Study on Fracturing Fluid Formulated with Ultra-High Temperature Retarded Crosslinking Polymers

-

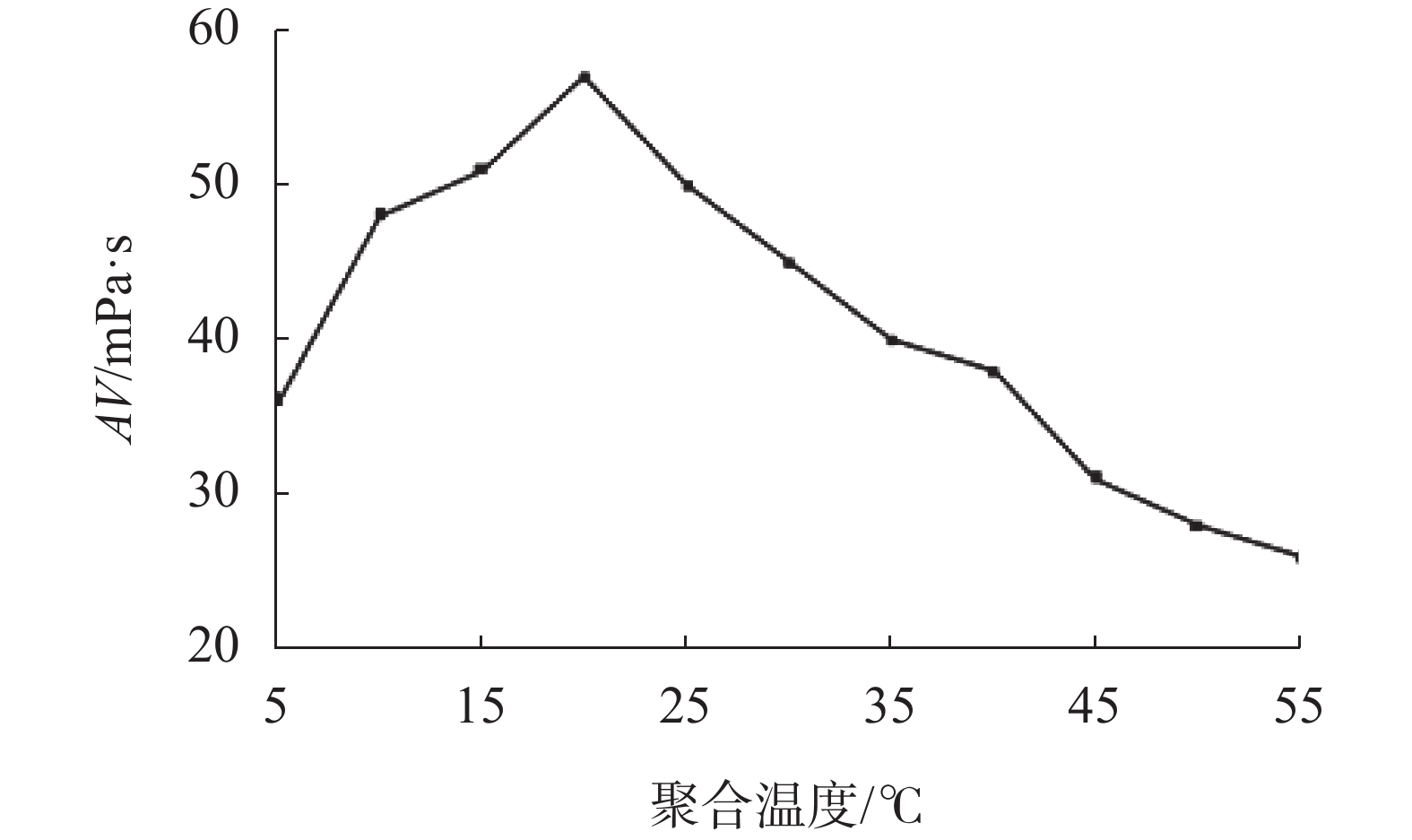

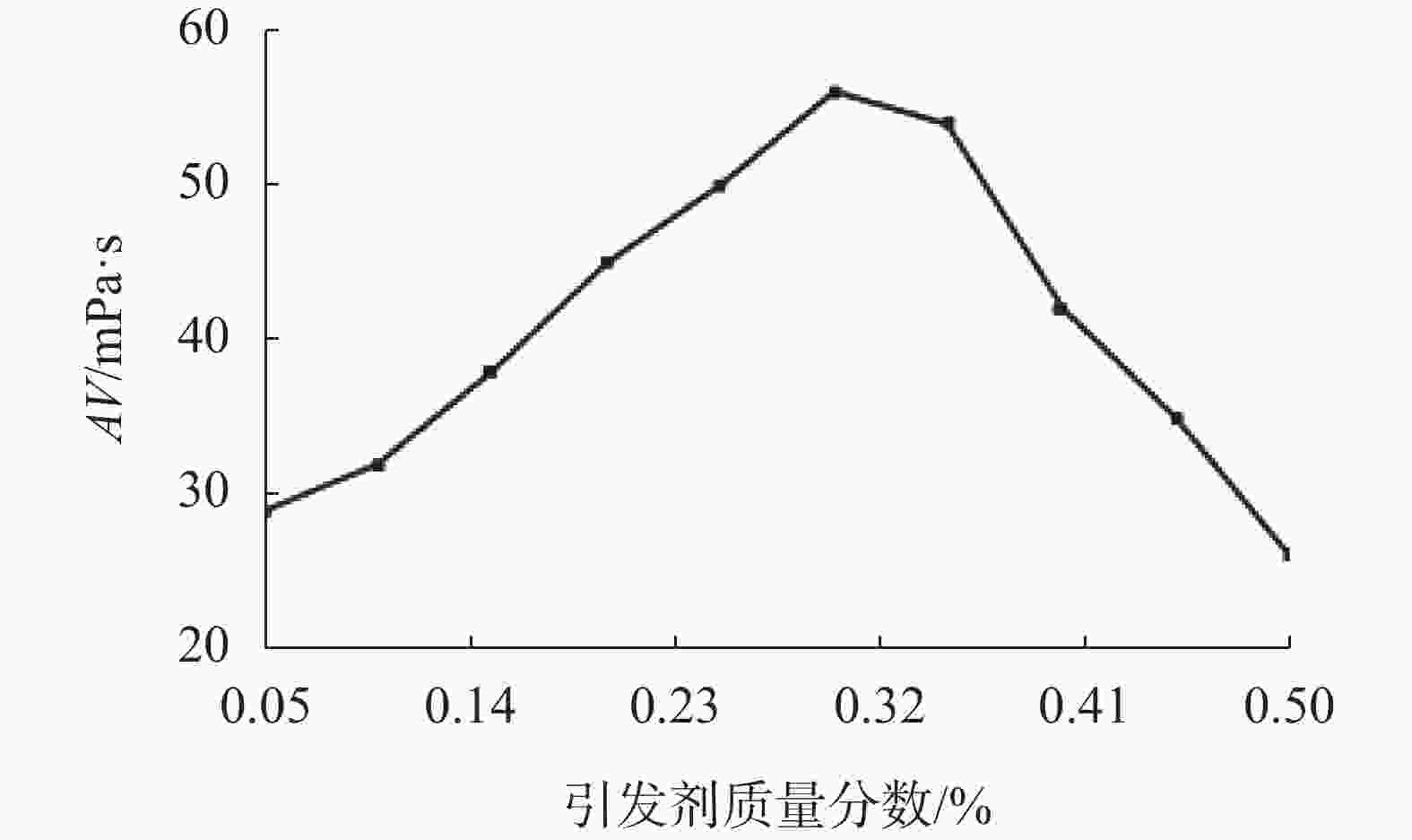

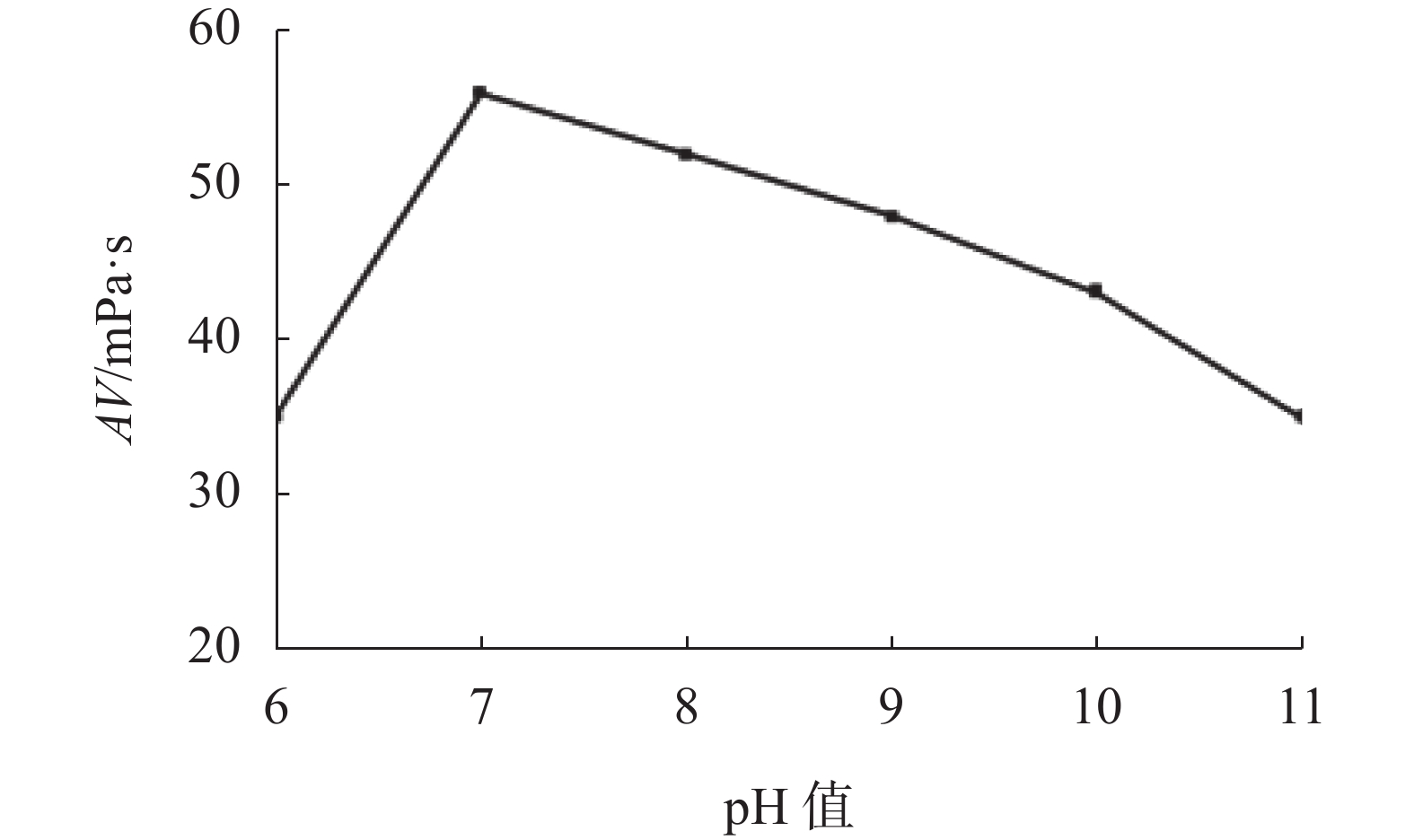

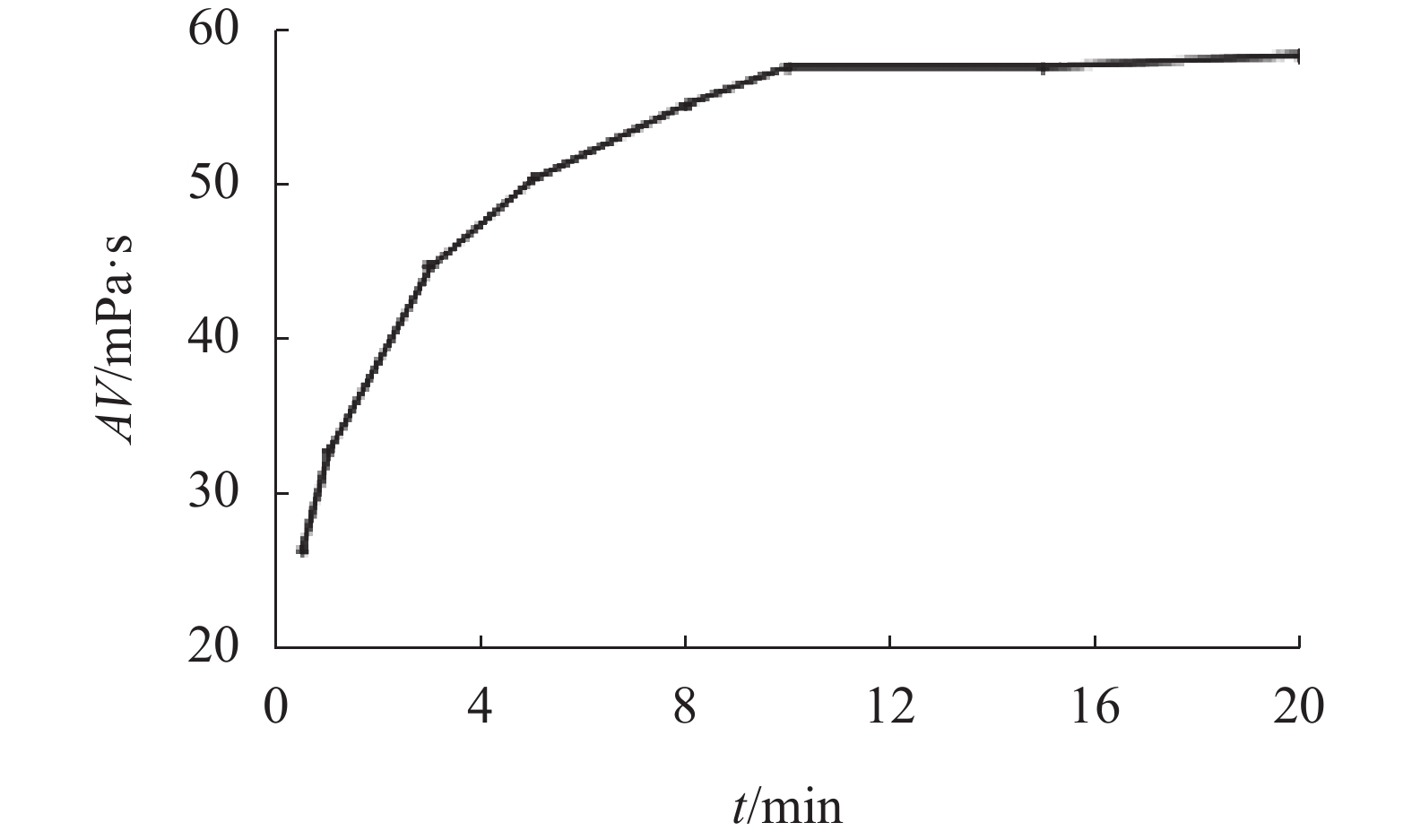

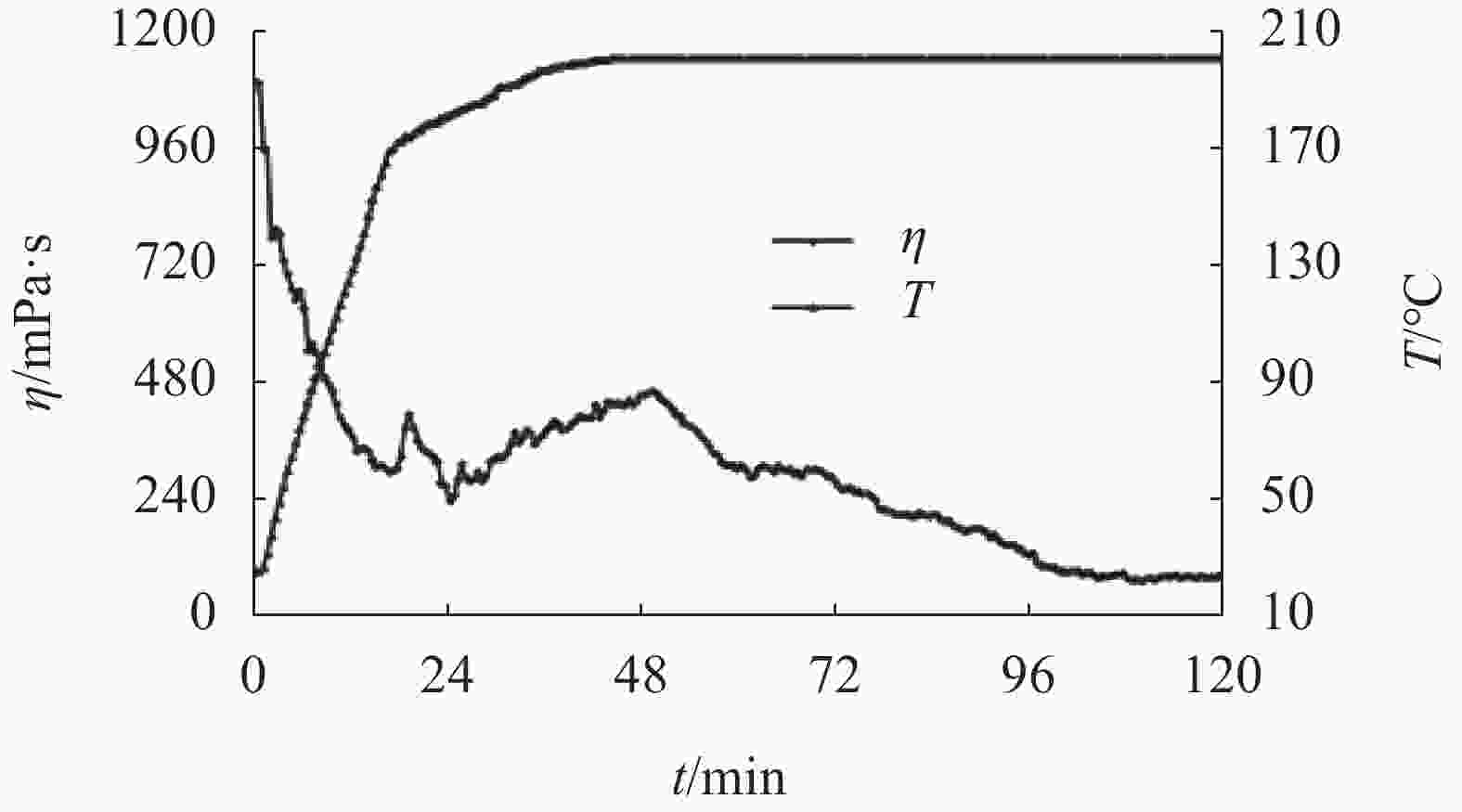

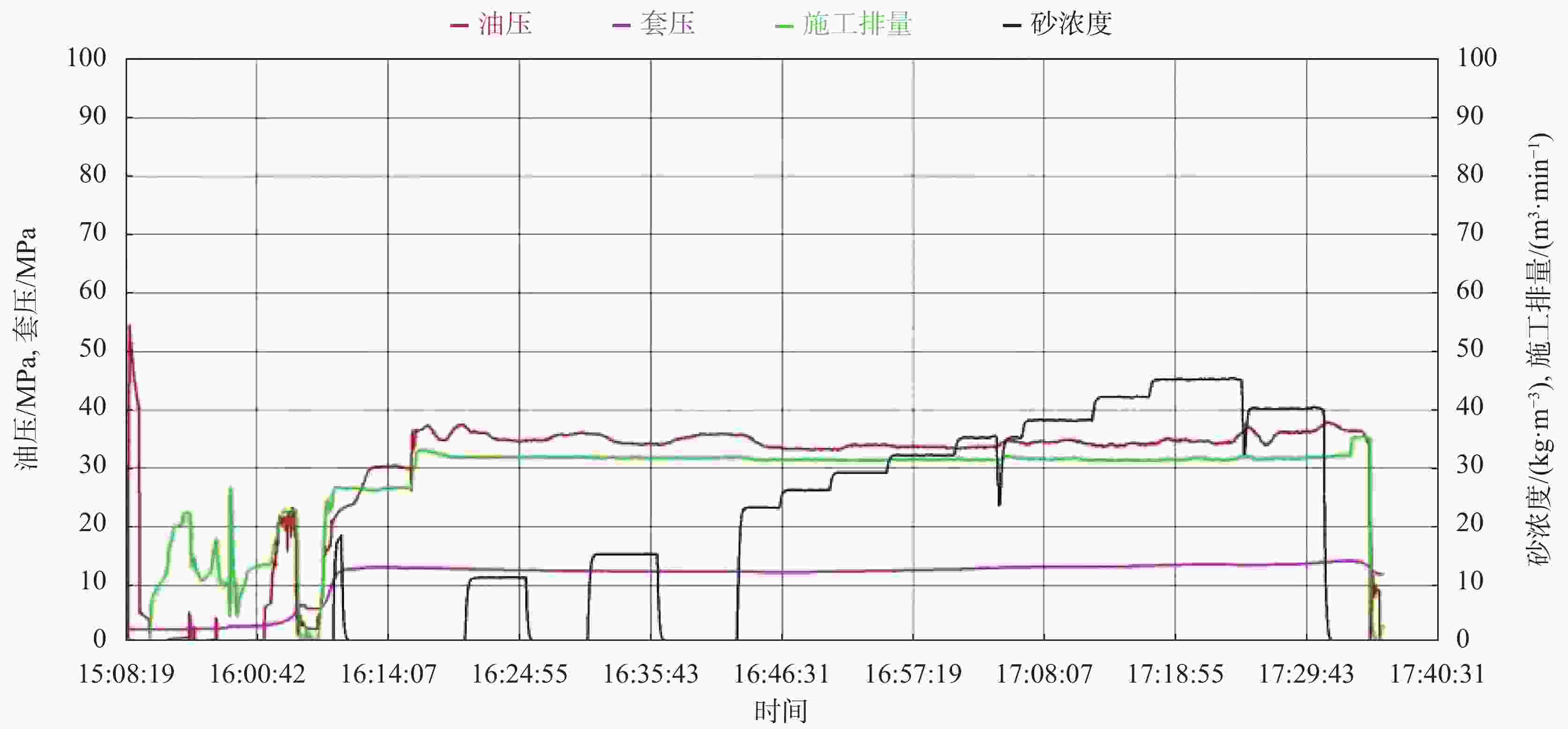

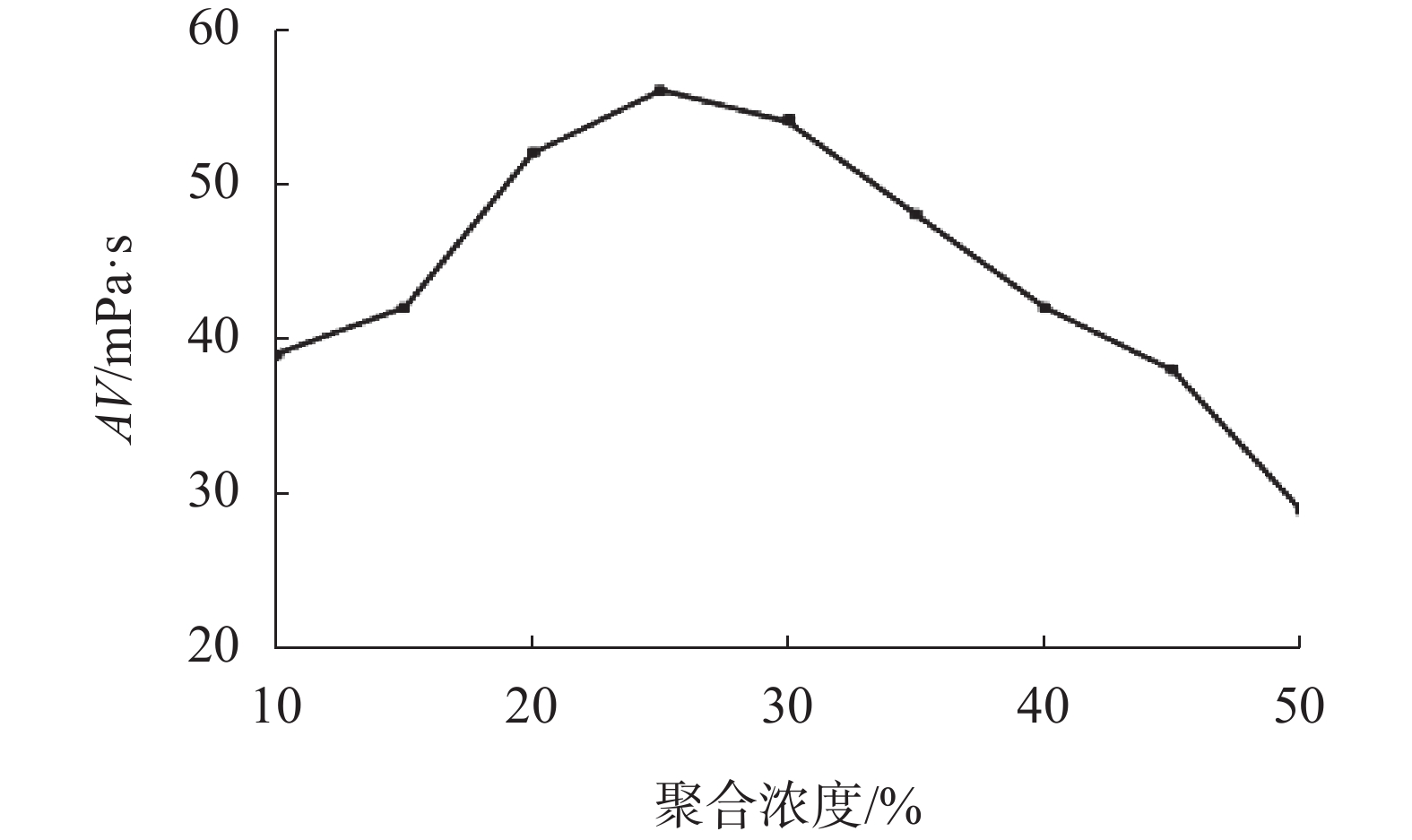

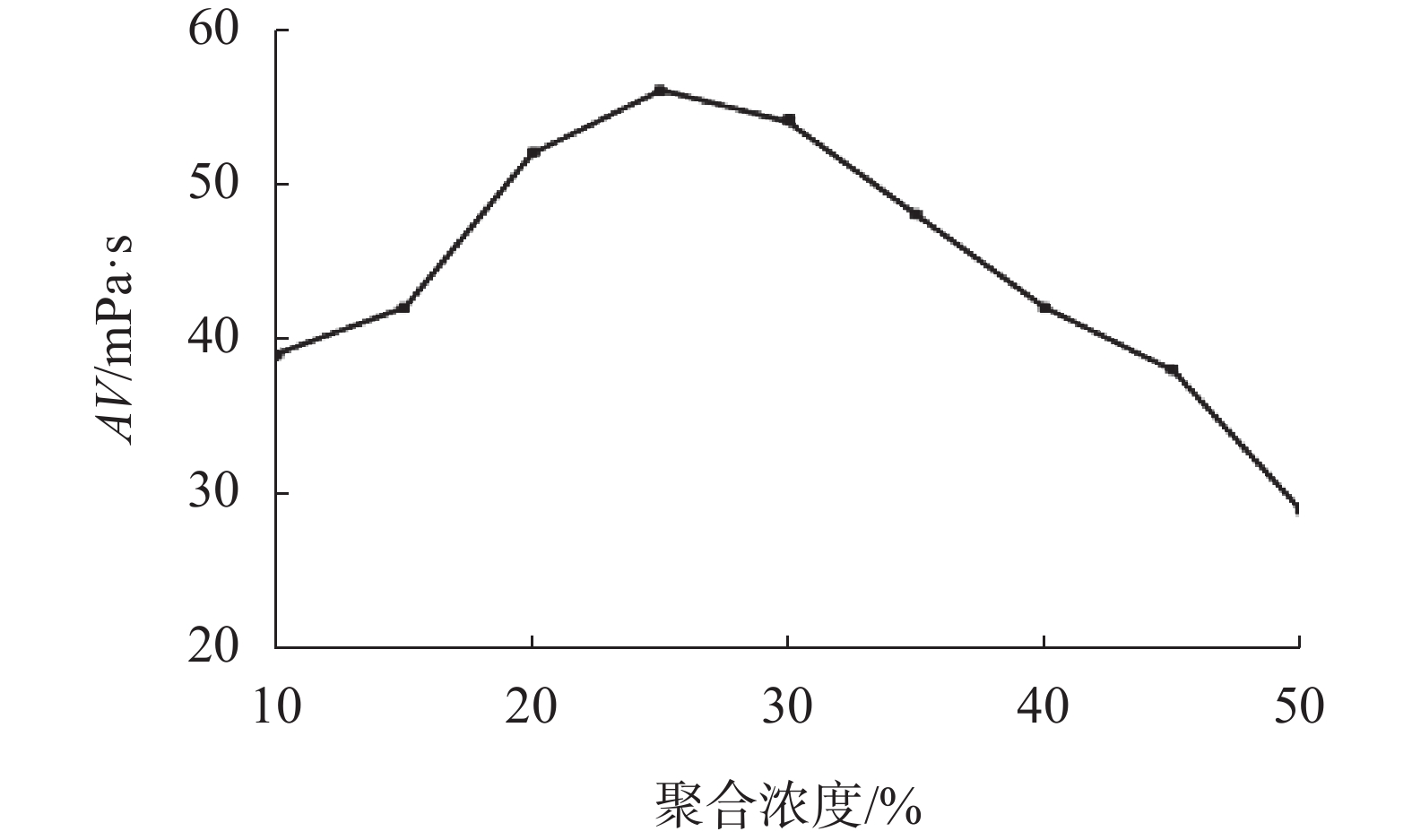

摘要: 针对水基压裂液体系中植物胶稠化剂及其衍生物存在残渣含量高、耐温差和易腐败变质等问题,基于水溶性高分子自由基合成理论,经室内高分子合成实验,研究了各种合成条件(引发剂浓度、聚合温度、反应pH值、聚合浓度、链转移剂含量、水解度)对稠化剂性能的影响规律。以丙烯酰胺(AM)、功能性单体(SP)、耐温单体(AMPS)作为共聚单体,采用控制变量法,通过合成条件优化,形成了一套性能优异的合成聚合物稠化剂基础配方,聚合浓度25%,单体配比(AMPS∶SP∶AM)30%∶25%∶45%,聚合温度20 ℃,引发剂浓度0.3%,聚合反应pH值为7,甲酸钠质量分数为0.2%,反应时间4 h。该稠化剂具备耐温、速溶、水不溶物含量低、增稠能力强,且与有机锆交联剂交联性能好,满足200 ℃地层的应用需要。Abstract: Plant gum thickening agents and their derivatives used in water based fracturing fluids have some shortages such as high residue content, poor thermal stability and easy spoilage. To solve these problems, a new thickening agent was developed with acrylamide (AM), a functional monomer SP and 2-Acrylamido-2-methylpropane sulfonic acid (AMPS) as the reaction monomers. In laboratory synthesis of this new thickening agent, based on the free radical polymerization of water-soluble polymer theory, the effects of the various synthesis conditions (such as concentration of the initiator, reaction temperature, pH of the reaction system, polymer concentration, content of the chain transfer agent and the degree of hydrolysis) on the performance of the final thickening agent were studied. Using the method of control variates, the reaction conditions are as follows: Polymer concentration = 25%, ratio of monomers (AMPS∶SP∶AM) = 30%∶25%∶45%, reaction temperature = 20 ℃, concentration of initiator = 0.3%, pH = 7, mass fraction of sodium formate = 0.2%, reaction time = 4 h. The thickening agent synthesized has good high temperature resistance, low water insoluble and high thickening capacity. It is instantly soluble and can be easily crosslinked with the organozirconium crosslinking agent. This thickening agent can be used in formation temperatures as high as 200 ℃.

-

Key words:

- Fracturing fluid /

- Thickening agent /

- Functional monomer

-

表 1 不同水解度稠化剂交联性能

水解度/% 交联时间/s 初始黏度/mPa·s 0 490 132.5 0.5 280 196.2 1.0 156 562.2 1.5 57 756.3 2.0 35 可挑挂部分絮状沉淀 2.5 完全沉淀 表 2 不同稠化剂水不溶物含量

稠化剂 稠化剂浓度/% 水不溶物/% 羟丙基胍胶 0.5 5.28 羧甲基纤维素 0.5 6.32 聚合物稠化剂 0.5 0.21 表 3 岩心基质渗透率损害率结果

名称 K0/mD Kd/mD 损害率/% 平均值/% 缓释交联压 3.35 3.07 8.36 9.11 裂液 2.23 2.01 9.87 -

[1] 徐敏杰,管保山,刘萍,等. 近十年国内超高温压裂液技术研究进展[J]. 油田化学,2018,35(4):721-725.XU Minjie, GUAN Baoshan, LIU Ping, et al. Research progress of domestic ultra-high temperature fracturing fluid technology in recent ten years[J]. Oilfield Chemistry, 2018, 35(4):721-725. [2] 郭建春,王世彬,伍林. 超高温改性瓜胶压裂液性能研究与应用[J]. 油田化学,2011,28(2):201-205.GUO Jianchun, WANG Shibin, WU Lin. research and application of ultra-high temperature modified guar gum fracturing fluid[J]. Oilfield Chemistry, 2011, 28(2):201-205. [3] 严芳芳. 有机锆交联聚合物和羟丙基瓜胶压裂液及流变动力学研究[D]. 华东理工大学, 2014.YAN Fangfang. Study on rheological properties of organic zirconium crosslinked polymer and hydroxypropyl guar gum fracturing fluid [D]. East China University of science and technology, 2014. [4] 邹鹏,杨庭安,任秋军. 复合压裂液耐温性的影响因素研究[J]. 石油化工应用,2015,34(1):22-25. doi: 10.3969/j.issn.1673-5285.2015.01.006ZOU Peng, YANG Ting'an, REN Qiujun. Study on Influencing Factors of temperature resistance of composite fracturing fluid[J]. Petrochemical Application, 2015, 34(1):22-25. doi: 10.3969/j.issn.1673-5285.2015.01.006 [5] 许可,侯宗锋,常进,等. 耐245℃超高温压裂液稠化剂的制备与性能分析[J]. 应用化工,2020,49(12):3031-3033. doi: 10.3969/j.issn.1671-3206.2020.12.016XU Ke, HOU Zongfeng, CHANG Jin, et al. Preparation and performance analysis of thickener for 245 ℃ ultra high temperature fracturing fluid[J]. Applied Chemical Engineering, 2020, 49(12):3031-3033. doi: 10.3969/j.issn.1671-3206.2020.12.016 [6] 赵珣,万美,吴海平,等. 水分散聚合合成两性聚丙烯酰胺[J]. 精细与专用化学品,2014,22(01):18-22. doi: 10.3969/j.issn.1008-1100.2014.01.006ZHAO Xun, WAN Mei, WU Haiping, et al. Synthesis of amphoteric polyacrylamide by water dispersion polymerization[J]. Fine and Special Chemicals, 2014, 22(01):18-22. doi: 10.3969/j.issn.1008-1100.2014.01.006 [7] 孙新随. 水分散聚合制备反应性两性PAM纸张增干强剂及其应用研究[D]. 陕西科技大学, 2014.SUN Xinsui. Preparation and application of reactive amphoteric PAM dry strength agent by water dispersion polymerization [D]. Shaanxi University of science and technology, 2014. [8] 寇玉霞. 超支化聚醚的改性、载药及其性能的研究[D]. 上海交通大学, 2009.KOU Yuxia. Modification, drug loading and properties of hyperbranched polyether [D]. Shanghai Jiaotong University, 2009. [9] 陈其政. 甲基丙烯酸丁酯/丙烯酰胺共聚物的合成及性能研究[D]. 浙江理工大学, 2015.CHEN Qizheng. Synthesis and properties of butyl methacrylate / acrylamide copolymer [D]. Zhejiang University of technology, 2015. [10] 祝仰文,郭拥军,徐辉,等. 耐温抗盐疏水缔合聚合物的制备与性能评价[J]. 油田化学,2021,38(2):317-323.ZHU Yangwen,GUO Yongjun,XU Hui,et al. Preparation and performance evaluation of hydrophobically associating polymer with temperature resistance and salt tolerance[J]. Oilfield Chemistry, 2021, 38(2):317-323. [11] 王春蕾. 压裂液用疏水缔合聚合物稠化剂的合成及性能评价[D]. 中国石油大学(北京), 2018.WANG Chunlei. Synthesis and performance evaluation of hydrophobically associating polymer thickener for fracturing fluid [D]. China University of Petroleum (Beijing), 2018. [12] 申艳敏,孙保帅,王天贵. 红薯淀粉—丙烯酰胺—丙烯酸三元共聚吸水性树脂的研究[J]. 粮油食品科技,2013,21(5):16-18,22. doi: 10.3969/j.issn.1007-7561.2013.05.005SHEN Yanmin, SUN Baoshuai, WANG Tiangui. Study on the water absorbent resin of sweet potato starch acrylamide acrylic acid ternary copolymer[J]. Cereal, Oil and Food Science and Technology, 2013, 21(5):16-18,22. doi: 10.3969/j.issn.1007-7561.2013.05.005 [13] 郭兴. 低黏压裂液体系及低黏压裂液用疏水缔合聚合物的制备与性能研究[D]. 陕西科技大学, 2017.Guo Xing. Preparation and properties of low viscosity fracturing fluid system and hydrophobically associating polymer for low viscosity fracturing fluid [D]. Shaanxi University of science and technology, 2017. [14] 李杨,郭建春,王世彬,等. 耐高温压裂液研究现状与发展趋势[J]. 现代化工,2019,39(0):95-98.LI Yang, GUO Jianchun, WANG Shibin, et al. Research status and development trend of high temperature resistant fracturing fluid[J]. Modern Chemical Industry, 2019, 39(0):95-98. [15] 张昀. 低分子聚合物压裂液体系流变性能及携砂规律研究[D]. 2016.ZHANG Yun. Rheological properties and sand carrying law of low molecular polymer fracturing fluid system [D]. 2016. [16] 杨洋,陈奇,李治鹏,等. 用于压裂液改性的耐高温锆硼交联剂的制备及评价[J]. 应用化学,2021,38(4):431-438.YANG Yang, CHEN Qi, LI Zhipeng, et al. Preparation and evaluation of high temperature resistant zirconium boron crosslinker for fracturing fluid modification[J]. Applied Chemistry, 2021, 38(4):431-438. [17] 潘一,夏晨,杨双春,等. 耐高温水基压裂液研究进展[J]. 化工进展,2019,38(4):1913-1920.PAN Yi, XIA Chen, YANG Shuangchun, et al. Research progress of high temperature resistant water-based fracturing fluid[J]. Progress in Chemical Industry, 2019, 38(4):1913-1920. -

下载:

下载: