Study on Selection of Weighting Agent for Hhigh-Ttemperature and High-Density Anticorrosive Cement Slurry

-

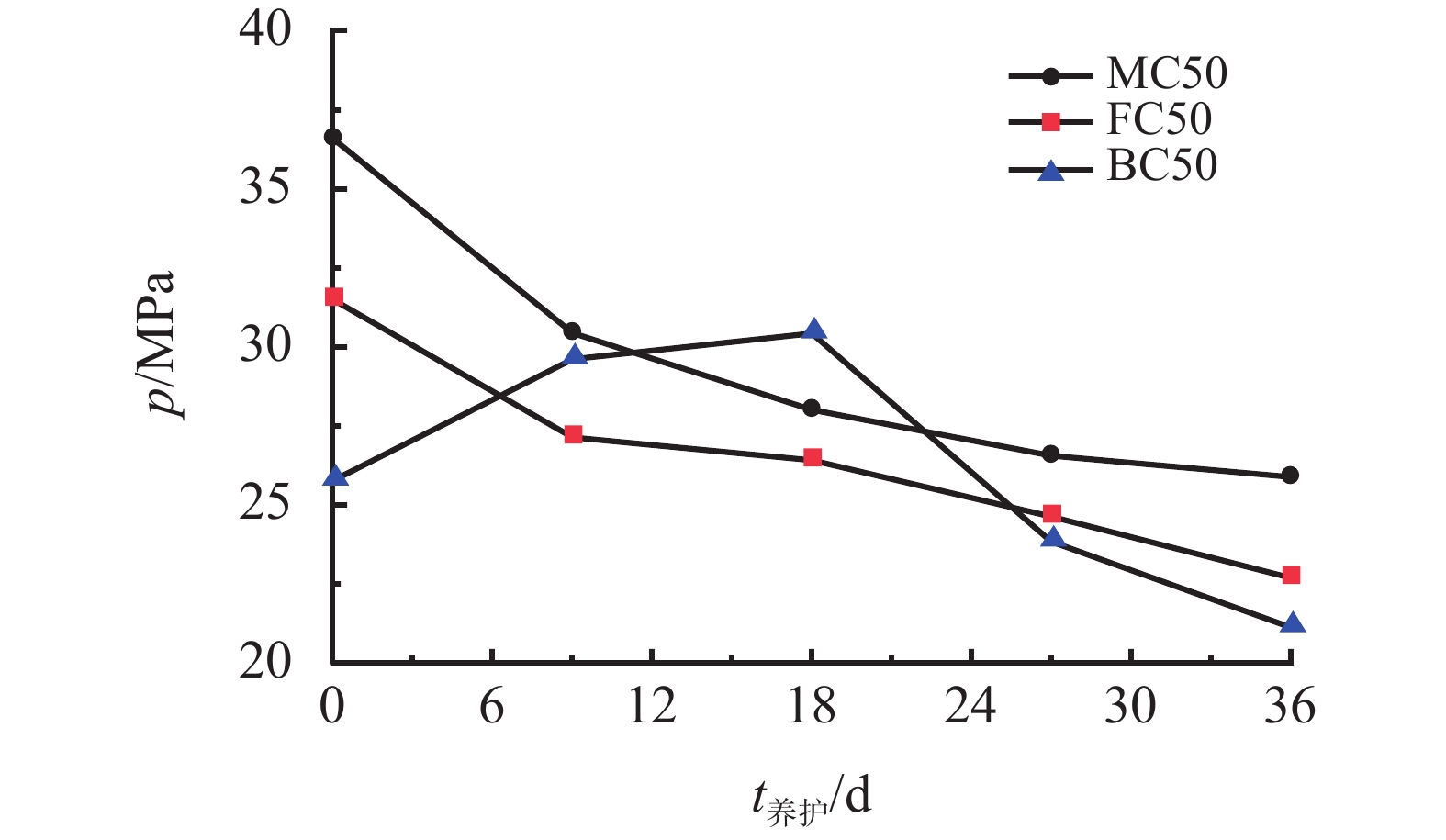

摘要: 针对富含CO2的高温高压油气井中水泥环的腐蚀问题,进行了高温高密度防腐水泥浆体系加重剂的研究,并对比了相同粒度的锰矿粉、赤铁矿和重晶石3种加重剂对水泥浆性能的影响,在150 ℃、CO2分压20 MPa的环境下进行了腐蚀实验。研究结果表明,锰矿粉水泥浆需水量最少,相同条件下具有较好的流变性和较低的失水量;锰矿粉水泥石腐蚀后渗透率最小,抗压强度较高;腐蚀30 d后,锰矿粉水泥石腐蚀深度最低,重晶石水泥石的腐蚀深度约为锰矿粉水泥石的1.5倍;腐蚀后锰矿粉水泥石结构最致密,腐蚀后生成物的特征峰最低;锰矿粉加量为25%、50%和75%的3种水泥石腐蚀27 d后,加量为50% 的水泥石腐蚀深度最小。与赤铁矿和重晶石相比,锰矿粉为较好的选择,但加量过多时会对水泥浆防腐蚀性能产生不利影响。Abstract: High temperature high pressures wells rich in CO2 are often faced with the corrosion of cement sheaths. In this study, a suitable weighting agent for high temperature high density corrosion inhibitive cement slurries was selected, and the effects of three weighting agents on the properties of cement slurries were compared. These three weighting agents include manganese ore powder, hematite and barite, which have the same particle size distribution. The corrosion test was performed at 150 °C and CO2 partial pressure of 20 MPa. The study results showed that the cement slurry weighted with manganese powder requires the least amount of water, and thus has good rheology and lower filtration rate in the same conditions. The set cement of the manganese powder treated cement slurry has the lowest permeability and higher compressive strength after corrosion test. After 30 d of corrosion, the corrosion depth of the manganese set cement is the minimum among others, the corrosion depth of the barite set cement is 1.5 times of the corrosion depth of the manganese set cement. After corrosion, the manganese set cement has the densest structure, and the characteristic peak of the corrosion products is the lowest. Among the three cement slurries treated with 25%, 50% and 75% manganese ore powder respectively, the corrosion depth of the set cement from the cement slurry containing 50% manganese ore powder is the minimum after 27 d of corrosion. Compared with the other two weighting agents, the manganese ore powder is a better choice, only over treatment of the cement slurry with the manganese ore powder should be avoided to prevent negative effects on the corrosion property of the cement slurry.

-

表 1 实验过程中使用的水泥浆配方

配方编号 各组分加量/% 缓凝剂 分散剂 锰矿粉 赤铁矿 重晶石 MC50 0.5 2.5 50 FC50 0.5 2.5 50 BC50 0.5 2.5 50 JPC JMC 50 JFC 50 JBC 50 MC25 0.5 2.5 25 MC75 0.5 2.5 75 表 2 加重剂对水泥浆常规性能的影响

配方 ρ/(g·cm−3) φ300 φ200 φ100 φ6 φ3 FLAPI/mL Δρ/(g·cm−3) MC50 2.19 225 150 75 4 2 62 0.14 FC50 2.20 252 115 5 3 92 0.09 BC50 2.16 204 96 4 2 106 0.06 表 3 不同水泥石腐蚀前后的渗透率

水泥石 渗透率/mD 未腐蚀 腐蚀36 d 锰矿粉 0.0085 0.0104 铁矿粉 0.0096 0.0216 重晶石 0.0053 0.0139 -

[1] 张景富,徐明,朱健军,等. 二氧化碳对油井水泥石的腐蚀[J]. 硅酸盐学报,2007(12):1651-1656. doi: 10.3321/j.issn:0454-5648.2007.12.018ZHANG Jingfu, XU Ming, ZHU Jianjun, et al. Corrosion of oil well cement by carbon dioxide[J]. Journal of the Chinese Ceramic Society, 2007(12):1651-1656. doi: 10.3321/j.issn:0454-5648.2007.12.018 [2] SILVA J C, MILESTONE N B. Cement/rock interaction in geothermal wells. The effect of silica addition to the cement and the impact of CO2 enriched brine[J]. Geothermics, 2018, 73:16-31. doi: 10.1016/j.geothermics.2018.01.004 [3] 黄柏宗,谢承斌,蔡久能. 深井固井的若干问题[J]. 钻井液与完井液,2003(5):51-54.HUANG Bozong, XIE Chengbin, CAI Jiuneng. Some problems of deep well cementing[J]. Drilling Fluid & Completion Fluid, 2003(5):51-54. [4] 赵密锋,付安庆,秦宏德,等. 高温高压气井管柱腐蚀现状及未来研究展望[J]. 表面技术,2018,47(6):44-50.ZHAO Mifeng, FU Anqing, QIN Hongde, et al. Overview and future research prospect of tubing string corrosion of high pressure and high temperature gas well[J]. Surface Technology, 2018, 47(6):44-50. [5] 谢仁军,吴怡,袁俊亮,等. 南海超高温高压气田开发钻完井技术可行性评估与关键技术研究[J]. 中国海上油气,2021,33(5):122-129.XIE Renjun, WU Yi, YUAN Junliang, et al. Technical feasibility evaluation and key technologies study of drilling and completion for development of UHTHP gas fields in South China Sea[J]. China Offshore Oil and Gas, 2021, 33(5):122-129. [6] WANG D, NOGUCHI T, NOZAKI T, et al. Investigation of the carbonation performance of cement-based materials under high temperatures[J]. Construction and Building Materials, 2020, 272:121634. [7] JANI P, IMQAM A. Class C fly ash-based alkali activated cement as a potential alternative cement for CO2 storage applications[J]. Journal of Petroleum Science and Engineering, 2021, 201:108408. doi: 10.1016/j.petrol.2021.108408 [8] MARTA K S, SANTOS L M D, PATRICIA M C, et al. Evaluation of CO2 attack in wellbore class G cement: influence of epoxy resins, composites and minerals as additives[J]. Greenhouse Gases:Science and Technology, 2019, 9(6):261-268. [9] 杨雪. 矿渣抗腐蚀水泥的性能评价[J]. 科学技术与工程,2012,12(6):1390-1392,1396. doi: 10.3969/j.issn.1671-1815.2012.06.040YANG Xue. Performance evaluation of slag corrosion resistant cement[J]. Science Technology and Engineering, 2012, 12(6):1390-1392,1396. doi: 10.3969/j.issn.1671-1815.2012.06.040 [10] 陆沛青,刘仍光,杨广国,等. 增强油井水泥石抗二氧化碳腐蚀方法[J]. 材料科学与工程学报,2020,38(4):566-570.LU Peiqing, LIU Rengguang, YANG Guangguo, et al. Methods of strengthening anti-CO2 corrosion of oil well cement stone[J]. Journal of Materials Science and Engineering, 2020, 38(4):566-570. [11] CARITEY J P, BRADY J. Performance of thermal cements with different weighting materials[C]// Society of Petroleum Engineers. Society of Petroleum Engineers, 2013. [12] AHMED A, MADMOUD A A, ELKATATNY S, et al. The Effect of Weighting Materials on Oil-Well Cement Properties While Drilling Deep Wells[J]. Sustainability, 2019, 11(23):6676. doi: 10.3390/su11236676 [13] 王成文,王桓,薛毓铖,等. 高密度水泥浆高温沉降稳定调控热增黏聚合物研制与性能[J]. 石油学报,2020,41(11):1416-1424. doi: 10.7623/syxb202011011WANG Chengwen, WANG Heng, XUE Yucheng, et al. Development and performance of thermo-viscosifying polymer for high temperature sedimentation control of high density cement slurry[J]. Acta Petrolei Sinica, 2020, 41(11):1416-1424. doi: 10.7623/syxb202011011 [14] 刘崇建, 黄柏宗, 徐同台, 等. 油气井注水泥理论与应用[M]. 石油工业出版社, 2001: 63-64.LIU Chongjian, HUANG Bozong, XU Tongtai, et al. Theory and application of cementing in oil and gas wells[M]. Petroleum industry press, 2001: 63-64. [15] BX A, BY A, YW A, et al. Nanosilica-latex reduction carbonation-induced degradation in cement of CO2 geological storage wells[J]. Journal of Natural Gas Science and Engineering, 2019, 65:237-247. doi: 10.1016/j.jngse.2019.03.013 [16] OMOSEBI O, MAHESHWARI H, AHMED R, et al. Degradation of well cement in HPHT acidic environment: Effects of CO2 concentration and pressure[J]. Cement & Concrete Composites, 2016, 74:54-70. [17] FUMIAKI M, YOSHIMICHI A, SUMIO S. Calcium silicate structure and carbonation shrinkage of a tobermorite-based material[J]. Cement & Concrete Research, 2004, 34(7):1251-1257. [18] COSTA B L S. FREITAS J C O, ARAUJO R G S, et al. Analysis of different oil well cement slurry formulations exposed to a CO2-rich environment[J]. Journal of CO2 Utilization, 2021, 51:101636. doi: 10.1016/j.jcou.2021.101636 [19] R BJØRGE, GAWEL K, PANDURO E C, et al. Carbonation of silica cement at high-temperature well conditions[J]. International Journal of Greenhouse Gas Control, 2019, 82:261-268. doi: 10.1016/j.ijggc.2019.01.011 [20] NIKOLAOS, KOUKOUZAS, ZACHARENIA, et al. Geochemical modeling of carbonation of hydrated oil well cement exposed to CO2-saturated brine solution[J]. Applied Geochemistry, 2017, 85(A):35-48. -

下载:

下载: