Development and Application of Comb-like Polymer Filter Loss Reducer with High Temperature and High Calcium Contamination Resistance

-

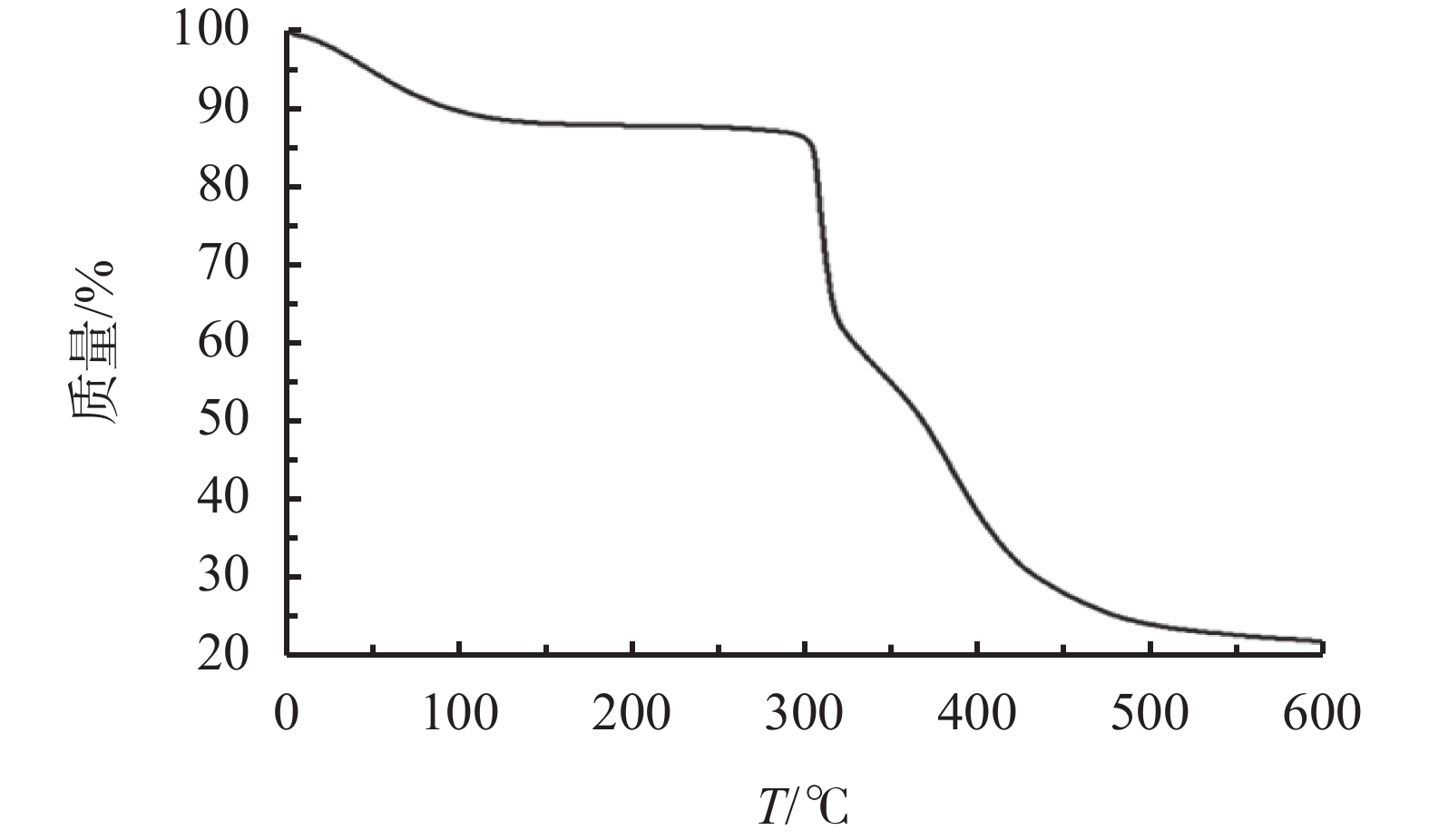

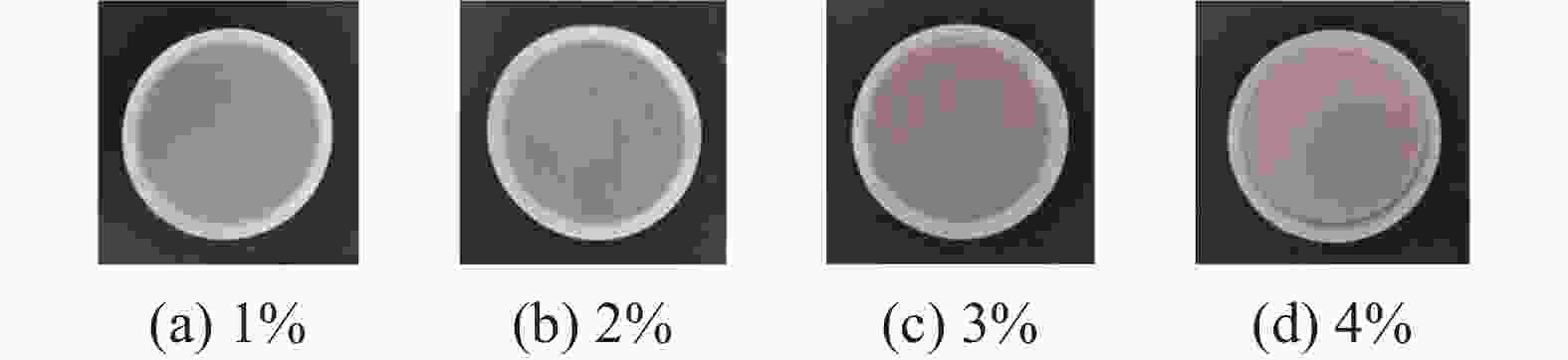

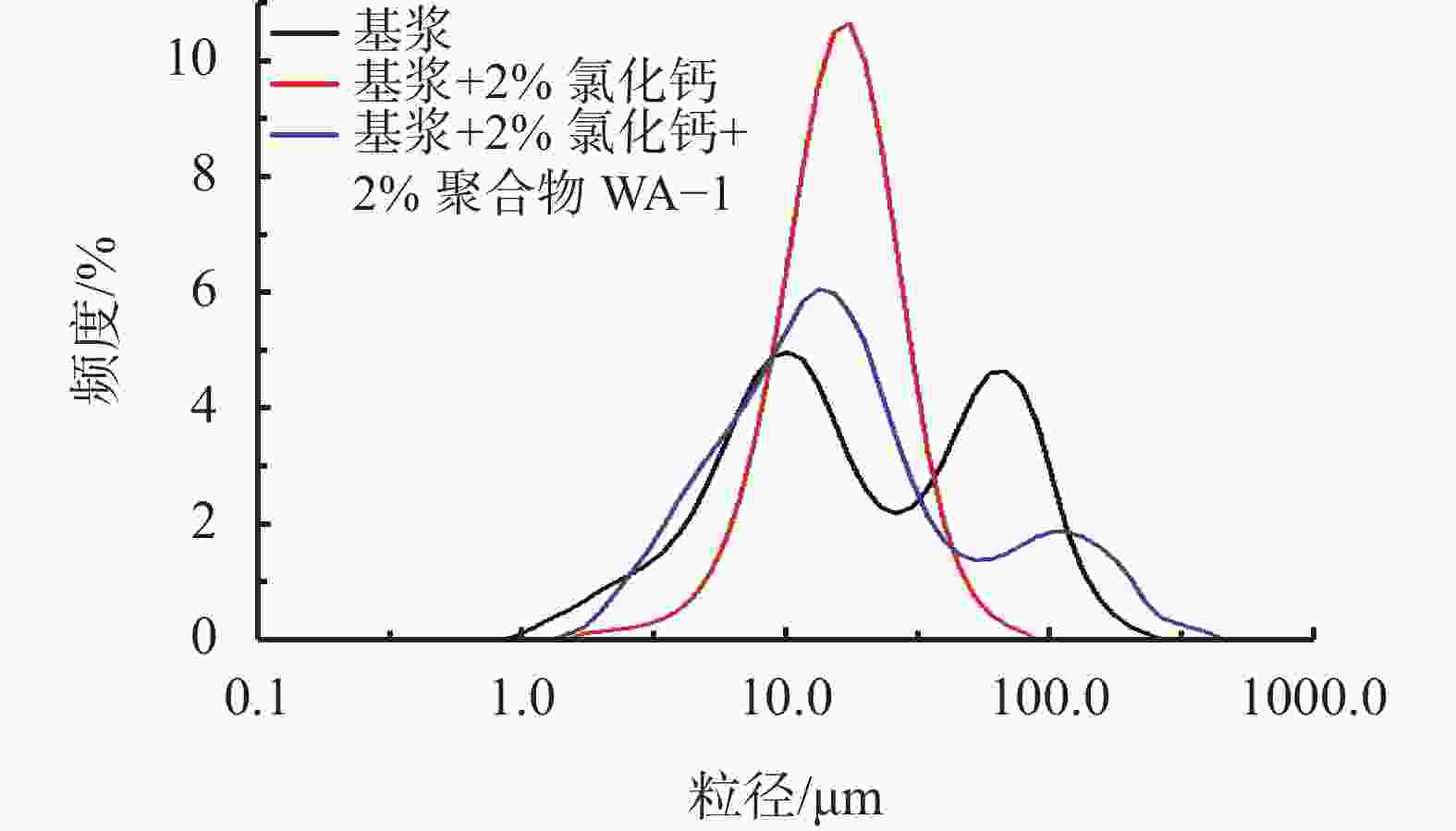

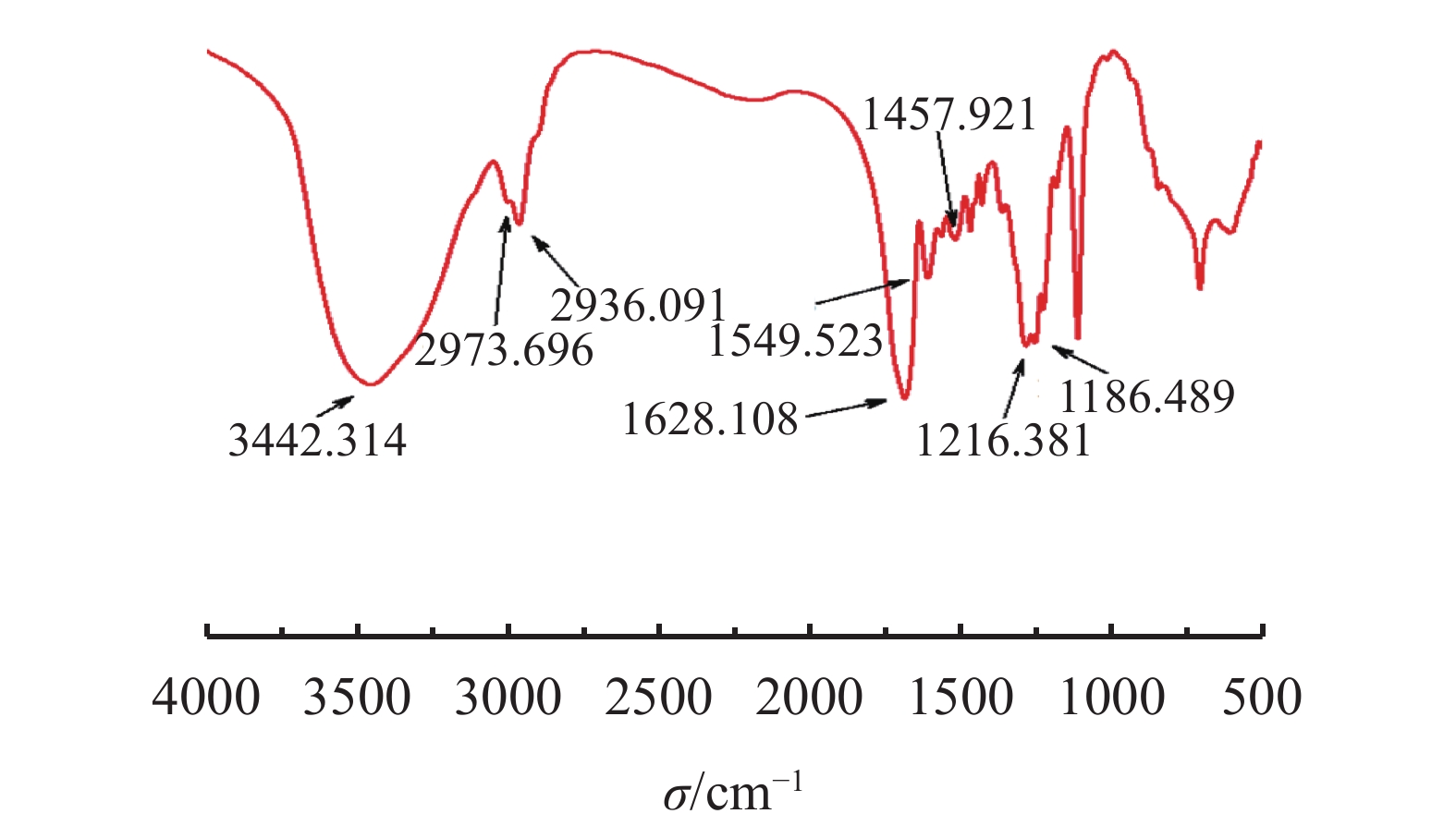

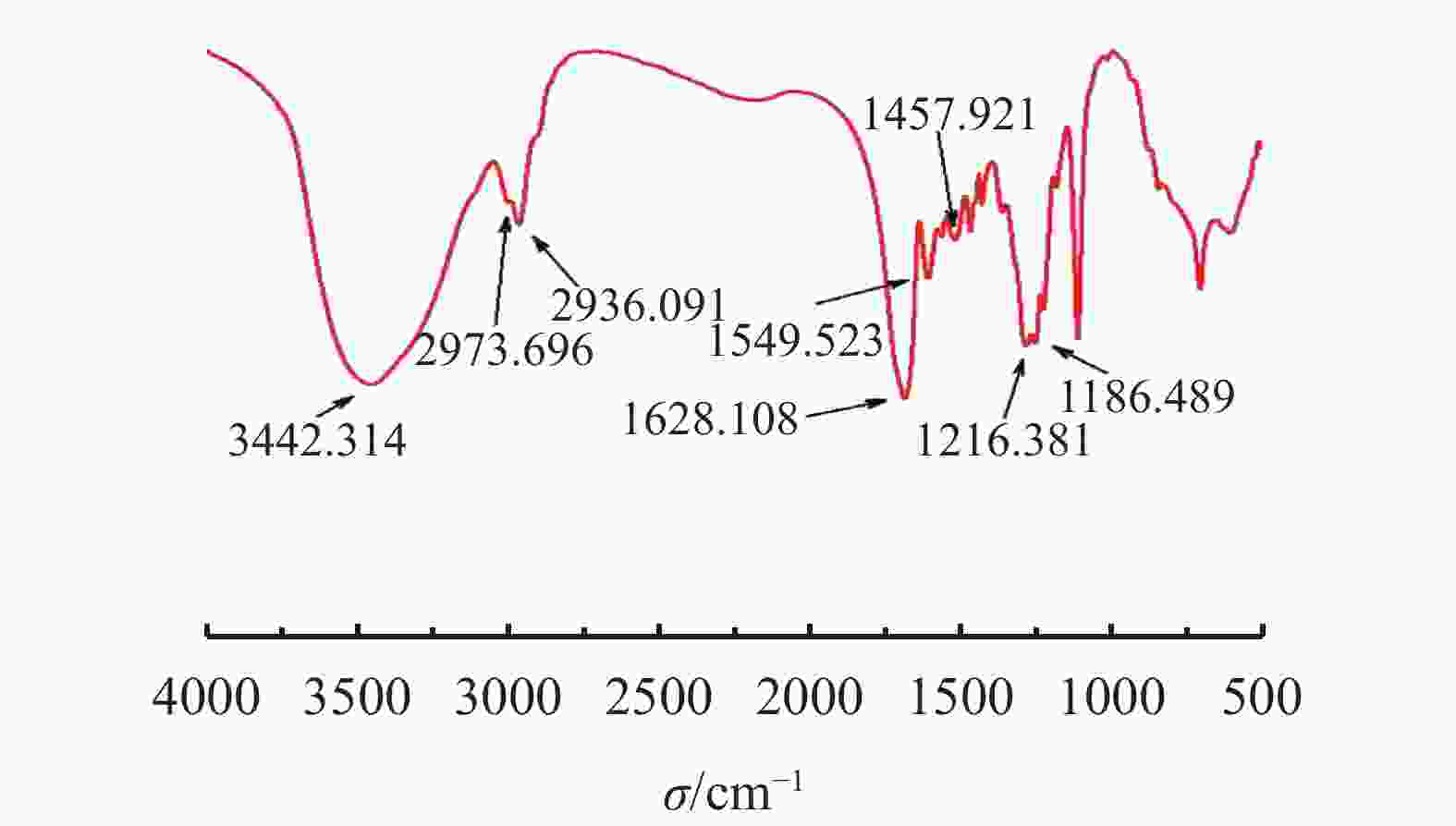

摘要: 选择几种不同的单体,按照一定配比,优选最佳方案合成梳型聚合物降滤失剂WA-1,并通过对比实验对其进行性能评价。选用2-丙烯酰胺基-2-甲基丙磺酸(AMPS)、二甲基二烯丙基氯化铵(DMDAAC)、N-乙烯基吡咯烷酮(NVP)和N,N-二甲基丙烯酰胺(DMAA)为单体,合成质量配比AMPS∶DMDAAC∶NVP∶DMAA=5∶3∶1∶1,总单体浓度19.8%,加0.2%过硫酸钾作为引发剂,反应温度为60 ℃,反应时间共5 h,pH值为7。性能评价结果表明,WA-1可抗温180 ℃,具有良好的流变性和降滤失性,抗钙性能良好;含2%CaCl2的基浆中加2%WA-1,在180 ℃老化16 h后,中压滤失量为11.2 mL,降滤失效果优于线性聚合物。对WA-1进行红外光谱表征、热重量分析、钻井液Zeta电位和粒径分布分析,结果表明,WA-1作为梳型聚合物降滤失剂,能够抗高温高钙,提高钻井液的稳定性,具备独特的性能优势。Abstract: A comb polymer filter loss reducer, WA-1, was synthesized with different monomers in a specific ratio. Comparative experiments were designed, and the optimum reaction program selected for the synthesis reaction. Monomers used in the synthesis of WA-1 included 2-acrylamido-2-methylpropanesulfonic acid (AMPS), dimethyl diallyl ammonium chloride (DMDAAC), N-vinyl pyrrolidone (NVP) and N, N-dimethyl acrylamide (DMAA) in a mass ratio of AMPS∶DMDAAC∶NVP∶DMAA = 5∶3∶1∶1. The total concentration of the monomers was 19.8%. Potassium persulphate of 2‰ was used as the reaction initiator. The monomers were allowed to react for 5 hours at 60 ℃ and pH of 7. Evaluation of the final product has shown that WA-1 can be used at temperatures up to 180 ℃. Drilling fluids treated with WA-1 have good rheology, filtration property and calcium contamination resistance. In laboratory experiment, a base mud containing 2%CaCl2 was treated with 2%WA-1. The mud was aged at 180 ℃ for 16 hours and then tested. The API filtration rate of the mud was 11.2 mL, which was less than the filtration rate of the mud treated with linear polymers. Infrared spectroscopy characterization, thermogravimetric analysis, Zeta-potential measurement and particle size distribution analysis of drilling fluids treated with WA-1 have shown that, as a comb polymer filter loss reducer, WA-1 is able to resist the adverse effects of high temperature and high calcium, and to improve the stability of drilling fluids.

-

Key words:

- High temperature resistant /

- High calcium resistant /

- Comb polymer /

- Filter loss reducer

-

表 1 方案优选

方案 溶剂 骨架

单体支链

单体pH

中性FLAPI/mL 1 甲醇 AMPS+

DMAA+NVPDMDAAC 否 全漏 2 是 全漏 3 乙醇 AMPS+NVP+

DMDAACDMAA 是 8.4 4 AMPS+

DMAA+NVPDMDAAC 是 全漏 5 去离子水 PVA AMPS+DMAA+NVP+DMDA 否 17.3 6 AC 是 42.4 注:滤失量在25 ℃测定,方案1、2、3引发剂使用过硫酸钾;方案4、5、6引发剂使用硝酸铈铵 表 2 加入WA-1后基浆的流变参数和滤失性

WA-1/

%实验

条件AV/

mPa·sPV/

mPa·sYP/

PaYP/PV/

Pa/mPa·sFLAPI/

mL0.5 老化前 12.5 8 4.5 0.56 12.4 老化后 17.5 13 4.5 0.35 18.8 1.0 老化前 13.0 9 4.0 0.44 10.4 老化后 30.5 24 6.5 0.27 14.8 1.5 老化前 11.5 8 3.5 0.44 8.4 老化后 23.0 17 6.0 0.35 13.6 2.0 老化前 12.0 9 3.0 0.33 7.20 老化后 19.5 15 4.5 0.30 7.60 注:老化条件为180 ℃、16 h 表 3 加入2%WA-1基浆在不同温度老化16 h后的抗温性

T老化/

℃AV/

mPa·sPV/

mPa·sYP/

PaYP/PV/

Pa/mPa·sFLAPI/

mL25 19.5 15 4.5 0.30 7.6 120 15.0 11 4.0 0.36 10.6 150 26.0 21 5.0 0.24 11.2 180 19.5 15 4.5 0.30 11.6 200 10.0 8 2.0 0.25 15.2 表 4 WA-1的抗钙实验(180 ℃、16 h)

氯化钙/

%实验

条件$ {\mathrm{\varphi }}_{600} $ $ {\mathrm{\varphi }}_{300} $ AV/

mPa·sPV/

mPa·sYP/

PaFLAPI/

mL1 老化前 27 17 13.5 10 3.5 5.6 老化后 19 10 9.5 9 0.5 9.6 2 老化前 25 14 12.5 11 1.5 6.4 老化后 16 9 8.0 7 1.0 11.2 3 老化前 13 8 6.5 5 1.5 9.6 老化后 13 7 6.5 6 0.5 22.4 4 老化前 12 11 6.0 1 5.0 12.8 老化后 10 6 5.0 4 1.0 64.0 表 5 在2%CaCl2基浆中加入不同聚合物的性能

聚合物 实验

条件AV/

mPa·sPV/

mPa·sYP/

PaFLAPI/

mL0 老化前 5.0 4 1.0 105 180 ℃、16 h 2.5 1 1.5 194 2%线性

聚合物老化前 20.0 14 6.0 18.4 180 ℃、16 h 5.0 5 0 54.0 2%WA-1

聚合物老化前 12.5 11 1.5 6.4 180 ℃、16 h 8.0 7 1.0 11.2 表 6 不同基浆的Zeta电位分析

配方 ξ/mV 基浆 −30.5 基浆+2%CaCl2 −12.0 基浆+2%CaCl2+2%WA-1 −20.0 -

[1] 杨小华. 再论国内近5年钻井液处理剂研究与应用进展[C]//2009中国油田化学品发展研讨会(第23次全国工业表面活性剂发展研讨会)论文集. 2009: 222-230.YANG Xiaohua. Review on the research and application progress of drilling fluid additives in China in the past five years [C]//2009 China Oilfield Chemical Development Seminar (23rd National Industrial Surfactant Development Seminar). 2009 : 222-230. [2] 牛龙飞. 水溶性梳型聚合物降滤失剂的合成与性能评价[D]. 山东大学, 2012.NIU Longfei. Synthesis and performance evaluation of water-soluble comb polymer filtrate reducer [D]. Shandong University, 2012. [3] 迟姚玲,郑力会,冀德坤,等. 抗温环保型降滤失剂改性玉米淀粉的合成与评价[J]. 中国石油大学学报(自然科学版),2011,35(1):151-154.CHI Yaoling, ZHENG Lihui, JI Dekun, et al. Synthesis and evaluation of heat-resistant and environment-friendly filtrate reducer modified corn starch[J]. Journal of China University of Petroleum (Natural Science Edition) , 2011, 35(1):151-154. [4] 乔英杰,王慎敏,甄捷,等. 抗高温抗盐降滤失剂SHK-AN的合成及性能研究[J]. 哈尔滨师范大学自然科学学报,2001(5):86-90.QIAO Yingjie, WANG Shenmin, ZHEN Jie, et al. Synthesis and properties of high-temperature and salt-resistant filtrate reducer SHK-AN[J]. Journal of Natural Science, Harbin Normal University, 2001(5):86-90. [5] 王小石,唐仕忠,刘传禄. 新型高温抗盐降滤失剂RSTF的研究[J]. 钻井液与完井液,1997(2):28-30.WANG Xiaoshi, TANG Shizhong, LIU Chuanlu. Study on a new high temperature salt resistant filtrate reducer RSTF[J]. Drilling Fluid & Completion Fluid, 1997(2):28-30. [6] 史俊,李谦定,王涛. 硅化腐植酸钠GFN-1的研制[J]. 钻井液与完井液,2007(4):12-14.SHI Jun, LI Qianding, WANG Tao. Preparation of sodium silicified humic acid GFN-1[J]. Drilling Fluid & Completion Fluid, 2007(4):12-14. [7] 胡俊明,沈埜,徐僖,等. 接枝改性纤维素及其对水泥浆降失水性能的研究[J]. 油田化学,1989(2):100-104.HU Junming, SHEN Ye, XU Xi, et al. Grafted cellulose and its effect on water loss reduction of cement paste[J]. Oilfield Chemistry, 1989(2):100-104. [8] PATEL A D. Water-based drilling fluids with high temperature fluid loss control additive: U.S. Patent 5,789,349[P]. 1998-8-4. [9] SEPEHRI S, SOLEYMAN R, VARAMESH A, et al. Effect of synthetic water-soluble polymers on the properties of the heavy water-based drilling fluid at high pressure-high temperature (HPHT) conditions[J]. Journal of Petroleum Science and Engineering, 2018, 166:850-856. [10] 王艳新,陈艳玲,宋俊庭. Hofmann法制备新型两性离子AM-AMPS共聚物降滤失剂[J]. 地质科技情报,2008(4):107-110.WANG Yanxin, CHEN Yanling, SONG Junting. Hofmann method to prepare new amphoteric AM-AMPS copolymer filtrate reducer[J]. Geological Science and Technology Information, 2008(4):107-110. [11] 白秋月. DMAA/AMPS/DMDAAC/NVP四元共聚耐温耐盐钻井液降滤失剂的研制[J]. 油田化学,2017,34(1):1-5.BAI Qiuyue. Development of DMAA/AMPS/DMDAAC/NVP quaternary copolymer temperature-resistant and salt-tolerant drilling fluid filtrate reducer[J]. Oilfield Chemistry, 2017, 34(1):1-5. [12] 王茂功,颜星,彭洁. 爆聚法合成抗高温抗盐水基降滤失剂及性能评价[J]. 钻井液与完井液,2019,36(2):148-152.WANG Maogong, YAN Xing, PENG Jie. Synthesis and performance evaluation of anti-high temperature and anti-salt water base filtrate reducer by explosive polymerization[J]. Drilling Fluid and Completion Fluid, 2019, 36(2):148-152. [13] 卢潮陵. 高吸水树脂的研究现状及其应用前景[J]. 能源与环境,2011(2):7-9.LU Chaoling. Research status and application prospect of super absorbent resin[J]. Energy and Environment, 2011(2):7-9. [14] 鄢捷年,罗平亚. 抗高温抗盐失水控制剂磺甲基酚醛树脂(SMP)作用机理的研究[J]. 钻井泥浆,1984(2):1-12.YAN Jienian, LUO Pingya. Study on the action mechanism of sulfomethylphenolic resin ( SMP ), a high temperature and salt resistance water loss control agent[J]. Drilling Mud, 1984(2):1-12. [15] 周启成,单海霞,位华,等. 环保型生物质合成树脂降滤失剂[J]. 钻井液与完井液,2020,37(5):593-596.ZHOU Qicheng, SHAN Haixia, WEI Hua, et al. Environmentally friendly biomass synthetic resin filtrate reducer[J]. Drilling Fluid and Completion Fluid, 2020, 37(5):593-596. [16] 程桂玲. 无机-有机聚合物降滤失剂PTF的研制及应用[J]. 钻井液与完井液,2009,26(3):29-31.CHENG Guiling. Development and application of inorganic-organic polymer filtrate reducer PTF[J]. Drilling Fluid & Completion Fluid, 2009, 26(3):29-31. [17] 张永明,朱红,王芳辉,等. CTAB/聚合物复合插层膨润土降滤失剂的制备与表征[J]. 功能材料,2008,39(12):2028-2031.ZHANG Yongming, ZHU Hong, WANG Fanghui, et al. Preparation and characterization of CTAB/polymer composite intercalated bentonite filtrate reducer[J]. Functional Materials, 2008, 39(12):2028-2031. [18] 蒲晓林,雷刚,罗兴树,等. 钻井液隔离膜理论与成膜钻井液研究[J]. 钻井液与完井液,2005(6):1-4.PU Xiaolin, LEI Gang, LUO Xingshu, et al. Drilling fluid isolation membrane theory and film-forming drilling fluid research[J]. Drilling Fluid & Completion Fluid, 2005(6):1-4. [19] 徐同台,赵忠举,袁春. 国外钻井液和完井液技术的新进展[J]. 钻井液与完井液,2004(2):3-12.XU Tongtai, ZHAO Zhongju, YUAN Chun. New progress of drilling fluid and completion fluid technology abroad[J]. DrillinG Fluid & Completion Fluid, 2004(2):3-12. [20] BOUHAMED H, BOUFI S, MAGNIN A. Dispersion of alumina suspension using comb-like and diblock copolymers produced by RAFT polymerization of AMPS and MPEG[J]. Journal of Colloid and Interface Science, 2007, 312(2):279-291. [21] RAN Q, SOMASUNDARAN P, MIAO C, et al. Effect of the length of the side chains of comb-like copolymer dispersants on dispersion and rheological properties of concentrated cement suspensions[J]. Journal of Colloid and Interface Science, 2009, 336(2):624-633. [22] 徐运波,蓝强,张斌,等. 梳型聚合物降滤失剂的合成及其在深井盐水钻井液中的应用[J]. 钻井液与完井液,2017,34(1):33-38. doi: 10.3696/j.issn.1001-5620.2017.01.006XU Yunbo, LAN Qiang, ZHANG Bin, et al. Synthesis of comb polymer filtrate reducer and its application in deep well brine drilling fluid[J]. Drilling Fluid & Completion Fluid, 2017, 34(1):33-38. doi: 10.3696/j.issn.1001-5620.2017.01.006 -

下载:

下载: