| [1] |

付晓颖,朱世飞,钟文,等. 钻井液综合参数在线测量方法的研究[J]. 甘肃科技,2015,31(9):78-80. doi: 10.3969/j.issn.1000-0952.2015.09.026FU Xiaoying, ZHU Shifei, ZHONG Wen, et al. Research on on-line measurement method of comprehensive parameters for drilling fluid[J]. Gansu Science and Technology, 2015, 31(9):78-80. doi: 10.3969/j.issn.1000-0952.2015.09.026

|

| [2] |

PIROOZIAN A, ISMAIL I, YAACOB Z, et al. Impact of drilling fluid viscosity, velocity and hole inclination on cuttings transport in horizontal and highly deviated wells[J]. J Petrol Explor Prod Technol, 2012(2):149-156.

|

| [3] |

MARSH, HALLAN N. Properties and treatment of rotary mud[J]. Transactions of the AIME, 1931, 92(1):234-251. doi: 10.2118/931234-G

|

| [4] |

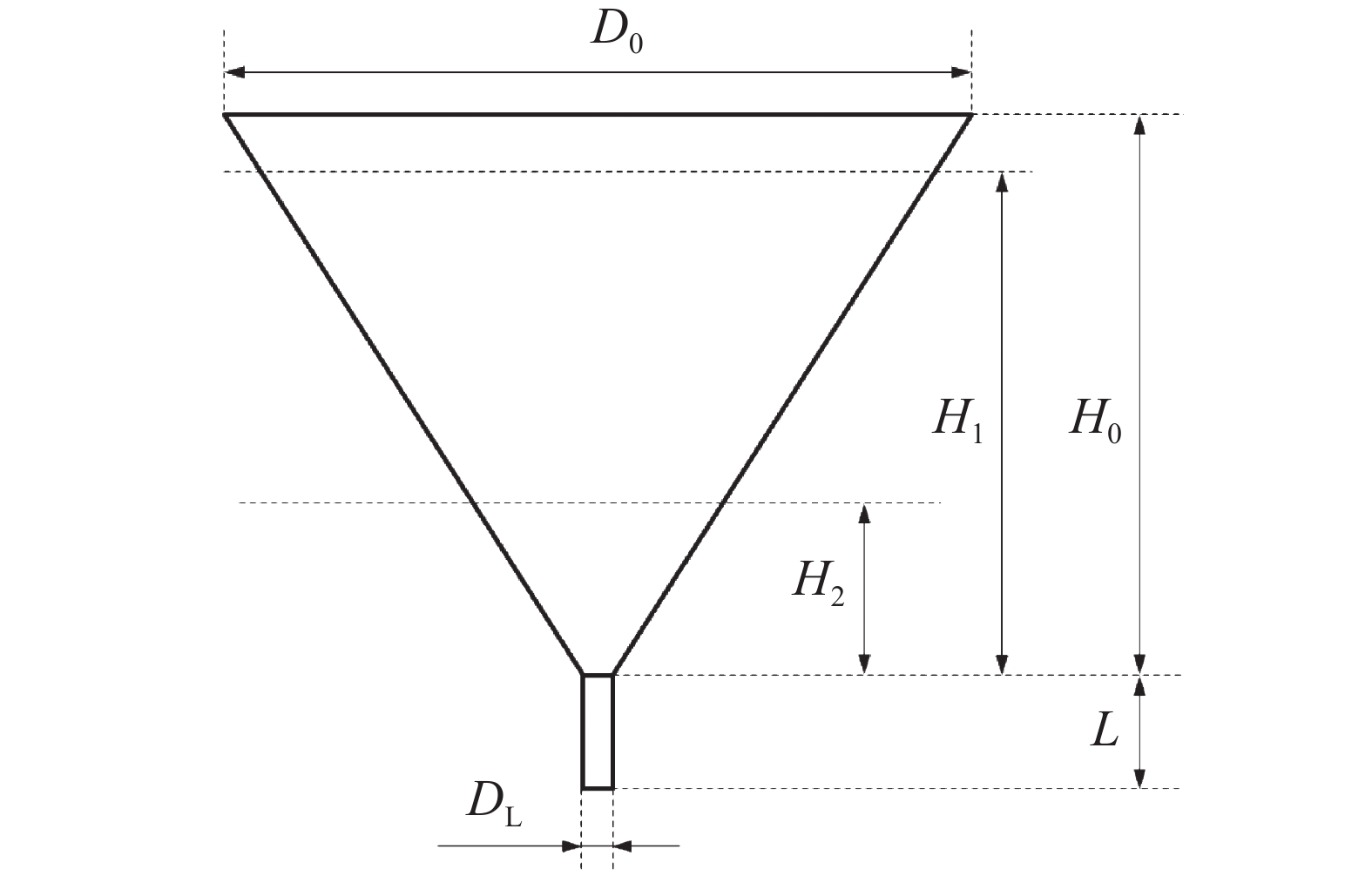

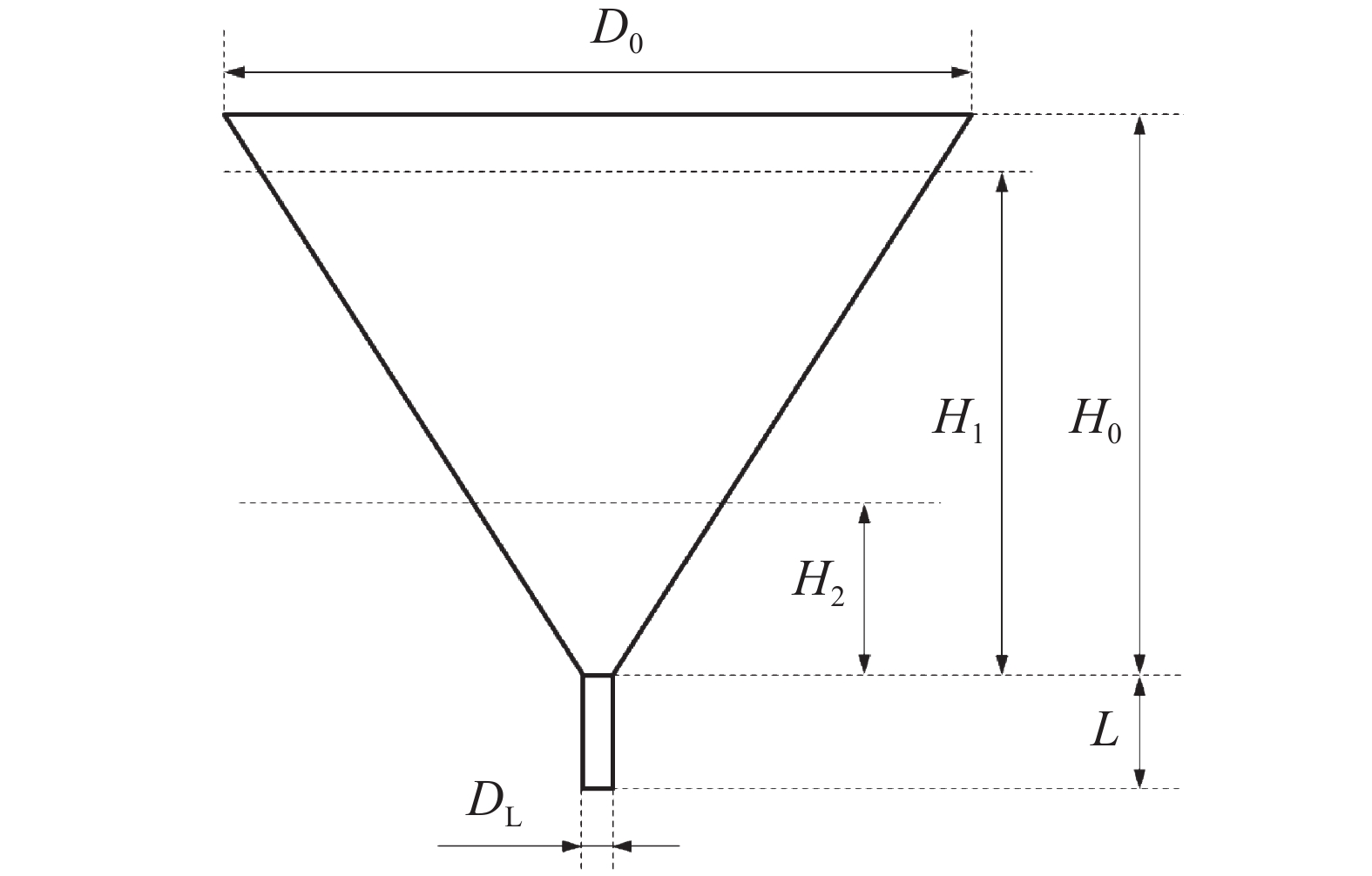

李照川,郑力会,吴通,等. 马氏漏斗黏度计测定钻井流体流变参数新方法的建立[J]. 钻井液与完井液,2021,38(1):54-61. doi: 10.3969/j.issn.1001-5620.2021.01.009LI Zhaochuan, ZHENG Lihui, WU Tong, et al . A new method of measuring rheological properties of drilling fluids with Marsh funnel viscometer[J]. Drilling Fluid & Completion Fluid, 2021, 38(1):54-61. doi: 10.3969/j.issn.1001-5620.2021.01.009

|

| [5] |

SEDAGHAT, AHMAD. A novel and robust model for determining rheological properties of Newtonian and non-Newtonian fluids in a marsh funnel[J]. Journal of Petroleum Science & Engineering, 2017, 156:896-916.

|

| [6] |

GURIA C, KUMAR R, MISHRA P. Rheological analysis of drilling fluid using Marsh Funnel[J]. Journal of Petroleum Science and Engineering, 2013, 105(105):62-69.

|

| [7] |

杨莉, 李家学, 刘会锋. 钻井液马氏漏斗黏度与表观黏度的关系[J]. 钻井液与完井液, 2012, 29(1): 12-14.YANG Li, LI Jiaxue, LIU Huifeng. Study on relationship between mash funnel viscosity and apparent viscosity of drilling fluids [J]. Drilling Fluid & Completion Fluid, 2012, 29(1): 12-14.

|

| [8] |

刘扣其,邱正松,罗洋,等. 应用马氏漏斗测定钻井液流变参数[J]. 钻井液与完井液,2014,31(5):60-62. doi: 10.3969/j.issn.1001-5620.2014.05.017LIU Kouqi, QIU Zhengsong, LUO Yang, et al. Measure rheology of drilling fluids with marsh funnel viscometer[J]. Drilling Fluid & Completion Fluid, 2014, 31(5):60-62. doi: 10.3969/j.issn.1001-5620.2014.05.017

|

| [9] |

ZHANG Y , WU D, GAI Y , et al. Investigation on the countersink errors in the drilling of thin-wall stacked structures[J]. International Journal of Advanced Manufacturing Technology, 2020, 108(7):2497-2514.

|

| [10] |

CAO G Q, SUN Y Y. Finite Element analysis of deformation of the multipoint flexible clamped thin-Wall component during machining[J]. Advanced Materials Research, 2012, 542:519-522. doi: 10.4028/www.scientific.net/AMR.542-543.519

|

| [11] |

ZHOU W Q, DONG P S, LILLEM E I, et al. Analytical treatment of distortion effects on fatigue behaviors of lightweight shipboard structures[J]. International Journal of Fatigue, 130(C): 105-286.

|

| [12] |

FRICKE W, REMES H, FELTZ O, et al. Fatigue strength of laser-welded thin-plate ship structures based on nominal and structural hot-spot stress approach[J]. Ships and Offshore Structures, 2013, 10(1):39-44.

|

| [13] |

LILLEM E I, REMES H, LIINALAMPI S, et al. Influence of weld quality on the fatigue strength of thin normal and high strength steel butt joints[J]. Welding in the World, 2016, 60(4):731-740. doi: 10.1007/s40194-016-0326-8

|

| [14] |

LILLEM E I, LIINALAMPI S, REMES H, et al. Fatigue strength of thin laser-hybrid welded full-scale deck structure[J]. International Journal of Fatigue, 2017, 95:282-292. doi: 10.1016/j.ijfatigue.2016.11.012

|

| [15] |

REMES H, ROMANOFF J, LILLEM E I, et al. Factors affecting the fatigue strength of thin-plates in large structures[J]. International Journal of Fatigue, 2017, 101(2):397-407.

|

| [16] |

CHATTERJEE S, MAHAPATRA S S, ABHISHEK K. Simula-tion and optimization of machining parameters in drilling of ti-tanium alloys[J]. Simulation Modelling Practice and Theory, 2016, 62:31-48. doi: 10.1016/j.simpat.2015.12.004

|

| [17] |

SENTHILKUMAR M, PRABUKARTHI A, PRAKASH U, et al. Finite element analysis and experimental investiga-tion of drilling of titanium alloy(Ti6Al4V)[J]. Applied Mechanics and Materials, 2015, 813:342-346. doi: 10.4028/www.scientific.net/AMM.813-814.342

|

| [18] |

MA X, WU D, GAO Y, et al. An approach to countersink depth control in the drilling of thin-wall stacked structures with low stiffness[J]. Int J Adv Manuf Technol, 2018, 95(1):785-795. doi: 10.1007/s00170-017-1234-9

|

| [19] |

DENG Dean ,LIU Xiaozhan , HE Jing , et al. Investigating the influence of external restraint on welding distortion in thin-plate bead-on joint by means of numerical simulation and experiment[J]. The International Journal of Advanced Manufacturing Technology, 2016, 82(5):1049-1062. doi: 10.1007/s00170-015-7413-7

|

| [20] |

MANURUNG Y, SULAIMAN M S, ABAS S K, et al. Investigation on welding distortion of combined butt and T-joints with 9-mm thickness using FEM and experiment[J]. The International Journal of Advanced Manufacturing Technology, 2015, 77(5/8):775-782. doi: 10.1007/s00170-014-6268-7

|

| [21] |

YI Jie, ZHANG Jianming, GAO Shufen, et al. Effect of welding sequence on residual stress and deformation of 6061-T6 aluminium alloy automobile component[J]. Transactions of Nonferrous Metals Society of China, 2019, 29(2):287-295. doi: 10.1016/S1003-6326(19)64938-1

|

| [22] |

金业权. 非牛顿流体漏斗黏度与塑性黏度的实验研究[J]. 西部探矿工程,2004,16(2):37-38.JIN Yequan. Experimental study on funnel viscosity and plastic viscosity of non-newtonian fluid[J]. West-china Exploration Engineering, 2004, 16(2):37-38.

|

| [23] |

王富华,李雪雨,赵海艳,等. 基于马氏漏斗黏度的油基钻井液表观黏度预测方法[J]. 石油钻探技术,2016,44(5):60-64.WANG Fuhua,LI Xueyu,ZHAO Haiyan,et al. Determination of the apparent viscosity of oil-based drilling fluid by using marsh funnel viscosity[J]. Petroleum Drilling Techniques, 2016, 44(5):60-64.

|

下载:

下载: