Laboratory Study on Low Temperature Synthetic Based Drilling Fluid

-

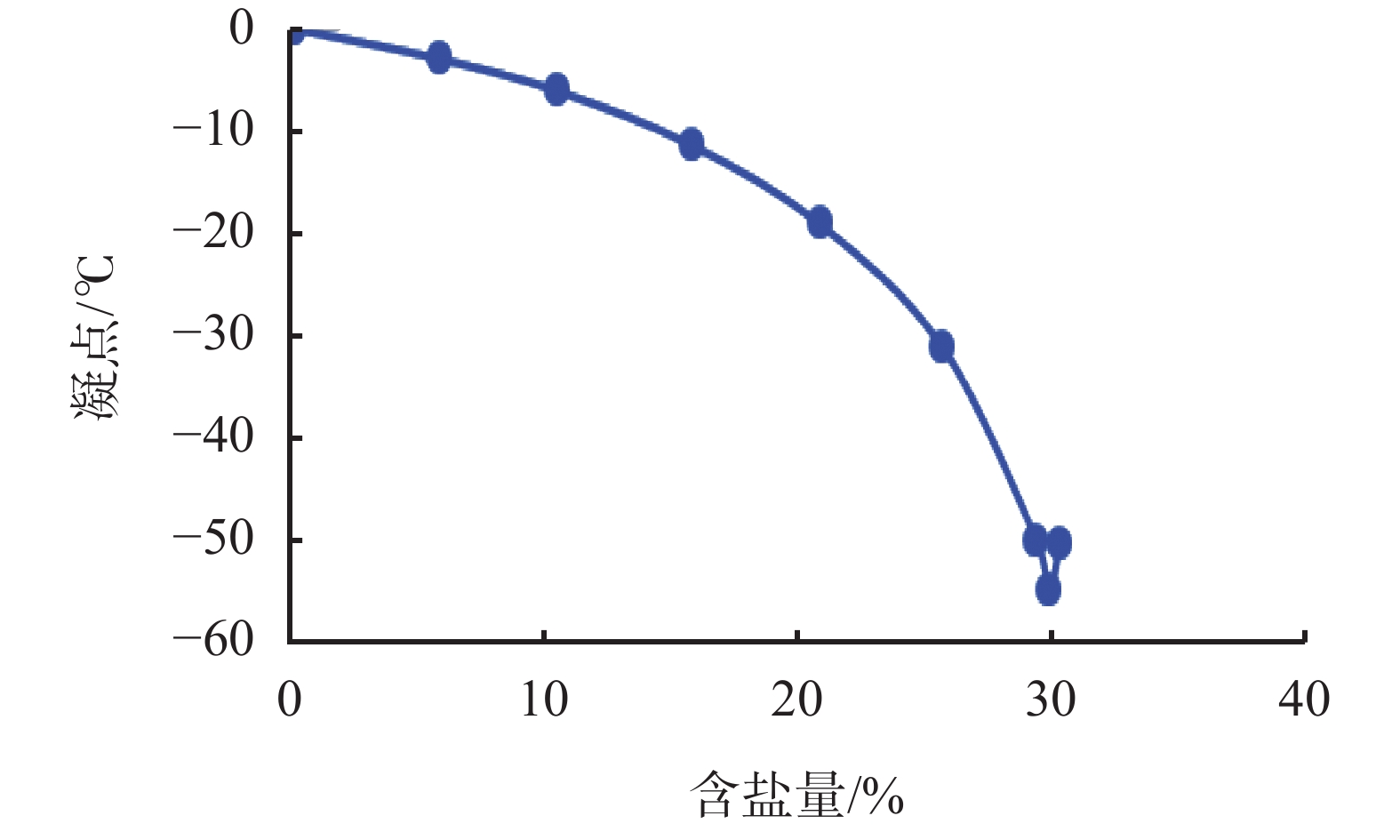

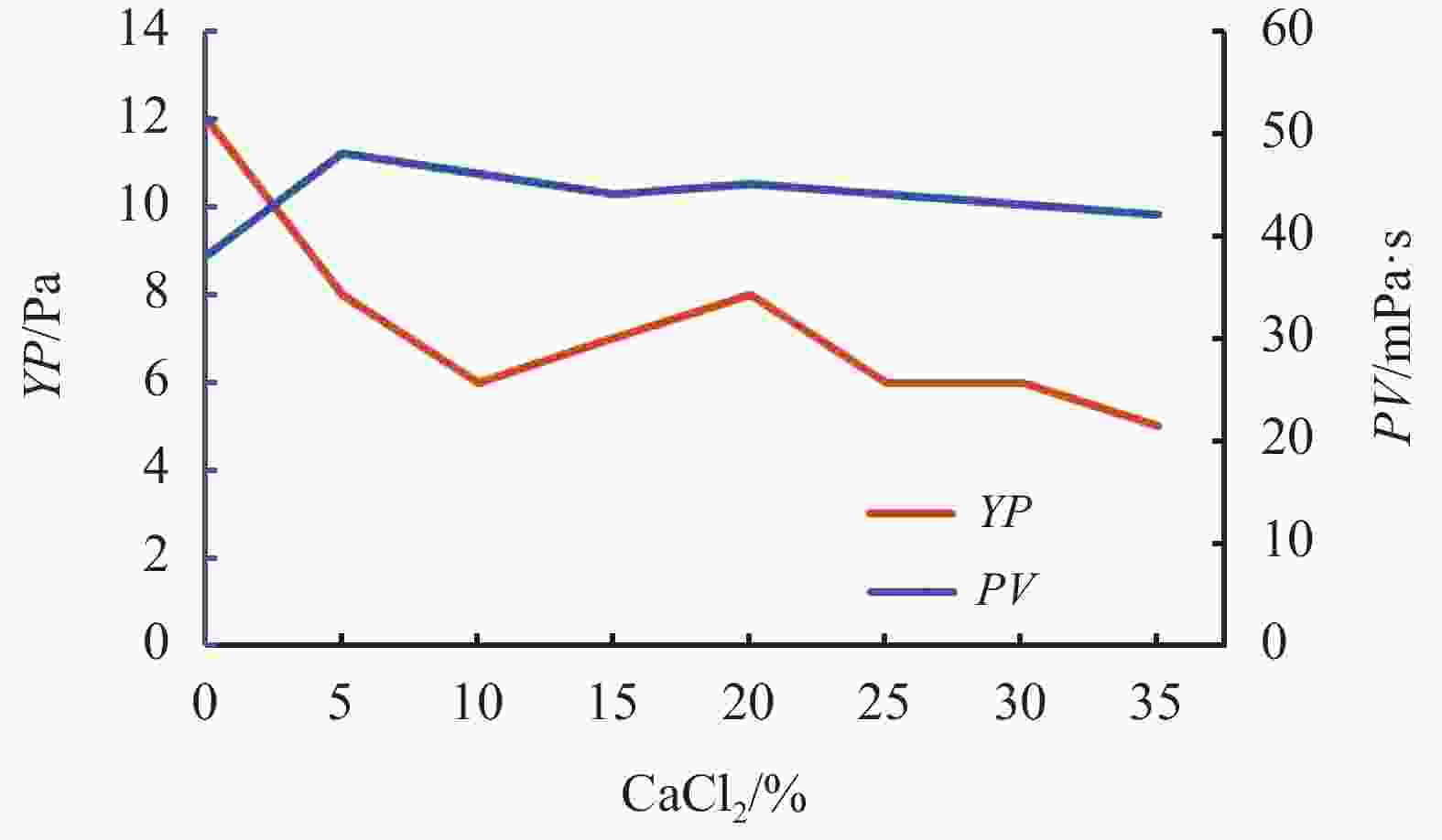

摘要: 油基钻井液作为复杂地层开发的首选钻井液,零下低温环境中存在黏度、切力明显增大的问题。为解决这一问题,室内选用性能与油基钻井液相近的合成基钻井液,研发了一种耐低温乳化剂、采用低凝点的气制油作为油相和质量分数为30%的CaCl2作为水相,优选流型调节剂,研制了一套耐低温的合成基钻井液体系。该体系在2.0 g/cm3的高密度下,经过180 ℃老化16 h后,依然能在−10 ℃时保持良好的黏度、切力和电稳定性,维持较好的流动性能,高温高压滤失量小于2 mL;能有效预防因当量循环密度过高引起的井下复杂情况、低温造成的管线堵塞问题。Abstract: Oil based drilling fluid as the first choice of drilling complex formations has unwanted high viscosity and high gel strengths at low temperatures below zero degree Celsius. To solve this problem, a low temperature synthetic based drilling fluid was developed with low temperature emulsifiers, low freezing point gas-to-oil as oil phase, 30% CaCl2 solution as the water phase, and other optimized flow pattern modifiers. This synthetic based drilling fluid has properties that can be as good as those of oil based drilling fluids. At density of 2.0 g/cm3, the synthetic based drilling fluid, after aging at 180 ℃ for 16 hours, still had viscosity, gel strengths, electrical stability and flow property perfectly suitable for normal operation at -10 ℃. The HTHP filtration rate of this drilling fluid was less than 2 mL. This drilling fluid can effectively prevent downhole troubles arising from high equivalent circulating densities (ECD) and pipeline blocking caused by low temperatures.

-

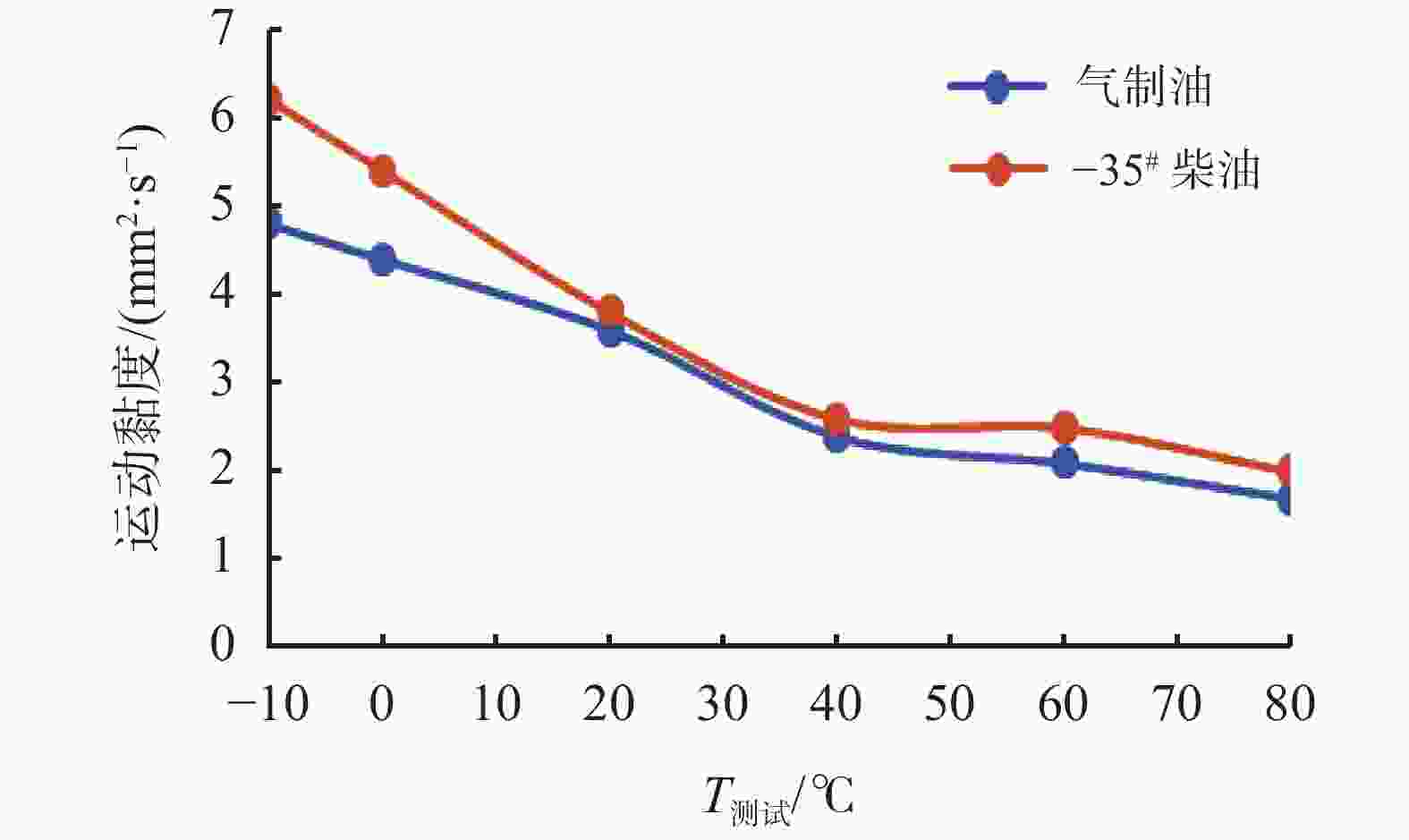

表 1 2种油相的理化性能

油相 凝点/

℃倾点/

℃运动黏度/

mm2·s−1ρ/

g·cm−3芳香烃 气制油 −40 −37.0 4.4 0.78 无 −35#柴油 −35 −32.5 5.4 0.83 有 注:密度在15 ℃下测定,运动黏度在0 ℃下测定 表 2 流型调节剂对耐低温合成基钻井液性能的影响

流型调节剂 T测试/

℃AV/

mPa·sPV/

mPa·sYP/

PaES/

VFLHTHP/

mL空白 −10 85 75 10 1500 1.6 0 78 66 12 1359 50 63 57 6 1199 DEHEO −10 73 56 17 1866 1.1 0 67 51 16 1633 50 51 39 12 1402 HIRHEO-A −10 84 68 16 1664 1.2 0 76 62 14 1395 50 53 44 9 1228 注:FLHTHP在120 ℃测定 表 3 耐低温合成基钻井液体系的抗温能力

T老化/

℃T测试/

℃AV/

mPa·sPV/

mPa·sYP/

PaES/

VFLHTHP/

mL120 −10 79 60 19 1899 1.1(120 ℃) 0 67 50 17 1627 50 50 39 11 1322 160 −10 72 48 14 1740 1.8(160 ℃) 0 59 47 12 1388 50 42 32 10 1210 180 −10 62 47 15 1655 2.3(180 ℃) 0 46 34 12 1402 50 37 29 8 1161 表 4 密度对耐低温合成基钻井液的影响

ρ/

g·cm−3T测试/

℃AV/

mPa·sPV/

mPa·sYP/

PaES/

VFLHTHP/

mL1.4 −10 66 48 18 1988 0.8 0 45 30 15 1576 50 30 20 10 1017 1.8 −10 70 51 19 1848 1.0 0 54 40 14 1411 50 36 27 9 1244 2.0 −10 80 55 25 2000 1.2 0 64 48 16 1582 50 47 39 8 1390 注:FLHTHP在120 ℃测定 表 5 耐低温合成基钻井液的抗污染能力(120 ℃、16 h)

污染物 AV/

mPa·sPV/

mPa·sYP/

Paφ6/φ3 ES/

VFLHTHP/

mL空白 36 26 10 6/5 1221 1.2 5%钻屑 39 30 9 6/5 1008 1.2 10%钻屑 39 28 11 6/5 1042 1.0 10%劣质土 46 36 10 8/7 1320 2.8 20%劣质土 57 45 12 10/8 1290 3.4 10%CaCl2盐水 33 22 9 6/5 1058 20%CaCl2盐水 47 34 13 14/12 890 注:钻井液密度为1.8 g/cm3,钻屑、劣质土过100目筛,抗污染能力在50 ℃下测定 -

[1] 邱正松,刘扣其,曹杰,等. 油基钻井液低温流变特性实验研究[J]. 钻井液与完井液,2014,31(3):32-34. doi: 10.3969/j.issn.1001-5620.2014.03.008QIU Zhengsong, LIU Kouqi, CAO Jie, et al. Study on low temperature rheology of oil base drilling fluid[J]. Drilling Fluid & Completion Fluid, 2014, 31(3):32-34. doi: 10.3969/j.issn.1001-5620.2014.03.008 [2] 纪健, 袁华玉, 李建, 等. 深水钻井环境下低温高压对油基钻井液流变性的影响[J]. 内蒙古石油化工, 2009, 35(21): 134-136.JI Jian, YUAN Huayu, LI Jian, et al. Influence of low temperature and high pressure on rheological properties of oil-based drilling fluids in deep offshore conditions[J]. Inner Mongolia Petrochemical Industry, 2009, 35(21): 134-136. [3] 田荣剑, 王楠, 李松, 等. 深水作业中钻井液在低温高压条件下的流变性[J]. 钻井液与完井液, 2010, 27(5): 5-7.TIAN Rongjian, WANG Nan, LI Song, et al. Research on drilling fluid rheology with low temperature and high pressure in deep water operation[J]. Drilling Fluid & Completion Fluid, 2010, 27(5): 5-7 . [4] 陈鸵,张楠,杨双春,等. 低温钻井液研究和应用进展[J]. 应用化工,2021,50(7):1998-2001. doi: 10.3969/j.issn.1671-3206.2021.07.054CHEN Tuo, ZHANG Nan, YANG Shuangchun, et al. Research and application progress of low temperature drilling fluid[J]. Applied Chemical Industry, 2021, 50(7):1998-2001. doi: 10.3969/j.issn.1671-3206.2021.07.054 [5] 付超胜, 杨玉海, 张希勋. 基于低温条件的油基钻井液流变特性探究[J]. 中国石油和化工标准与质量, 2021, 41(14): 123-124.FU Chaosheng, YANG Yuhai, ZHANG Xixun. Research on rheological properties of oil-based drilling fluid based on low temperature[J]. China Petroleum and Chemical Standards & Quality, 2021, 41(14): 123-124. [6] 可点. 环保型气制油合成基钻井液体系研究[D]. 北京: 中国石油大学(北京), 2017.KE Dian. Study on synthetic base and gas to liquid fuel drilling fluid system for environmentally friendly[D]. Beijing:China University of Petroleum (Beijing), 2017. [7] 王茂功,徐显广,孙金声,等. 气制油合成基钻井液关键处理剂研制与应用[J]. 钻井液与完井液,2016,33(3):30-34. doi: 10.3969/j.issn.1001-5620.2016.03.006WANG Maogong, XU Xianguang, SUN Jinsheng, et al. Study and application of additives for synthetic fluids with GTL as the base fluid[J]. Drilling Fluid & Completion Fluid, 2016, 33(3):30-34. doi: 10.3969/j.issn.1001-5620.2016.03.006 [8] 万绪新,张海青,沈丽,等. 合成基钻井液技术研究与应用[J]. 钻井液与完井液,2014,31(4):26-29. doi: 10.3969/j.issn.1001-5620.2014.04.008WAN Xuxin, ZHANG Haiqing, SHEN Li, et al. Study and application of synthetic base drilling fluid technology[J]. Drilling Fluid & Completion Fluid, 2014, 31(4):26-29. doi: 10.3969/j.issn.1001-5620.2014.04.008 [9] 徐同台,彭芳芳,潘小镛,等. 气制油的性质与气制油钻井液[J]. 钻井液与完井液,2010,27(5):75-78. doi: 10.3969/j.issn.1001-5620.2010.05.023XU Tongtai, PENG Fangfang, PAN Xiaoyong, et al. The properties of GTL and GTL based drilling fluids[J]. Drilling Fluid & Completion Fluid, 2010, 27(5):75-78. doi: 10.3969/j.issn.1001-5620.2010.05.023 [10] 由福昌, 许明标, 文华, 等. 一种具有低温流动性的油基钻井液乳化剂: 中国, 113773817A[P]. 2021-12-10.YOU Fuchang, XU Mingbiao, WEN Hua, et al. Emulsifier for oil base drilling fluid with low temperature fluidity: China,113773817A[P], 2021-12-10. [11] KATHERINE AUGHENBAUGH, SRIRAMYA DUDDUKURI NAIR, KENNETH COWAN, et al. Contamination of deepwater well cementations by synthetic-based drilling fluids[J]. SPE 170325, 2014. [12] 罗健生,莫成孝,刘自明,等. 气制油合成基钻井液研究与应用[J]. 钻井液与完井液,2009,26(2):7-11. doi: 10.3969/j.issn.1001-5620.2009.02.002LUO Jiansheng, MO Cheng xiao, LIU Ziming, et al. The study and application of a GTL based drilling fluid[J]. Drilling Fluid & Completion Fluid, 2009, 26(2):7-11. doi: 10.3969/j.issn.1001-5620.2009.02.002 [13] 王荐. 环保型深水恒流变生物质合成基钻井液体系研究[D]. 中国地质大学, 2020.WANG Jian. Research of environmental protection deep water constant rheological biomass synthetic based drilling fluid system[D]. China University of Geosciences, 2020. [14] 朱秀玉. 恒流变合成基钻井液的研究与评价[D]. 东北石油大学, 2020.ZHU Xiuyu. The research and evaluation of flat- rheological synthetic-based drilling fluid[D]. Northeast Petroleum University, 2020. [15] 陈磊, 郭昭学, 孙凯, 等. 海洋深水钻井技术研究[J]. 天然气技术, 2009, 3(6): 37-39.CHEN Lei, GUO Zhaoxue, SUN Kai, et al. Studies on offshore deep-water drilling technology[J]. Natural Gas Technology, 2009, 3(6): 37-39. [16] 杨洪烈,吴娇,汪夯志,等. 海洋深水钻井液体系研究进展[J]. 化学与生物工程,2019,36(12):12-16.YANG Honglie, WU Jiao, WANG Hangzhi, et al. Research on offshore deepwater drilling fluid system[J]. Chemistry & Bioengineering, 2019, 36(12):12-16. [17] 余意,王雪瑞,柯珂,等. 极地钻井井筒温度压力预测模型及分布规律研究[J]. 石油钻探技术,2021,49(3):11-20. doi: 10.11911/syztjs.2021047YU Yi, WANG Xuerui, KE Ke, et al. Prediction model and distribution law study of temperature and pressure of the wellbore in drilling in Arctic region[J]. Petroleum Drilling Techniques, 2021, 49(3):11-20. doi: 10.11911/syztjs.2021047 -

下载:

下载: