Mechanisms of Borehole Wall Instability in Fukang Sag Block and an Oil Based Drilling Fluid with Plugging and Inhibitive Capacities

-

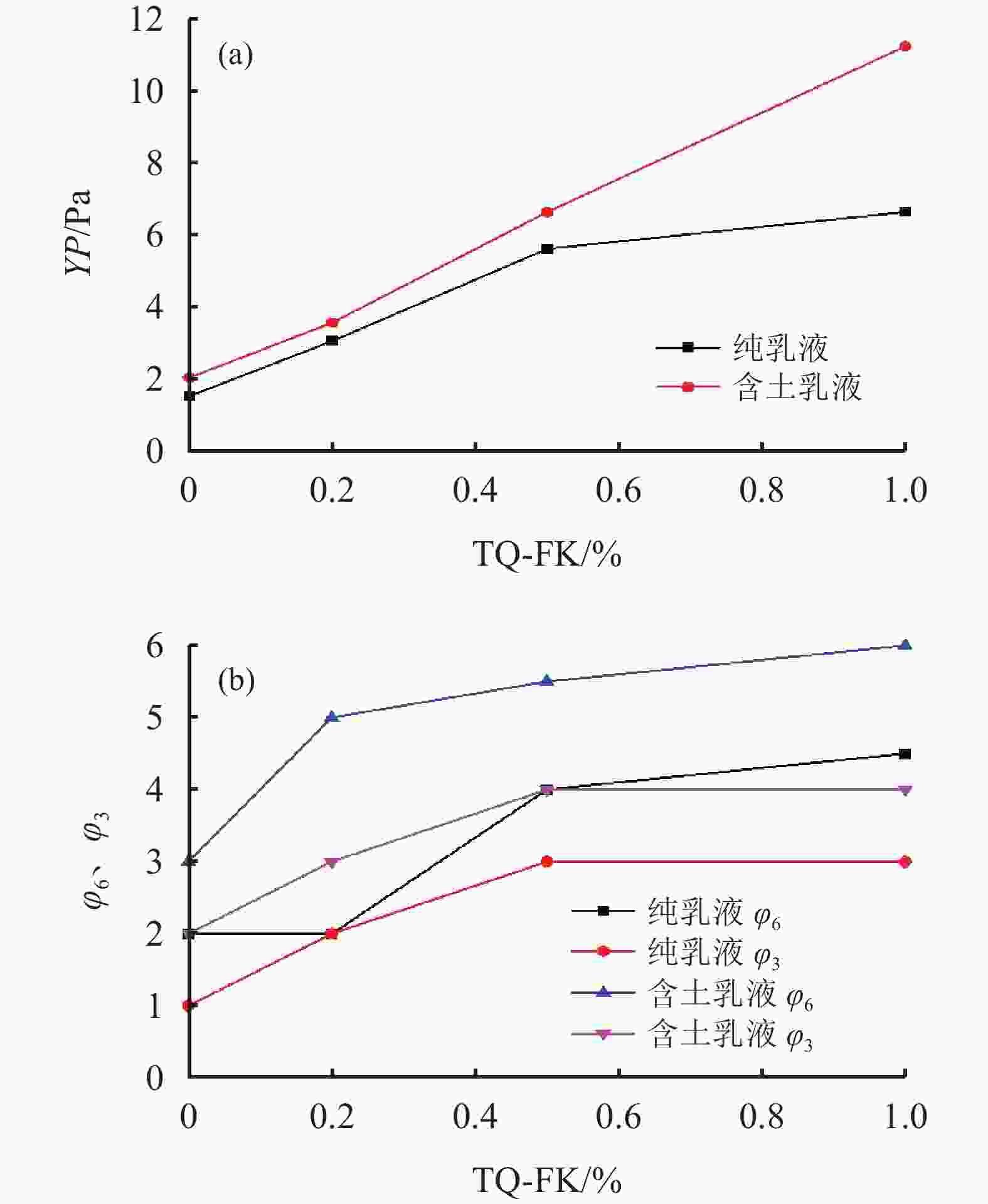

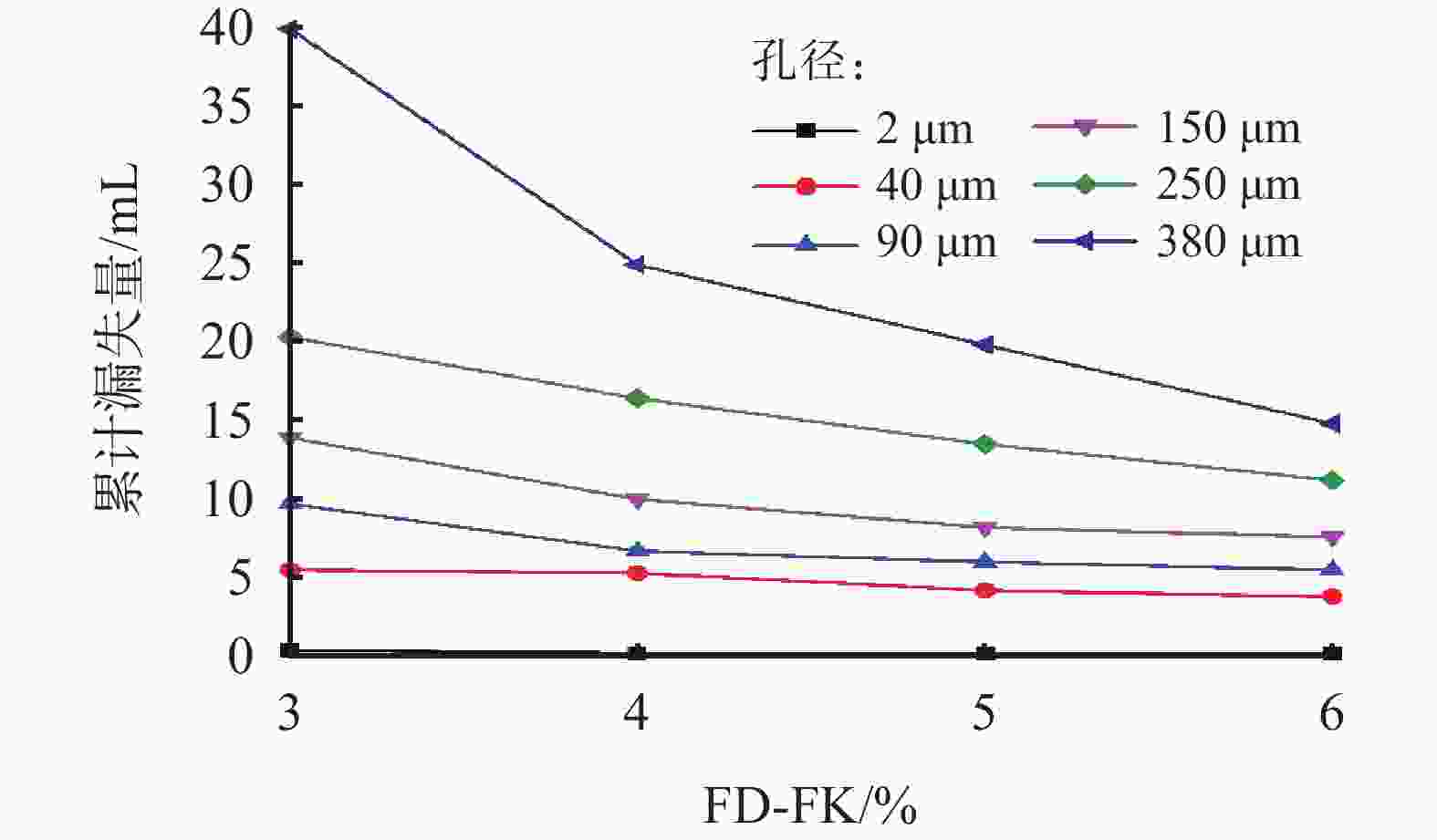

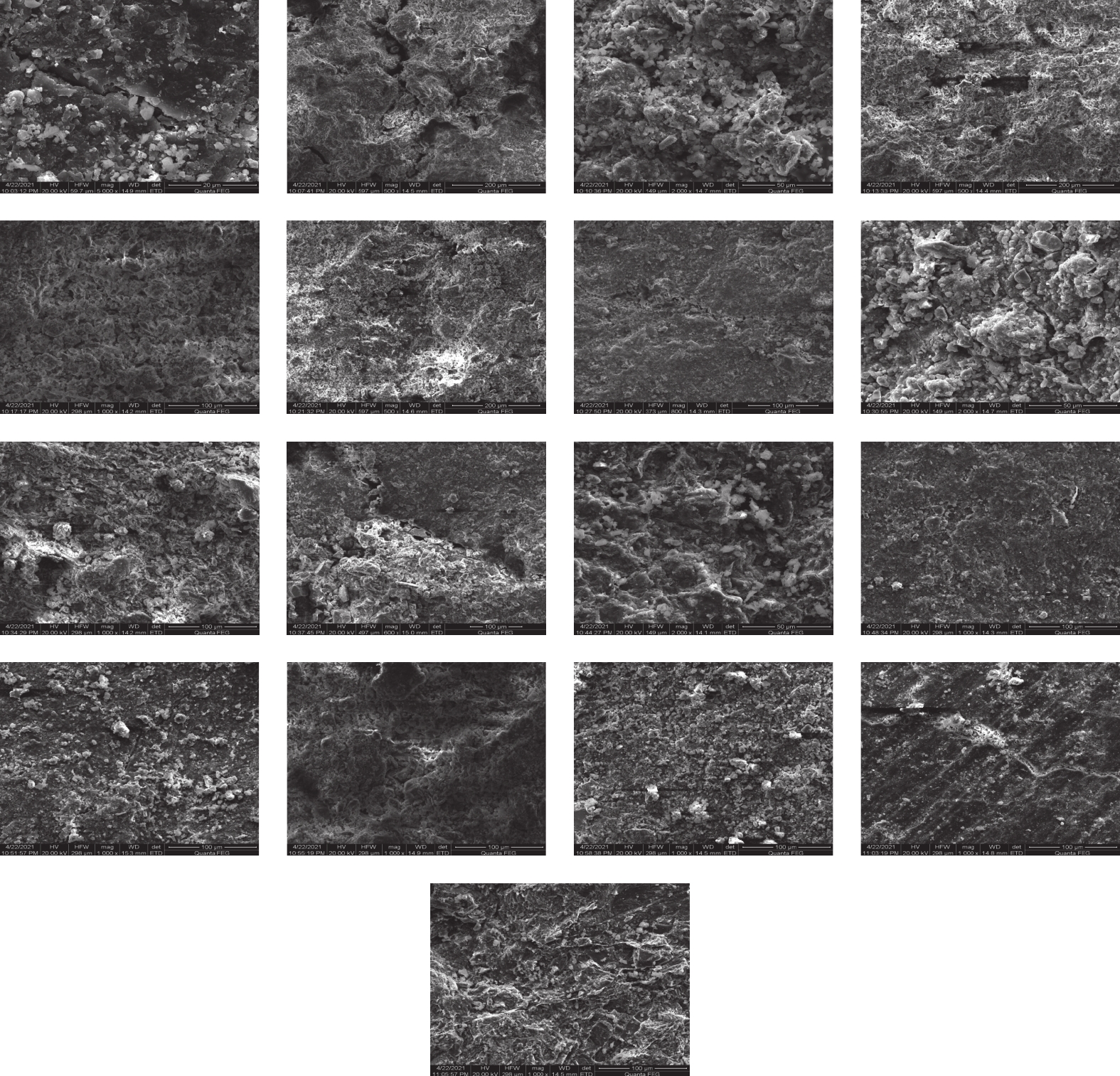

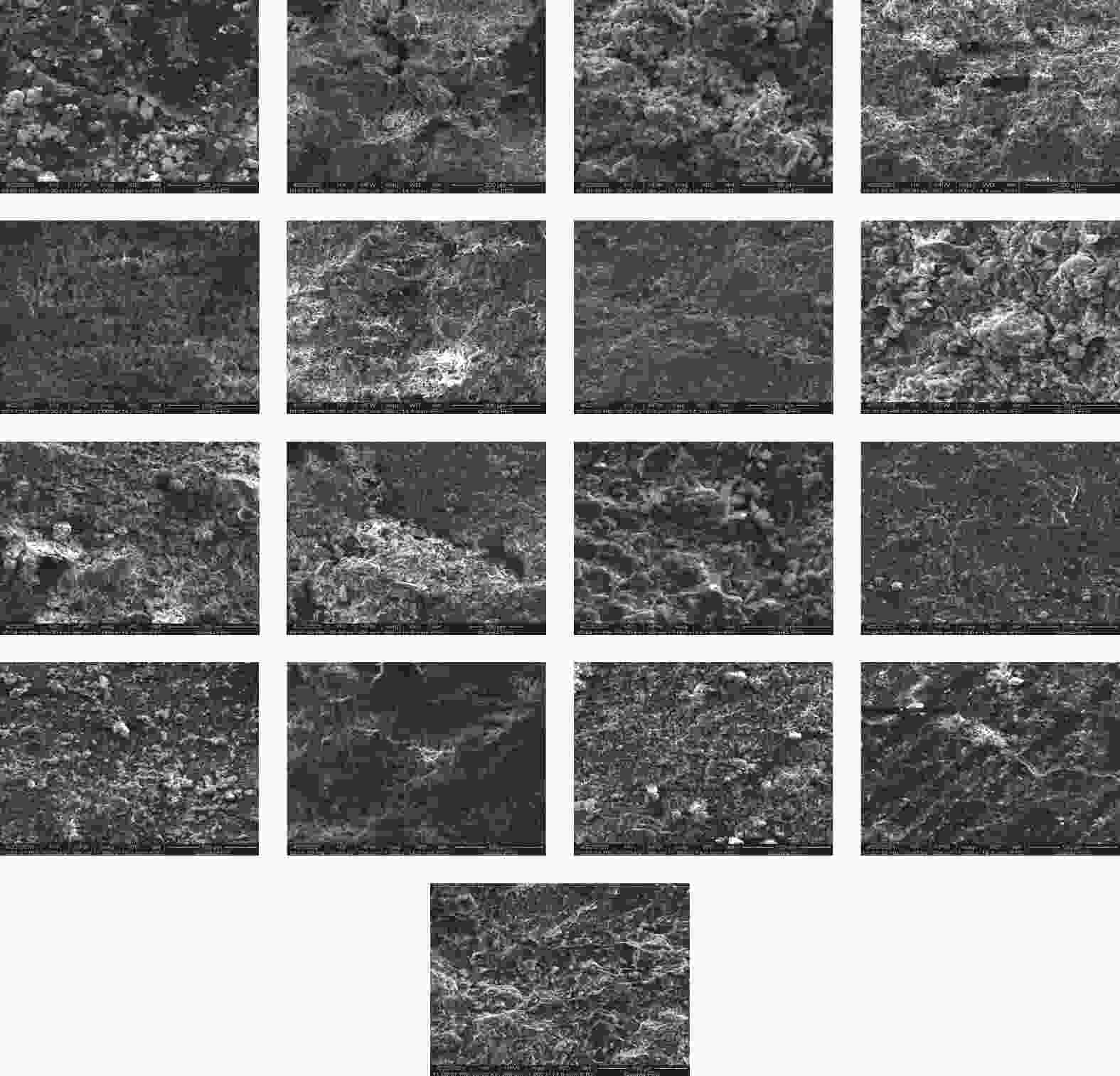

摘要: 针对阜康凹陷区块钻井遭遇的井壁失稳难题,通过全岩矿物分析、黏土矿物分析、岩石微观结构特征分析研究了区块不同层位岩石的特性,发现以高岭土为主的易水化分散矿物含量高和岩石存在大量孔缝微结构是导致井壁失稳的主要原因。以F49井油基钻井液为典型,基于井壁失稳机理提出了钻井液性能优化方向;合成了双亲性聚丙烯酸树脂颗粒作为油基钻井液胶结型封堵剂FD-FK、多聚脂肪酸作为油基钻井液提切剂TQ-FK,经FD-FK与TQ-FK优化后,钻井液的低剪切速率下黏度与动塑比大幅提高,可封堵的孔隙直径范围从2~90 μm扩大至2~380 μm,承压达8 MPa,封堵防塌性能优良。在阜47井三开井段现场应用优化后的防塌封堵油基钻井液,复杂井段的平均井径扩大率仅为3.35%,应用效果优良,为阜康凹陷油气“安全、高效”钻井提供了一项有力技术支撑。Abstract: Whole rock mineral analysis, clay mineral analysis and microstructure analysis of rock have been performed on rock samples taken from different formations to find the root causes of borehole wall instability encountered in the Fukang sag block. The analyses results indicated that it is the high content of kaolinite and large amount of micro pores and fractures developed in the formations that cause the borehole wall to loss its stability. Base on these borehole wall instability mechanisms, the oil based drilling fluid used to drill the well F49 was selected to determine the direction of mud property optimization. FD-FK, an amphiphilic polyacrylic acid resin, was synthesized as a cementitious plugging agent, and TQ-FK, a poly fatty acid was developed as a gelling agent, were developed for use in oil based drilling fluids. The oil based drilling fluid used in drilling the well F49, after treatment with FD-FK and TQ-FK, had its low-shear-rate viscosity and YP/PV ratio greatly increased, and the sizes of fractures that can be plugged by the drilling fluid were increased from 2~90 μm to 2~380 μm. The plugged fractures had pressure bearing capacity increased to 8 MPa, indicating that the oil based drilling fluid had good plugging capacity. The 3rd interval of the well Fu-47 was drilled with the oil based drilling fluid optimized with FD-FK and TQ-FK, the average percent hole enlargement of the problematic sections was only 3.35%. The application of this optimized oil based drilling fluid has provided a effective technical support to the safe and efficient drilling operation in the Fukang sag.

-

表 1 阜康凹陷地层各层位岩石全岩矿物组成

岩样 井深/m 层位 矿物含量/% 石英 钾长石 斜长石 方解石 菱铁矿 菱镁矿 石盐 黄铁矿 赤铁矿 重晶石 硬石膏 锐钛矿 片沸石 黏土矿物 1# 2256~2266 K1tg 42.3 9.4 15.5 1.8 1.7 29.3 2# 2592~2596 J2t 37.4 5.4 17.5 1.6 2.9 1.5 4.6 29.1 3# 2900~2906 J2t 56.2 5.3 14.1 0.9 23.5 4 3003~3019 J2x 38.3 2.9 6.3 5.7 4.4 42.4 5# 3240~3247 J1s 47.7 4.4 12.0 35.9 6# 3449~3454 J1b 50.3 11.0 1.1 37.6 7# 3934~3940 T2k 33.7 2.6 11.7 2.0 2.1 2.5 45.4 8# 4297~4317 T1s 27.4 3.0 11.6 4.3 2.0 9.8 10.1 31.8 9# 4460 T1j 28.6 8.0 7.4 56.0 10# 4540~4550 P3W3 27.8 8.1 6.3 3.1 3.1 11.0 40.6 11# 4580左右 P3W3 37.6 4.8 57.6 12# 4650~4660 P3W3 36.6 3.8 4.6 1.3 11.7 42.0 13# 4710~4720 P3W1 31.3 2.3 11.1 6.1 1.9 11.5 35.8 14# 4970~4980 P2l 31.1 26.5 20.1 1.8 20.5 15# 5020~5022 P2l 35.1 30.2 3.1 1.8 5.9 23.9 16# 5218~5222 P2l 28.7 3.3 24.3 6.5 0.9 3.8 4.9 6.7 20.9 17# 5307~5314 P2l 27.3 34.6 7.9 2.4 27.8 表 2 阜康凹陷各地层岩石黏土矿物组成

岩样 黏土矿物相对含量/% 混层比/% I/S I K C C/S I/S C/S 1# 65 15 1 1 18 20 25 2# 66 30 2 2 20 3# 31 41 28 4# 51 14 17 12 6 20 55 5# 47 19 22 12 20 6# 52 22 14 12 20 7# 57 15 16 12 20 8# 67 13 2 1 17 20 10 9# 80 12 4 4 50 10# 75 13 6 6 20 11# 82 7 5 6 40 12# 73 8 9 10 22 13# 57 33 5 5 20 14# 45 34 8 13 15 15# 65 11 11 13 15 16# 56 17 6 21 20 17# 66 15 4 10 5 20 55 表 3 F49井油基钻井液基本性能

实验

条件PV/

mPa·sYP/

Paφ6/φ3 Gel/

Pa/PaFLHTHP/

mLES/

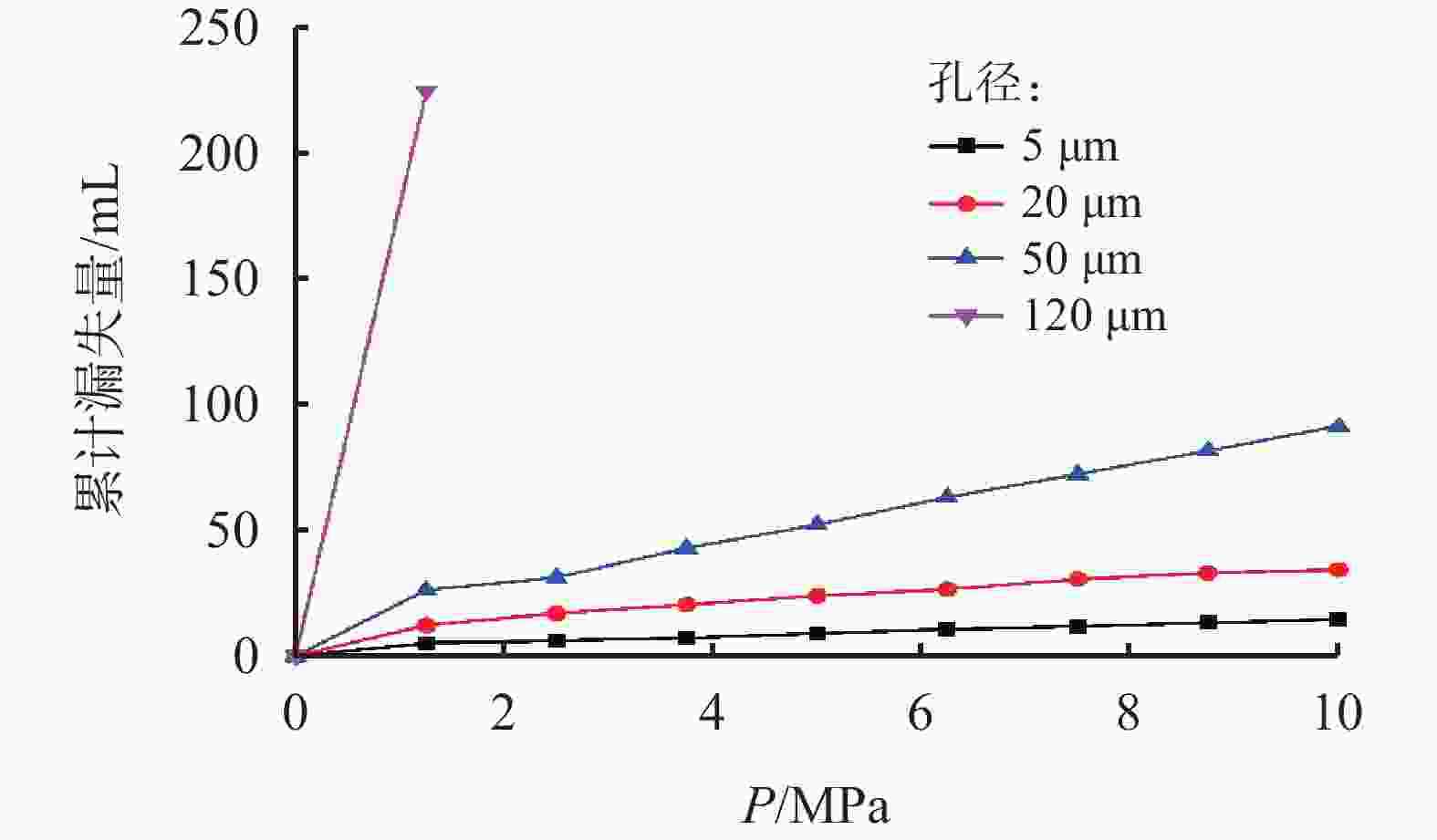

V热滚前 66 5.62 3/2 1.0/1.5 345 热滚后 68 1.02 2/1 0.5/0.5 3.6 454 注:热滚条件为150 ℃、16 h;流变性测试温度为50 ℃;FLHTHP在3.5 MPa下测定,下同 表 4 F49井油基钻井液在不同砂盘中的承压及累计漏失量

砂盘孔径/

μm不同压力(MPa)下的累计漏失量/mL 1 2 3 4 5 6 7 8 250 205.9 漏光 150 145.2 漏光 90 40.1 42.2 43.5 45.4 47.0 50.4 54.2 57.7 40 27.1 28.4 30.3 32.3 34.1 35.9 37.7 40.0 2 2.6 2.8 3.1 3.5 3.7 4.0 4.2 4.5 注:测试温度为150 ℃,下同 表 5 TQ-FK对F49井油基钻井液基本性能的影响

TQ-KF/

%PV/

mPa·sYP/

PaYP/PV/

Pa/mPa·sφ6/φ3 Gel/

Pa/PaFLHTHP/

mLES/

V0 68 1.02 0.015 2/1 1.0/1.5 3.6 454 0.2 68 6.64 0.098 4/3 2.0/3.5 3.8 642 0.5 69 7.66 0.111 7/6 4.0/6.0 4.0 661 1.0 71 7.66 0.109 8/7 4.5/8.0 4.0 650 表 6 加入TQ-FK后F49井油基钻井液在不同孔径砂盘中的承压及累计漏失量

砂盘孔

径/μm在不同压力(MPa)下的累计漏失量/mL 1 2 3 4 5 6 7 8 250 185.9 漏光 150 94.2 122.5 154.9 222.2 漏光 90 34.2 35.3 36.8 38.0 38.9 39.8 41.1 43.3 40 18.1 19.4 20.3 21.9 22.5 24.0 25.1 26.0 2 2.2 2.6 2.9 3.1 3.2 3.2 3.3 3.4 表 7 FD-FK对F49井油基钻井液 性能的影响(150 ℃、16 h)

FD-FK/

%PV/

mPa·sYP/

PaYP/PV/

Pa/mPa·sφ6/φ3 Gel/

Pa/PaFLHTHP/

mLES/

V3 71 8.69 0.122 9/6 4.0/6.5 3.4 695 4 73 8.69 0.119 9/8 5.0/8.0 3.2 723 5 77 11.75 0.153 11/10 6.5/8.5 3.2 757 6 80 12.78 0.160 14/12 7.0/9.5 3.0 791 表 8 阜47井三开井段钻井液的基本性能

ρ/

g·cm−3井深/

mPV/

mPa·sYP/

Paφ6/φ3 Gel/

Pa/PaFLHTHP/

mLES/

V1.70 3702 41 13.80 11/10 5.5/9.5 3.8 638 1.74 3904 44 13.29 11/9 5.5/9.0 4.2 647 1.76 4435 46 12.26 12/10 6.0/10.0 4.2 621 1.79 4768 47 14.31 12/10 6.0/10.0 4.0 666 1.81 5289 50 13.80 14/12 7.5/11.0 4.2 702 -

[1] 何海清,支东明,唐勇,等. 准噶尔盆地阜康凹陷康探1井重大突破及意义[J]. 中国石油勘探,2021,26(2):1-11. doi: 10.3969/j.issn.1672-7703.2021.02.001HE Haiqing, ZHI Dongming, TANG Yong, et al. A great discovery of well Kangtan 1 in the Fukang sag in the Junggar basin and its significance[J]. China Petroleum Exploration, 2021, 26(2):1-11. doi: 10.3969/j.issn.1672-7703.2021.02.001 [2] 邹晓峰,杜欣来. 提高井壁强度技术与方法[J]. 中国井矿盐,2013,44(5):25-28. doi: 10.3969/j.issn.1001-0335.2013.05.009ZOU Xiaofeng, DU Xinlai. Technology and methods to improve well wall strength[J]. China Well and Rock Salt, 2013, 44(5):25-28. doi: 10.3969/j.issn.1001-0335.2013.05.009 [3] 邱春阳,张翔宇,赵红香,等. 顺北区块深层井壁稳定钻井液技术[J]. 天然气勘探与开发,2021,44(2):81-86.QIU Chunyang, ZHANG Xiangyu, ZHAO Hongxiang, et al. Drilling-fluid system for deep borehole stability in Shunbei block, Tarim basin[J]. Natural Gas Exploration and Development, 2021, 44(2):81-86. [4] 罗健生,蒋官澄,王国帅,等. 一种无氯盐环保型强抑制水基钻井液体系[J]. 钻井液与完井液,2019,36(5):594-599. doi: 10.3969/j.issn.1001-5620.2019.05.012LUO Jiansheng, JIANG Guancheng, WANG Guoshuai, et al. Development of an environmentally friendly strongly inhibitive chloride-free water base drilling fluid[J]. Drilling Fluid & Completion Fluid, 2019, 36(5):594-599. doi: 10.3969/j.issn.1001-5620.2019.05.012 [5] 陈彬,张伟国,姚磊,等. 基于井壁稳定及储层保护的钻井液技术[J]. 石油钻采工艺,2021,43(2):184-188.CHEN Bin, ZHANG Weiguo, YAO Lei, et al. Drilling fluid technology based on well stability and reservoir protection[J]. Drilling Fluid & Production Technology, 2021, 43(2):184-188. [6] 王建华,张家旗,谢盛,等. 页岩气油基钻井液体系性能评估及对策[J]. 钻井液与完井液,2019,36(5):555-559. doi: 10.3969/j.issn.1001-5620.2019.05.005WANG Jianhua, ZHANG Jiaqi, XIE Sheng, et al. Evaluation and improvement of the performance of oil base drilling fluids for shale gas drilling[J]. Drilling Fluid & Completion Fluid, 2019, 36(5):555-559. doi: 10.3969/j.issn.1001-5620.2019.05.005 [7] 李茂森,刘政,胡嘉. 高密度油基钻井液在长宁——威远区块页岩气水平井中的应用[J]. 天然气勘探与开发,2017,40(1):88-92.LI Maosen, LIU Zheng, HU Jia. Application of high density oil-based drilling fluid in shale gas horizontal wells of Changning-Weiyuan block[J]. Natural Gas Exploration and Development, 2017, 40(1):88-92. [8] 吴雄军,林永学,王显光,等. 顺北5-7井超深层奥陶系地层油基钻井液技术[J]. 长江大学学报(自然科学版),2021,18(1):100-106.WU Xiongjun, LIN Yongxue, WANG Xianguang, et al. Oil-based drilling fluid technology for ultra-deep Ordovician strata of well Shunbei 5-7[J]. Journal of Yangtze University (Natural Science Edition) , 2021, 18(1):100-106. [9] 左京杰,张振华,姚如钢,等. 川南页岩气地层油基钻井液技术难题及案例分析[J]. 钻井液与完井液,2020,37(3):294-300. doi: 10.3969/j.issn.1001-5620.2020.03.005ZUO Jingjie, ZHANG Zhenhua, YAO Rugang, et al. Technical difficulties and case study of oil base drilling fluid operation in shale gas drilling in south Sichun[J]. Drilling Fluid & Completion Fluid, 2020, 37(3):294-300. doi: 10.3969/j.issn.1001-5620.2020.03.005 [10] 汪洪民,刘海声,庞怀玮,等. 青海祁漫塔格那西郭勒泥质岩地层水敏性及其钻井液配方研究[J]. 矿产勘查,2020,11(4):811-817. doi: 10.3969/j.issn.1674-7801.2020.04.027WANG Hongmin, LIU Haisheng, PANG Huaiwei, et al. Water sensitivity of argillaceous rocks and drilling fluid formulation in Naxigole of Qimantagana, Qinghai province[J]. Mineral Exploration, 2020, 11(4):811-817. doi: 10.3969/j.issn.1674-7801.2020.04.027 [11] 李辉,郑义平,陈亮,等. 抗高温高密度钻井液配方的研制与性能评价[J]. 长江大学学报(自然科学版),2019,16(11):27-31.LI Hui, ZHENG Yiping, CHEN Liang, et al. Development and performance evaluation of high temperature and high density drilling fluid formulation[J]. Journal of Yangtze University (Natural Science Edition) , 2019, 16(11):27-31. [12] 王星媛,陆灯云,吴正良. 抗220 ℃高密度油基钻井液的研究与应用[J]. 钻井液与完井液,2020,37(5):550-554,560.WANG Xingyuan, LU Dengyun, WU Zhengliang. Study and application of a high density oil base drilling fluid with high temperature resistance of 220 ℃[J]. Drilling Fluid & Completion Fluid, 2020, 37(5):550-554,560. [13] 潘谊党,于培志. 密度对油基钻井液性能的影响[J]. 钻井液与完井液,2019,36(3):273-279. doi: 10.3969/j.issn.1001-5620.2019.03.002PANG Yidang, YU Peizhi. Effect of density on the performance of oil base drilling fluid[J]. Drilling Fluid & Completion Fluid, 2019, 36(3):273-279. doi: 10.3969/j.issn.1001-5620.2019.03.002 [14] 王伟,赵春花,罗健生,等. 抗高温油基钻井液封堵剂PF-MOSHIELD的研制与应用[J]. 钻井液与完井液,2019,36(2):153-159.WANG Wei, ZHAO Chunhua, LUO Jiansheng, et al. Development and application of the high temperature plugging agent PF-MOSHIELD for oil base drilling fluids[J]. Drilling Fluid & Completion Fluid, 2019, 36(2):153-159. [15] 王伟吉,邱正松,黄维安,等. 纳米聚合物微球封堵剂的制备及特性[J]. 钻井液与完井液,2016,33(1):33-36. doi: 10.3969/j.issn.1001-5620.2019.02.004WANG Weiji, QIU Zhengsong, HUANG Weian, et al. Preparation and characteristics of nano polymer microsphere used as plugging agent in drilling fluid[J]. Drilling Fluid & Completion Fluid, 2016, 33(1):33-36. doi: 10.3969/j.issn.1001-5620.2019.02.004 [16] SVETLANA R DERKACH. Rheology of emulsions[J]. Advances in Colloids and Interfaces Science, 2009, 151:1-23. doi: 10.1016/j.cis.2009.07.001 [17] XUAN Yang, JIANG Guancheng , LI Yingying, et al. A biomimetic drilling fluid for wellbore strengthening[J]. Petroleum Exploration and Development, 2013, 40(4):531-536. doi: 10.1016/S1876-3804(13)60069-5 [18] JIANG Guancheng, SUN Jinsheng, HE Yinbo, et al. Novel water-based drilling and completion fluid technology to improve well-bore quality during drilling and protect unconventional reservoirs[J]. Engineering,2021. -

下载:

下载: