Synthesis and Properties of High Temperature Resistant Environmental Protection Shear Strength Improving Agent

-

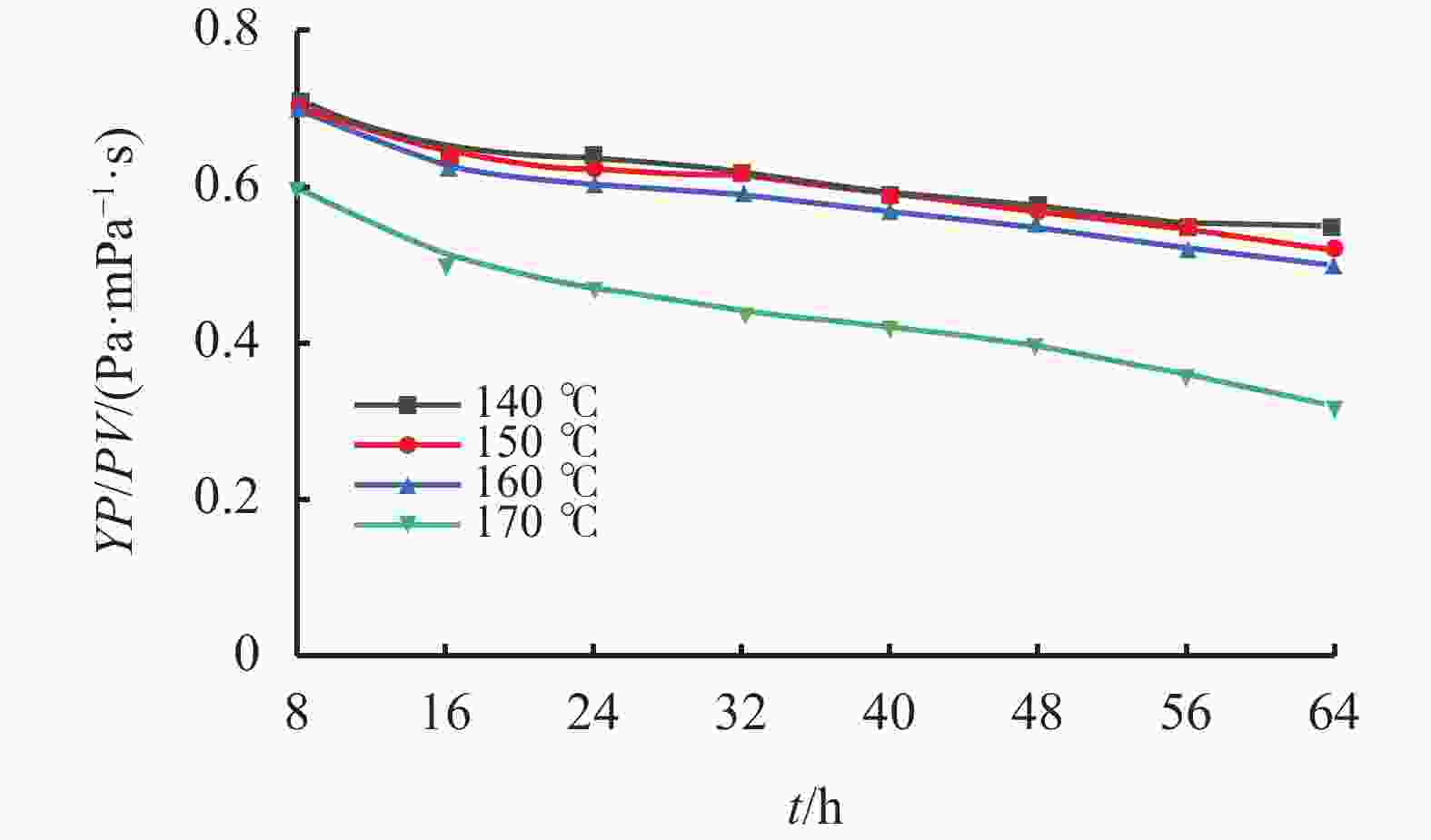

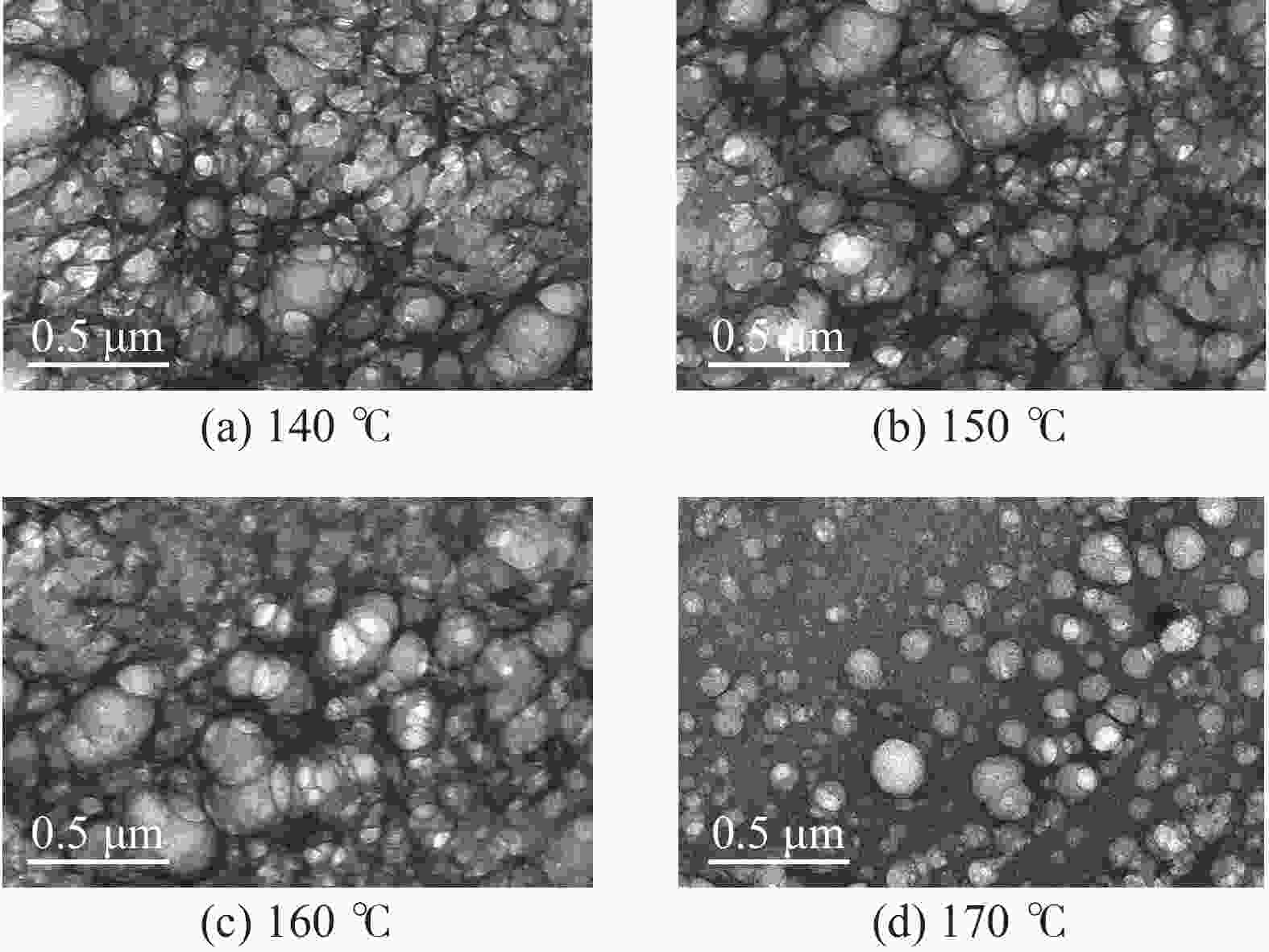

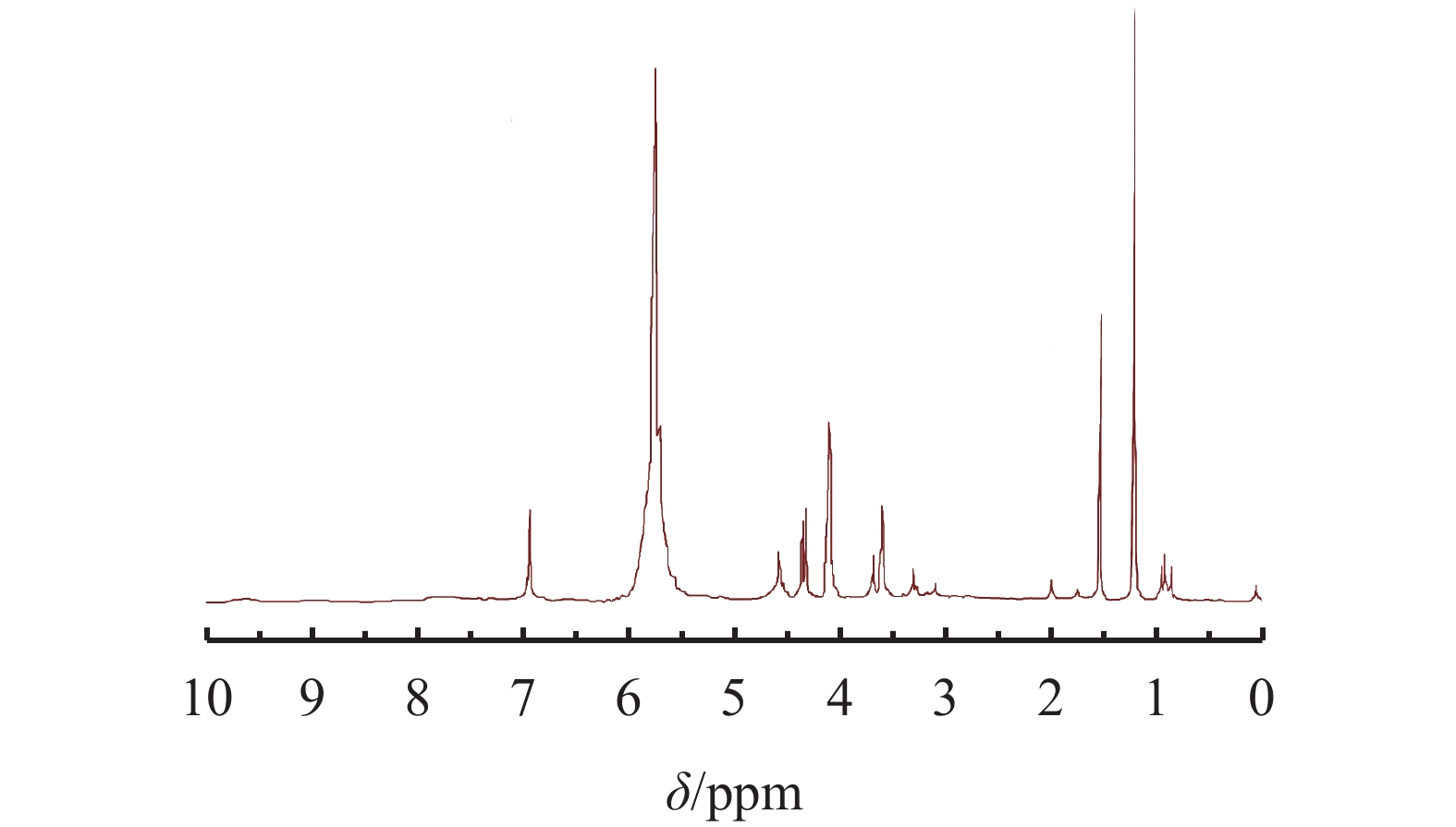

摘要: 为提高水基钻井液用提切剂抑黏提切效果和环保性能,以低黏聚阴离子纤维素钠盐(PAC-LV)和十六烷基异氰酸酯为原料,二丁基二月桂酸锡(DBTDL)为催化剂,合成了一种疏水缔合型天然改性产物作为抗高温环保型低增黏提切剂LVHY-1。通过正交实验确定了最佳合成条件:PAC-LV与十六烷基异氰酸酯的质量比为4∶1、反应温度为60 ℃、反应时间为12 h、DBTDL浓度为0.4%。借助核磁共振光谱仪(1H-NMR)进行了分子结构表征。流变性能测试结果显示,在120 ℃老化实验中,动塑比随LVHY-1加量的增大而提高。加量为0.2% LVHY-1的钻井液经170 ℃老化16 h后,其动塑比仍可达0.5 Pa/mPa·s,高温作用时间达64 h后仍保持良好的提切效果,表现出良好的抗温性和耐候性。透射电镜(TEM)观测结构显示,LVHY-1在溶液中可形成立体的网络结构,这是其具备提切效果的原因。环保性能测试结构显示,LVHY-1的半致死浓度EC50为30 100 mg/L,生物降解性评价指标(Y)为18.25,达到排放标准,易被微生物降解。Abstract: In order to improve the anti-viscosity and environmental performance of the extractant used for water-based drilling fluid, LVHY-1 was synthesized by using low viscosity anionic cellulose sodium salt (PAC-LV) and hexadecyl isocyanate as raw materials, and dibutyltin dilaurate (DBTDL) as catalyst. The optimum synthesis conditions were determined by orthogonal experiment: mass ratio of PAC-LV to cetyl isocyanate 4:1, reaction temperature 60 ℃, reaction time 12 h, DBTDL concentration 0.4%. The molecular structure was characterized by 1H-NMR. Rheological property test results showed that the dynamic plastic ratio (RYP) increased with the increase of LVHY-1 after hot aging test at 120 ℃. After hot aging at 170 ℃ for 16 h, the RYP of 0.2% LVHY-1 drilling fluid still reached 0.5 Pa/mPa·s, and kept good effect after hot aging for 64 h, showing excellent temperature and weather resistance. Transmission electron microscopy (TEM) observation showed that LVHY-1 could form a three-dimensional network structure in solution, which was the reason for the effect of LVHY-1. The test structure of environmental performance showed that the semi-maximum effective concentration (EC50) of LVHY-1 was 30 100 mg/L, and the biodegradability evaluation index (Y) was 18.25, which met the emission standard and was easy to be degraded by microorganisms.

-

表 1 L9(34)正交实验

水平 A B C D 质量比 T/℃ t/h DBTDL/% 1 3∶1 50 8 0.2 2 4∶1 60 12 0.4 3 5∶1 70 16 0.8 表 2 L9(34)正交实验结果

实验号 A B C D YP/PV/

Pa/mPa·s1# 3∶1 50 8 0.2 0.59 2# 3∶1 60 12 0.4 0.65 3# 3∶1 70 16 0.8 0.58 4# 4∶1 50 12 0.8 0.59 5# 4∶1 60 16 0.2 0.65 6# 4∶1 70 8 0.4 0.63 7# 5∶1 50 16 0.4 0.55 8# 5∶1 60 8 0.6 0.50 9# 5∶1 70 12 0.2 0.58 均值1 0.607 0.577 0.573 0.607 均值2 0.623 0.600 0.607 0.610 均值3 0.543 0.597 0.593 0.557 极差(R) 0.080 0.023 0.034 0.053 表 3 不同LVHY-1浓度下钻井液的流变性能

LVHY-1/% 实验条件 AV/

mPa·sPV/

mPa·sYP/

PaYP/PV /

Pa/mPa·s0.05 老化前 9.5 7.0 2.5 0.36 老化后 8.0 6.0 2.0 0.33 0.10 老化前 10.5 7.5 3.0 0.40 老化后 10.5 7.5 3.0 0.40 0.15 老化前 14.5 10.0 4.5 0.45 老化后 14.0 9.5 4.5 0.47 0.20 老化前 19.0 11.0 8.0 0.72 老化后 18.5 11.0 7.5 0.68 0.25 老化前 23.5 13.5 10.0 0.74 老化后 22.0 13.0 9.0 0.69 0.30 老化前 27.5 15.5 12.0 0.77 老化后 26.0 15.0 11.0 0.73 注:实验条件为120 ℃×16 h 表 4 热滚温度对钻井液流变性能的影响

T/

℃AV/

mPa·sPV/

mPa·sYP/

PaYP/PV /

Pa/mPa·s100 20.5 12.0 8.5 0.71 110 19.5 11.5 8.0 0.70 120 18.5 11.0 7.5 0.68 130 18.5 11.0 7.5 0.68 140 18.0 11.0 7.0 0.64 150 18.0 11.0 7.0 0.64 160 17.0 10.5 6.5 0.62 170 15.0 10.0 5.0 0.50 180 6.5 5.5 1.0 0.18 表 5 LVHY-1和常规处理剂的生物毒性和生物降解性

试剂 EC50/(mg/L) Y LVHY-1 30 100 18.25 XG 52 400 28.85 FHG 54 100 26.17 CTS 51 770 25.50 HV-CMC 30 020 19.20 PAC-HV 31 000 18.77 HEC 30 430 18.52 -

[1] CAMARA P C F, MADRUGA L Y C, MARQUES N N, et al. Evaluation of polymer/bentonite synergy on the properties of aqueous drilling fluids for high-temperature and high-pressure oil wells[J]. Journal of Molecular Liquids, 2021, 327:114808. doi: 10.1016/j.molliq.2020.114808 [2] ZHUANG G Z, ZHANG Z Z, PENG S. M., et al. Enhancing the rheological properties and thermal stability of oil-based drilling fluids by synergetic use of organo-montmorillonite and organo-sepiolite[J]. Applied Clay Science, 2018, 161:505-512. doi: 10.1016/j.clay.2018.05.018 [3] AGWU O E, AKPABIO J U, EKPENYONG M E, et al. A critical review of drilling mud rheological models[J]. Journal of Petroleum Science and Engineering, 2021, 203:108659. doi: 10.1016/j.petrol.2021.108659 [4] SUN J S, CHANG X F, LYU K H, et al. Salt-responsive zwitterionic copolymer as tackifier in brine drilling fluids[J]. Journal of Molecular Liquids, 2020, 319:114345. doi: 10.1016/j.molliq.2020.114345 [5] VILLADA Y, GALLARDO F, ERDMANN E, et al. Functional characterization on colloidal suspensions containing xanthan gum (XGD) and polyanionic cellulose (PAC) used in drilling fluids for a shale formation[J]. Applied Clay Science, 2017, 149:59-66. doi: 10.1016/j.clay.2017.08.020 [6] GAUTAM S, GURIA C, RAJAK V K. A state of the art review on the performance of high-pressure and high-temperature drilling fluids: Towards understanding the structure-property relationship of drilling fluid additives[J]. Journal of Petroleum Science and Engineering, 2022:110318. [7] RK RODRIGUES,M NACCACHE,PRDS MENDES, et al. Rheological modifiers in drilling fluids[J]. Journal of Non-Newtonian Fluid Mechanics, 2020:104397. [8] 褚奇,石秉忠,李涛,等. 水基钻井液用低增黏提切剂的合成与性能评价[J]. 钻井液与完井液,2019,36(6):689-693.CHU Qi, SHI Bingzhong, LI Tao, et al. Synthesis and evaluation of a low viscosity gelling agent for water base drilling fluids[J]. Drilling Fluid & Completion Fluid, 2019, 36(6):689-693. [9] CHU Q, LIN L. Synthesis and properties of an improved agent with restricted viscosity and shearing strength in water-based drilling fluid[J]. Journal of Petroleum Science and Engineering, 2019, 173:1254-1263. doi: 10.1016/j.petrol.2018.10.074 [10] GB/T 16783.1—2014. 石油天然气工业 钻井液现场测试 第1部分: 水基钻井液[S]. 2014.GB/T 16783.1—2014. Oil and gas industry drilling fluid field test Part 1: water-based drilling fluid [S]. 2014. [11] GB/T 15441—1995. 水质 急性毒性的测定 发光细菌法[S]. 1995.GB/T 15441-1995. Water quality determination of acute toxicity luminescent bacterial method [S]. 1995. [12] HJ 828—2017. 水质 化学需氧量的测定 重铬酸盐法[S]. 2017.HJ 828-2017. Water quality determination of the chemical oxygen demand dichromate method [S]. 2017. [13] HJ 505—2009. 水质 五日生化需氧量(BOD5)的测定 稀释与接种法[S]. 2009.HJ 505—2009. Water quality determination of biochemical oxygen demand after 5 days(BOD5) of dilution and seeding method [S]. 2009. [14] 易绍金, 佘跃惠. 石油与环境微生物技术[M]. 北京: 中国地质大学出版社, 2002.YI Shaojin, She Yuehui. Petroleum and environmental microbiology technology [M]. Beijing: China University of Geosciences Press, 2002. -

下载:

下载: