Application of Ultra-low Friction Wwater-based Ddrilling Ffluid in Shale Gas Horizontal Wells

-

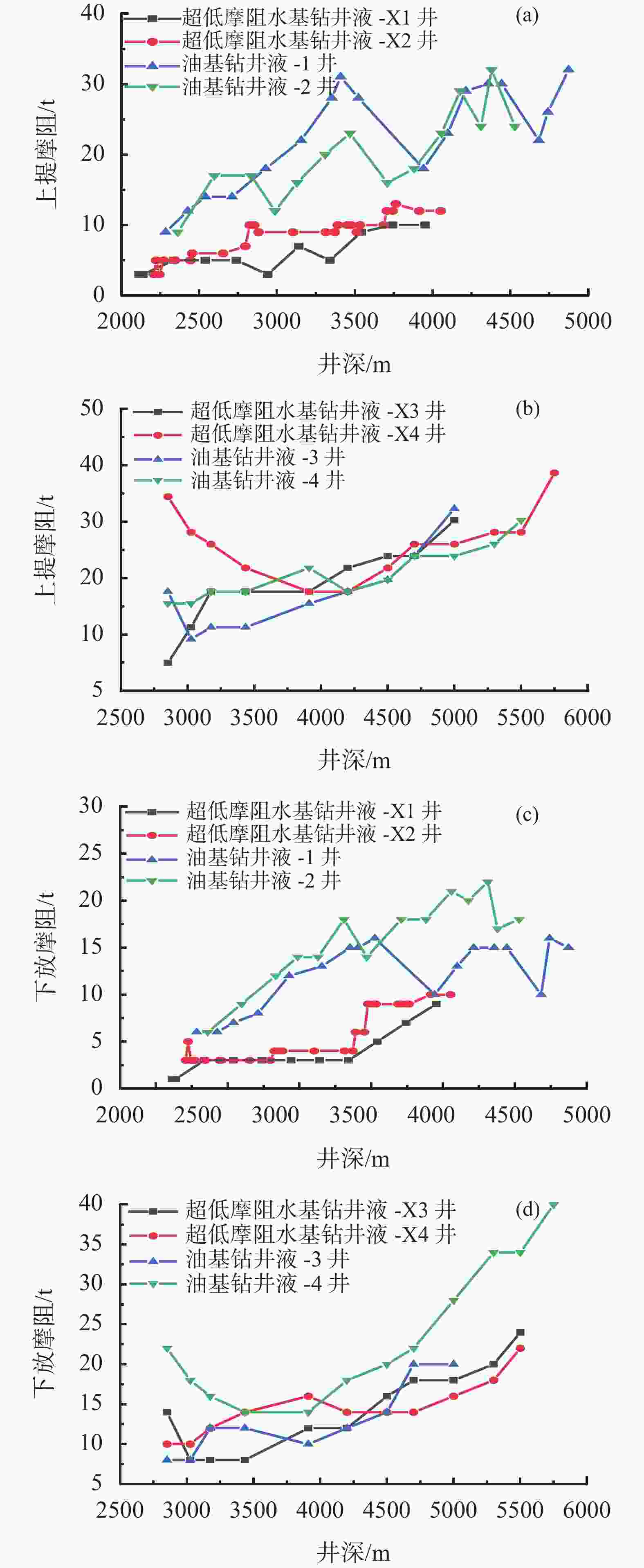

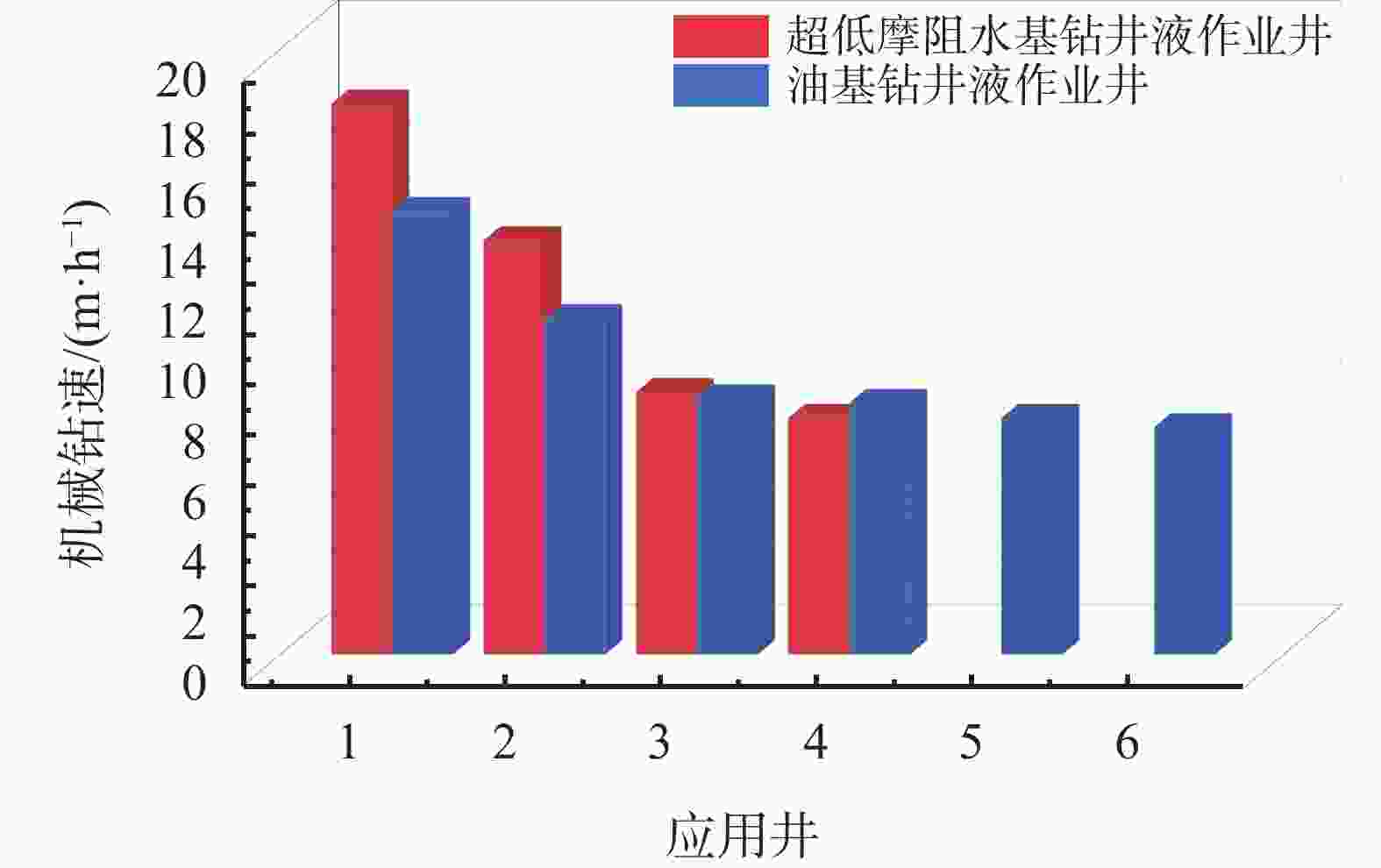

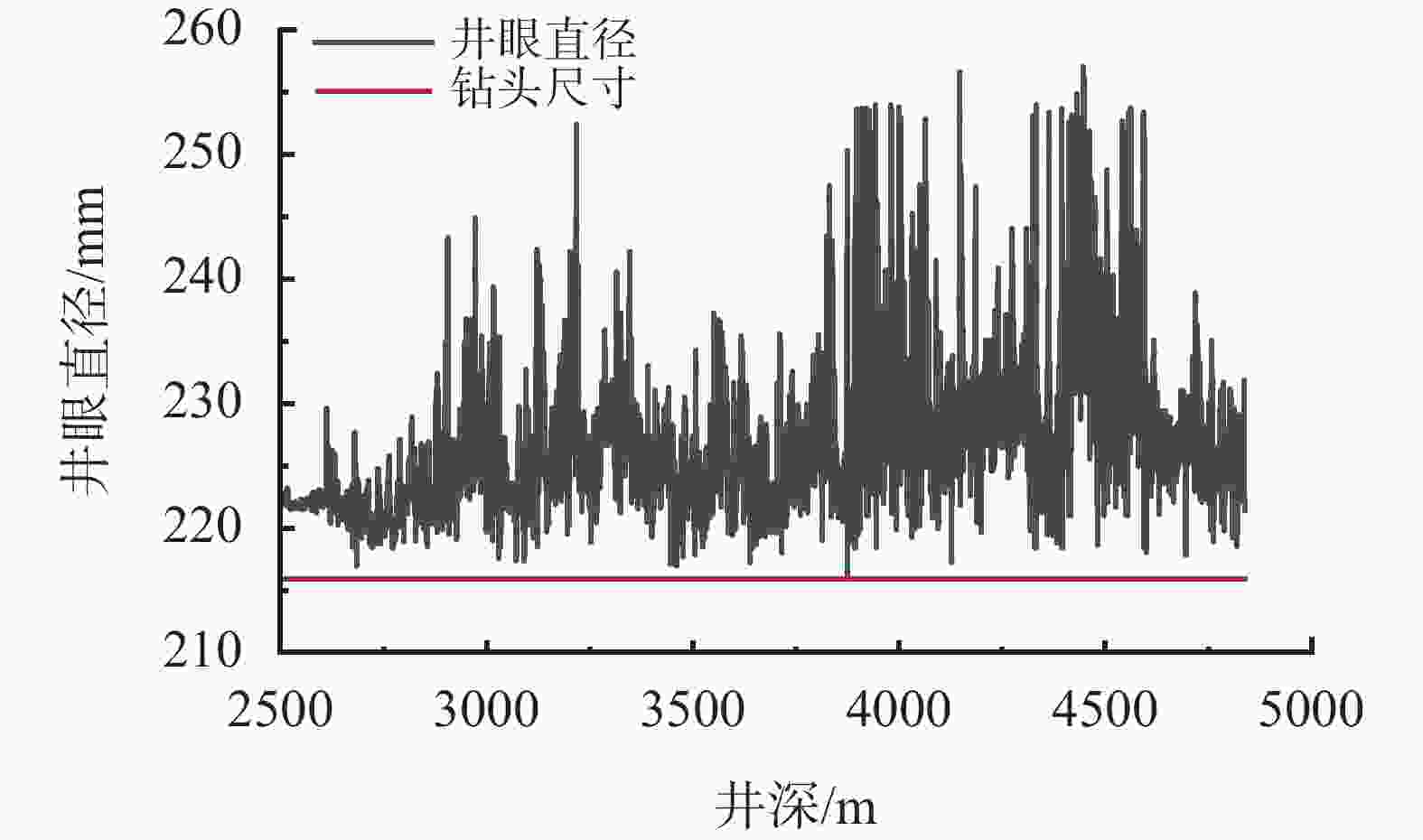

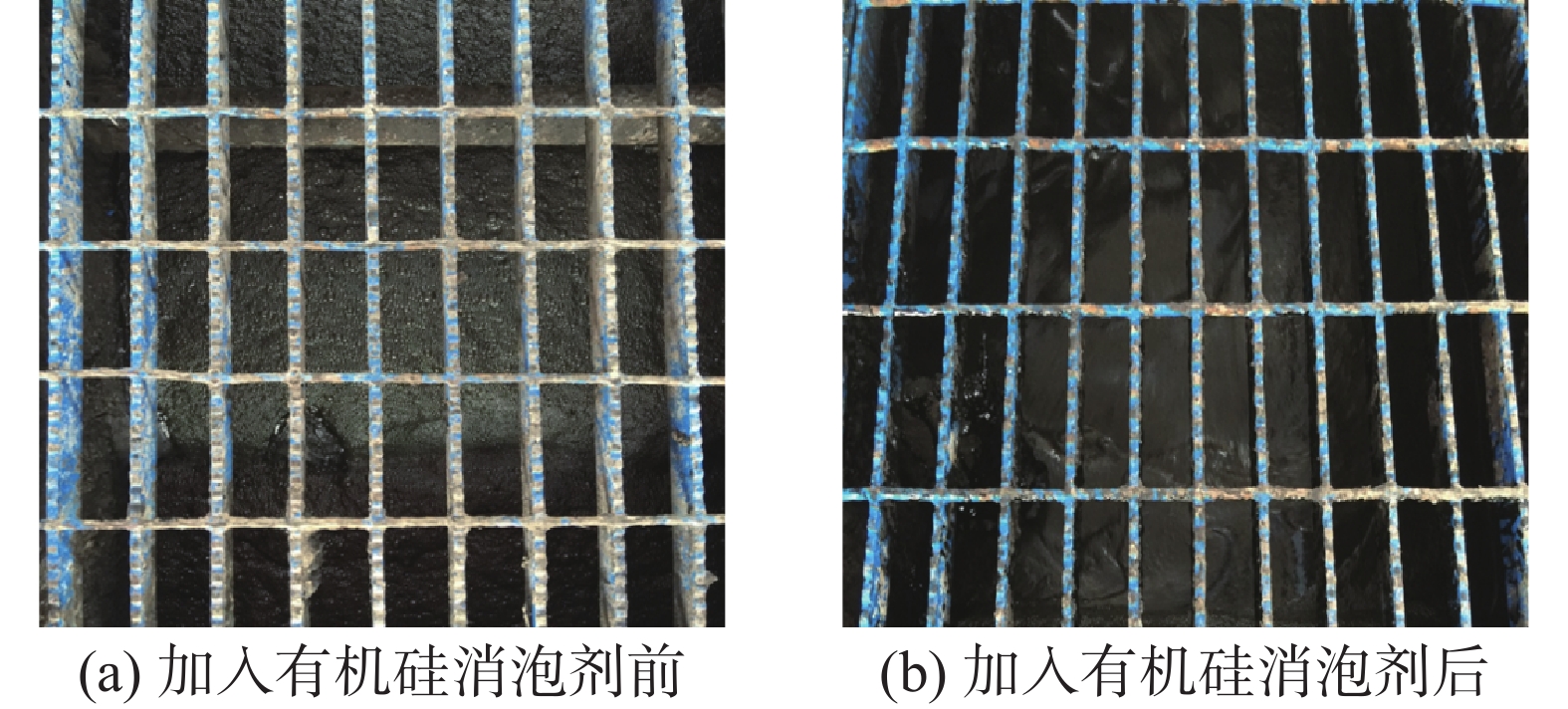

摘要: 油基钻井液具有优异的抑制性、封堵性、润滑性,是目前页岩气井作业的主要钻井液类型,但其对生态环境造成严重影响、过高的成本及废弃钻井液和钻屑处理压力限制了其在钻井中的应用。涪陵焦石部署4口水平井,钻探目的层为龙马溪组-五峰组,目的层含大段泥页岩,裂缝发育,易水化分散、垮塌漏失风险大。针对涪陵水平井要求低摩阻及地层泥页岩易发生井壁失稳的特点,研究了一套超低摩阻水基钻井液体系。该体系具有较好的流变和抑制性能,同时具有和油基钻井液相当的润滑性能。现场应用表明,超低摩阻水基钻井液实现了页岩气井水平段全流程高效安全作业,与同区块油基钻井液相比机械钻速提高了24.7%,每米钻时降低了6.2%,水平段起下钻1~2次,而油基钻井液需要2~3次,其中涪陵X4井水平段长2235 m,创完钻时国内页岩气水平井水基作业记录。该超低摩阻水基钻井液在涪陵页岩气的成功应用有望实现页岩气水基钻井液替代油基钻井液作业。Abstract: Oil-based drilling fluid has excellent inhibition, blocking and lubrication properties, and it is currently the main type of drilling fluid for shale gas well operations. With the increasing pressure on environmental protection and waste mud disposal, shale gas drilling has put forward an urgent demand for water-based drilling fluid. Four horizontal wells are deployed in Fuling Jiao Shi, and the drilling target formation is Longmaxi Formation-Wufeng Formation. The target formation contains large sections of mud shale and fracture development, which is easy to hydrate and disperse, and has high risk of collapse and leakage. In response to the low friction requirement of the Fuling horizontal well and the vulnerability of the formation mud shale to well wall destabilization, an ultra-low friction water-based drilling fluid system was developed. The field application shows that the ultra-low friction water-based drilling fluid has achieved efficient and safe operation of the horizontal section of shale gas wells, with a 24.7% increase in mechanical drilling speed and a 6.2% reduction in drilling time per meter compared with oil-based drilling fluid in the same block. record. The successful application of this ultra-low friction water-based drilling fluid in Fuling shale gas is expected to realize the replacement of oil-based drilling fluid by water-based drilling fluid in shale gas.

-

Key words:

- Shale gas /

- Water-based drilling fluid /

- Oil-based drilling fluid /

- ROP /

- Field application

-

表 1 超低摩阻水基钻井液的基本性能

测试

条件φ6/φ3 AV/

mPa·sPV/

mPa·sYP/

PaFLAPI/

mLFLHTHP/

mLEP 老化前 5.5/4.0 31.0 22.0 9.0 2.2 140 ℃、16 h 4.5/3.0 37.5 27.0 10.5 8.0 0.051 表 2 涪陵区块超低摩阻水基钻井液应用井工程情况

井号 中途完钻

井深/m完钻井

深/m裸眼段

长/m水平段

长/m四开钻井

周期/dX1 2113 3983 1870 1397 14.0 X2 2182 4052 1870 1507 15.6 X3 2585 4917 2332 1603 28.0 X4 2706 5724 3018 2235 28.1 表 3 超低摩阻水基钻井液在X4井中的性能

井深/

mFV/

sPV/

mPa·sYP/

PaGel/

Pa/Pa

φ6 φ3 FLHTHP/

mL2990 47 19.0 10.0 2.0/4.0 6.0 5.0 7.8 3400 48 24.0 9.0 2.0/4.0 5.0 4.0 7.6 4330 52 28.0 12.0 4.0/7.0 8.0 7.0 7.6 5200 54 29.0 12.0 3.5/7.0 10.0 9.0 7.6 5724 56 33.0 13.0 4.0/8.0 11.0 10.0 7.4 表 4 涪陵新型水基钻井液与邻井钻井液的性能对比

钻井液 AV/

mPa·sPV/

mPa·sYP/

Paφ6 φ3 pH FLAPI/

mLFLHTHP/

mL新型水基 49.0 35.0 14.0 7.0 5.0 9 1.8 6.0 油基 39.0 31.0 8.0 9.0 8.0 0 2.4 钾基聚合物 42.0 39.0 13.0 8.0 7.0 9 2.4 8.2 表 5 涪陵作业井与邻井油基钻井液工程参数对比

钻井液 钻压/t 转速/(r·min-1) 泵压/MPa 排量/(L·s−1) 下放摩阻/t 平均机械钻速/(m·h−1) 起下钻/次 平均每米钻时/h 超低摩阻水基 8~10 50 16~20 30 3~9 12.02 1~2 0.305 油基 10~14 50 22~24 30 6~22 9.64 2~3 0.325 -

[1] 游云武,梁文利,宋金初,等. 焦石坝页岩气高性能水基钻井液的研究及应用[J]. 钻采工艺,2016,39(5):80-83. doi: 10.3969/J.ISSN.1006-768X.2016.05.26YOU Yunwu, LIANG Wenli, SONG Jinchu, et al. Research and application of high-performance water based drilling fluid for Jiaoshiba shale gas reservoir[J]. Drlling & Production Technology, 2016, 39(5):80-83. doi: 10.3969/J.ISSN.1006-768X.2016.05.26 [2] 万伟,葛炼. 高性能水基钻井液在长宁页岩气区块研究与应用[J]. 钻采工艺,2019,42(1):83-87. doi: 10.3969/J.ISSN.1006-768X.2019.01.25WAN Wei, GE Lian. Research on high performance WBM for Changning shale gas reservoir and its application[J]. Drlling & Production Technology, 2019, 42(1):83-87. doi: 10.3969/J.ISSN.1006-768X.2019.01.25 [3] 刘畅,许洁,冉恒谦. 干热岩抗高温环保水基钻井液体系[J]. 钻井液与完井液,2021,38(4):412-422.LIU Chang, XU Jie, RAN Hengqian. An environmentally friendly high temperature water based drilling fluid for hot-dry-rock well drilling[J]. Drilling Fluid & Completion Fluid, 2021, 38(4):412-422. [4] 陈俊斌,明显森,陶怀志,等. 页岩气水基钻井液在YS-AB井现场试验与认识[J]. 钻采工艺,2021,44(4):98-103.CHEN Junbin, MING Xiansen, TAO Huaizhi, et al. Application and recognition of shale gas water-based drilling fluid in well YS-AB[J]. Drilling & Production Technology, 2021, 44(4):98-103. [5] 李茜,周代生,彭新侠,等. 生物合成基钻井液在长宁页岩气水平井的应用[J]. 钻井液与完井液,2018,34(4):28-32.LI Qian, ZHOU Daisheng, PENG Xinxia, et al. Application of a biosynthetic base drilling fluid in shale gas drilling in black Changning[J]. Drilling Fluid & Completion Fluid, 2018, 34(4):28-32. [6] 万小迅. 川西页岩气藏超低摩阻水基钻井液体系的性能评价及现场应用[J]. 石油与天然气化工,2015,44(6):96-99. doi: 10.3969/j.issn.1007-3426.2015.06.018WAN Xiaoxun. Performance evaluation and field application of new water-based drilling fluid system in western Sichuan shale gas reservoir[J]. Chemical Engineering of Oil & Gas, 2015, 44(6):96-99. doi: 10.3969/j.issn.1007-3426.2015.06.018 [7] 梁文利,宋金初,陈智源,等. 涪陵页岩气水平井油基钻井液技术[J]. 钻井液与完井液,2016,33(5):19-24.LIANG Wenli, SONG Jinchu, CHEN Zhiyuan, et al. Oil base drilling fluid for drilling shale gas wells in Fuling[J]. Drilling Fluid & Completion Fluid, 2016, 33(5):19-24. [8] 孙欢,陈华,贾彦强. 宁217井直改平龙马溪组低密度油基钻井液技术[J]. 钻采工艺,2019,42(6):113-115.SUN Huan, CHEN Hua, JIA Yanqiang. Ning 217 well straight well to horizontal well Longmaxi formation low-density oil-based drilling fluid technology[J]. Drilling & Production Technology, 2019, 42(6):113-115. [9] 宋然然,蒋官澄,宣扬,等. 超支化聚乙烯亚胺作为高效水基钻井液页岩抑制剂的研究[J]. 油田化学,2017,34(3):390-396.SONG Ranran, JIANG Guancheng, XUAN Yang, et al. Hyper-branched Polyethyleneimine Using as Efficient Shale Inhibitor for Water-based Drilling Fluid[J]. Oilfield Chemistry, 2017, 34(3):390-396. [10] 罗涛,郭小文,舒志国,等. 四川盆地焦石坝南部地区五峰组-龙马溪组裂缝脉体流体来源及形成时间[J]. 石油学报,2021,42(5):612-620.LUO Tao, GUo Xiaowen, SHU Zhi guo, et al. Fluid source and formation time of fracture veins of Wufeng formation and longmaxi formation in the south of Jiaoshiba area, Sichuan Basin[J]. Acta Pettrolei Sinica, 2021, 42(5):612-620. [11] YAN Xiaopeng, YOU Lijun, KANG Yili, et al. Impact of drilling fluids on friction coefficient of brittle gas shale[J]. International Journal of Rock Mechanics and Mining Sciences , 2018 (106): 144-152. [12] 陈斌, 周姗姗, 赵远远,等. 适用于大位移井新型水基钻井液室内研究[J]. 钻井液与完井液,2021,38(1):42-46.CHEN bin, ZHOU shanshan, ZHAO yuanyuan, et al. laboratory study on new water base drilling fluid for extended reach wells[J]. Drilling Fluid & Completion Fluid, 2021, 38(1):42-46. [13] 孙金声,黄贤斌,吕开河,等. 提高水基钻井液高温稳定性的方法、技术现状与研究进展[J]. 中国石油大学学报(自然科学版),2019,43(5):73-81.SUN Jinsheng, HUANG Xianbin, LYU Kaihe, et al. Methods, technical progress and research advance of improving high-temperature stability of water based drilling fluids[J]. Journal of China University of Petroleum (Edition of Natural Science) , 2019, 43(5):73-81. [14] 张县民,姜雪清,黄宁,等. 油基钻井液堵漏用共混聚合物研究[J]. 钻井液与完井液,2021,38(5):593-597.ZHANG Xianmin, JIANG Xueqing, HUANG Ning, et al. Study on polymer blend used for controlling loss of oil based drilling fluids[J]. Drilling Fluid & Completion Fluid, 2021, 38(5):593-597. -

下载:

下载: