Study on Degradable Fiber Fracturing Fluid and Its Application in Sulige Gas Field

-

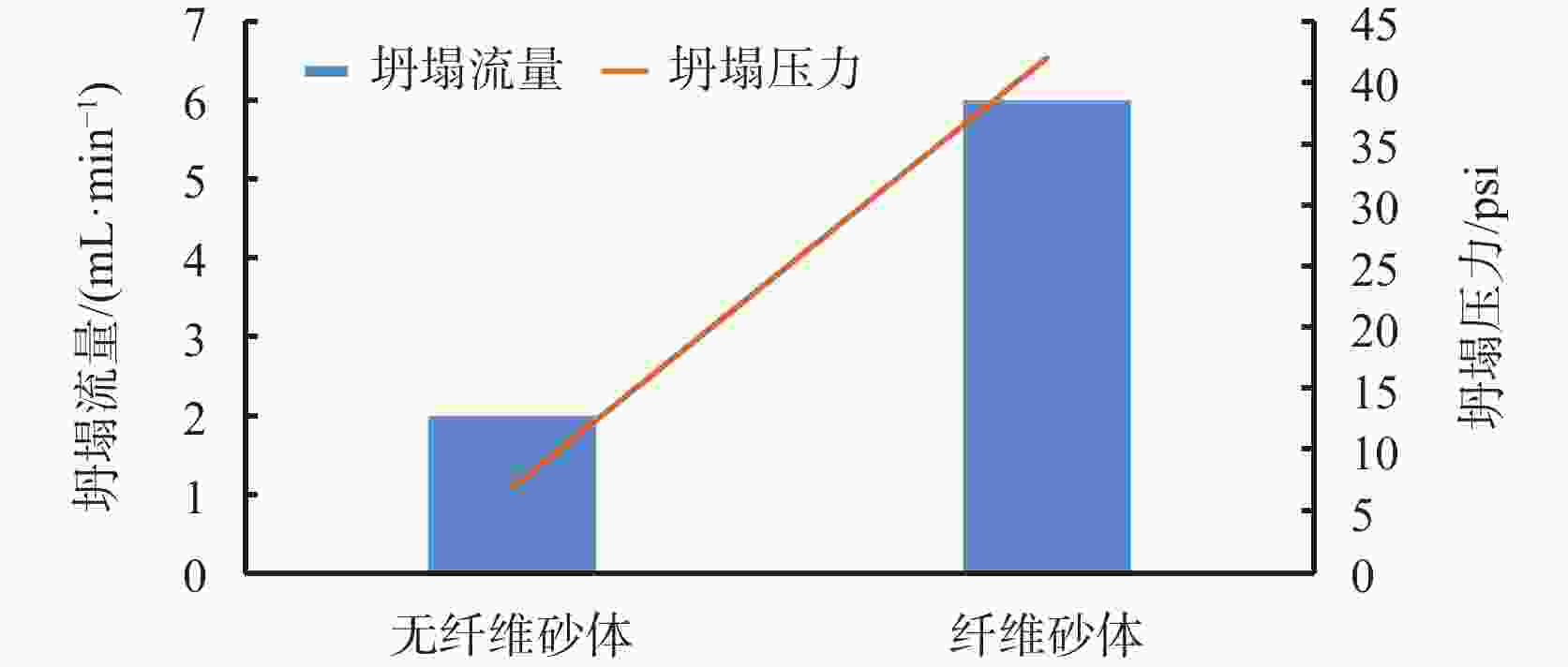

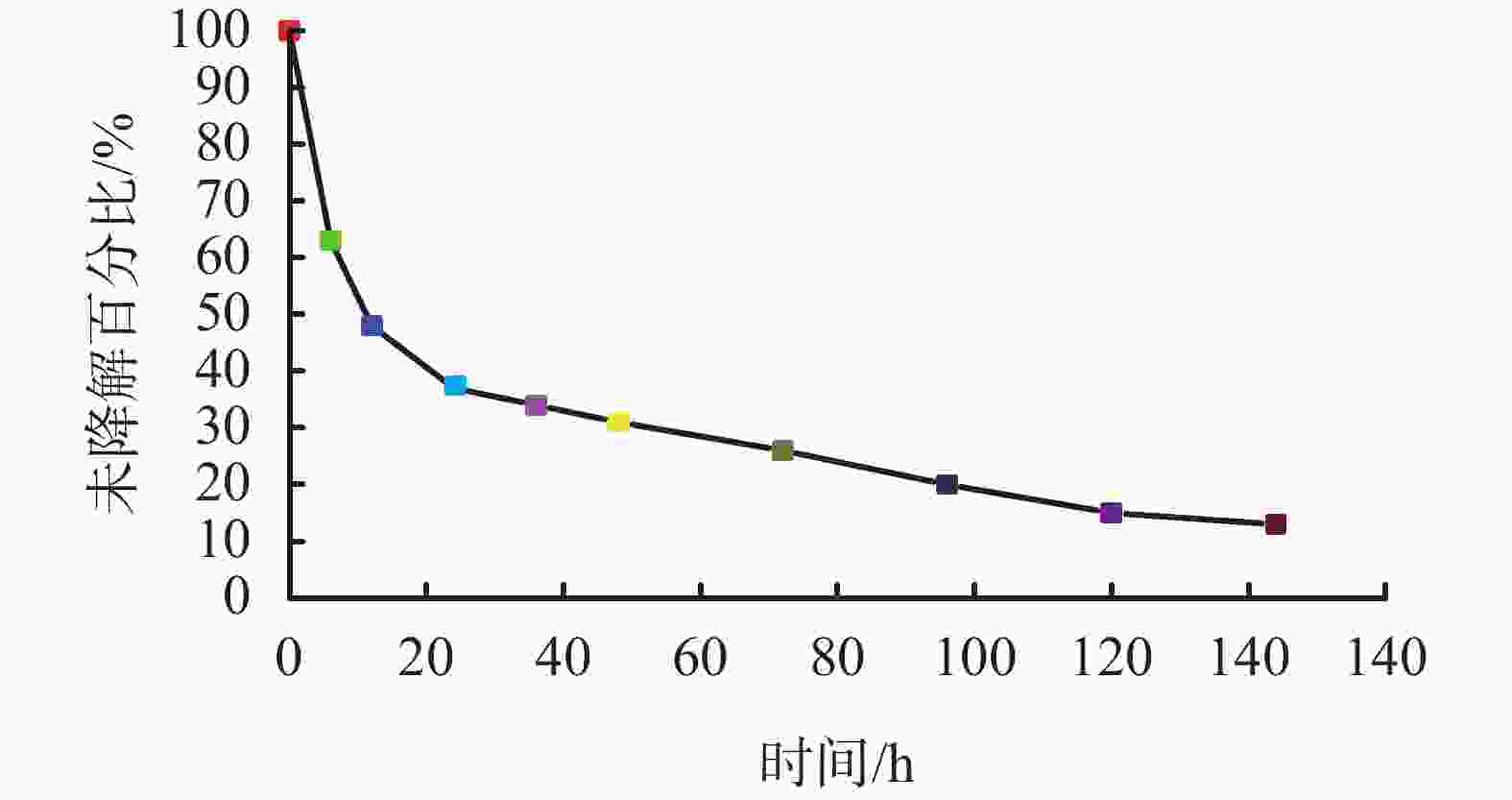

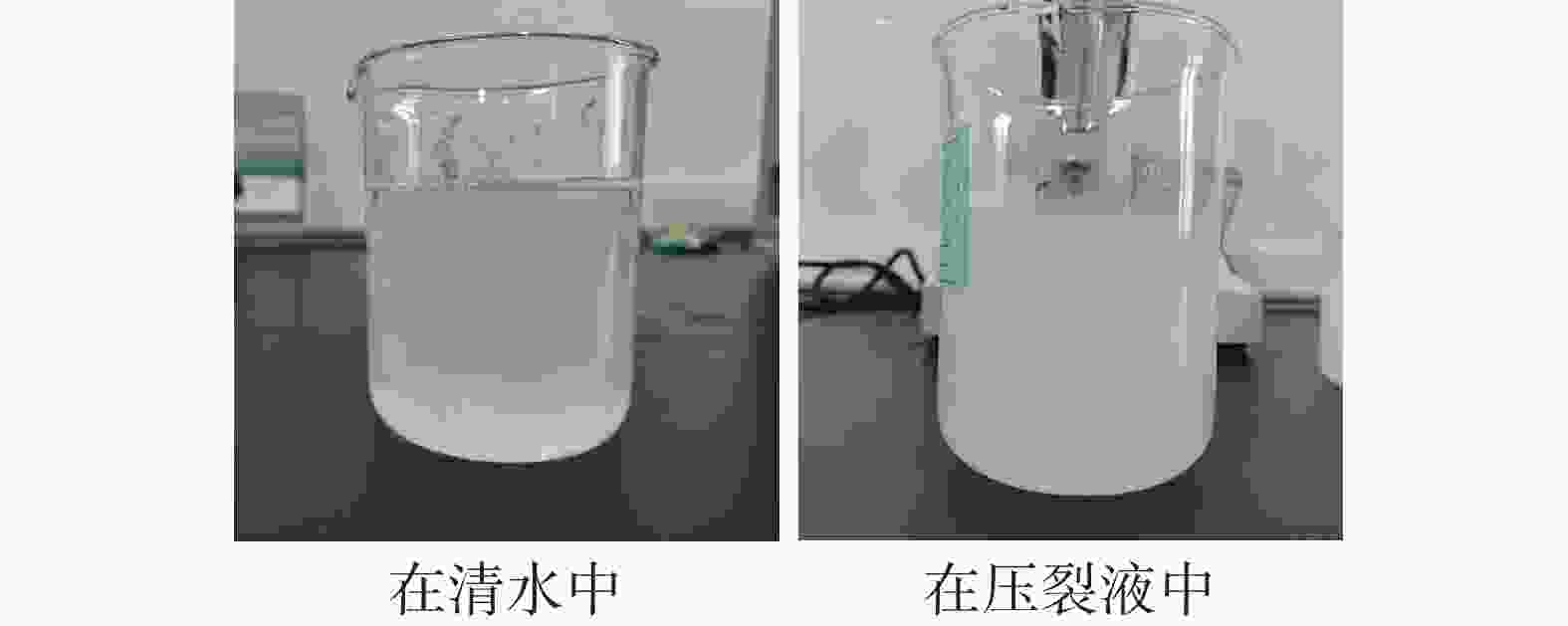

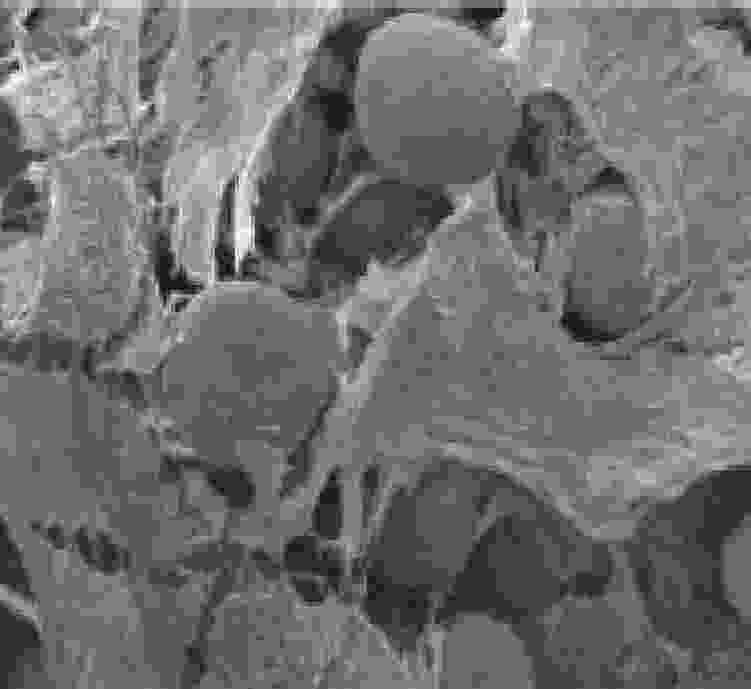

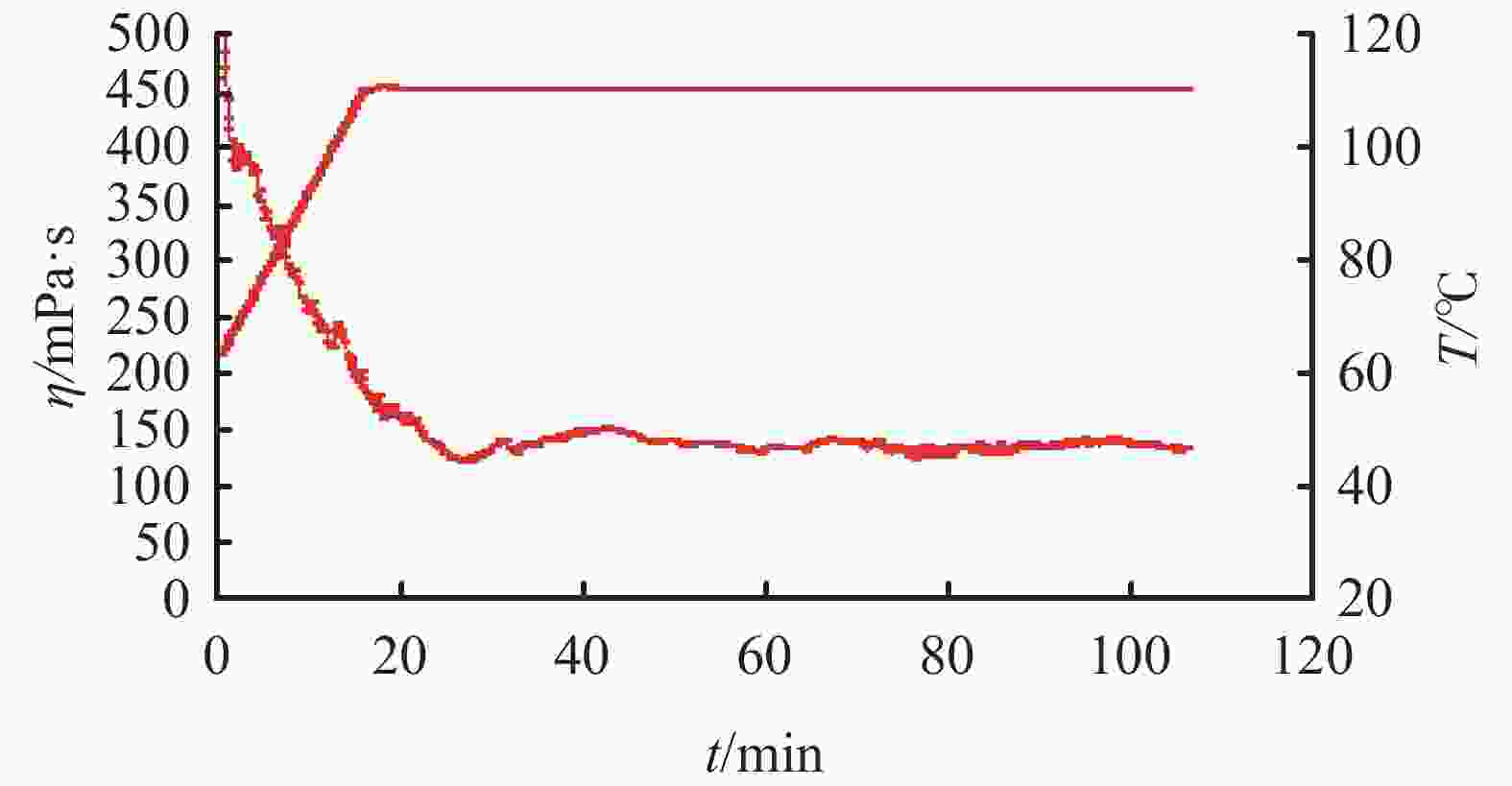

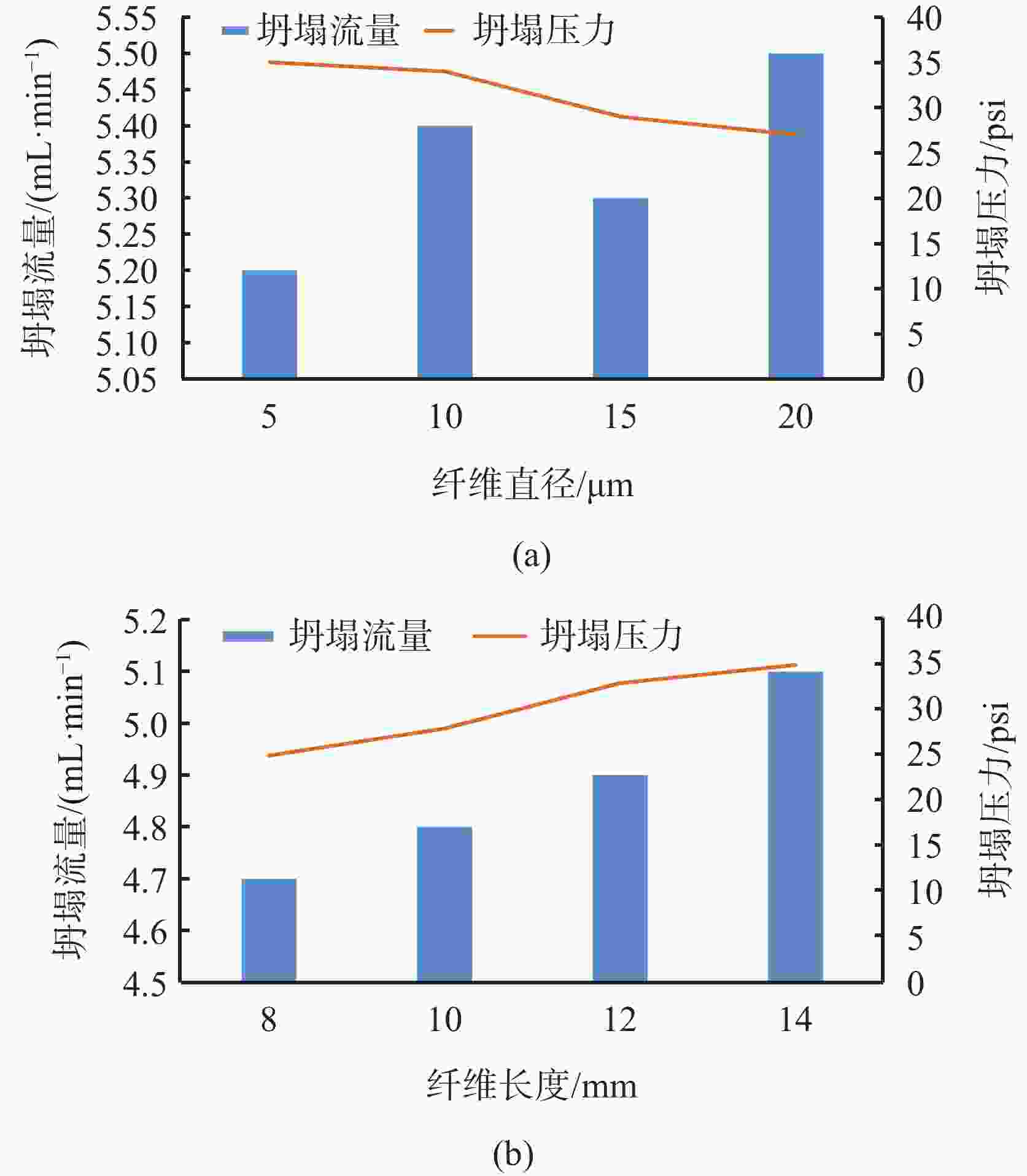

摘要: 为了提升苏里格气田支撑剂铺置效果,防止出砂和支撑剂回流,对纤维进行了表面改性处理,优化了纤维尺寸、加量,对纤维降解性、分散性、岩心伤害、悬砂性能、压裂液体系耐温耐剪切性能、破胶等性能进行了评价。结果表明,纤维直径为10 μm、长度为12 mm,加量为0.15%,在压裂液中分散良好,120 h可降解80%以上,降解后纤维溶液伤害率小于5%,纤维压裂液增黏性能优异,在剪切速率170 s−1、110 ℃下剪切120 min后黏度保持在120 mPa·s以上。纤维通过桥接作用形成网状结构,将支撑剂束缚于其中,降低支撑剂沉降速度,现场试验未发生出砂和支撑剂回流现象,压后无阻流量为108.61×104 m3/d,现场压裂效果良好。Abstract: To improve the placement efficiency of proppants in the Sulige gas field, prevent sand production and backflow of the proppants, a fiber used in fracturing fluids was surface modified, and the size distribution and concentration of the fiber particles were optimized. Laboratory experiments on several parameters related to fracturing job, such as the degradability, dispersibility, damage to core, sand suspension performance of fiber, high temperature resistance and gel breaking property of fracturing fluid, were performed. It was found that fiber particles with diameter of 10 μm and length of 12 mm have good dispersibility in a fracturing fluid at concentration of 0.15%, and 80% of the fiber particles can be degraded after 120 h of dissolution in the fracturing fluid. Rate of core damage caused by the degraded fibers is less than 5%. The fiber has good viscosifying performance in the fracturing fluid, the viscosity of the fracturing fluid after shearing at 170 s-1 and 110 ℃ for 120 min was still higher than 120 mPa·s. The fiber, by the bridging action between the particles, forms a network structure, thereby bonding the proppant particles within the fracturing fluid and reducing the settling velocity of the proppant. Field experiment found no sand production and backflow of proppant, and the open flow capacity of the well fractured with the GT-1 fracturing fluid is 108.61 × 104 m3/d, indicating that the fracturing job has met the expected goal.

-

Key words:

- Fracturing fluid /

- Degradable Fiber /

- Network structure /

- Blackflow of proppant

-

表 1 岩心伤害性能评价

编号 层位 K0/mD Kd/mD 伤害率/% 1# 山1 0.98 0.94 4.1 2# 盒8 1.01 0.96 4.9 -

[1] 任山,向丽,黄禹忠,等. 纤维网络加砂压裂技术研究及其在川西低渗透致密气藏的应用[J]. 油气地质与采收率,2010,17(5):86-89.REN Shan, XIANG Li, HUANG Yuzhong, et al. Study on fiber network sand fracturing technique and application in the low permeable reservoir of Chuanxi area[J]. Petroleum Geology and Recovery Efficiency, 2010, 17(5):86-89. [2] 吕芬敏,金建国. 纤维复合压裂防砂技术研究与应用[J]. 吐哈油气,2008(2):130-133.LYU Fengmin, JIN Jianguo. Research and application of fiber compound fracturing for sand control[J]. Tuha Oil & Gas, 2008(2):130-133. [3] 张朝举,张绍彬,谭明文,等. 预防支撑剂回流的纤维增强技术实验研究[J]. 钻采工艺,2005(4):90-91,94. doi: 10.3969/j.issn.1006-768X.2005.04.031ZHANG Chaoju, ZHANG Shaobin, TAN Mingwen, et al. Lab. study on fiber enhanced proppant to prevent flowback after fracturing[J]. Drilling & Production Technology, 2005(4):90-91,94. doi: 10.3969/j.issn.1006-768X.2005.04.031 [4] 桂阳,陈恒,曹阳. 纤维加砂压裂在靖边气田水平井的应用[J]. 现代盐化工,2017(4):21-24.GUI Yang, CHEN Heng, CAO Yang. Application of fiber sand fracturing to horizontal wells in Jingbian gas field[J]. Modern Salt and Chemical Industry, 2017(4):21-24. [5] 杨国威,白建文,池晓明,等. 可降解纤维压裂暂堵剂表面改性与性能研究[J]. 应用化工,2014,43(8):1431-1436.YANG Guowei, BAI Jianwen, CHI Xiaoming, et al. Study on performance and surface modification of the degradable fiber plugging agent hydraulic fracturing[J]. Applied Chemical Industry, 2014, 43(8):1431-1436. [6] 乔东宇,郑义平,冉照辉,等. 低伤害压裂液在苏里格气田的应用[J]. 钻井液与完井液,2012,29(2):71-72. doi: 10.3969/j.issn.1001-5620.2012.02.023QIAO Dongyu, ZHENG Yiping, RAN Zhaohui, et al. Application of low-damage fracturing fluid system in block Su77 of Sulige gas field[J]. Drilling Fluid & Completion Fluid, 2012, 29(2):71-72. doi: 10.3969/j.issn.1001-5620.2012.02.023 [7] 官长质, 何秉兰, 卢拥军, 等.SY/T 5107-2016水基压裂液性能评价方法[S].GUAN Changzhi,HE Binglan, LU Yongjun,et al .SY/T 5107-2016 Recommended practices on measuring the properties of water-based fracturing fluid[S]. [8] 胡光明,姬随波,高宇,等. 鄂尔多斯盆地东部纤维携砂压裂技术研究及应用[J]. 石油天然气工业,2021,49(10):78-84.HU Guangming, JI Suibo, GAO Yu, et al. Research and application of fiber carrying proppant fraturing technology in Eastern Ordos basin[J]. China Petroleum Machinery, 2021, 49(10):78-84. [9] 庄照锋,张士诚,张劲,等. 可降解纤维压裂液的破胶性能实验研究[J]. 油田化学,2010,27(1):26-28.ZHUANG Zhaofeng, ZHANG Shicheng, ZHANG Jin, et al. Effect of degradable fiber on BXHPG fracturing fluid[J]. Oilfield Chemistry, 2010, 27(1):26-28. [10] 赵海峰,王伟,蒋成银,等. 纤维压裂液性能研究[J]. 钻采工艺,2017,40(6):90-92.ZHAO Haifeng,WANG Wei, JIANG Chenyin,et al. Study on fibrous fracturing fluid properties[J]. Drilling & Production Technology, 2017, 40(6):90-92. -

下载:

下载: