The Development and Application of High-Temperature and High-Performance Water Base Drilling Fluid on the well Shunbei 801X

-

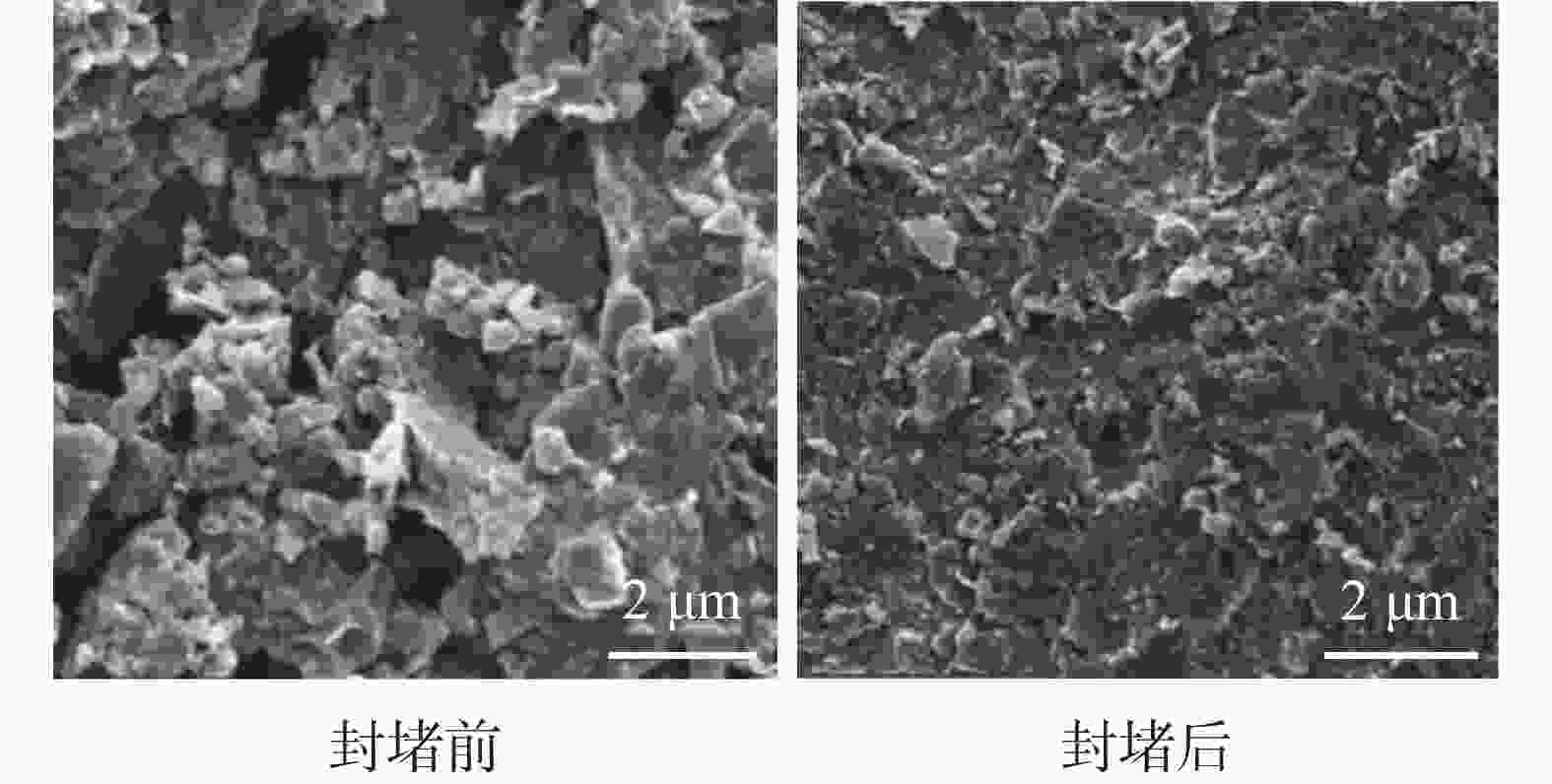

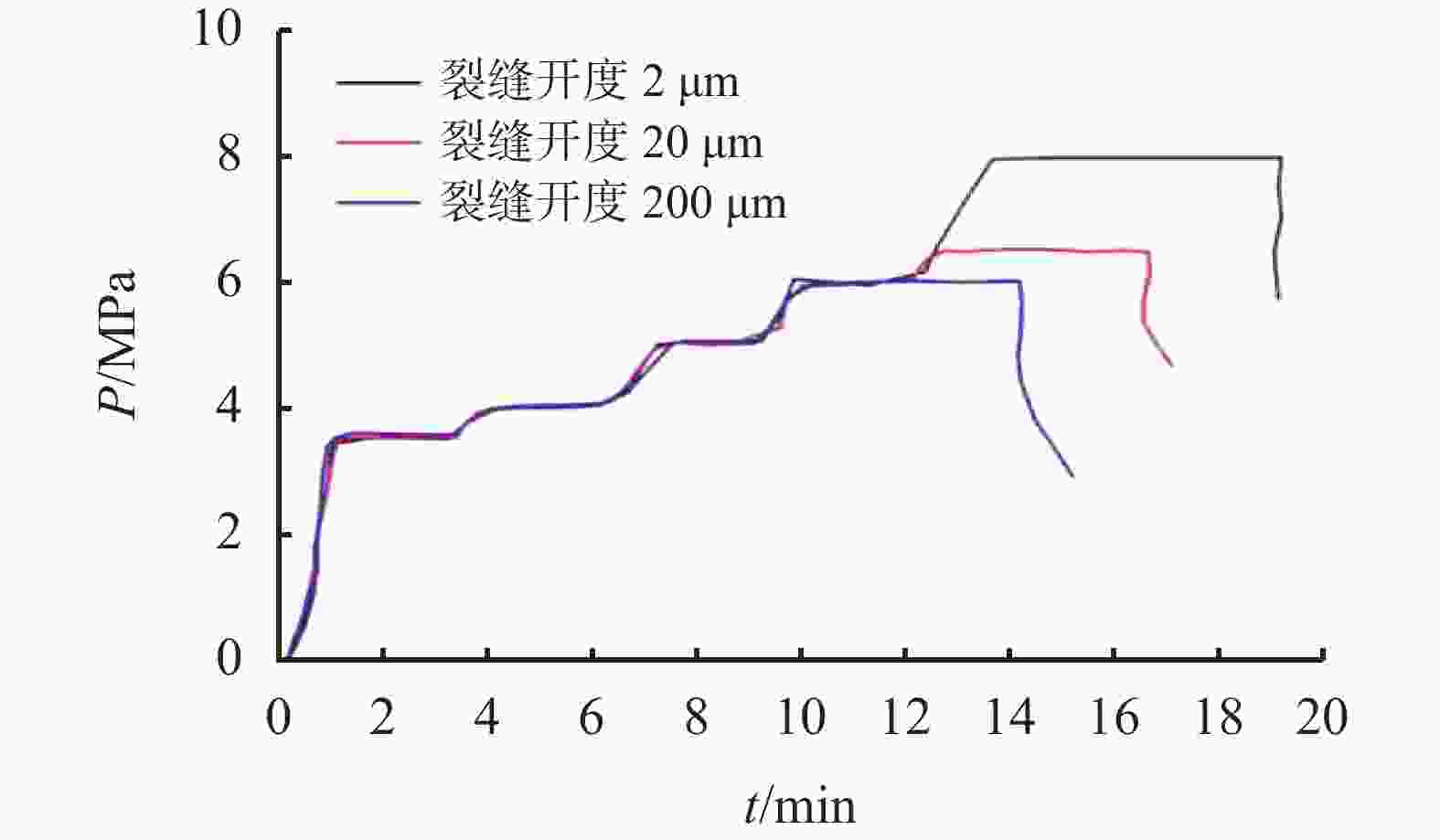

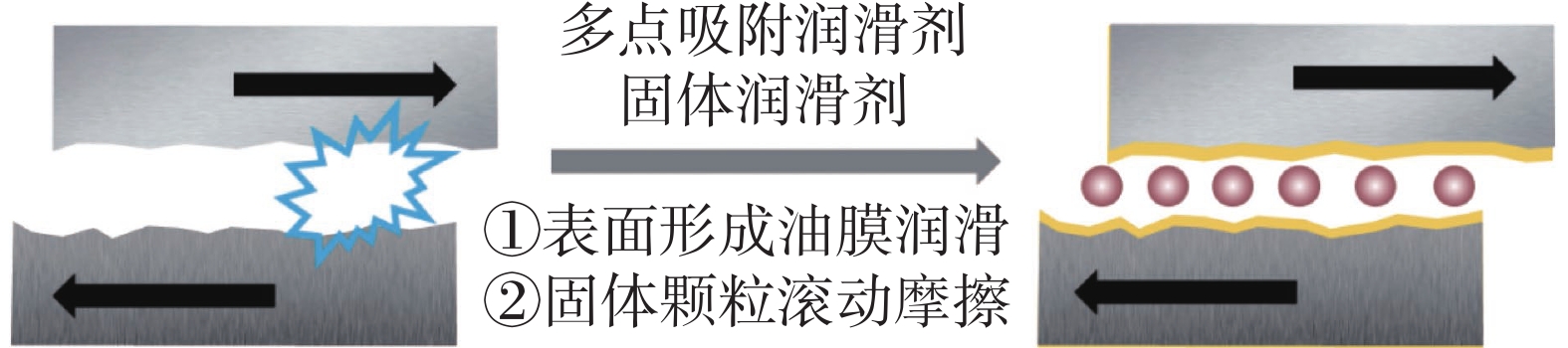

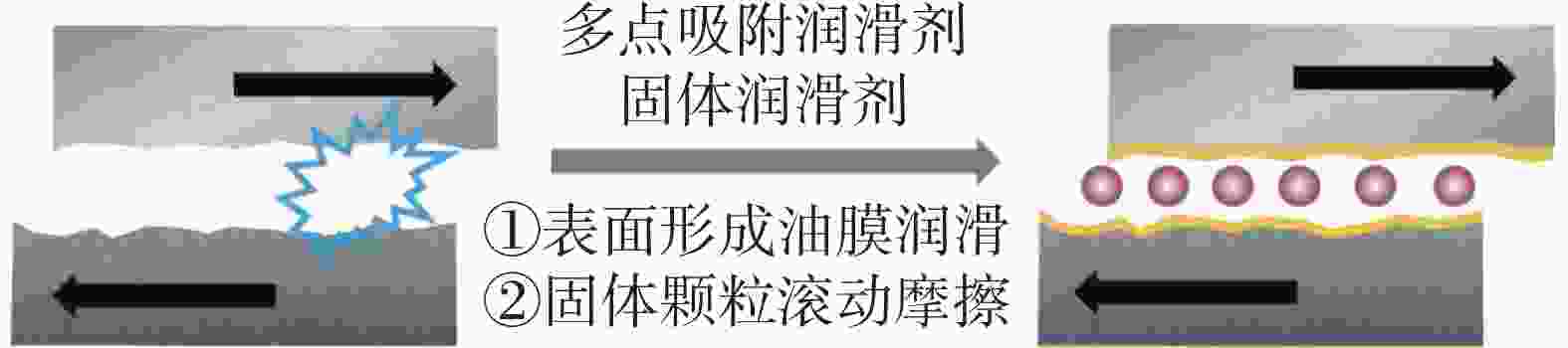

摘要: 顺北801X井是塔里木盆地顺托果勒区块的一口重点探井,完钻井深为9145 m,最大井斜为71°,水平位移为1075.77 m,为国内陆上采用水基钻井液完钻的最深定向井。针对顺北801X井高温高压地层的特点,通过优选抗温处理剂,优化钻井液性能参数,研制出一套密度达2.0 g/cm3的高性能水基钻井液体系。室内评价结果表明,该钻井液抗温可达200 ℃,在高温下具有良好的流变性能,能较好地封堵泥页岩微裂缝,在180 ℃下的滤失量为13.8 mL,滤饼质量薄且有韧性,能抗CO32−、HCO3−污染及盐水侵污染。现场应用表明,该钻井液在高温井段性能稳定,维护简单,起下钻顺利,未出现复杂情况,保证了井下安全、快速钻进,该井试油产量折算油气当量达1007.6 t。该钻井液的成功应用,为顺北区块后续施工井钻井液体系的优选提供很好的借鉴。Abstract: The well 801X in Shunbei area is a key exploratory well located in the Shuntuoguole block in Tarim Basin. This well has total depth of 9,145 m, maximum well angle of 71° and horizontal displacement of 1,075.77 m. To deal with the high temperature high pressure problems encountered during drilling, a high performance water based drilling fluid with density of 2.0 g/cm3 was developed by high temperature additive selection and drilling fluid parameter optimization. Laboratory experimental results have shown that this drilling fluid can function normally at temperatures up to 200 ℃. It has good rheology at high temperatures and can effectively plug the microfractures developed in the shale formations. Filtration rate of this drilling fluid at 180 ℃ was 13.8 mL, and the mud cake was thin and tough. This drilling fluid can also stand the contamination from CO32-, HCO3- and salt water. Field application has shown that this drilling fluid had stable properties in drilling the high temperature formations, and its properties were easy to maintain. Tripping of drilling tools was done smoothly, and no downhole troubles were encountered. The well was safely drilled in high rate of penetration. In well testing, the converted oil and gas equivalent was 1,007.6 t. The development of this drilling fluid has provided a useful reference for the optimization of drilling fluids for subsequent drilling operations in the Shunbei block.

-

Key words:

- Water based drilling fluid /

- Shale /

- High temperature resistant /

- CO2 contamination /

- Shunbei block

-

表 1 不同聚合物对钻井液流变性能的影响

聚合物 实验

条件AV/

mPa·sPV/

mPa·sYP/

Paφ6/φ3 Gel/

Pa/Pa1.0%NX-1 老化前 66.0 59 7.0 7/6 3.0/8.0 200 ℃、16 h 43.0 39 4.0 3/2 1.5/2.0 1.0%DSP-1 老化前 37.5 29 8.5 4/3 1.5/3.5 200 ℃、16 h 26.5 23 3.5 3/2 1.0/2.0 0.5%NX-1+

0.5%DSP-1老化前 48.0 37 11.0 5/4 2.0/5.5 200 ℃、16 h 46.0 38 8.0 4/3 1.5/4.0 注:基浆为3#配方;参数在60 ℃下测定 表 2 0.5%降黏剂和0.5%FS-1对加重 钻井液沉降稳定性能的影响

处理剂 实验

条件PV/

mPa·sYP/

Paφ6/φ3 Gel/

Pa/Pa沉降指数 16 h 48 h 72 h 老化前 57 12.0 7/5 3.0/9.0 老化后 55 10.0 4/3 2.0/4.5 0.736 0.869 0.875 降黏剂 老化前 49 10.0 4/3 2.0/5.0 老化后 44 7.0 3/2 1.5/3.0 0.536 0.593 0.657 FS-1 老化前 52 13.0 6/4 2.5/8.0 老化后 49 11.5 5/4 2.0/6.5 0.514 0.516 0.520 注:配方为:3#+0.5%NX-1+0.5%DSP-1;老化条件为200 ℃、16 h;其他参数在60 ℃下测定 表 3 抗高温高性能水基钻井液在不同温度下的基本性能

T老化/

℃PV/

mPa·sYP/

Paφ6/φ3 Gel/

Pa/PaFLAPI/

mLFLHTHP/

mL润滑

性沉降

指数180 51.0 12.0 6/5 3/9 1.8 12.2 0.06 0.506 200 46.5 10.5 5/4 2/6 3.6 13.8 0.08 0.514 注: FLHTHP 在180 ℃下测定;其他参数在60 ℃下测定 表 4 抗高温高性能水基钻井液抗污染性评价

污染物 浓度 ρ/

g·cm−3PV/

mPa·sYP/

PaGel/

Pa/PaFLHTHP/

mL空白 2.03 46.5 10.5 2.0/6.0 12.2 Na2CO3 10 g/L 2.04 50.0 11.0 2.0/7.0 14.2 Na2CO3 30 g/L 2.05 57.0 16.0 4.0/12.0 15.8 盐水 10 mL/L 46.0 10.5 2.0/6.0 盐水 30 mL/L 44.0 9.0 2.0/5.0 盐水 50 mL/L 39.0 8.0 2.0/4.0 注:FLHTHP 在180 ℃下测定;其他参数在60 ℃下测定 表 5 顺北801X井四开井段抗高温水基钻井液的性能

井深/

mρ/

g·cm−3PV/

mPa·sYP/

PaGel/

Pa/Paφ6/φ3 Kf FLHTHP/

mL7736 1.65 23 8 3.0/9.0 5/4 8.8 7964 1.45 24 10 2.0/8.5 6/5 0.0349 9.0 8412 1.28 27 9 2.0/6.0 4/3 0.0349 9.0 9145 1.28 28 9 2.0/7.5 5/4 0.0349 9.0 -

[1] 赵志国,白彬珍,何世明,等. 顺北油田超深井优快钻井技术[J]. 石油钻探技术,2017,45(6):8-13.ZHAO Zhiguo, BAI Binzhen, HE Shimin, et al. Optimization of fast drilling technology for ultra-deep wells in the Shunbei Oilfield[J]. Petroleum Drilling Techniques, 2017, 45(6):8-13. [2] 刘彪,潘丽娟,张俊,等. 顺北区块超深小井眼水平井优快钻井技术[J]. 石油钻探技术,2016,44(6):11-16.LIU Biao, PAN Lijuan, ZHANG Jun, et al. The optimized drilling techniques used in ultra-deep and slim-hole horizontal wells of the Shunbei Block[J]. Petroleum Drilling Techniques, 2016, 44(6):11-16. [3] 林永学,王伟吉,金军斌. 顺北油气田鹰1井超深井段钻井液关键技术[J]. 石油钻探技术,2019,47(3):113-120. doi: 10.11911/syztjs.2019068LIN Yongxue, WANG Weiji, JIN Junbin. Key drilling fluid technology in the ultra deep section of well Ying-1 in the Shunbei oil and gas field[J]. Petroleum Drilling Techniques, 2019, 47(3):113-120. doi: 10.11911/syztjs.2019068 [4] 蒋祖军, 郭新江, 王希勇. 天然气深井超深井钻井技术[M]. 北京: 中国石化出版社, 2011: 1-21.JIANG Zujun, GUO Xinjiang, WANG Xiyong. Drilling technology for natural gas deep/ultra-deep wells[M]. Beijing: Sinopec Press, 2011: 1-21. [5] 金军斌. 塔里木盆地顺北地区长裸眼钻井液技术[J]. 探矿工程(岩土钻掘工程),2017,44(4):5-9.JIN Junbing. Drilling fluid technology of long open hole section in Shunbei area of Tarim Basin[J]. Exploration Engineering (Rock & Soil Drilling and Tunneling) , 2017, 44(4):5-9. [6] 林四元,李中,黄熠,等. 高性能水基钻井液在莺歌海盆地高温高压井的应用[J]. 钻井液与完井液,2018,35(2):44-48. doi: 10.3969/j.issn.1001-5620.2018.02.007LIN Siyuan, LI Zhong, HUANG Yi, et al. The development and application of high performance water base muds for HTHP wells in Ying ge hai basin[J]. Drilling Fluid & Completion Fluid, 2018, 35(2):44-48. doi: 10.3969/j.issn.1001-5620.2018.02.007 [7] 侯杰,刘永贵,李海. 高性能水基钻井液在大庆油田致密油藏水平井中的应用[J]. 石油钻探技术,2015,43(4):59-65.HOU Jie, LIU Yong gui, LI Hai. Application of high-performance water-based drilling fluid for horizontal wells in tight reservoirs of Da qing oilfield[J]. Petroleum Drilling Techniques, 2015, 43(4):59-65. [8] 刘翔,罗宇峰,王娟,等. 钻井液CO2污染的测试方法及处理技术[J]. 钻采工艺,2009,32(6):78-81. doi: 10.3969/j.issn.1006-768X.2009.06.024LIU Xiang, LUO Yufeng, WANG Juan, et al. Testing method and treating technology for CO2 pollution of drilling fluid[J]. Drilling & Production Technology, 2009, 32(6):78-81. doi: 10.3969/j.issn.1006-768X.2009.06.024 [9] 骆小虎. 抗高温高密度钻井液在印尼LOFIN-2井的研究和应用[J]. 钻井液与完井液,2019,36(1):60-64. doi: 10.3969/j.issn.1001-5620.2019.01.012LUO Xiaohu. Study on a High temperature high density drilling fluid used on the well LOFIN-2, In donesia[J]. Drilling Fluid & CompletionFluid, 2019, 36(1):60-64. doi: 10.3969/j.issn.1001-5620.2019.01.012 [10] 吴雄军,林永学,王显光,等. 顺北5-7井超深层奥陶系地层油基钻井液技术[J]. 长江大学学报(自然科学版),2021,18(1):100-106.WU Xiongjun, LIN Yongxue, WANG Xianguang, et al. Oil-based drilling fluid technology for ultra-deep Ordovician strata of Well Shunbei 5-7[J]. Journal of Yangtze University (Natural Science Edition) , 2021, 18(1):100-106. [11] 陈修平,李双贵,于洋,等. 顺北油气田碳酸盐岩破碎性地层防塌钻井液技术[J]. 石油钻探技术,2020,48(2):12-16. doi: 10.11911/syztjs.2020005CHEN Xiuping , LI Shuanggui, YU Yang, et al. Anti-collapse drilling fluid technology for broken carbonate formation in Shunbei oil and gas field[J]. Petroleum Dilling Techniques, 2020, 48(2):12-16. doi: 10.11911/syztjs.2020005 [12] 魏昱,白龙,王骁男. 川深1井钻井液关键技术[J]. 钻井液与完井液,2019,36(2):194-201. doi: 10.3969/j.issn.1001-5620.2019.02.011WEI Yu, BAI Long, WANG Xiaonan. Key drilling fluid technology for well Chuan Shen-1[J]. Drilling Fluid & Completion Fluid, 2019, 36(2):194-201. doi: 10.3969/j.issn.1001-5620.2019.02.011 [13] 宣扬,蒋官澄,李颖颖,等. 基于仿生技术的强固壁型钻井液体系[J]. 石油勘探与开发,2013,40(4):497-501. doi: 10.11698/PED.2013.04.17XUAN Yang, JIANG Guancheng, LI Yingying, et al. A biomimetic drilling fluid for wellbore strengthening[J]. Petroleum Exploration and Development, 2013, 40(4):497-501. doi: 10.11698/PED.2013.04.17 -

下载:

下载: