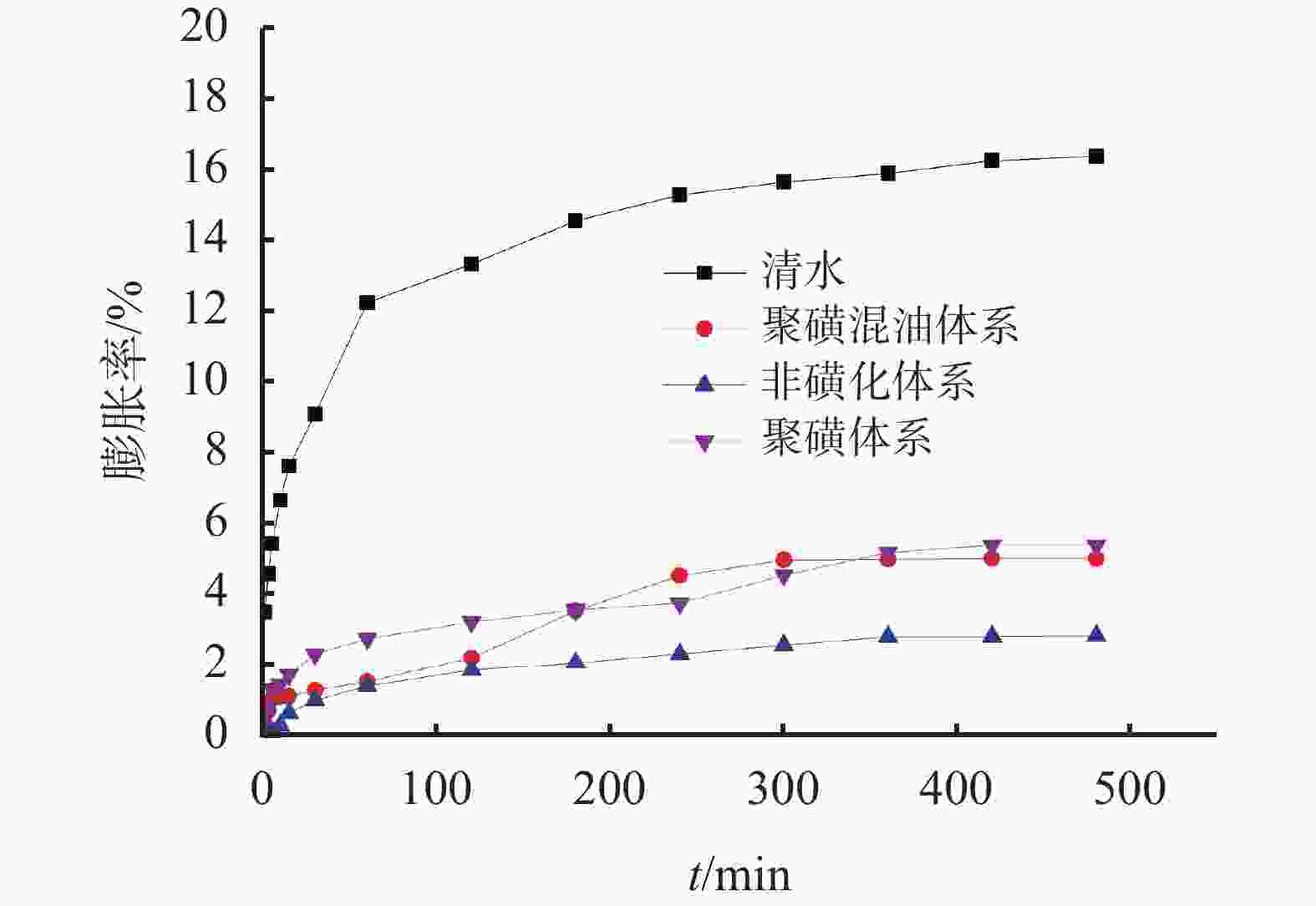

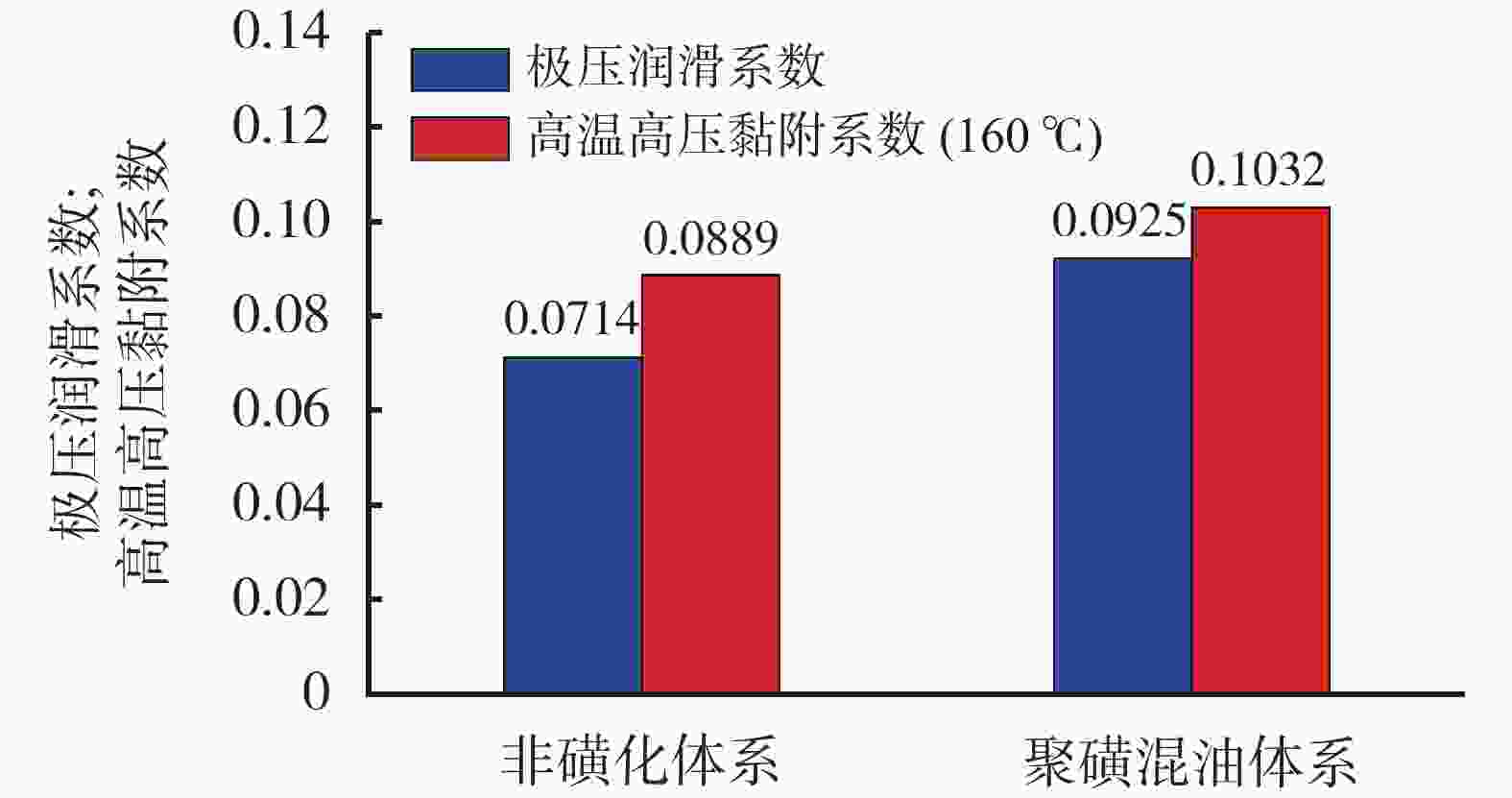

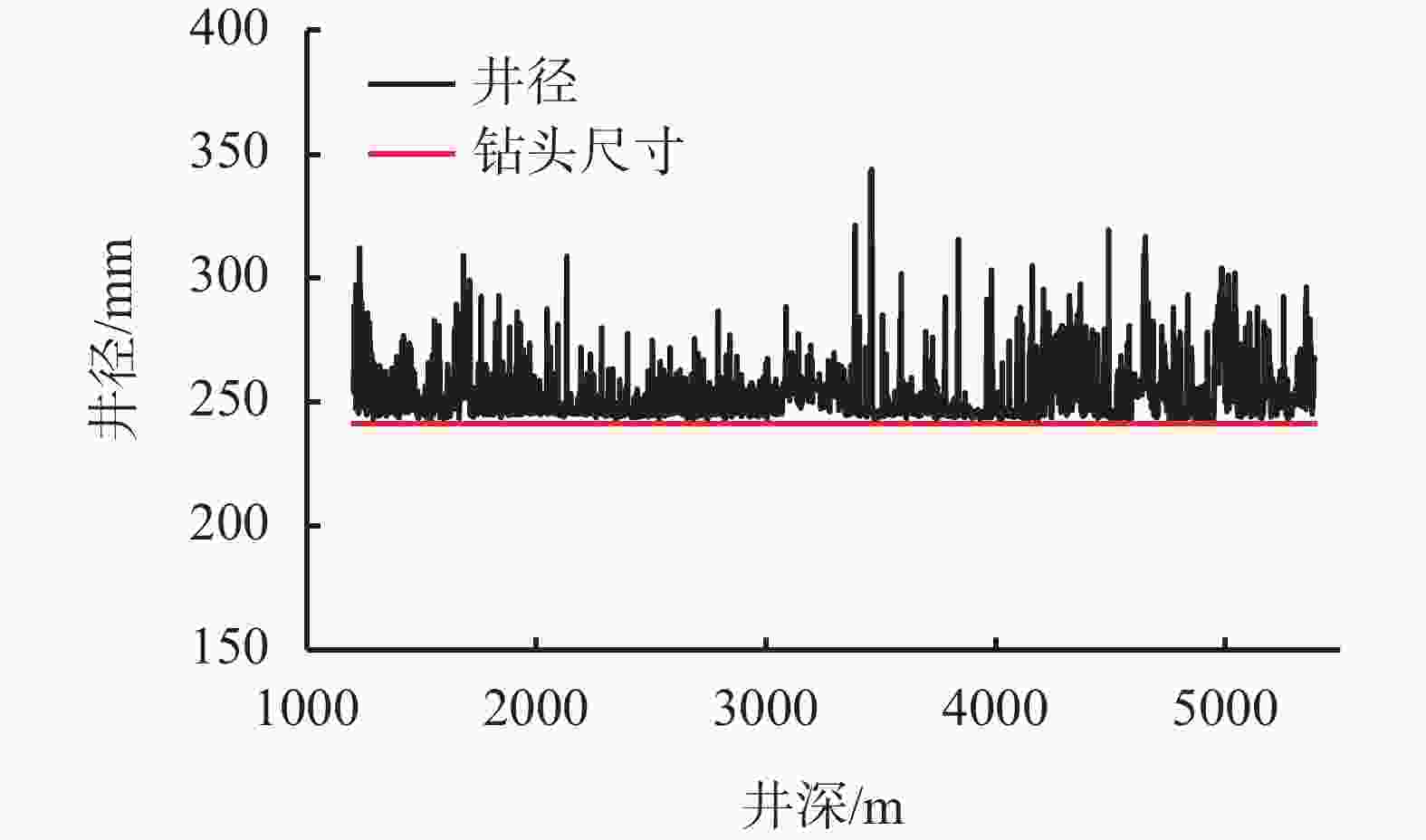

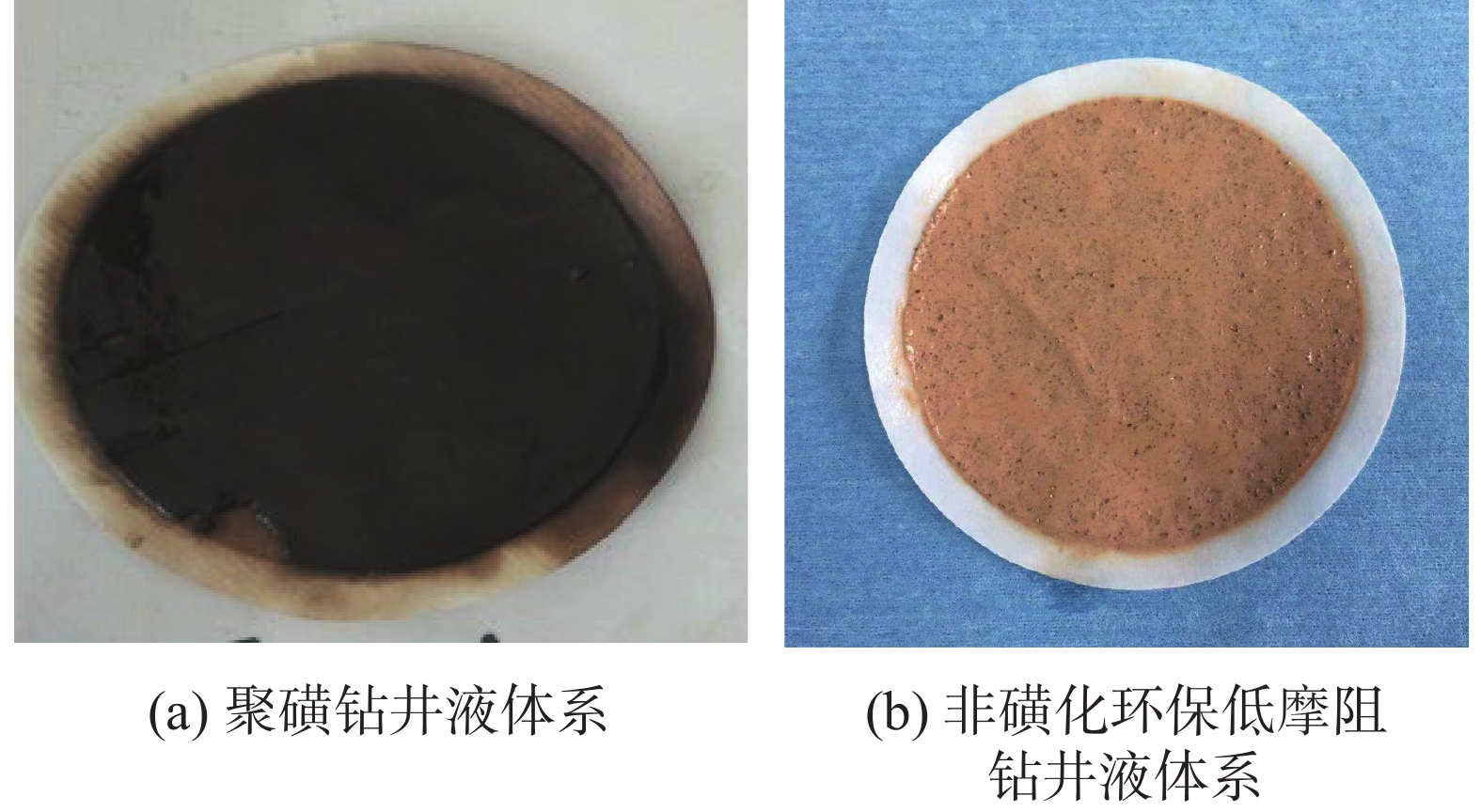

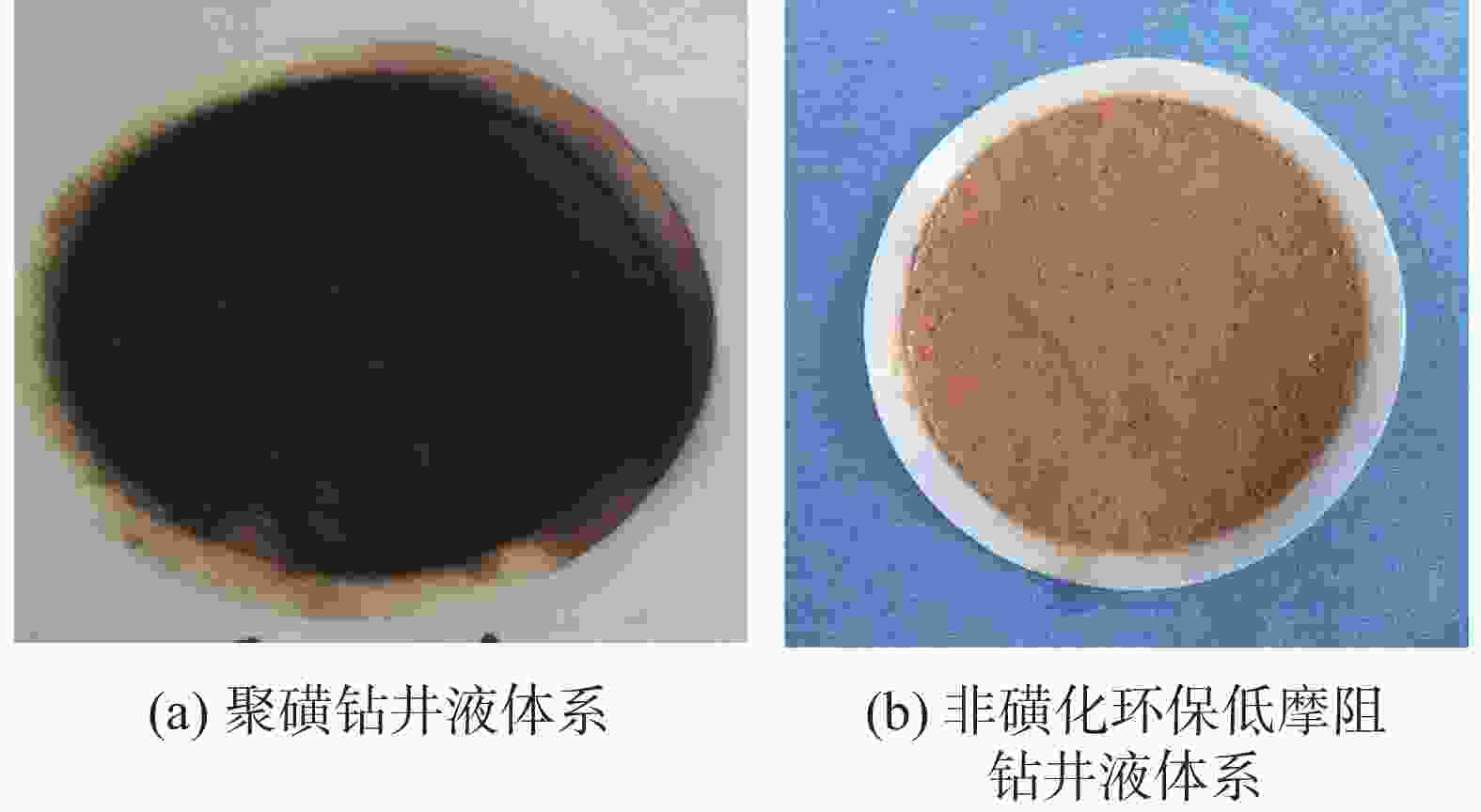

摘要: 深井、超深井钻探普遍采用耐温性较好的聚磺钻井液,其中磺化褐煤等磺化材料具有生物毒性、可降解性差,导致聚磺钻井液处理难度大、成本高。推荐了一套适用性强的钻井液环保性能评价标准,测试了聚磺钻井液及其主要处理剂的环保性能。以抗高温环保降滤失剂、流型调节剂代替传统磺化材料;以树枝状聚合物封堵抑制剂、纳微米封堵剂等代替磺化沥青、乳化沥青;以环保润滑剂替代原油,研发了一种新型非磺化环保低摩阻钻井液,并在塔河TK4120井进行了试验应用。结果表明,现场聚磺钻井液样本呈现中等毒性、较难生物降解、部分重金属含量超标,主要是磺化材料及原油生物降解性差和具有毒性所导致。非磺化环保低摩阻钻井液具有较强的抑制、封堵防塌及润滑性能,无毒,易生物降解。现场应用表明,该体系性能稳定,具有较强的抗温性,防塌能力强,润滑性能好,易塌地层平均井径扩大率仅为4.39%,4209 m长裸眼电测、下套管一次成功,取得了较好的应用效果。Abstract: Polymer-sulfonate drilling fluids, which have good resistance to high temperatures, are generally used to drill deep and ultra-deep wells. Chemicals used in these drilling fluids, such as sulfonated lignite and sulfonated methyl phenolic resin, have biotoxicity and poor degradability, resulting in difficulties in the disposal of the polymer sulfonate drilling fluids and high cost. In a laboratory study an applicable evaluation practice for testing the environmental friendliness of drilling fluids was recommended for testing the effects of polymer sulfonate drilling fluids and the main additives on the protection of environment. A new non-sulfonate drilling fluid with a balance between the functionality of the drilling fluid and environment protection was developed. This drilling fluid, with low friction coefficient, was successfully used in drilling the well TK4120 in Tahe block. Polymer sulfonate drilling fluids used in this block have moderate toxicity, poor degradability, and the contents of some heavy metals exceed the national standards. These problems come from the poor biodegradability and toxicity of the sulfonates and the crude oil used. Compared with the polymer sulfonate drilling fluids, the non-sulfonate drilling fluid developed has strong inhibitive capacity, plugging capacity and the ability to prevent the borehole wall from collapsing. It is nontoxic, easy to biologically degrade and environmentally friendly. Field application of this non-sulfonate drilling fluid indicated that this drilling fluid had stable property, good high-temperature resistance, strong ability to prevent borehole wall from collapsing, and good lubricity. The average rate of hole enlargement in the easy-to-collapse formations was only 4.39%. Wireline logging and running casing into a long open hole of 4,209 m were done successfully in the first try.

-

表 1 钻井液及其处理剂的环保性能检测推荐指标

环保性能 环保性能检测参数 环保性能要求 主要参考标准 生物毒性 EC50/(mg·L−1) ≥30 000 Q SY/TZ 0111—2004 生物降解性 化学需氧量(CODCr)/(mg·L−1) <50 SY/T 6787—2010 BOD5/CODCr/% ≥10 SY/T 6787—2010

Q SY/TZ 0111—2004化学毒性 总汞/(mg·kg−1) ≤15 Q SY/TZ 0111—2004 总镉/(mg·kg−1) ≤20 Q SY/TZ 0111—2004 总铬/(mg·kg−1) ≤13 DB 65/T3997—2017 总铅/(mg·kg−1) ≤600 DB 65/T3997—2017 总砷/(mg·kg−1) ≤75 Q SY/TZ 0111—2004 表 2 生物毒性及生物可降解性分级参考标准

生物毒性 EC50/(mg·L−1) <1 1~100 100~1000 1000~10000 >10000 >30000 毒性分级 剧毒 高毒 中等毒性 微毒 无毒 排放限制标准 生物降

解性BOD5/CODCr/% ≥25 15~25 5~15 <5 降解性分级 容易 较易 较难 难 表 3 5个现场聚磺钻井液样品的环保性能

样品 EC50/

mg·L−1化学毒性/(mg·kg−1) BOD5/CODCr/

%总汞 总镉 总铬 总铅 总砷 1# 543.4 2.08 466.4 803.4 465.4 54.6 9.15 2# 487.2 3.45 621.5 676.5 889.3 39.9 7.24 3# 865.6 1.33 484.4 908.4 901.2 101.5 6.64 4# 503.5 1.97 439.5 811.5 622.4 55.3 9.02 5# 811.2 3.65 500.3 774.9 582.4 79.2 8.39 表 4 现场聚磺钻井液体系主要处理剂的环保性能

处理剂 BOD5/CODCr/% EC50/mg·L−1 SMC 4.23 6210.1 SMP-2 3.12 5548.6 SPNH 2.97 5846.8 磺化沥青 2.58 789.8 轻质原油 1.91 854.9 XC 26.21 1.98×106 PAC-LV 16.45 1.08×106 LV-CMC 19.56 1.32×106 KPAM 17.22 2.94×104 改性淀粉类降滤失剂 20.23 2.58×104 表 5 不同钻井液体系的流变滤失性能(160 ℃、16 h)

钻井液 ρ/

g·cm−3PV/

mPa·sYP/

PaGel/

Pa/PaFLAPI/

mLFLHTHP/

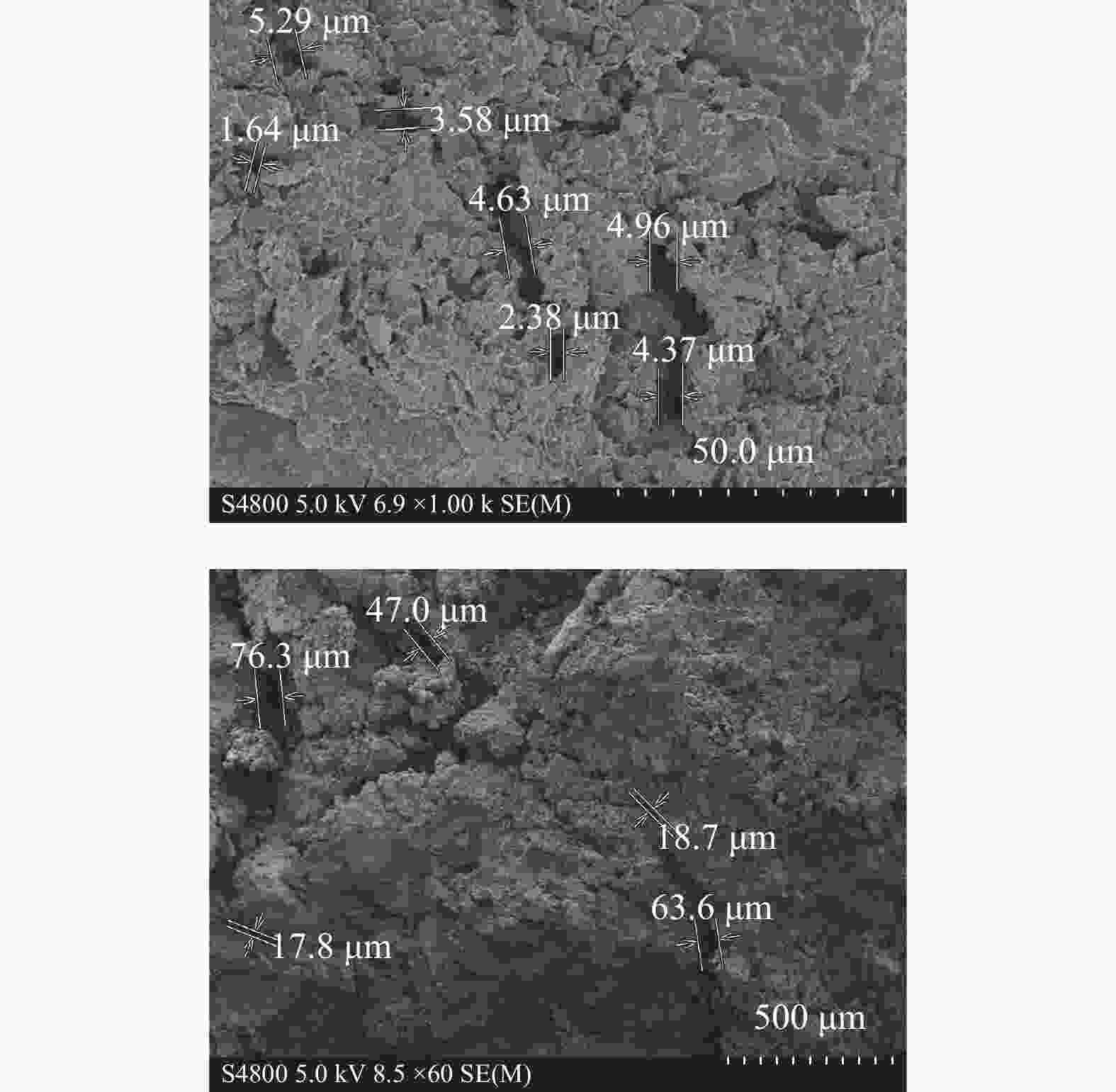

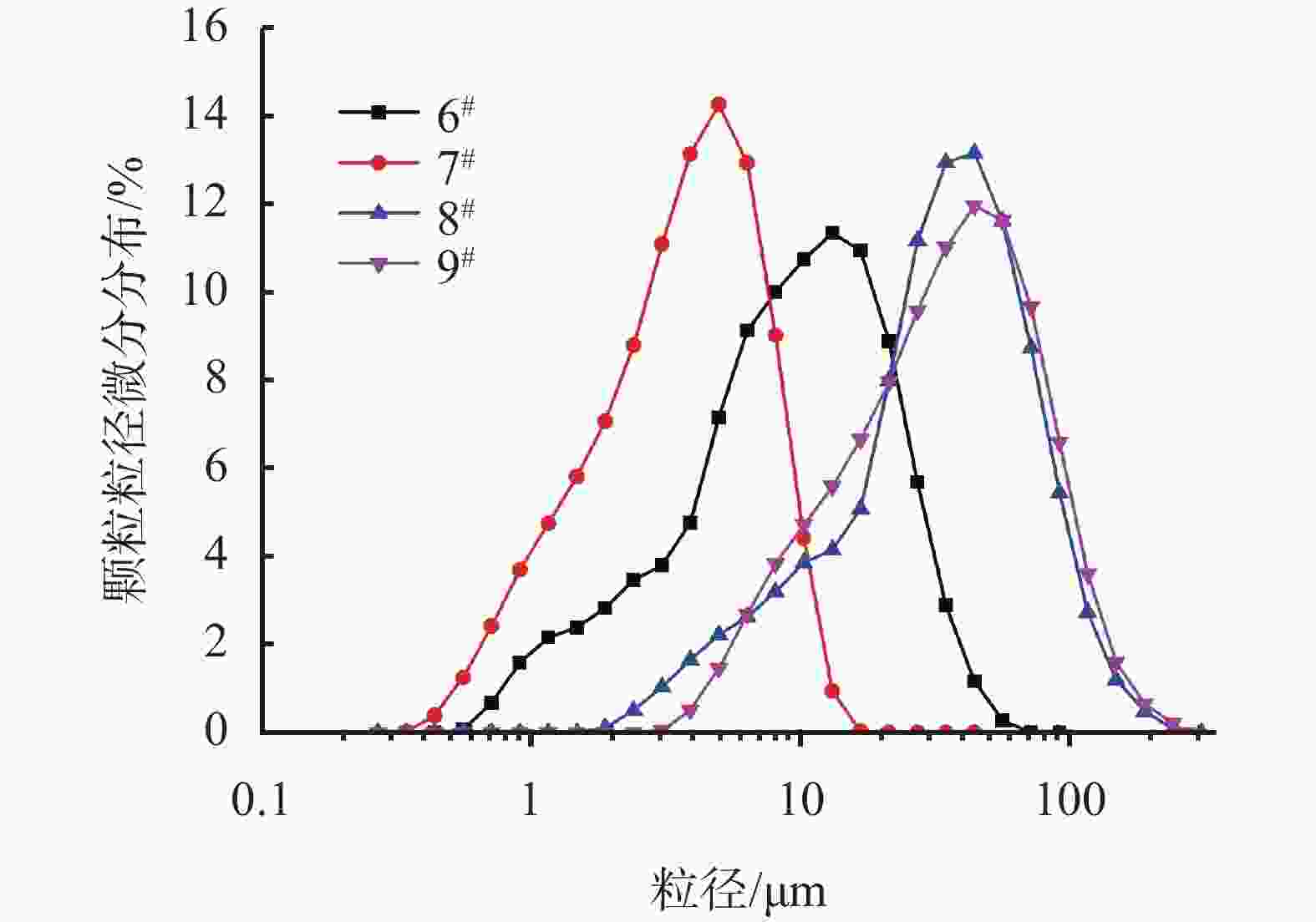

mL聚磺钻井液 1.8 34 16 4.0/15.0 4.8 12.4 聚磺混油钻井液 1.8 36 18 3.0/16.5 4.2 11.8 非磺化环保低摩阻体系 1.8 27 12 2.0/13.0 2.0 8.2 注:钻井液基础配方0#:(2%~4%)膨润土+ (0.1%~0.2%)烧碱 + (0.2%~0.5%)纯碱 + (1%~2%)PAC-LV +(2%~3%)SMP-2 +(1%~2%)SPNH +(2%~4%)FT342+(1%~2%)超细碳酸钙(2500~3000目) + (5%~7%)KCl+重晶石;聚磺钻井液配方:0#+(2%~4%)液体润滑剂; 聚磺混油钻井液配方:0#+( 2%~4%)原油 表 6 封堵剂配方及粒径分布

配方 封堵剂 粒径分布/μm D90/μm 6# 2%超细CaCO3(2500~3000目) 1~95 76.72 7# 6#+1%SMDP-2+1%SMNP-1 0.5~20 10.25 8# 2%超细CaCO3(1500~2500目) 2~240 128.43 9# 8#+1%SMDP-2+1%SMNP-1 5~260 132.22 表 7 非磺化环保低摩阻钻井液的环保性

生物毒性 生物可降解性 化学毒性/(mg·kg−1) EC50/(mg·L−1) BOD5/CODCr/% 总汞 总镉 总铬 总铅 总砷 24 300 20.12 0.43 15.75 11.24 212.13 27.45 -

[1] 鲁雪松,赵孟军,刘可禹,等. 库车前陆盆地深层高效致密砂岩气藏形成条件与机理[J]. 石油学报,2018,39(4):365-378. doi: 10.7623/syxb201804001LU Xuesong, ZHAO Mengjun, LIU Keyu, et al. Forming condition and mechanism of highly effective deep tight sandstone gas reservoir in Kuqa foreland basin[J]. Acta Petrolei Sinica, 2018, 39(4):365-378. doi: 10.7623/syxb201804001 [2] 袁国栋,王鸿远,陈宗琦,等. 塔里木盆地满深1井超深井钻井关键技术[J]. 石油钻探技术,2020,48(4):21-27. doi: 10.11911/syztjs.2020067YUAN Guodong, WANG Hongyuan, CHEN Zongqi, et al. Key drilling technologies for the ultra-deep well manshen 1 in the Tarim basin[J]. Petroleum Drilling Techniques, 2020, 48(4):21-27. doi: 10.11911/syztjs.2020067 [3] 宣扬,刘珂,郭科佑,等. 顺北超深水平井环保耐温低摩阻钻井液技术[J]. 特种油气藏,2020,27(3):163-168. doi: 10.3969/j.issn.1006-6535.2020.03.027XUAN Yang, LIU Ke, GUO Keyou, et al. Environmental anti-temperature low friction drilling fluid technology of ultra-deep horizontal well in Shunbei oil & gas field[J]. Special Oil & Gas Reservoirs, 2020, 27(3):163-168. doi: 10.3969/j.issn.1006-6535.2020.03.027 [4] 钱晓琳,柴龙,宣扬,等. SMO-FREE钻井液在塔河油田TP154XCH井的应用[J]. 断块油气田,2018,25(4):525-528.QIAN Xiaolin, CHAI Long, XUAN Yang, et al. Field application of SMO-FREE drilling fluid in well TP154XCH of Tahe oilfield[J]. Fault-Block Oil & Gas Field, 2018, 25(4):525-528. [5] 张淑侠,裴婷,原敏,等. 废弃钻井液分类处理及其效能分析[J]. 应用化工,2021,50(9):2453-2456. doi: 10.3969/j.issn.1671-3206.2021.09.027ZHANG Shuxia, PEI Ting, YUAN Min, et al. Classification treatment and efficiency analysis of waste drilling fluid[J]. Applied Chemical Industry, 2021, 50(9):2453-2456. doi: 10.3969/j.issn.1671-3206.2021.09.027 [6] 李青洋,蒋官澄,谢水祥,等. 一种适用于聚磺钻井液废液的高效脱色剂[J]. 钻井液与完井液,2014,31(6):43-46. doi: 10.3969/j.issn.1001-5620.2014.06.012LI Qingyang, JIANG Guancheng, XIE Shuixiang, et al. High performance decolorant for waste polymer sulfonate mud treatment[J]. Drilling Fluid & Completion Fluid, 2014, 31(6):43-46. doi: 10.3969/j.issn.1001-5620.2014.06.012 [7] 宋淑芬,马立安,胡传炯,等. 一株磺化钻井液降解菌的筛选鉴定及其降解特性[J]. 石油钻采工艺,2018,40(5):589-595.SONG Shufen, MA Li’an, HU Chuanjiong, et al. Screening, evaluation and degradation property of the degrading bacteria suitable for sulphonated drilling fluid[J]. Oil Drilling & Production Technology, 2018, 40(5):589-595. [8] 王伟吉. 抗温环保纳米纤维素降滤失剂的研制及特性[J]. 钻井液与完井液,2020,37(4):421-426. doi: 10.3969/j.issn.1001-5620.2020.04.003WANG Weiji. Development and characteristics of a high temperature environmentally friendly nanocellulose filter loss reducer[J]. Drilling Fluid & Completion Fluid, 2020, 37(4):421-426. doi: 10.3969/j.issn.1001-5620.2020.04.003 [9] 刘均一,郭保雨,王勇,等. 环保型水基钻井液在胜利油田的研究与应用[J]. 钻井液与完井液,2020,37(1):64-70.LIU Junyi, GUO Baoyu, WANG Yong, et al. Study and application of environmentally friendly water base drilling fluid in Shengli oilfield[J]. Drilling Fluid & Completion Fluid, 2020, 37(1):64-70. [10] 刘畅,许洁,冉恒谦. 干热岩抗高温环保水基钻井液体系[J]. 钻井液与完井液,2021,38(4):412-422.LIU Chang, XU Jie, RAN Hengqian. An environmentally friendly high temperature water based drilling fluid for hot-dry-rock well drilling[J]. Drilling Fluid & Completion Fluid, 2021, 38(4):412-422. [11] 钟汉毅,高鑫,邱正松,等. 树枝状聚合物在钻井液中的应用研究进展[J]. 钻井液与完井液,2019,36(4):397-406. doi: 10.3969/j.issn.1001-5620.2019.04.001ZHONG Hanyi, GAO Xin, QIU Zhengsong, et al. Progress in applying and studying dendrimers in drilling fluids[J]. Drilling Fluid & Completion Fluid, 2019, 36(4):397-406. doi: 10.3969/j.issn.1001-5620.2019.04.001 [12] 金军斌. 钻井液用润滑剂研究进展[J]. 应用化工,2017,46(4):770-774. doi: 10.3969/j.issn.1671-3206.2017.04.039JIN Junbin. Research advances of the lubricants for drilling fluid[J]. Applied Chemical Industry, 2017, 46(4):770-774. doi: 10.3969/j.issn.1671-3206.2017.04.039 [13] 张平. 顺北蓬1井Φ444.5 mm长裸眼井筒强化钻井液技术[J]. 石油钻探技术,2018,46(3):27-33.ZHANG Ping. Wellbore enhancing technology for Φ444.5 mm open hole section in well SHBP1 by means of drilling fluid optimization[J]. Petroleum Drilling Techniques, 2018, 46(3):27-33. [14] 林永学,王伟吉,金军斌. 顺北油气田鹰1井超深井段钻井液关键技术[J]. 石油钻探技术,2019,47(3):113-120. doi: 10.11911/syztjs.2019068LIN Yongxue, WANG Weiji, JIN Junbin. Key drilling fluid technology in the ultra deep section of well Ying-1 in the Shunbei oil and gas field[J]. Petroleum Drilling Techniques, 2019, 47(3):113-120. doi: 10.11911/syztjs.2019068 [15] 牛晓,潘丽娟,甄玉辉,等. SHB1-6H井长裸眼钻井液技术[J]. 钻井液与完井液,2016,33(5):30-34.NIU Xiao, PAN Lijuan, ZHEN Yuhui, et al. Drilling fluid technology for long open hole section of well SHB1-6H[J]. Drilling Fluid & Completion Fluid, 2016, 33(5):30-34. [16] 刘湘华,陈晓飞,李凡,等. SHBP-1超深井三开长裸眼钻井液技术[J]. 钻井液与完井液,2019,36(6):721-726.LIU Xianghua, CHEN Xiaofei, LI Fan, et al. Drilling fluid technology for long open section of the third interval of the ultradeep well SHBP-1[J]. Drilling Fluid & Completion Fluid, 2019, 36(6):721-726. [17] 张金波,鄢捷年. 钻井液暂堵剂颗粒粒径分布的最优化选择[J]. 油田化学,2005,22(1):1-5. doi: 10.3969/j.issn.1000-4092.2005.01.001ZHANG Jinbo, YAN Jienian. Optimization of particle size distribution for temporarily plugging/shielding agents in water base reservoir drilling fluids[J]. Oilfield Chemistry, 2005, 22(1):1-5. doi: 10.3969/j.issn.1000-4092.2005.01.001 [18] 黄达全,许少营,田增艳. 广谱型屏蔽暂堵保护油层技术在大港油田的应用[J]. 钻井液与完井液,2004,21(6):23-27. doi: 10.3969/j.issn.1001-5620.2004.06.007HUANG Daquan, XU Shaoying , TIAN Zengyan. Application of general-purpose shielding temporary plugging technology in Dagang oilfieid[J]. Drilling Fluid & Completion Fluid, 2004, 21(6):23-27. doi: 10.3969/j.issn.1001-5620.2004.06.007 -

下载:

下载: