The Development and Function Mechanisms of an Zwitterionic Polymer/Polyol Borehole Wall Strengthening Additive

-

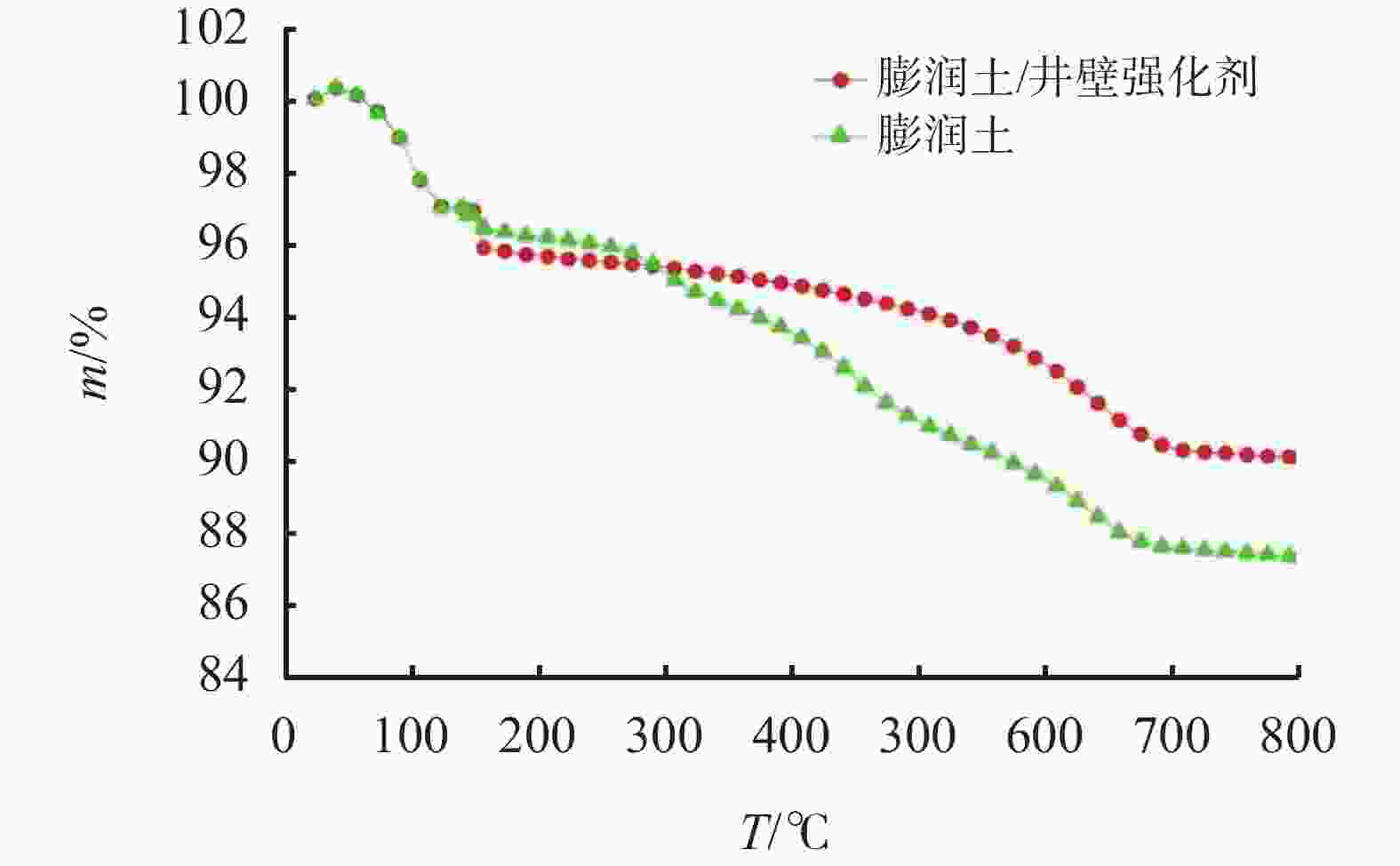

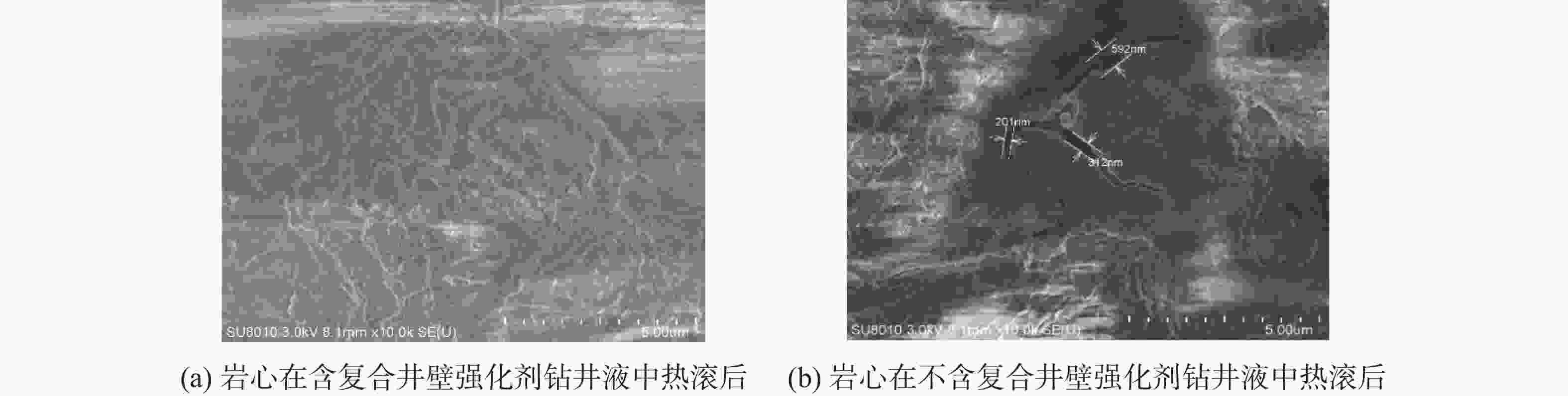

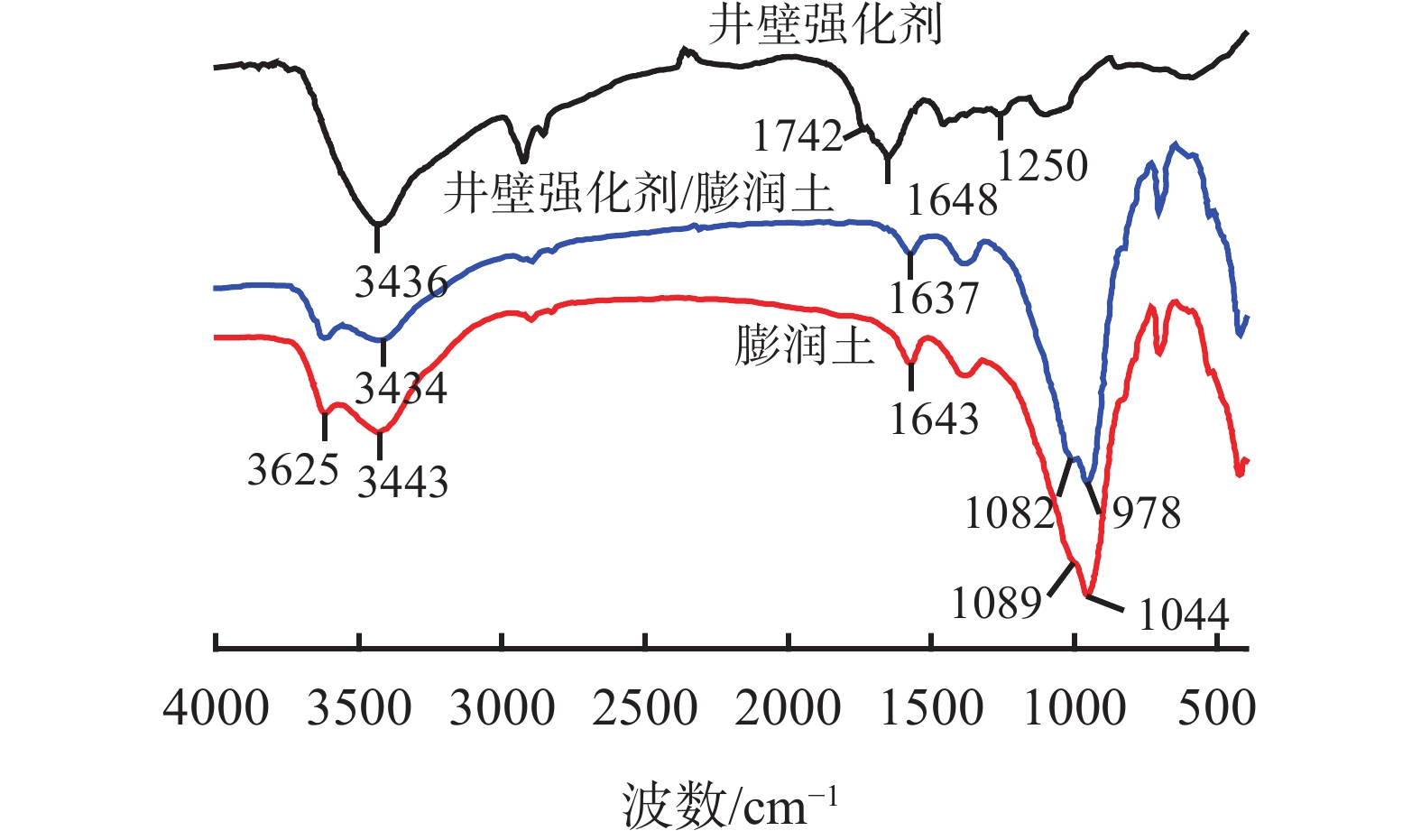

摘要: 针对水基钻井液钻探页岩油气频繁遭遇的井壁失稳难题,同时考虑阳离子基团与多重醇羟基在井壁上的吸附作用,通过酯化反应将两性离子聚合物丙烯酰胺(AM)-丙烯酸(AA)-二甲基二烯丙基氯化铵(DMDAAC)与聚乙烯醇接枝,研制了一种复合井壁强化剂(WSC-1)。性能评价结果表明,WSC-1对人造岩心点载荷强度的提高率达26.90%,页岩岩心浸泡后可保持71.3%的内聚力;3%加量下可控制页岩线性膨胀量为63.22%,页岩屑150 ℃的滚动回收率达87.2%,优于聚醚胺、聚合醇等常用井壁稳定剂,且兼具一定的降滤失性能。通过红外光谱分析、扫描电镜观察,并结合聚DMDAAC和聚乙烯醇的稳定井壁机理讨论了WSC-1的作用机理:WSC-1通过离子键与氢键强吸附在井壁岩石表面,抑制了黏土矿物水化、分散,且在聚乙烯醇的“多点吸附”作用下形成吸附膜,封堵裂缝并减少自由水向地层中的渗滤,有效强化了井壁。Abstract: A compound borehole wall strengthening agent WSC-1 was developed to deal with the borehole wall instability frequently encountered in shale oil development with water based drilling fluids. The WSC-1 additive was synthesized through esterification reaction with a zwitterionic polymer AM-AA-DMDAAC (acrylamide-acrylic acid-dimethyl diallyl ammonium chloride) and polyvinyl alcohol. WSC-1 possesses cationic groups and poly hydroxy groups which make it easy for the WSC-1 to be adsorbed onto the surfaces of the borehole walls. In laboratory evaluation, the point load strength of an artificial core was increased by 26.90% with the help of WSC-1, and the cohesion of the core after soaking was maintained at 71.3%. The linear expansion of shale cores can be reduced by 63.22% tested with a 3% WSC-1 solution. In hot rolling test, the percent recovery of shale cuttings after hot rolling at 150 ℃ was 87.2%, a recovery higher than the results tested with commonly used borehole wall stabilizers such as polyetheramine and polyglycol. WSC-1 also showed some filtration control capacity in the test. Using IR and SEM analyses, it was found that WSC-1 can be adsorbed on the surfaces of the rocks through ionic bonding and hydrogen bonding, thereby inhibiting the hydration and dispersion of clay minerals. WSC-1 can also form an adsorption film through the “multi-point adsorption” of the polyvinyl alcohol, the film can seal off the fractures in the formation rocks, thus minimizing the filtration of free water into the formation and strengthening the borehole walls.

-

Key words:

- Borehole collapse /

- Water based drilling fluid /

- Borehole wall strengthening /

- Polymer /

- Mechanism

-

表 2 页岩岩心在不同围压下的三轴抗压强度参数

溶液 围压

10 MPa围压

20 MPa围压

30 MPa内聚

力/MPaθ/

(°)p/

MPaE/

GPap/

MPaE/

GPap/

MPaE/

GPa岩心

干样150.4 20.6 203.5 30.4 235.4 21.0 27.03 38.25 清水 90.5 17.0 169.2 20.3 201.1 23.5 9.14 43.93 3%井壁

强化剂121.4 19.9 178.5 23.5 210.2 20.6 19.28 39.22 10%KCl 118.2 18.5 171.3 18.7 205.8 18.8 18.52 38.92 表 1 不同溶液中浸泡相同时间的人造岩心点载荷强度

液体 点载荷强度/N 强度提高率/% 清水 25.46 3%聚醚胺 27.24 6.70 3%聚乙烯醇 26.71 4.91 3%P-DMDAAC 28.50 11.94 3%井壁强化剂 32.31 26.90 表 3 不同溶液对膨润土的抑制性影响

液体 膨胀高度/mm 膨胀高度抑制率/% 清水 3.67 3%聚醚胺 2.40 34.60 3%聚乙烯醇 1.98 46.05 3%P-DMDAAC 1.50 59.12 3%井壁强化剂 1.35 63.22 表 4 加入井壁强化剂前后水基钻井液的性能(150 ℃、16 h)

3%WSC-1 φ6/φ3 PV/

mPa·sYP/

PaGel/

Pa/PaFLHTHP/

mL黏滞

系数滚动回

收率/%加入前 27/23 41 28 10/18 11.5 0.0526 70.20 加入后 25/24 42 31 11/19 8.1 0.0515 99.55 注:基浆为:0.1%包被剂+0.3%降滤失剂+0.2%流型调节剂+2%降滤失剂-Ⅲ+2%封堵剂+1%成膜剂+1%仿生抑制剂+2%CaCO3+1.5%键合润滑剂+5%KCl+0.5%双疏剂+1230 g重晶石(ρ=1.8 g/cm3);清水岩屑滚动回收率为43% -

[1] 蔚宝华,王治中,郭彬. 泥页岩地层井壁失稳理论研究及其进展[J]. 钻采工艺,2007,30(3):16-20. doi: 10.3969/j.issn.1006-768X.2007.03.006YU Baohua, WANG Zhizhong, GUO Bin. Borehole instability theory of shale and its research progress[J]. Drilling & Production Technology, 2007, 30(3):16-20. doi: 10.3969/j.issn.1006-768X.2007.03.006 [2] 黄荣樽,陈勉. 泥页岩井壁稳定力学与化学的耦合研究[J]. 钻井液与完井液,1995,12(3):15-21.HUANG Rongzun, CHEN Mian. Study on shale stability of wellbore by mechanics coupling with chemistry method[J]. Drilling Fluid & Completion Fluid, 1995, 12(3):15-21. [3] ZEYNALI M E. Mechanical and physico-chemical aspects of wellbore stability during drilling operations[J]. Journal of Petroleum Science and Engineering, 2012, 82:120-124. doi: 10.1016/j.petrol.2012.01.006 [4] 何世明,陈俞霖,马德新,等. 井壁稳定多场耦合分析研究进展[J]. 西南石油大学学报(自然科学版),2017,39(2):81-92.HE Shiming, CHEN Yulin, MA Dexin, et al. A review on wellbore stability with multi-field coupling analysis[J]. Southeast Petroleum University Acta(Science Technology Editon) , 2017, 39(2):81-92. [5] 唐林,罗平亚. 泥页岩井壁稳定性的化学与力学耦合研究现状[J]. 西南石油学院学报,1997(2):93-96.TANG Lin, LUO Pingya. A review on chemical and mechanical coupling of shale borehole stability[J]. Southeast Petroleum University Acta (Science Technology Editon) , 1997(2):93-96. [6] 刘敬平,孙金声. 页岩气藏地层井壁水化失稳机理与抑制方法[J]. 钻井液与完井液,2016,33(3):25-29. doi: 10.3969/j.issn.1001-5620.2016.03.005LIU Jingping, SUN Jinshen. Borehole wall collapse and control in shale gas well drilling[J]. Drilling Fluid & Completion Fluid, 2016, 33(3):25-29. doi: 10.3969/j.issn.1001-5620.2016.03.005 [7] 唐文泉,高书阳,王成彪,等. 龙马溪页岩井壁失稳机理及高性能水基钻井液技术[J]. 钻井液与完井液,2017,34(3):21-26. doi: 10.3969/j.issn.1001-5620.2017.03.004TANG Wenquan, GAO Shuyang, WANG Chengbiao, et al. Research on mechanisms of wellbore instability of Longmaxi shale formation and high performance water base drilling fluid technology[J]. Drilling Fluid & Completion Fluid, 2017, 34(3):21-26. doi: 10.3969/j.issn.1001-5620.2017.03.004 [8] JAIN R, MAHTO V. Formulation of a water based drilling fluid system with synthesized graft copolymer for troublesome shale formations[J]. Journal of Natural Gas Science and Engineering, 2017, 38:171-181. doi: 10.1016/j.jngse.2016.12.018 [9] KHODJA M, CANSELIER J P, BERGAYA F, et al. Shale problems and water-based drilling fluid optimisation in the Hassi Messaoud Algerian oil field[J]. Applied Clay Science, 2010, 49(4):383-393. doi: 10.1016/j.clay.2010.06.008 [10] 孙金声,刘敬平,闫丽丽,等. 国内外页岩气井水基钻井液技术现状及中国发展方向[J]. 钻井液与完井液,2016,33(5):1-8.SUN Jinshen, LIU Jingping, YAN Lili, et al. Status quo of water base drilling fluid technology for shale gas drilling in china and abroad and its developing trend in China[J]. Drilling Fluid & Completion Fluid, 2016, 33(5):1-8. [11] 孔勇,金军斌,林永学,等. 封堵防塌钻井液处理剂研究进展[J]. 油田化学,2017,34(3):556-560. doi: 10.19346/j.cnki.1000-4092.2017.03.034KONG Yong, JIN Junbin, LIN Yongxue, et al. A review on plugging and anti-slump drilling fluid treatment agent[J]. Oilfield Chemistry, 2017, 34(3):556-560. doi: 10.19346/j.cnki.1000-4092.2017.03.034 [12] 王赢,孙成科,张喜平,等. 点荷载试验在岩基评价中的应用[J]. 港工技术,2013,50(6):56-60. doi: 10.16403/j.cnki.ggjs2013.06.003WANG Ying, SUN Chengke, ZHANG Xiping, et al. The use of the point load test in batholite evaluation[J]. Port Engineering Technology, 2013, 50(6):56-60. doi: 10.16403/j.cnki.ggjs2013.06.003 -

下载:

下载: