A Strongly Adsorptive Hydrophobically Modified Nano SiO2 Plugging Agent

-

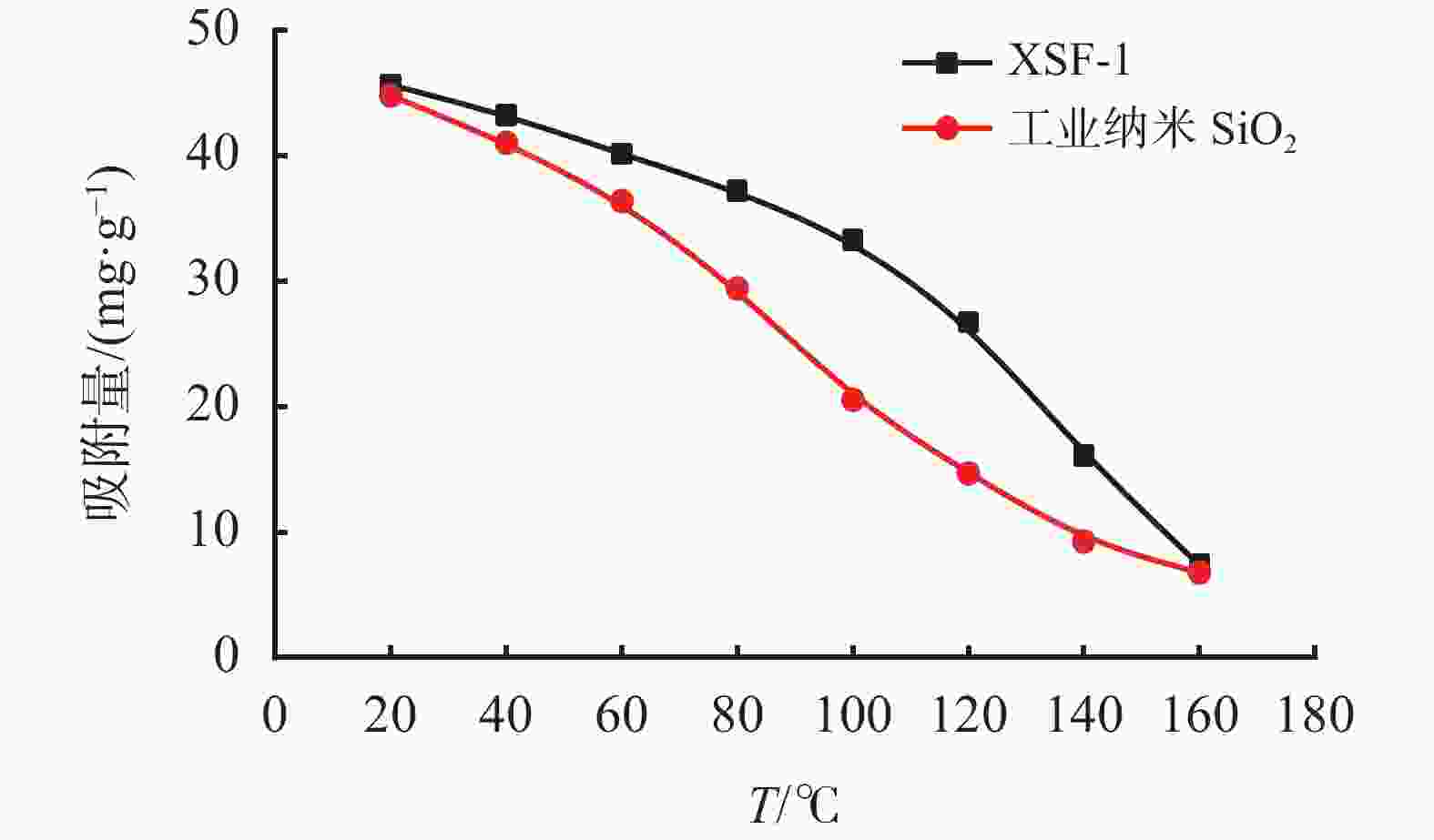

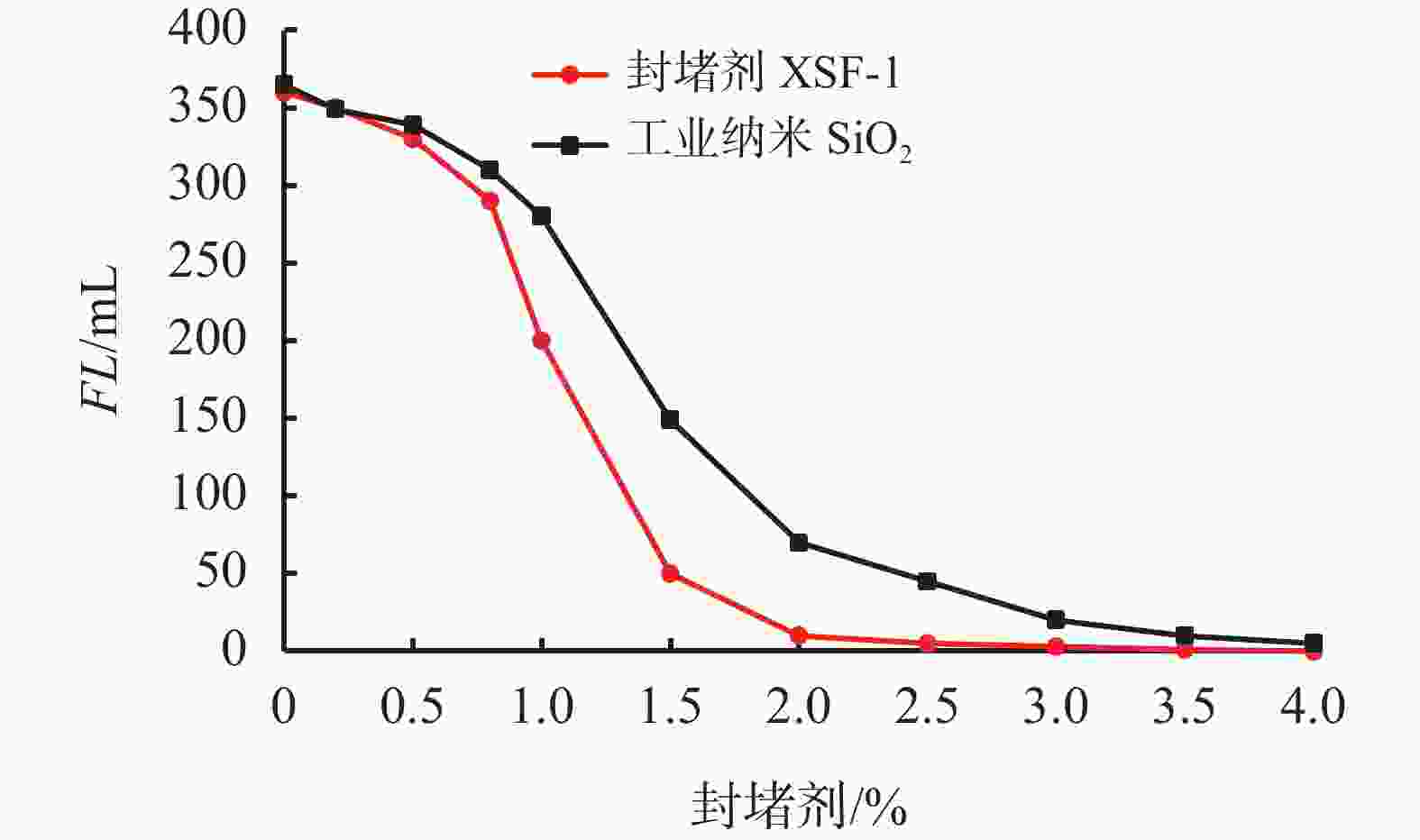

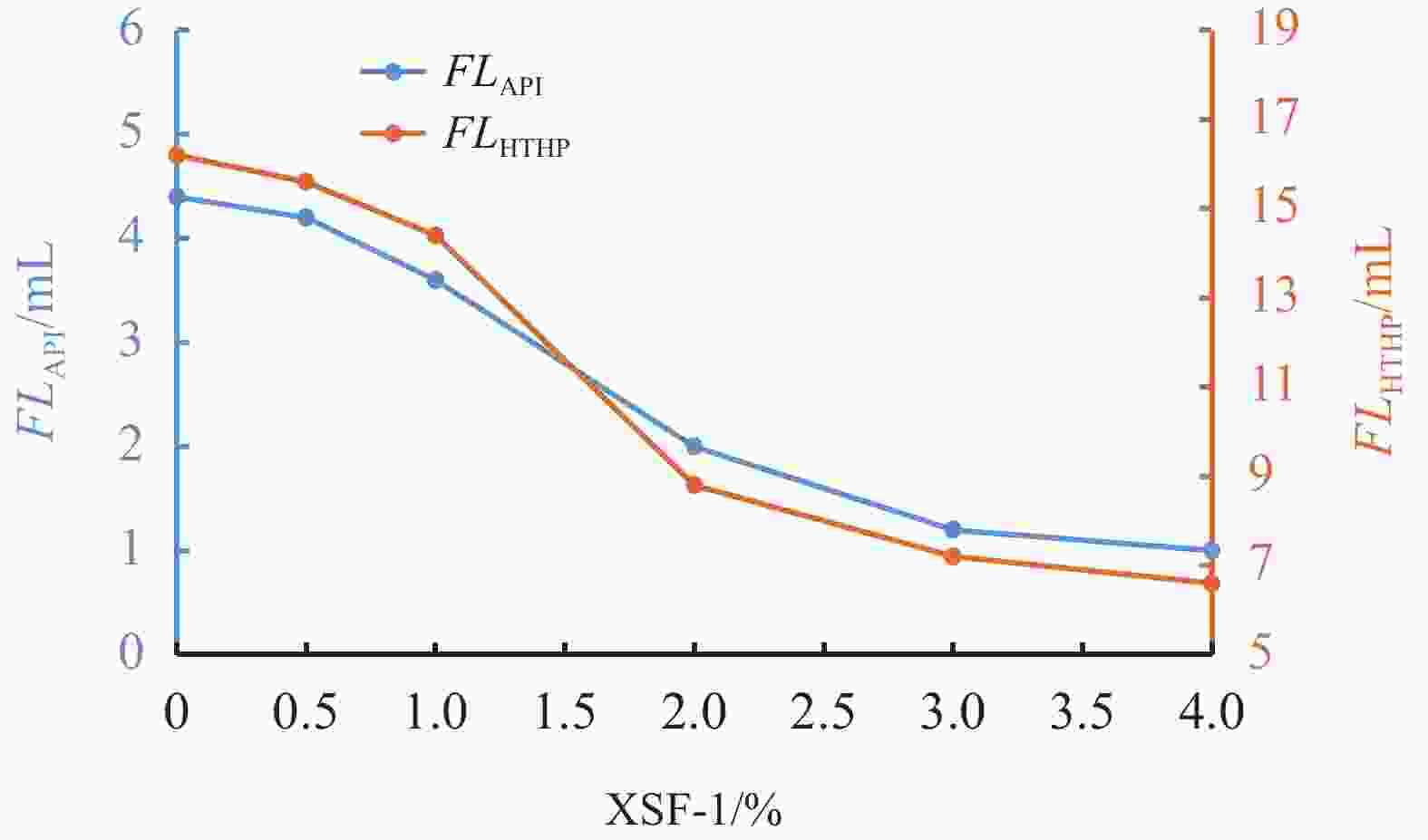

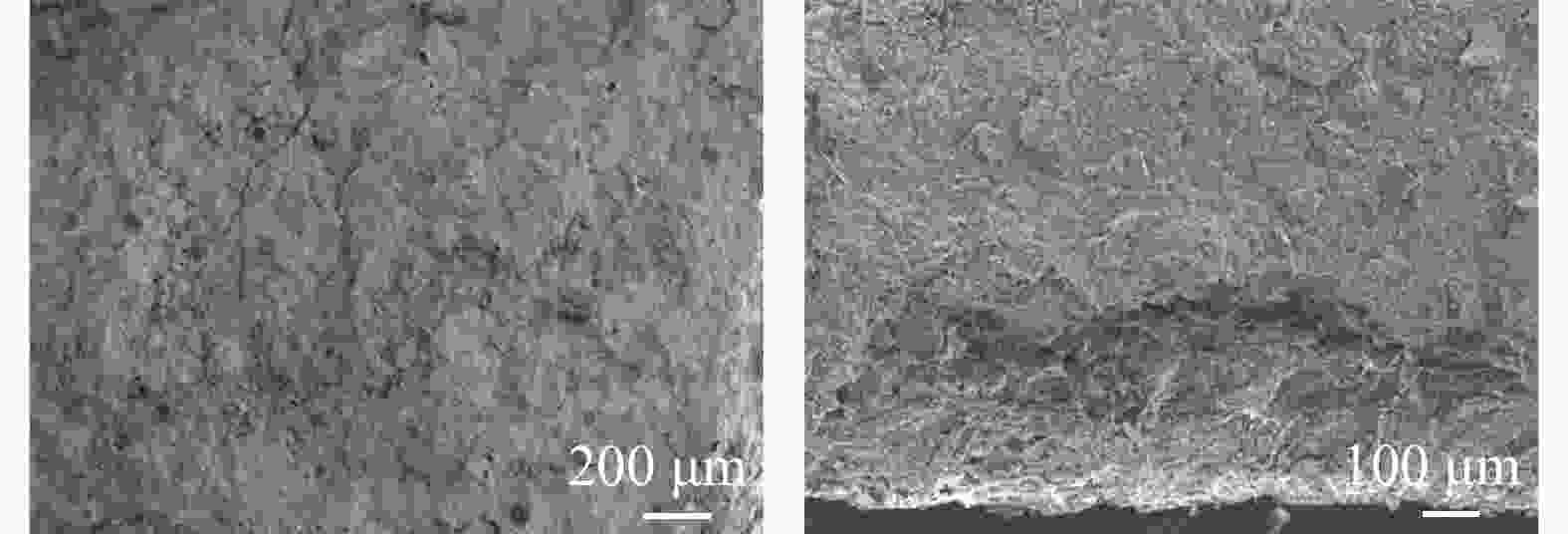

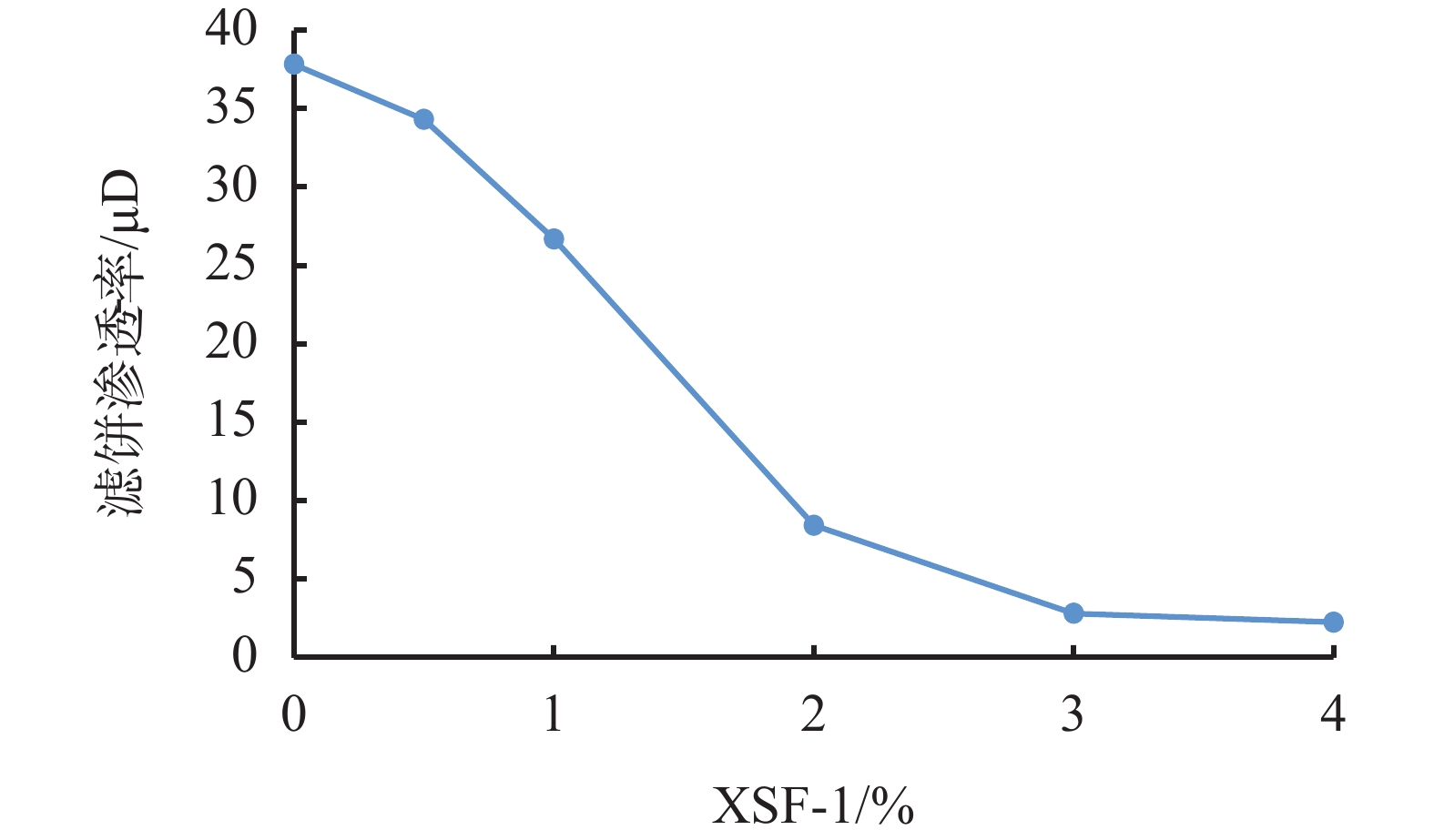

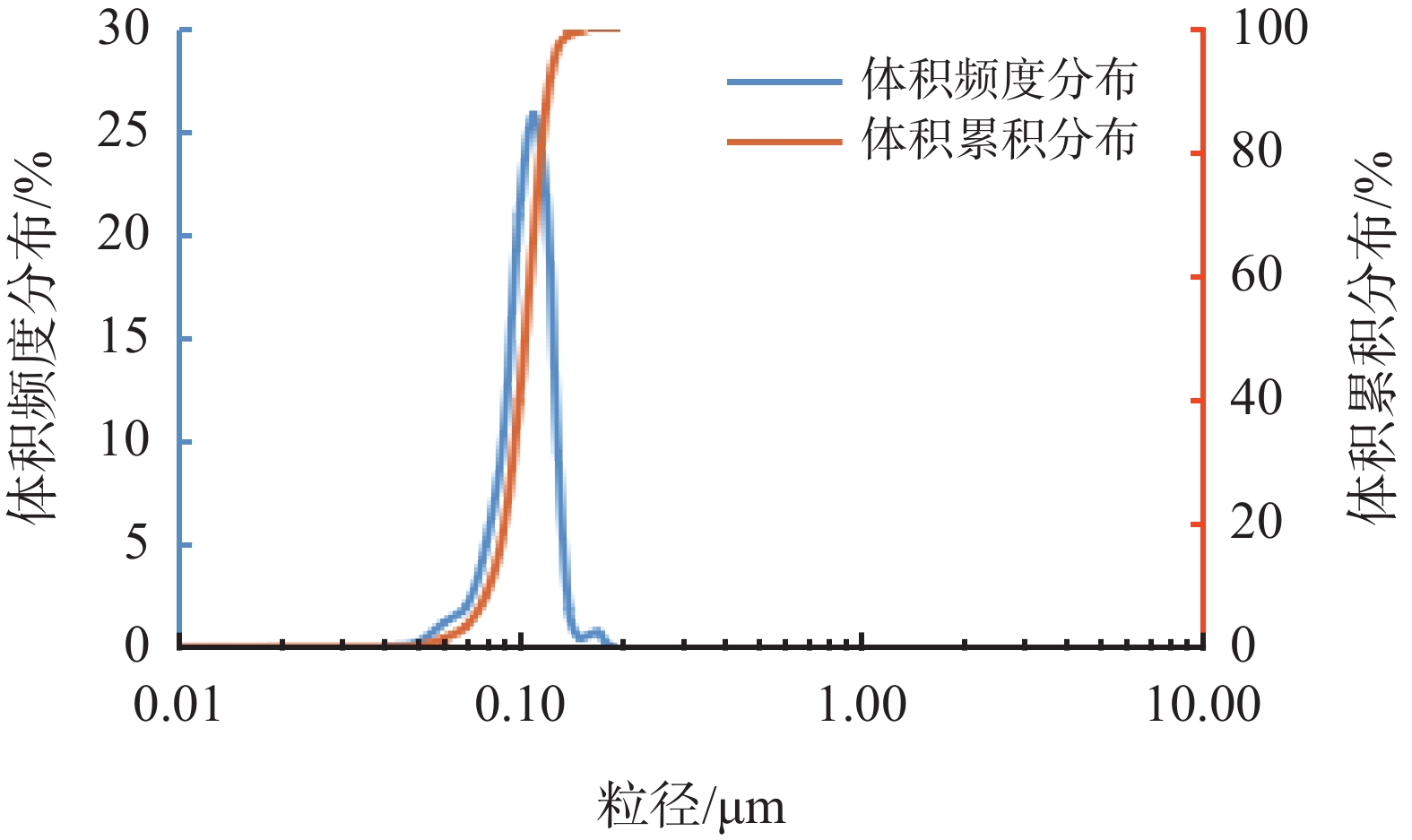

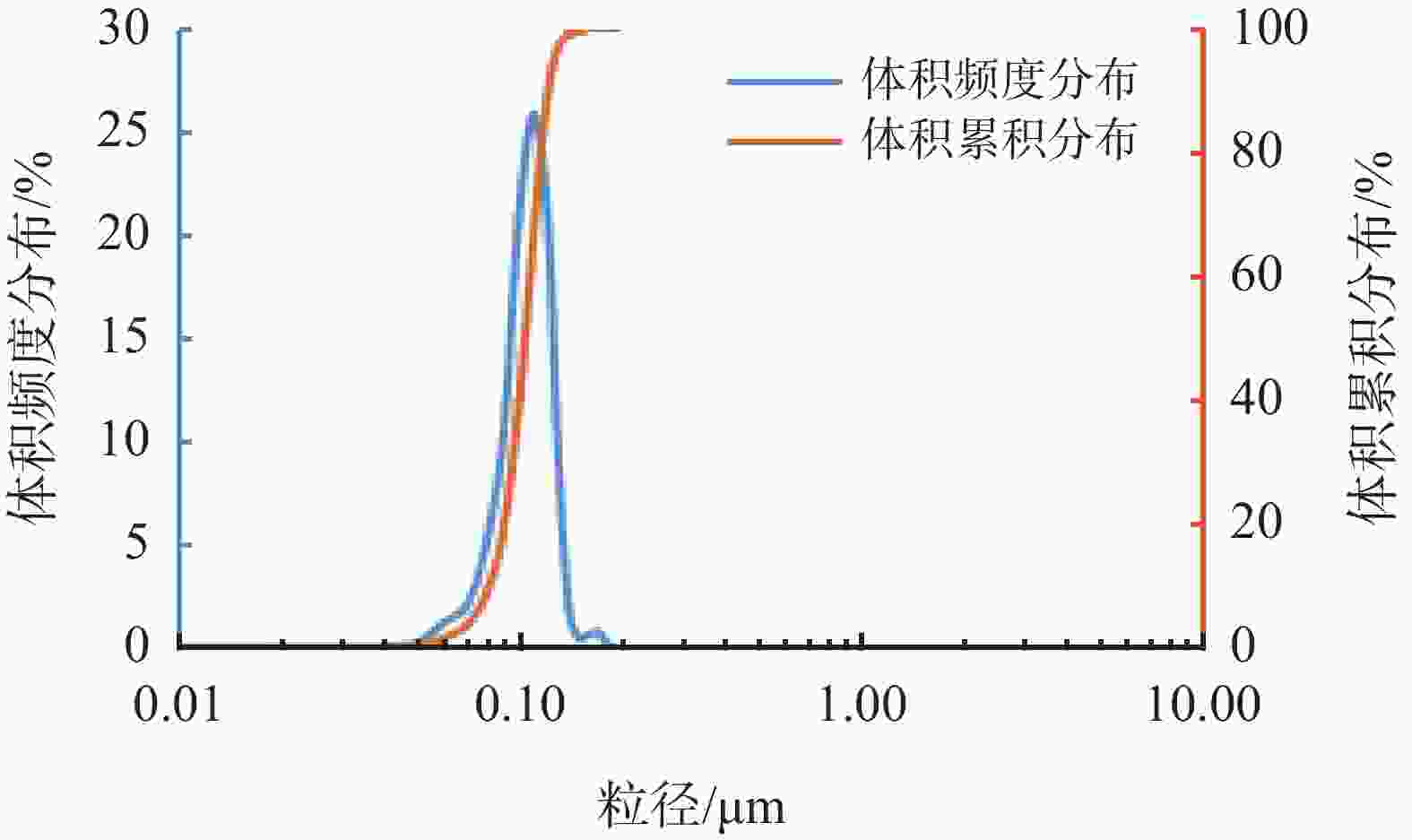

摘要: 钻井过程中钻遇稳定性较差的地层和承压能力较弱的地层时,经常出现井壁失稳和井下漏失等问题,为此开展了新型纳米封堵剂的研究与评价。合成了强吸附疏水纳米封堵剂,对其粒度分布、吸附性、润湿性和砂床封堵性能进行了测试。测试结果表明,该封堵剂粒度分布在100~150 nm,吸附性强,高温下能够将页岩表面水的润湿接触角增大到80.7°;加量为2.5%时,实验浆的砂床滤失量降低到5.0 mL;对钻井液流变性影响较小,API滤失量从4.4 mL降低到1.0 mL,高温高压滤失量从16.2 mL降低到6.2 mL;加量超过3.0 %时,渗透率降低到2.81 μD;PPA封堵率测试表明,该封堵剂能在陶瓷过滤盘内部形成封堵,钻井液的滤失速率降低到0.45 mL/min1/2,瞬时滤失量降低到2.58 mL。研究表明,强吸附疏水纳米封堵剂能够提高钻井液的封堵能力,降低钻井液对地层的侵入量,对保护井壁稳定有较好的作用。Abstract: Downhole troubles such as borehole instability and mud losses are frequently encountered when drilling formations with poor stability and low pressure bearing capacity. Study and evaluation of new nano plugging agents have recently been performed to solve these problems. Study on these issues gave birth to a strongly adsorptive hydrophobic nano plugging agent. Measurement of the particle size distribution, adsorptive ability and wettability of the plugging agent, as well as plugging capacity test performed on sand-bed have shown that the particle sizes of the plugging agent was distributed in a range of 100-150 nm. The plugging agent has good adsorptive ability; it can increase the contact angle of water on the surfaces of shale to 80.7°. A mud sample treated with 2.5% of the plugging agent had its filtration rate through a sand-bed tester reduced to 5.0 mL. The plugging agent has little, if any, effect on the rheology of the drilling fluid. The API filtration rate of the drilling fluid was reduced by the plugging agent from 4.4 mL to 1.0 mL, and the HTHP filtration rate was reduced from 16.2 mL to 6.2 mL. At concentrations in a mud above 3.0%, the permeability of the mud cakes was reduced to 2.8 μD. PPA plugging efficiency test has shown that the plugging agent can form a plugging layer on a ceramic filter disk, the filtration rate was reduced to 0.45 mL/min1/2, and the spurt loss was reduced to 2.58 mL. The study has demonstrated that the strongly adsorptive hydrophobic nano plugging agent can enhance the plugging capacity of the drilling fluid, reduce the amount of filtrate invasion of the drilling fluid into the formation and effectively help stabilize the borehole wall.

-

Key words:

- Drilling fluid /

- Nano plugging agent /

- Strong adsorption /

- Hydrophobic modification /

- Wettability

-

表 1 封堵剂XSF-1加量对页岩表面润湿性的影响

XSF-1/% 25 ℃接触角/(°) 120 ℃接触角/(°) 0.5 40.6 37.5 1.0 60.8 54.8 2.0 71.4 70.2 3.0 83.6 79.8 4.0 84.3 80.7 表 2 封堵剂XSF-1对钻井液流变性能的影响

XSF-1/% AV/(mPa·s) PV/(mPa·s) YP/Pa Gel/(Pa/Pa) 0 26.0 19.0 7.0 1.0/3.0 0.5 26.5 19.0 7.5 1.0/3.0 1.0 27.0 19.0 8.0 1.5/3.0 2.0 28.5 21.0 7.5 1.5/3.0 3.0 29.5 21.0 8.5 1.5/3.5 4.0 30.5 22.0 8.5 1.5/3.5 表 3 不同浓度XSF-1钻井液的PPA封堵效果

XSF-1/

%FLHTHP/

mLFLPPA/

mL滤失量降

低率/%0.0 16.2 15.2 6.17 0.5 15.6 14.0 10.26 1.0 14.4 10.4 27.78 2.0 8.8 7.2 18.18 3.0 7.2 6.0 16.67 4.0 6.6 5.6 15.15 表 4 钻井液PPA滤失速率和瞬时滤失量

XSF-1/% 滤失速率/(mL·min-1/2) 瞬时滤失量/mL 0 1.14 9.28 0.5 1.08 8.06 1.0 0.90 5.60 2.0 0.64 3.63 3.0 0.49 3.16 4.0 0.45 2.58 -

[1] 石秉忠,夏柏如,林永学,等. 硬脆性泥页岩水化裂缝发展的CT 成像与机理[J]. 石油学报,2012,33(1):137-142. doi: 10.7623/syxb201201020SHI Bingzhong, XIA Bairu, LIN Yongxue, et al. CT Imaging and mechanism analysis of crack development by hydration in hard-brittle shale formations[J]. Acta Petrolei Sinica, 2012, 33(1):137-142. doi: 10.7623/syxb201201020 [2] 张文哲,李伟,王波,等. 延长油田致密油藏水平井强封堵钻井液优选与现场应用[J]. 油田化学,2019,36(2):191-195.ZHANG Wenzhe, LI Wei, WANG Bo, et al. Optimization and application of strong plugging drilling fluid for horizontal well in tight oil of Yanchang oilfield[J]. Oilfield Chemistry, 2019, 36(2):191-195. [3] 金军斌. 塔里木盆地顺北区块超深井火成岩钻井液技术[J]. 石油钻探技术,2016,44(6):17-23.JIN Junbin. Drilling fluid technology for igneous rocks in ultra-deep wells in the Shunbei area, Tarim basin[J]. Petroleum Drilling Techniques, 2016, 44(6):17-23. [4] 李治衡,林海,董平华,等. 渤中区块火成岩地层钻井液优化研究[J]. 非常规油气,2019,6(3):81-86. doi: 10.3969/j.issn.2095-8471.2019.03.013LI Zhiheng, LIN Hai, DONG Pinghua, et al. Study on drilling fluid optimization in igneous rock formation in Bozhong block[J]. Unconventonal Oil & Gas, 2019, 6(3):81-86. doi: 10.3969/j.issn.2095-8471.2019.03.013 [5] KARCHER B J, GIGER F M, COMBE J. Some practical formulas to predict horizontal wells behavior[R]. SPE 15430, 1986. [6] 姜洪福,隋军,庞彦明,等. 特低丰度油藏水平井开发技术研究与应用[J]. 石油勘探与开发,2006,33(3):364-368. doi: 10.3321/j.issn:1000-0747.2006.03.022JIANG Hongfu, SUI Jun, PANG Yanming, et al. Technique of exceptionally low abundance oil reservoir development by horizontal wells and its application[J]. Petroleum Exploration and Development, 2006, 33(3):364-368. doi: 10.3321/j.issn:1000-0747.2006.03.022 [7] 褚奇,孔勇,杨帆,等. 多苯基芳基硅烷偶联剂改性纳米SiO2封堵剂[J]. 断块油气田,2017,24(2):281-284.CHU Qi, KONG Yong, YANG Fan, et al. Nano-silica dioxide plugging agent modified by polyphenyl aryl silanes coupling agent[J]. Fault-Block Oil & Gas Field, 2017, 24(2):281-284. [8] 王伟吉,邱正松,暴丹,等. 温压成膜封堵技术研究及应用[J]. 特种油气藏,2015,22(1):144-147. doi: 10.3969/j.issn.1006-6535.2015.01.035WANG Weiji, QIU Zhengsong, BAO Dan, et al. Warm-compaction film-forming plugging and its application[J]. Special Oil & Gas Reservoirs, 2015, 22(1):144-147. doi: 10.3969/j.issn.1006-6535.2015.01.035 [9] 徐琳,邓明毅,郭拥军,等. 纳米SiO2 接枝超支化聚酰胺的合成及性能评价[J]. 石油化工,2016,45(11):1352-1356. doi: 10.3969/j.issn.1000-8144.2016.11.011XU Lin, DENG Mingyi, GUO Yongjun, et al. Synthesis and performance evaluation of nano SiO2 grafted with hyper-branched polyamide[J]. Petrochemical Technology, 2016, 45(11):1352-1356. doi: 10.3969/j.issn.1000-8144.2016.11.011 [10] 唐文泉,王成彪,林永学,等. 页岩气地层纳微米孔隙结构特征及封堵实验评价[J]. 科学技术与工程,2017,17(12):32-38. doi: 10.3969/j.issn.1671-1815.2017.12.007TANG Wenquan, WANG Chengbiao, LIN Yongxue, et al. The characteristic analysis of micro-nano pore structure in shale gas formation and its sealing evaluation[J]. Science Technology and Engineering, 2017, 17(12):32-38. doi: 10.3969/j.issn.1671-1815.2017.12.007 [11] 余文可,林凌,罗云翔,等. 贝壳粉基自适应性封堵剂[J]. 钻井液与完井液,2021,38(6):715-720.YU Wenke, LIN Ling, LUO Yunxiang, et al. A self-adaptive shell powder plugging agent[J]. Drilling Fluid & Completion Fluid, 2021, 38(6):715-720. [12] 王力,孟尚志,陈万钢,等. 提高煤层强度的钻井液防塌封堵剂的研制[J]. 钻井液与完井液,2018,35(5):46-49. doi: 10.3969/j.issn.1001-5620.2018.05.009WANG Li, MENG Shangzhi, CHEN Wangang, et al. Development of and study on an anti-sloughing plugging agent used in drilling fluids to strengthen coal beds[J]. Drilling Fluid & Completion Fluid, 2018, 35(5):46-49. doi: 10.3969/j.issn.1001-5620.2018.05.009 [13] 陈修平,李双贵,于洋,等. 顺北油气田碳酸盐岩破碎性地层防塌钻井液技术[J]. 石油钻探技术,2020,48(2):12-16.CHEN Xiuping, LI Shuanggui, YU Yang, et al. Anti-collapse drilling fluid technology for broken carbonate formation in Shunbei oil and gas field[J]. Petroleum Drilling Techniques, 2020, 48(2):12-16. [14] 王翔. 鄂尔多斯盆地西部页岩油水平井井壁稳定技术[J]. 石油地质与工程,2019,33(4):88-91. doi: 10.3969/j.issn.1673-8217.2019.04.022WANG Xiang. Wellbore stability technique in horizontal wells for shale oil reservoirs in western Ordos basin[J]. Petroleum Geology and Engineering, 2019, 33(4):88-91. doi: 10.3969/j.issn.1673-8217.2019.04.022 [15] 罗勇,张海山,王荐,等. 东海油气田深部泥页岩特性及钻井液技术研究[J]. 西南石油大学学报(自然科学版),2019,41(4):90-98.LUO Yong, ZHANG Haishan, WANG Jian, et al. A study on the characteristics of deeply buried mud shale and drilling fluid techniques in oil and gas fields of east China sea[J]. Journal of Southwest Petroleum University(Science & Technology Edition ) , 2019, 41(4):90-98. [16] 徐哲,孙金声,吕开河,等. 一种新型外柔内刚型封堵剂的研制[J]. 钻井液与完井液,2020,37(6):726-730. doi: 10.3969/j.issn.1001-5620.2020.06.008XU Zhe, SUN Jinsheng, LYU Kaihe, et al. Research and development of a novel internal rigid external soft plugging agent[J]. Drilling Fluid & Completion Fluid, 2020, 37(6):726-730. doi: 10.3969/j.issn.1001-5620.2020.06.008 [17] GB/T 16783.1—2014 石油天然气工业钻井液现场测试: 第1部分: 水基钻井液[S].GB/T 16783.1—2014 Petroleum and natural gas industries-field testing of drilling fluids: part 1: water-based fluids[S]. -

下载:

下载: