Development and Evaluation of Sealant for Controlling Annular Pressure

-

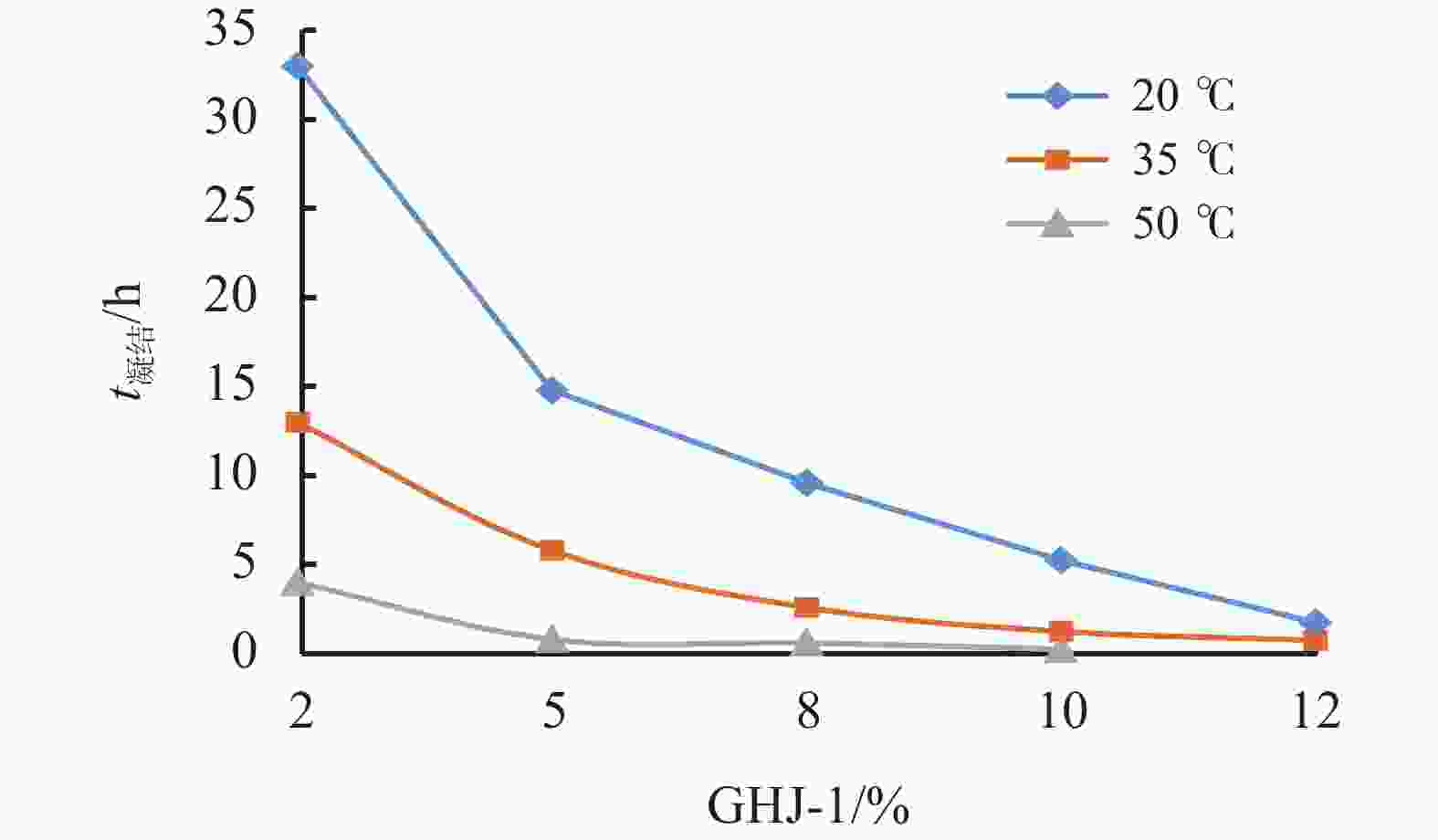

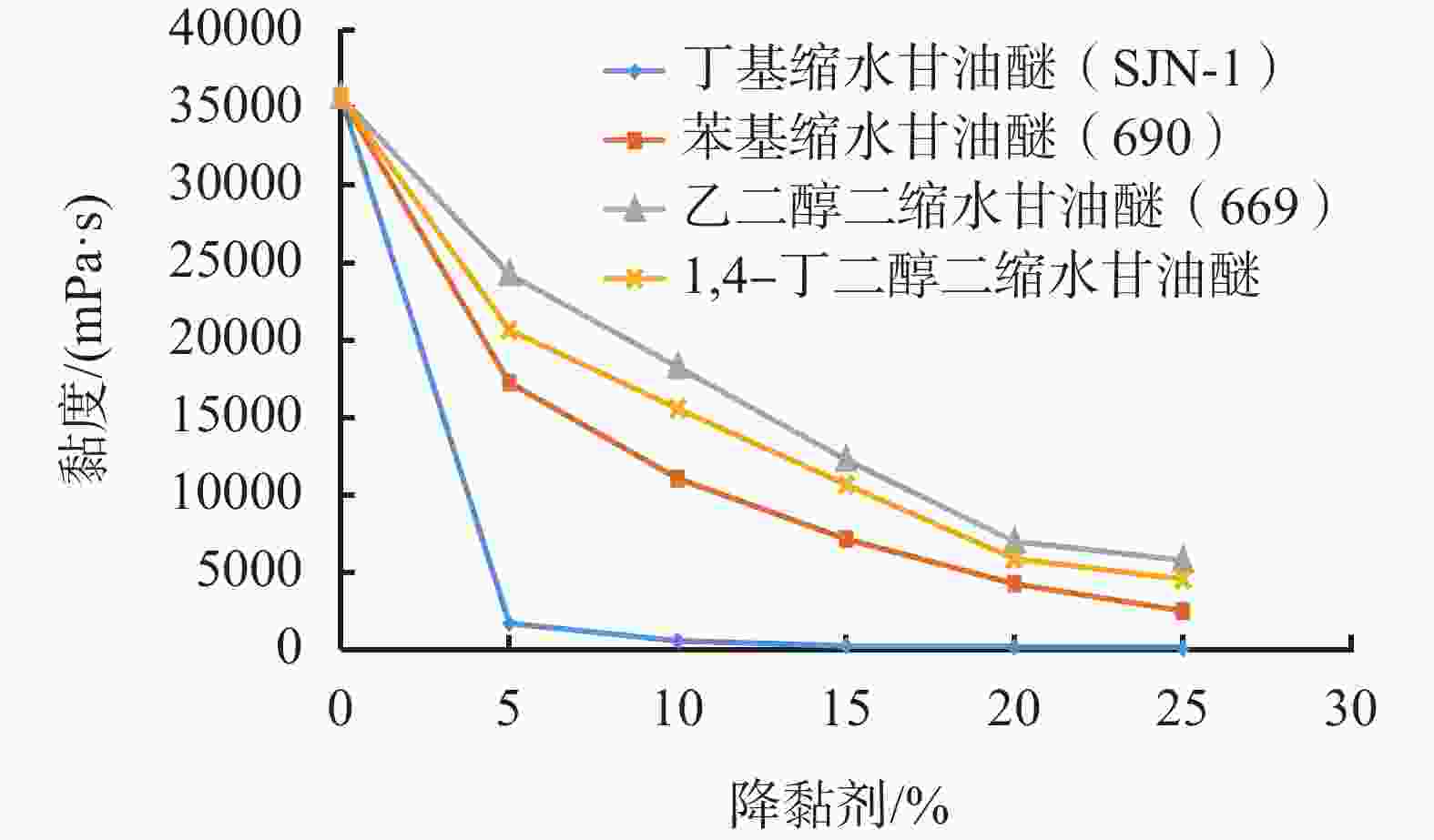

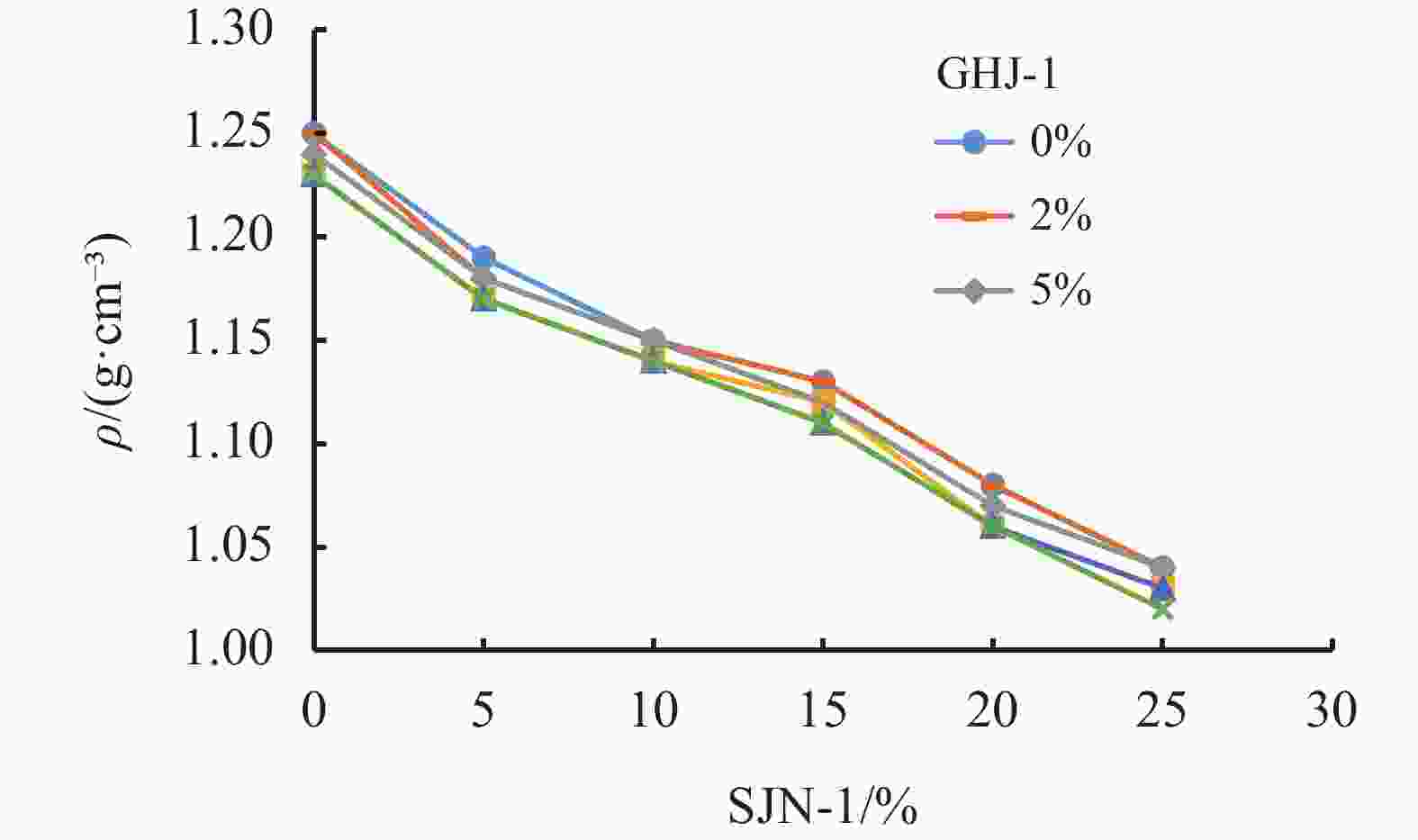

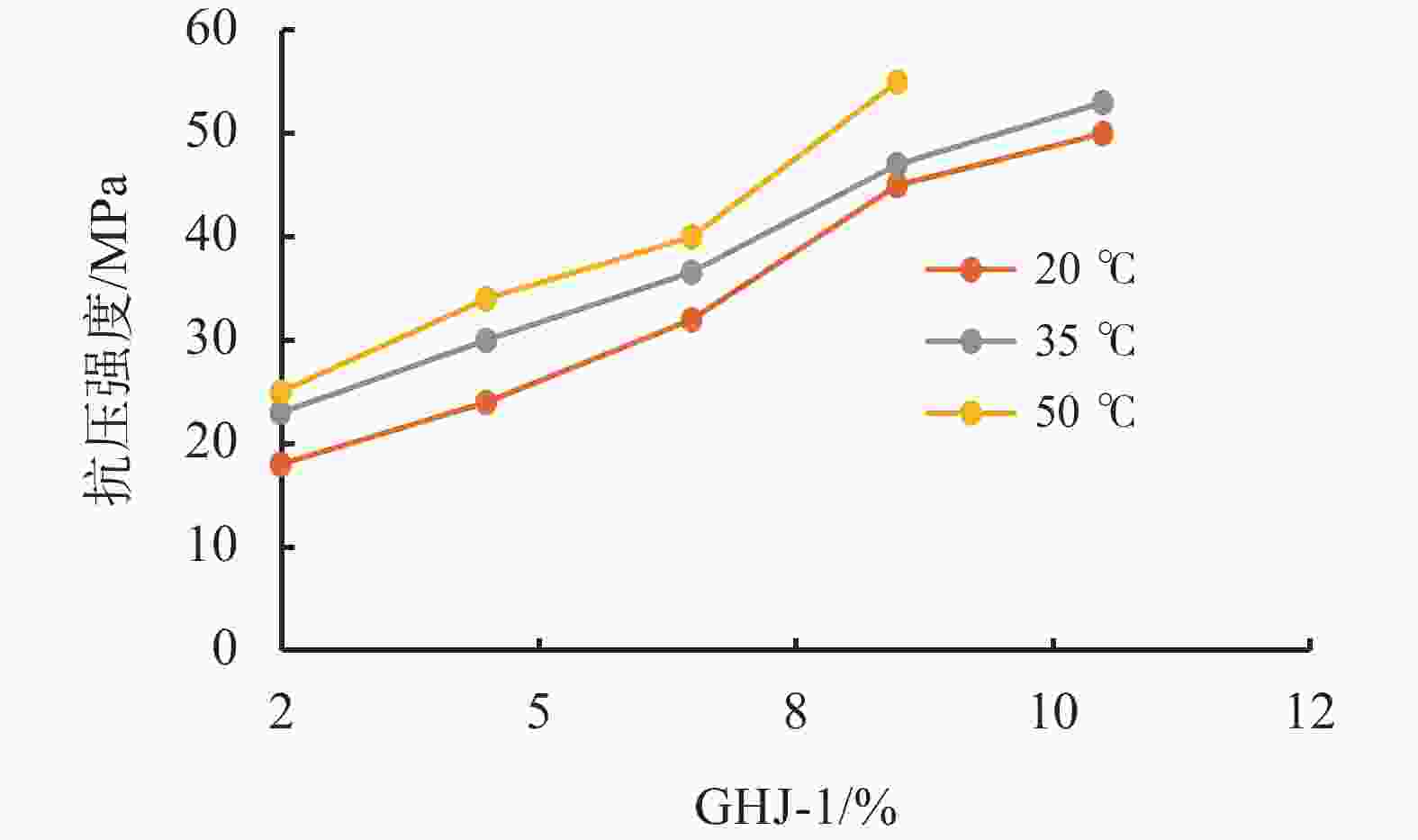

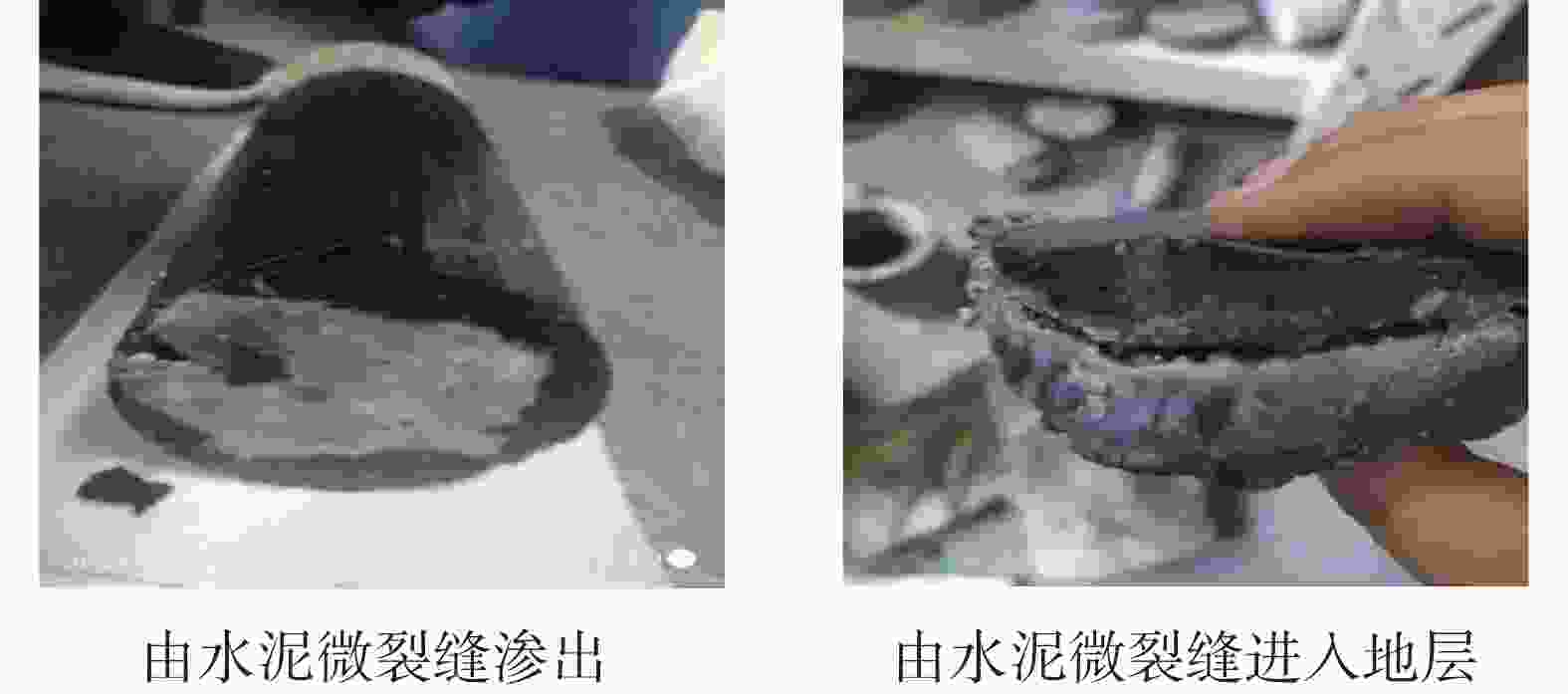

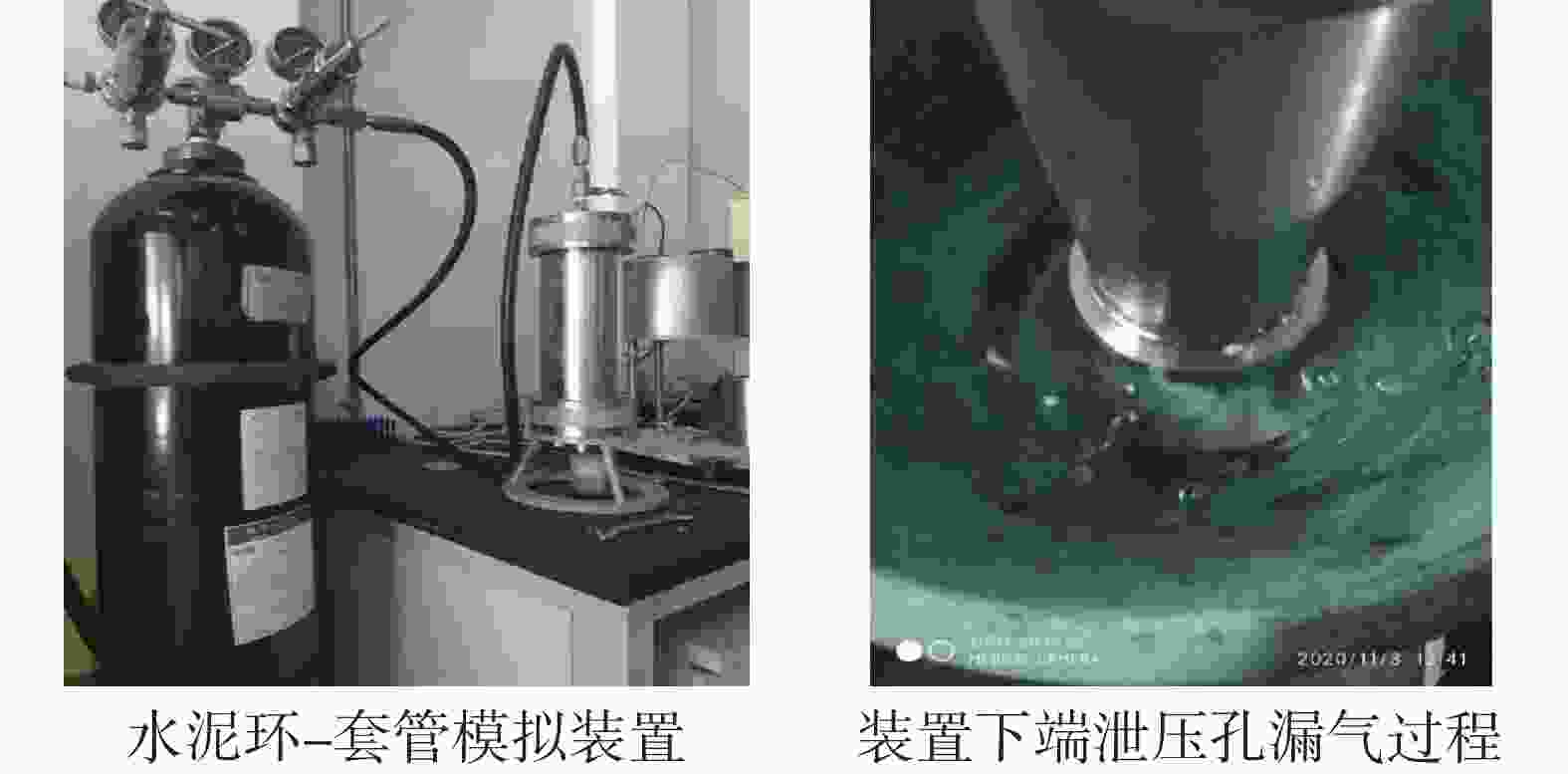

摘要: 针对传统水泥基材料含有固体颗粒,难以挤入并封堵,导致环空带压的水泥环微裂缝问题。以复合树脂为主要成分,通过调节固化引发剂加量控制凝固时间,优选降黏剂提高其流动性和渗透性,研制出一种无固相可室温固化的密封剂,并开展了水泥环-套管系统模拟密封剂封堵实验。由此可知,根据环境温度及固化引发剂不同,密封剂凝结时间可在1.25~20 h内调节;流动性好,黏度低至60 mPa·s;密度可由1.02 g/cm3调至1.25 g/cm3;机械性能良好,24 h抗压强度不小于18 MPa,最高可达53 MPa;水泥环-套管系统模拟密封剂封堵实验表明,密封剂治理环空带压效果良好,干燥环境下候凝24 h后可消除6 MPa以内的环空带压,潮湿环境下候凝24 h后可治理3 MPa以内的环空带压,在多种条件下提高了水泥环-套管环空密封性,可有效治理环空带压问题。Abstract: Solid particles in conventional cement materials are unable to be squeezed into and seal the micro fractures developed in cement sheaths in annular spaces with sustained pressures. To solve this problem, a solids-free sealant that is curable at room temperature was developed, with a composite resin as the main component. In developing the sealant, the solidification time of the cement slurry was controlled by optimizing the amount of a curing initiator, and the mobility and permeability of the cement slurry were enhanced using an optimized thinner. The sealant was tested in laboratory for its performance in sealing the cement sheath-casing system. It was found that at different environment temperatures and different concentrations of the curing initiator, the curing time of the sealant can be adjusted between 1.25 hours and 20 hours. The sealant has good flow property; its viscosity is as low as 60 mPa∙s. The density of the sealant can be raised from 1.02 g/cm3 to 1.25 g/cm3. The sealant has good mechanical properties, its compressive strength in 24 hours is greater than 18 MPa, with maximum compressive strength of 53 MPa. Laboratory experimental results have shown that the sealant can be used to effectively solve the problem of sustained annular pressure. In dry environment, the sustained annular pressure less than or equal to 6 MPa can be eliminated after WOC for 24 hours. In wet environment, the sustained annular pressure less than or equal to 3 MPa can be eliminated after WOC for 24 hours. This sealant can be used to solve the sustained annular pressure problem in different conditions by improving the tightness of the cement sheath in annular spaces.

-

表 1 水泥环-套管系统密封剂模拟挤注测试

裂缝直

径/mm模拟气窜

力/MPa密封剂

黏度/mPa·s挤注密封剂

压力/MPa封堵后模拟

气窜压力/MPa环空

流体1.00 ≤0.5 200 2 6.0 空气 1.00 ≤0.5 600 2 6.5 空气 1.00 ≤0.5 1000 2 7.0 空气 0.10 1.0 200 2 6.0 空气 0.10 1.0 600 4 6.5 空气 0.10 1.0 1000 8 6.5 空气 0.06 2.5 200 4 6.5 空气 0.06 2.5 600 8 6.0 空气 0.06 2.5 1000 14 7.0 空气 1.00 ≤0.5 200 2 3.0 水 0.10 1.0 200 4 3.0 水 0.06 2.5 200 4 3.5 水 注:密封剂配方:67%复合树脂+8%GHJ-1+25%SJN-1;密封剂的加量为320 mL,水泥柱的高度为190 mm -

[1] 陈钦伟, 司念亭, 龙江桥, 等, 渤海油田注水井高套压治理技术探索[J]. 海洋石油, 2017, 37(4): 77-80.CHEN Qinwei, SI Nianting, LONG Jiangqiao, et al. Discussion about technique for controlling high casing pressure in injection wells in Bohai oilfield[J]. Offshore Oil, 2017, 37(4): 76-80. [2] 卢海川,李宗要,高继超,等. 油气井用合成树脂胶凝材料研究综述[J]. 钻井液与完井液,2018,35(5):1-7. doi: 10.3969/j.issn.1001-5620.2018.05.001LU Haichuan, LI Zongyao, GAO Jichao, et al. Review of studies on synthetic resin cementitious materials used in oil and gas wells[J]. Drilling Fluid & Completion Fluid, 2018, 35(5):1-7. doi: 10.3969/j.issn.1001-5620.2018.05.001 [3] N MEDINA. Application of concentric coiled-tubing and well-vacuuming tool with chemical sand-consolidation resins for controlling sand production in wells with damaged screens or slotted liners : A rigless well-repair alternative[J]. SPE 136999. [4] JONES P J. Unconventional remediation in the utica shale using advanced resin technologies [J]. SPE 165699. [5] JONES P. J, KARCHER J, RUCH A, et al. Rigless operation to restore wellbore integrity using syntheticbased resin sealants[J]. SPE 167759, 2014 [6] 谭家顶,程珏,郭晶,等. 几种胺类固化剂对环氧树脂固化行为及固化物性能的影响[J]. 化工学报,2011,62(6):1723-1729. doi: 10.3969/j.issn.0438-1157.2011.06.037TAN Jiading, CHENG Jue, GUO Jing, et al. Effect of amine curing agents on curing behavior of epoxy resin and properties of cured compounds[J]. Ciesc Journal, 2011, 62(6):1723-1729. doi: 10.3969/j.issn.0438-1157.2011.06.037 [7] 苏曹宁,任明伟,何琪,等. 低粘度中温固化环氧树脂基体的研究[J]. 热固性树脂,2012,27(3):46-49.SU Caoning, REN Mingwei, HE Qi, et al. Study on moderate temperature curing epoxy resin with low viscosity[J]. Thermosetting Resin, 2012, 27(3):46-49. [8] 黎凌,李巍,欧阳伟. 遇水快速膨胀胶凝堵漏技术在长宁页岩气区块的应用[J]. 钻井液与完井液,2019,36(2):181-188.LI Ling, LI Wei, OU Yangwei. Application of a fast-swelling gel lost circulation material in shale gas drilling in block Changning[J]. Drilling Fluid & Completion Fluid, 2019, 36(2):181-188. [9] 刘江波, 白小佩, 王效明, 等. 注水井带压作业环氧树脂堵剂研究[J]. 油田化学, 2014, 31(3): 353-356.LIU JiangBo, BAI Xiaopei, WANG Xiaoming,et al. Research on epoxy plugging agent for snubbing service of water injection well [J]. Oilfield Chemistry, 2014, 31(3): 353-356. [10] ALKHAMIS M, IMQAM A, MILAD M. Evaluation of an ultra-high performance epoxy resin sealant for wellbore integrity applications [C]//SPE Symposium: Decommissioning and Abandonment OnePetro, 2019. [11] 胡红兵,林强,胡文祥. 环氧树脂流变学的研究进展[J]. 武汉工程大学学报,2021,43(3):248-255.HU Hongbing, LIN Qiang, HU Wenxiang. Progress in rheology of epoxy[J]. Journal of Wuhan Institute of echnology, 2021, 43(3):248-255. [12] 刘凡 ,刘钦政, 郝惠军,等. 高强度可固化树脂堵漏剂PMMM研制与评价[J]. 钻井液与完井液,2021,38(6):671-676.LIU Fan, LIU Qinzheng, HAO Huijun, et al. Synthesis and evaluation of a high strength curable resin LCM PMMM[J]. Drilling Fluid & Completion Fluid, 2021, 38(6):671-676. [13] 高堂铃,付刚,王先杰,等. RTM用低黏度树脂体系的工艺窗口预测[J]. 哈尔滨工业大学学报,2021,53(2):162-167.GAO Tangling, FU Gang, WANG Xianjie, et al. Prediction of processing windows for low viscosity epoxy resin system used in RTM[J]. Journal of Harbin Institute of Technology, 2021, 53(2):162-167. [14] 李辉,刘华康,何仲,等. 塔河油田碳酸盐岩储层恶性漏失空间堵漏凝胶技术[J]. 钻井液与完井液,2019,36(1):25-28.LI Hui, LIU Huakang, HE Zhong, et al. Use gel to control severe mud losses in carbonate reservoir formations in Tahe oilfield[J]. Drilling Fluid & Completion Fluid, 2019, 36(1):25-28. -

下载:

下载: