Study on Compound Fracturing of Maokou Formation Marl in Southeast Sichuan

-

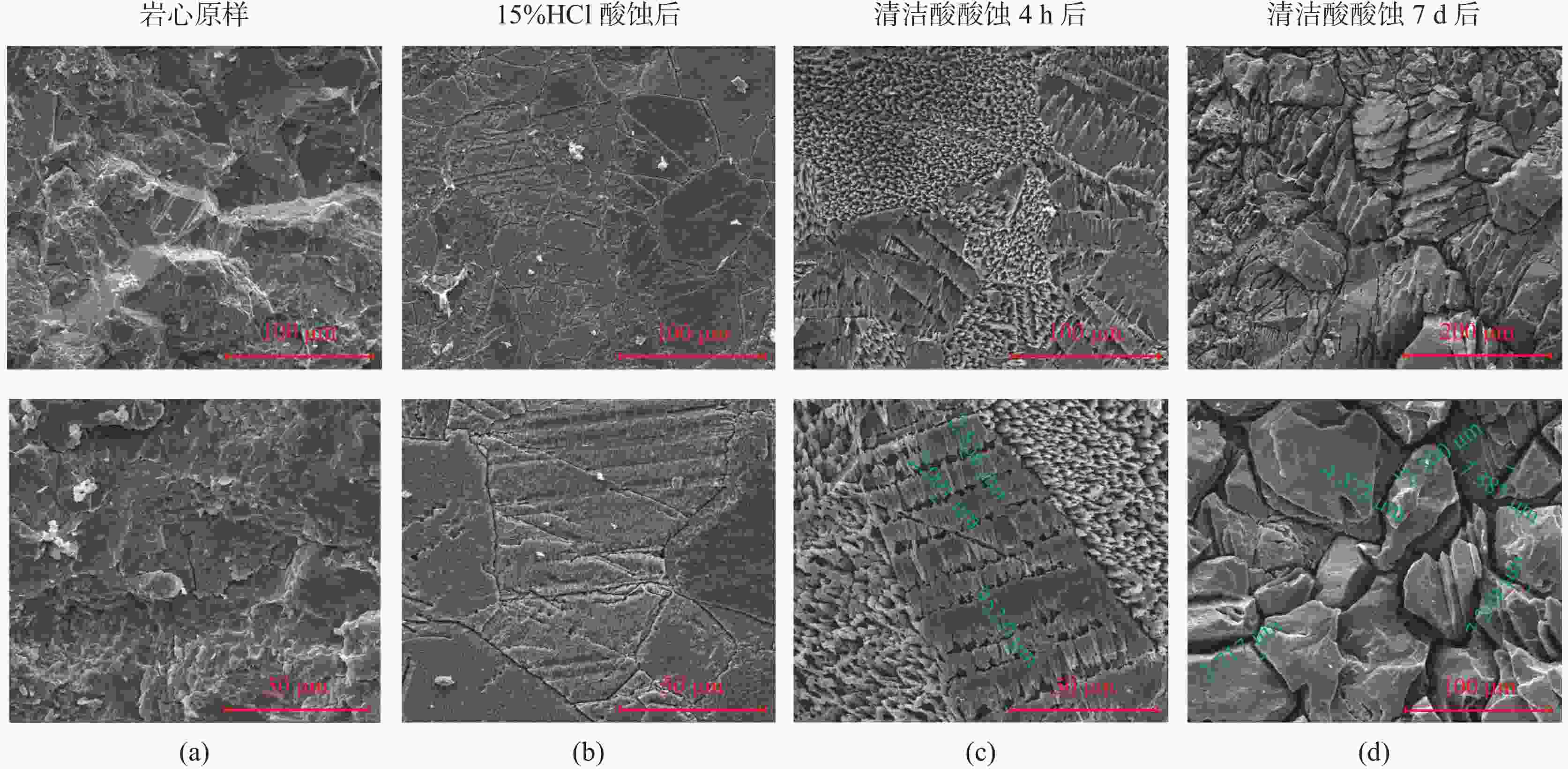

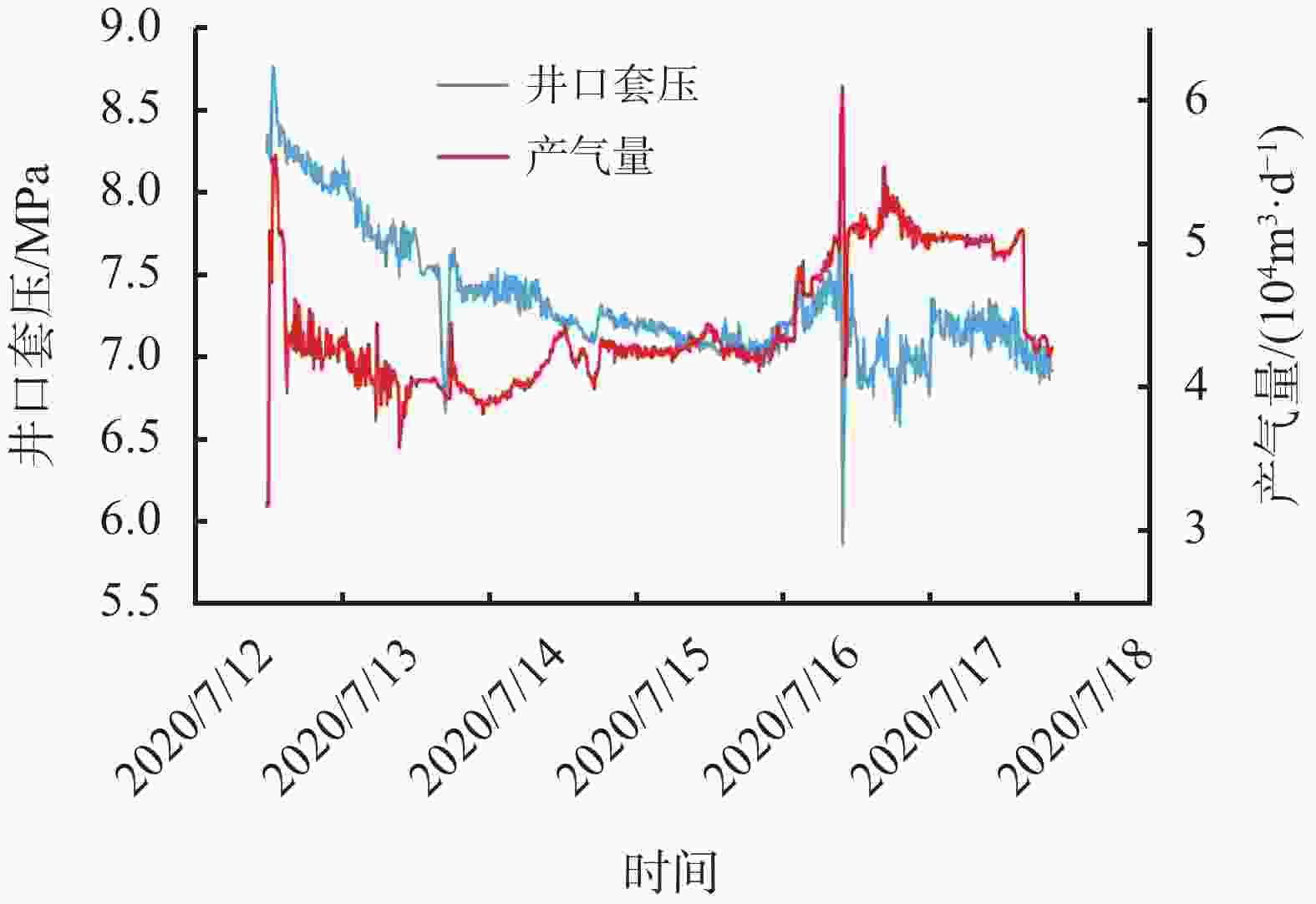

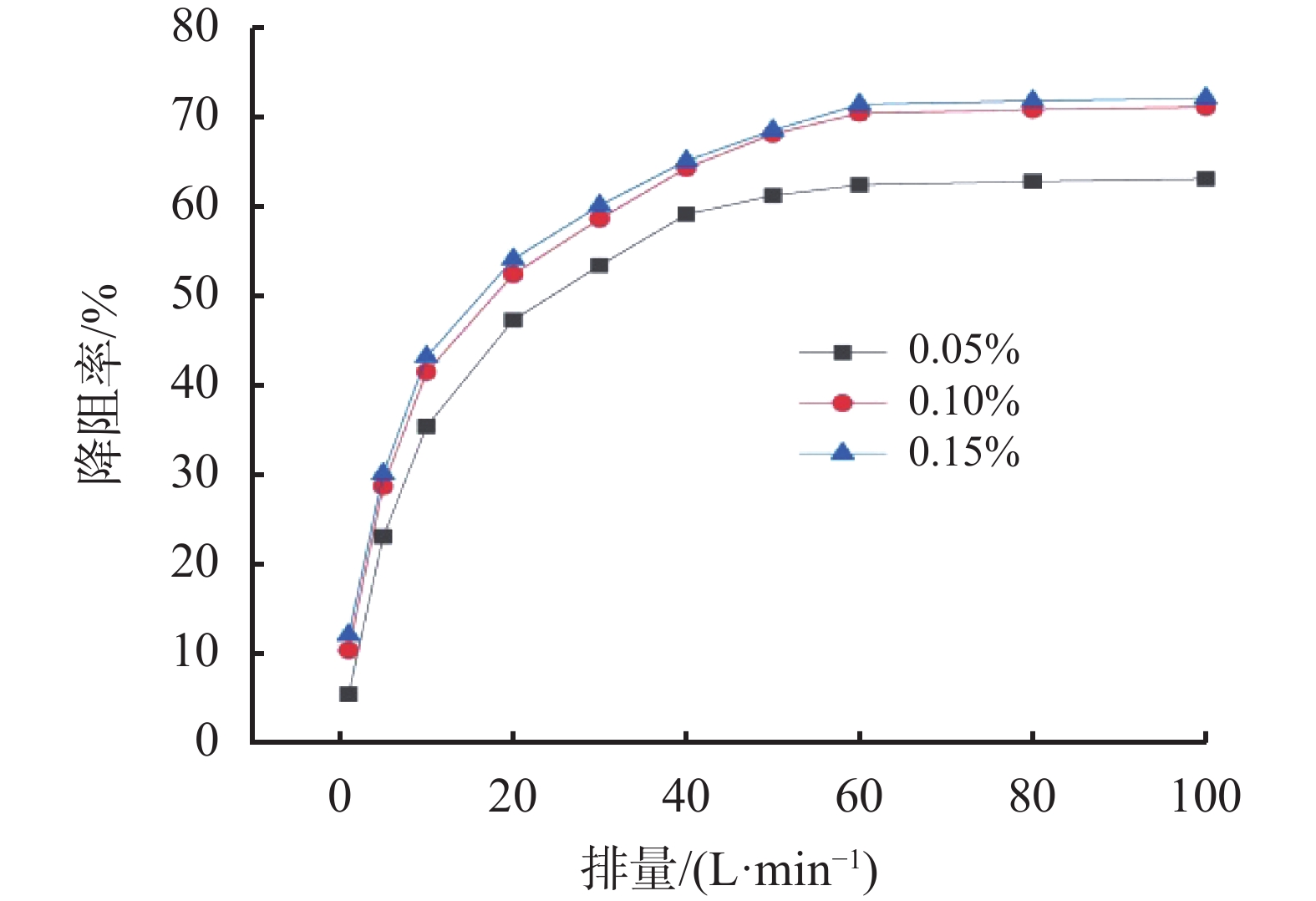

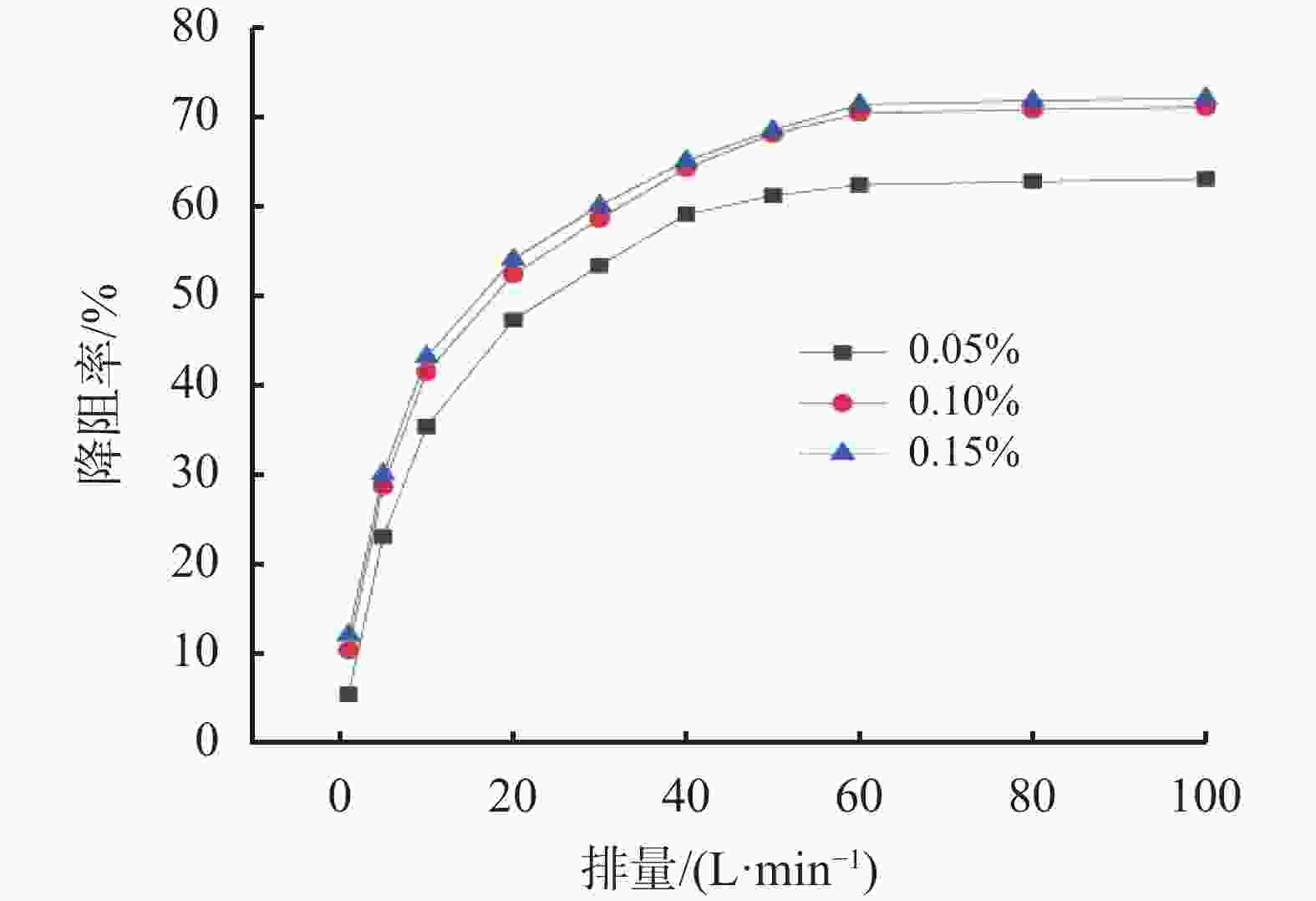

摘要: 针对川东南区块茅口组基质储层埋藏浅,敏感性矿物含量高且储层低孔低渗,采用了多簇限流射孔+降阻水加砂+清洁酸复合酸压工艺,扩大了储层改造体积,提升了地层裂缝导流能力。结合岩石力学参数,采用密切割射孔增加人工裂缝密度,通过增大簇间诱导应力优化了裂缝间距为10~15 m,当单段液量为1600~1800 m3,降阻水与清洁酸配比为6∶4时,可实现裂缝壁面的刻蚀,提升裂缝导流能力,强化渗流通道。研选了耐酸、高降阻率的清洁稠化剂,形成的清洁酸体系降阻率达63.5%,有效地降低了酸压施工摩阻,有利于大排量酸压施工,在闭合压力为30 MPa下的酸蚀裂缝导流能力达14.9 μm2·cm,且清洁酸与岩石反应前后的岩石表面结构特征基本一致,酸蚀蚓孔及裂缝表面无附着物,对储层伤害较小。并在FM1HF井成功应用,取得了Φ12 mm油嘴放喷条件下,日产4.12×104 m3工业气流,首次在川东南地区茅口组获得稳定工业气流,验证了该项技术在泥灰岩气藏中的应用可行性,对国内类似储层改造提供良好的借鉴和推广应用价值。Abstract: The Maokou formation in the southeast Sichuan is shallow buried. It is rich in sensitive minerals and has low porosity and low permeability. In reservoir stimulation operations, multi-cluster limited entry perforation, friction-reduced water with sand and fracturing with compound clear acids techniques were used to increase the volume of reservoir formations to be stimulated and to improve the conductivity of formation fractures. Based on the rock mechanics parameters, the artificial fracture density was increased using intensive cut perforation technique, the spacing between two fractures was optimized to 10 – 15 m by increasing the inducing force. When the fluid volume in a single section was 1,600 – 1,800 m3, and the ratio of friction-reduced water to clear acid was 6 : 4, the surfaces of the fractures can be itched away, thereby increasing the conductivity of the fractures and strengthening the seepage channels. A clear thickening agent with acid tolerance and high friction-reducing capacity was selected and used to formulate a clear acid with percent friction reduction of 63.5%. With this acid, the friction of acid fracturing operation was effectively reduced, which is beneficial to high flow rate acid fracturing job. At closure pressure of 30 MPa, the conductivity of the acid-itched fractures reached 14.9 μm2∙cm. The rocks, after being itched by the clear acid, had basically unform surface structures. The acid-itched wormholes and the surfaces of the factures are free of any attachment, which is less damaging to the reservoirs. This acid was used in the fracturing of the well FM1HF. Using a Φ12 mm choke, the daily gas production rate of the well reached 4.12 × 104 m3, a stable industrial gas production rate first obtained from the Maokou formation in southeast Sichuan, which proves the feasibility of this fracturing technology in stimulating marl reservoirs. This technology will provide a good reference and popularization value for stimulating similar reservoirs in China.

-

表 1 不同裂缝间距下缝间的诱导应力

裂缝间距/m 诱导应力/MPa 裂缝间距/m 诱导应力/MPa 5 7.3 20 3.9 10 6.1 25 3.4 15 4.8 30 2.8 注:水平应力差为4.6 MPa 表 2 不同施工规模下的裂缝参数对比

总液量/

m3裂缝半长/

m缝高/

m总液量/

m3裂缝半长/

m缝高/

m1400 185 18.6 1800 195 19.8 1600 191 19.3 2000 205 20.5 表 3 不同措施液配比下的酸蚀距离

降阻水∶

清洁酸缝高/

m酸蚀距离/

m降阻水∶

清洁酸缝高/

m酸蚀距离/

m3∶7 20.3 82.5 6∶4 18.7 73.2 4∶6 19.7 80.6 7∶3 16.1 64.7 5∶5 19.3 78.4 表 4 0.1%加量下不同清洁稠化剂的性能对比

清洁

稠化剂剪切黏度/

mPa·s(170 s−1)降阻率/

%酸岩反应速度/

mol/(cm2·s)RY120 9.7 53.5 2.935×10−6 KY51 1.3 32.6 4.631×10−6 WH-201 3.4 59.7 4.162×10−6 VT302 5.6 61.1 3.863×10−6 JY2 6.5 63.2 3.522×10−6 LH4 10.1 54.8 2.874×10−6 MK26 4.5 49.6 3.967×10−6 YH-5 2.8 60.4 4.283×10−6 表 5 研制的清洁酸体系的基本性能

AV/

mPa·s表面张力/

mN·m−1界面张力/

mN·m−1Fe3+稳定能力/

mg·L−1降阻率/

%防膨率/

%6.4 25.6 1.69 1037 63.5 79.2 注:表观黏度的测试条件为25 ℃,170 s−1;腐蚀速率的测试条件为65 ℃,值为0.32 g/(m2·h) -

[1] 陈宗清. 四川盆地中二叠统茅口组天然气勘探[J]. 中国石油勘探,2007,12(5):1-11. doi: 10.3969/j.issn.1672-7703.2007.05.001CHEN Zongqing. Exploration for natural gas in middle permian maokou formation of Sichuan Basin[J]. China Petroleum Exploration, 2007, 12(5):1-11. doi: 10.3969/j.issn.1672-7703.2007.05.001 [2] 耿宇迪,周林波,王洋,等. 超深碳酸盐岩复合高导流酸压技术[J]. 油气藏评价与开发,2019,9(6):56-60. doi: 10.3969/j.issn.2095-1426.2019.06.010GENG Yudi, ZHOU Linbo, WANG Yang, et al. High conductivity acid fracturing technology in ultra-deep carbonate reservoir[J]. Reservoir Evaluation and Development, 2019, 9(6):56-60. doi: 10.3969/j.issn.2095-1426.2019.06.010 [3] 漆立新. 塔里木盆地下古生界碳酸盐岩大油气田勘探实践与展望[J]. 石油与天然气地质,2014,35(6):771-780. doi: 10.11743/ogg20140604QI Lixin. Exploration practice and prospects of giant carbonate field in the Lower Paleozoic of Tarim Basin[J]. Oil & Gas Geology, 2014, 35(6):771-780. doi: 10.11743/ogg20140604 [4] 鲁新便,蔡忠贤. 缝洞型碳酸盐岩油藏古溶洞系统与油气开发: 以塔河碳酸盐岩溶洞型油藏为例[J]. 石油与天然气地质,2010,31(1):22-27. doi: 10.11743/ogg20100103LU Xinbian, CAI Zhongxian. A study of the paleo-cavern system in fractured-vuggy carbonate reservoirs and oil/gas development: taking there servoirs in Tahe oil field asan example[J]. Oil & Gas Geology, 2010, 31(1):22-27. doi: 10.11743/ogg20100103 [5] 张杨,杨向同,滕起,等. 塔里木油田超深高温高压致密气藏地质工程一体化提产实践与认识[J]. 中国石油勘探,2018,31(2):43-50.ZHANG Yang, YANG Xiangtong, TENG Qi, et al. Practice and cognition of geology- engineering integration for the production increasing of HTHP ultra-deep tight gas reservoir in Tarim oilfield[J]. China Petroleum Exploration, 2018, 31(2):43-50. [6] 周林波. 高导流自支撑酸化压裂室内实验研究[J]. 特种油气藏,2017,24(4):154-160.ZHOU Linbo. Laboratory experimental research on high conductivity self-supporting acid fracturing[J]. Special Oil and Gas Reservoirs, 2017, 24(4):154-160. [7] 牟建业,张士诚. 酸压裂缝导流能力影响因素分析[J]. 油气地质与采收率,2011,18(2):69-71. doi: 10.3969/j.issn.1009-9603.2011.02.018MOU Jianye, ZHANG Shicheng. Influence factor analysis on acid pressure rips diversion capacity[J]. Petroleum Geology and Recovery Efficiency, 2011, 18(2):69-71. doi: 10.3969/j.issn.1009-9603.2011.02.018 [8] 郝志伟,王宇宾,宋有胜,等. 高温深井碳酸盐岩储层降滤失酸体系研究与应用[J]. 钻井液与完井液,2012,29(4):69-71.HAO Zhiwei, WANG Yubin, SONG Yousheng, et al. Research and application on fluid loss control system used carbonatite in high temperature deep wells.[J]. Drilling Fluid & Completion Fluid, 2012, 29(4):69-71. [9] 叶颉枭,李力,韩慧芬,等. 多级交替注入酸压工艺优化研究——以磨溪龙女寺构造龙王庙组储层改造为例[J]. 油气藏评价与开发,2018,8(3):46-50. doi: 10.3969/j.issn.2095-1426.2018.03.009YE Jiexiao, LI Li, HAN Huifen, et al. Optimization research of multistage alternating acid fracturing: A case study of reservoir reconstruction for Longwangmiao Formation in Moxi-Longnvsi area[J]. Reservoir Evaluation and Development, 2018, 8(3):46-50. doi: 10.3969/j.issn.2095-1426.2018.03.009 [10] 刘辉,袁学芳,文果,等. 超深碳酸盐岩油藏水平井套管分段酸压技术实践[J]. 钻采工艺,2016,39(5):33-35. doi: 10.3969/J.ISSN.1006-768X.2016.05.11LIU Hui, YUAN Xuefang, WEN guo, et al. Practice of stage acid frac in cased horizonal well in ultradeep carbonate reservoir[J]. Drilling & Production Technology, 2016, 39(5):33-35. doi: 10.3969/J.ISSN.1006-768X.2016.05.11 [11] 吴亚红,吴虎,王明星,等. 基于导流能力评价实验的复合酸化压裂技术[J]. 科学技术与工程,2020,20(31):12776-12781. doi: 10.3969/j.issn.1671-1815.2020.31.014WU Yahong, WU Hu, WANG Mingxing, et al. Composite acid fracturing technology based on flow conductivity evaluation experiments[J]. Science Technology and Engineering, 2020, 20(31):12776-12781. doi: 10.3969/j.issn.1671-1815.2020.31.014 [12] 李军龙,袁操,詹媛珍,等. 缝洞型碳酸盐岩储层酸压停泵压降曲线分析[J]. 油气井测试,2017,26(5):24-27. doi: 10.3969/j.issn.1004-4388.2017.05.007LI Junlong, YUAN Cao, ZHAN Yuanzhen, et al. Analysis of pump-stopping pressure drop curves of acid fracturing for fracture-cavity carbonate reservoir[J]. Well Testing, 2017, 26(5):24-27. doi: 10.3969/j.issn.1004-4388.2017.05.007 -

下载:

下载: