Study on Formulating Fracturing Fluids with Used Fracturing Fluids for Tight Gas Reservoirs

-

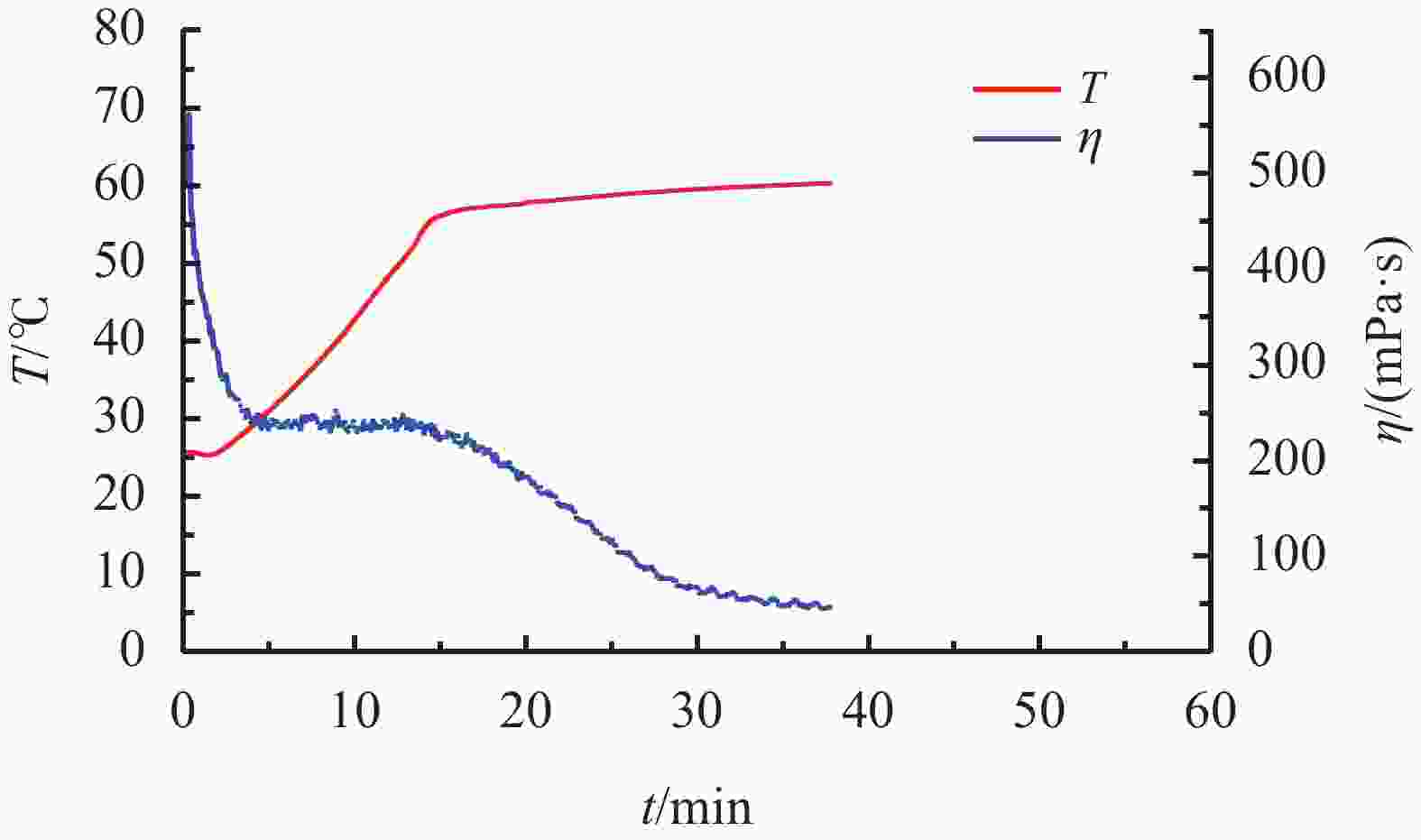

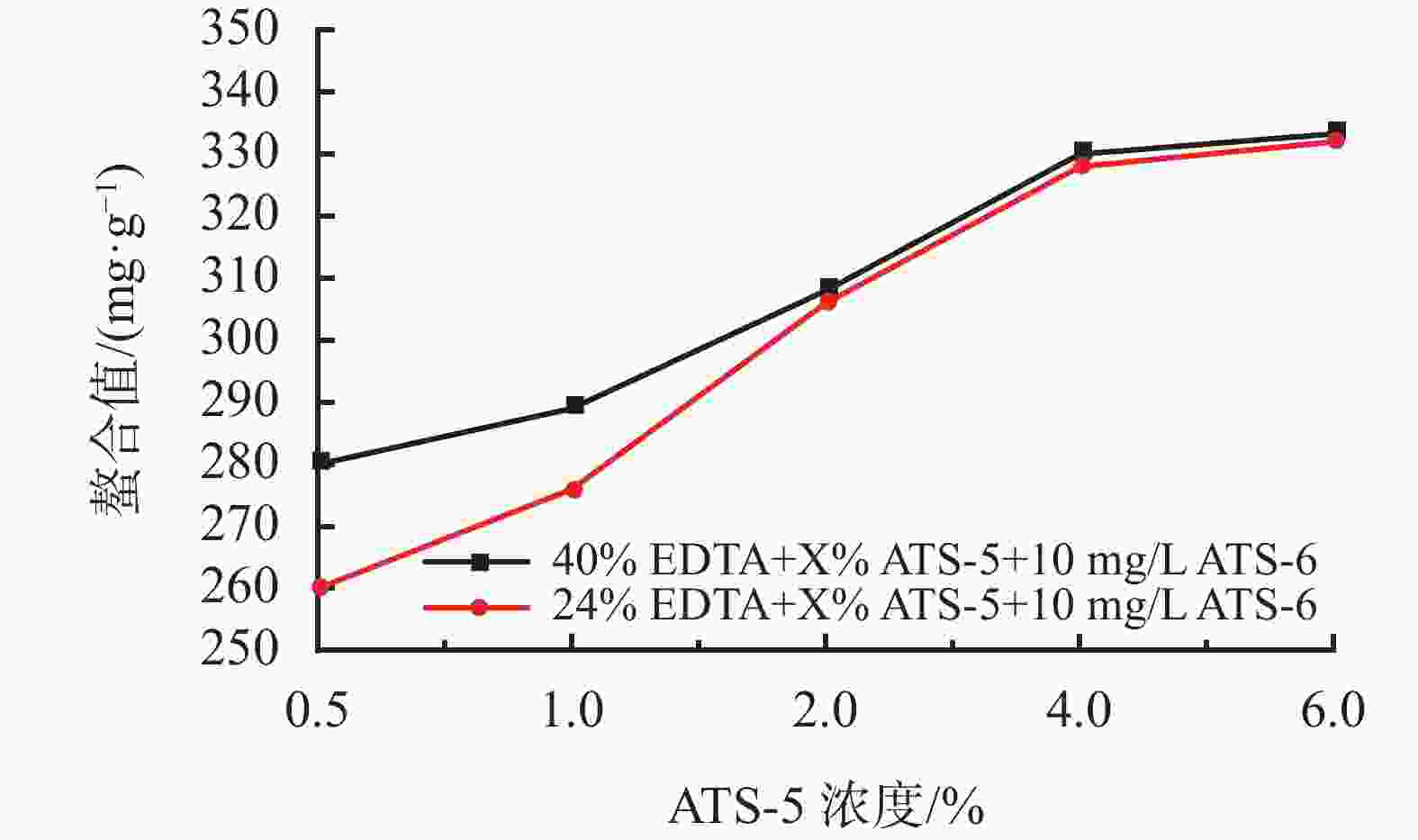

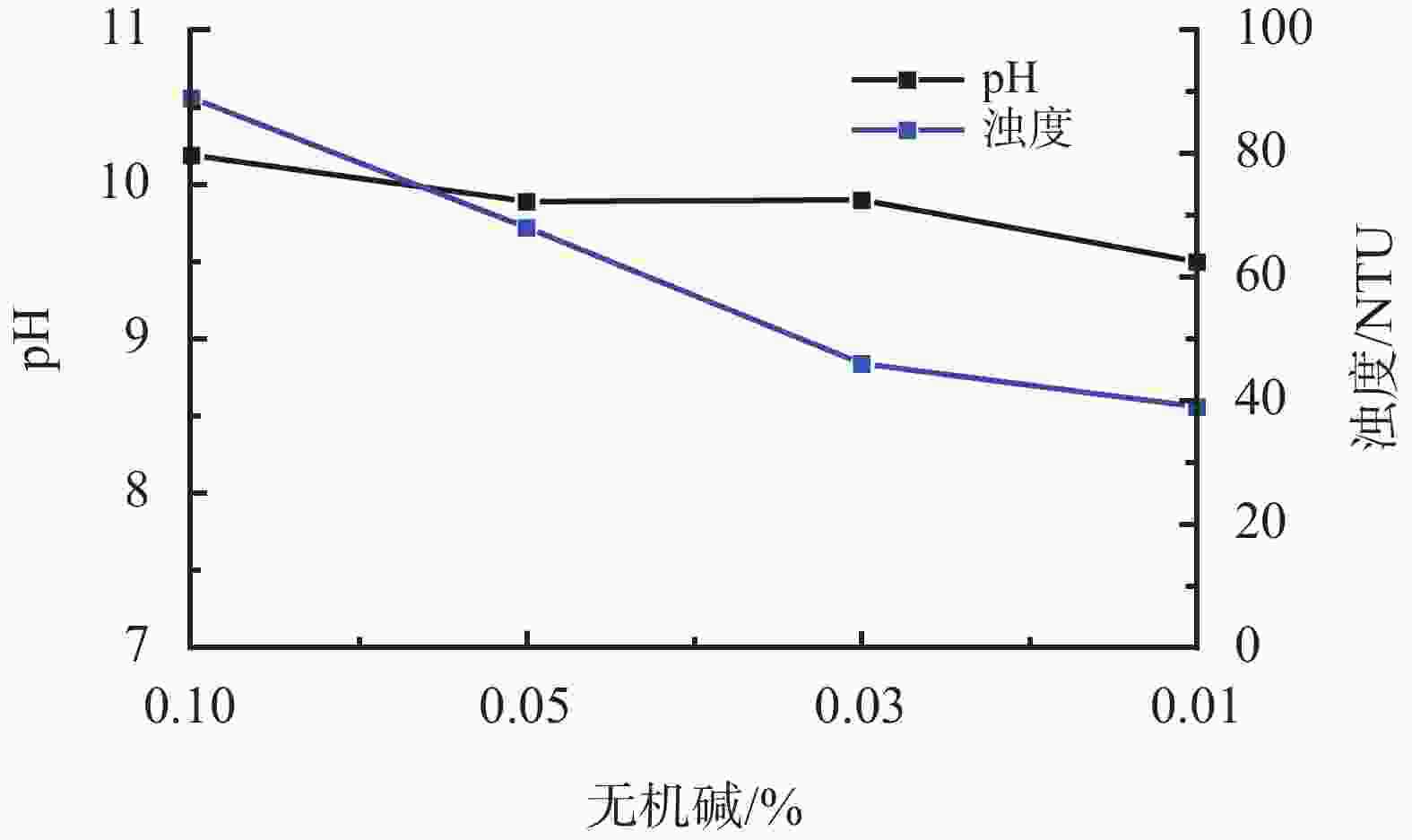

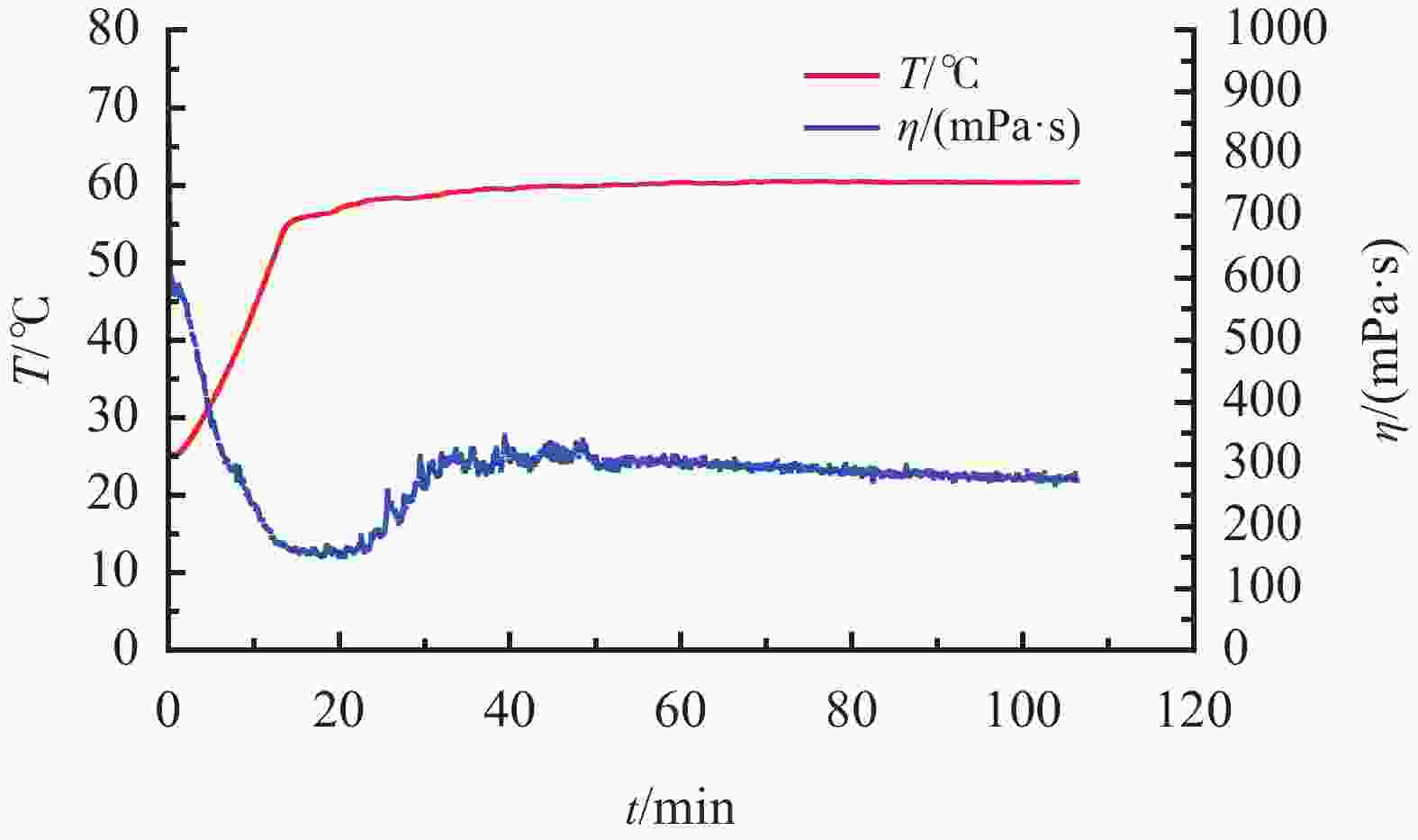

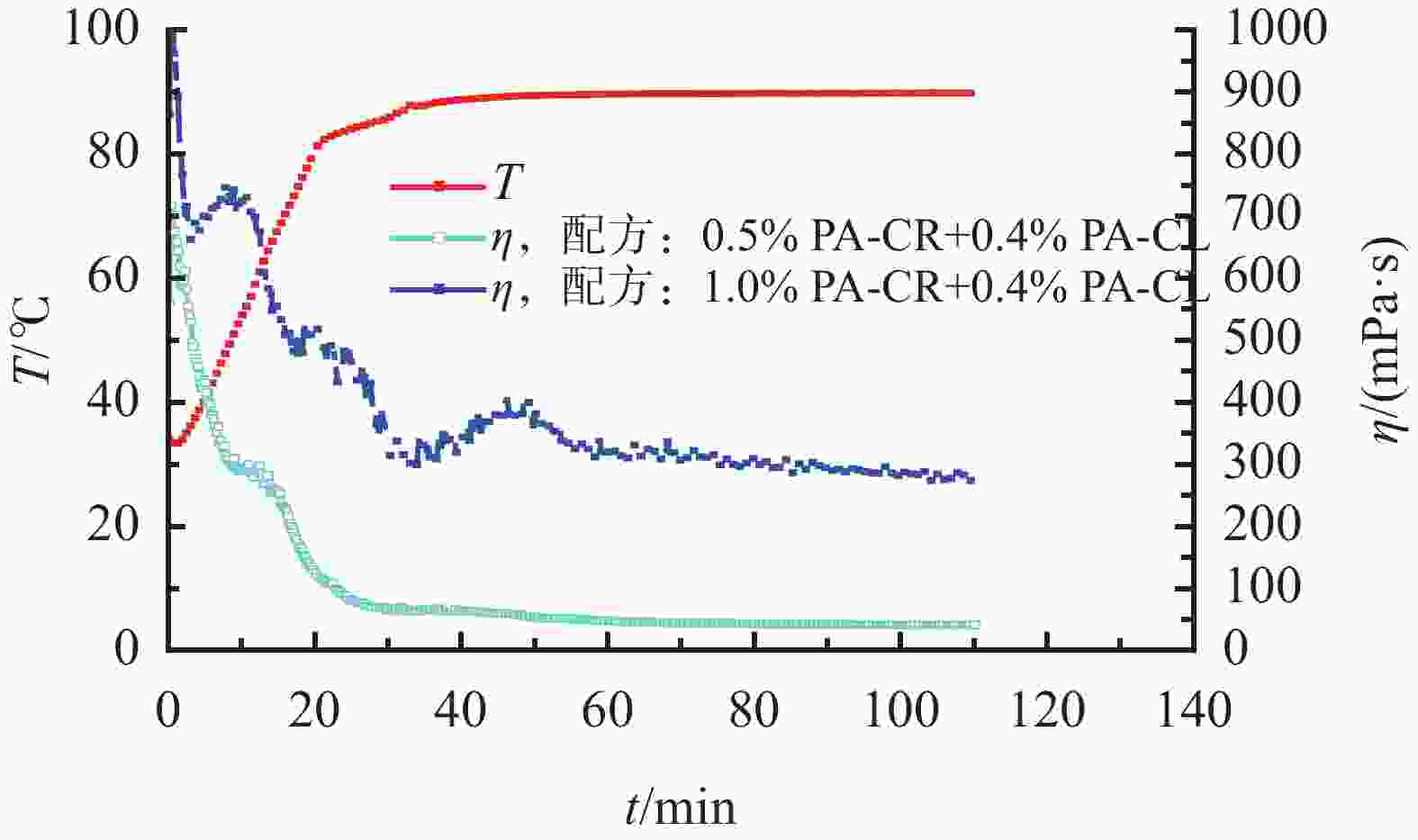

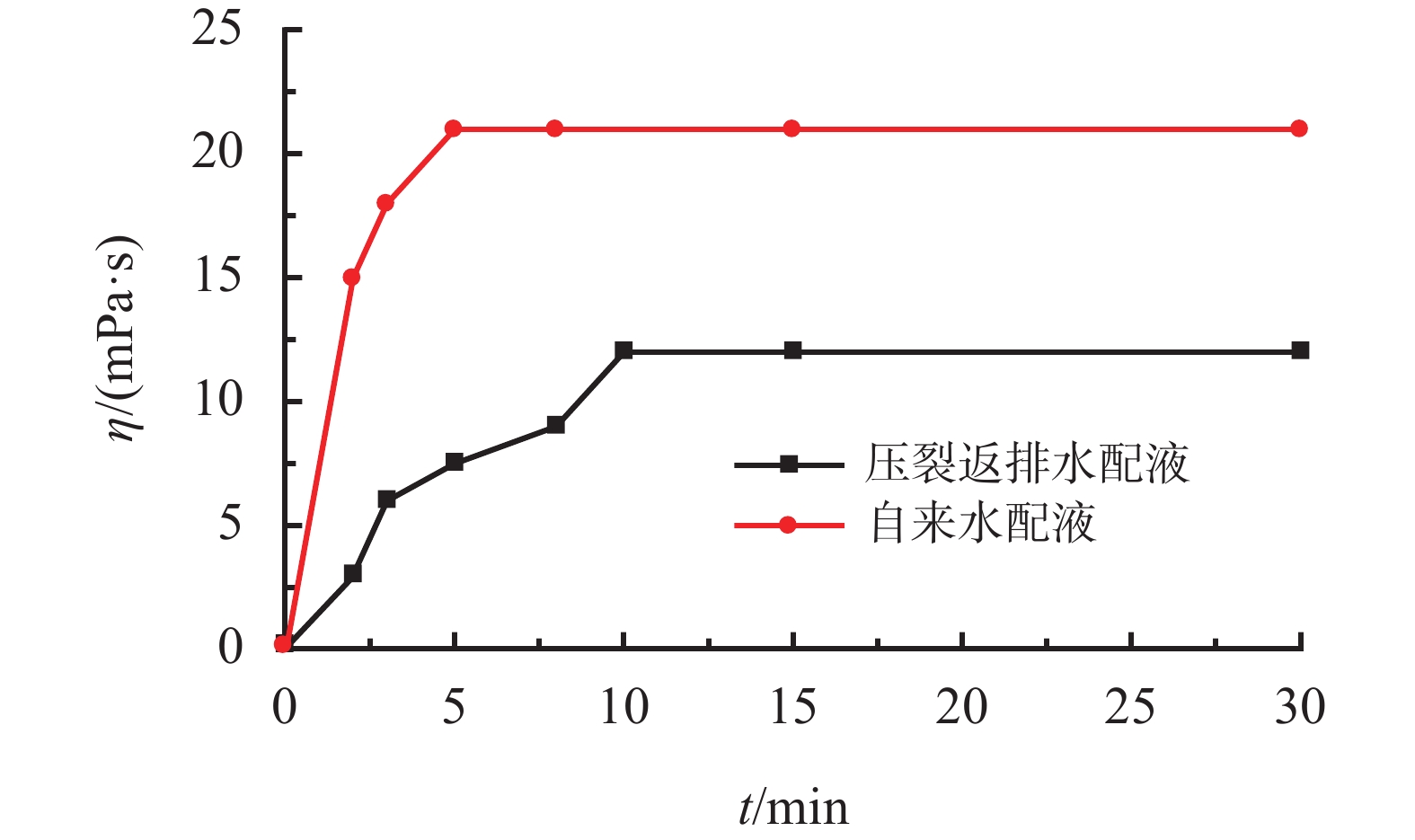

摘要: 为解决压裂返排处理水重复利用的问题,探讨了压裂返排处理水对胍胶压裂液的影响。针对胍胶压裂液在高矿化度水中溶胀和交联效果差的难题,通过优选耐盐胍胶PA-G、研制螯合调节剂PA-CR以及合成有机硼交联剂PA-CL,优化出一套适应于压裂返排处理水重复配制压裂液的配方。实验表明该配方可满足90 ℃耐温耐剪切要求,具有以下功能:①优选的耐盐胍胶PA-G溶胀速度快,黏度高,0.3%含量下5 min即可达到30 mPa·s;②研制的高效螯合调节剂,由有机碱、EDTA、有机膦酸盐和聚合物组成,可有效螯合钙、镁离子,可将含1500 mg/L钙镁离子高矿化度水的pH值调节至10以上时不发生沉淀;③研制的有机硼交联剂具有延迟交联功能。Abstract: In this paper, the effects of the water from the treatment of the flowback fracturing fluids on the properties of the guar gum fracturing fluid were discussed to solve the problem of the reuse of the water. In high salinity water, guar gum has poor swelling capacity and poor crosslinking performance. To overcome these problems, a salt-resistant guar gum PA-G, a chelating agent PA-CR and a synthesized organoboron crosslinking agent PA-CL were used to formulate a fracturing fluid with water from flowback fracturing fluids. Laboratory experimental results showed that this fracturing fluid is resistant to shearing damage at 90 °C. It has these functionalities such as: 1) the selected salt-resistant guar gum PA-G has high swelling rate and high viscosity; water solution containing 0.3% PA-G has its viscosity developed to 30 mPa·s in 5 min. 2) The high efficiency chelating agent, which was developed with organic base, EDTA, organophosphate and polymer, can effectively chelate calcium and magnesium ions. Using this chelating agent, the pH of a high salinity water containing 1,500 mg/L calcium and magnesium ions can be raised to above 10 without causing precipitation. 3) the organoboron crosslinking agent developed has the property of delaying crosslinking.

-

表 1 压裂返排液处理后的水成分

离子含量/(mg·L−1) pH 矿化度/(mg·L−1) COD/(mg·L−1) Cl− Br− F− Ca2+ Mg2+ SO42− Na+ K+ 8 124 472.3 5112.5 70 191 1592 136 8641.2 1336.5 480.3 37 086 5009.5 表 2 实验用螯合剂

螯合剂 规格 试剂种类 EDTA AR 氨基羧酸类 ATS-1 AR 有机多元磷酸 ATS-2 47% ATS-3 AR ATS-4 50% ATS-5 40% ATS-6

ATS-750% 聚合物类 AR ATS-8 40% 表 3 不同浓度螯合调节剂对返排处理水沉淀抑制效果评价

螯合调节剂/% 室温 90 ℃恒温2 h处理后 pH 浊度/NTU pH 浊度 0.50 10.53 6.1 10.16 7.4 0.25 10.38 5.2 10.28 6.0 0.125 10.30 2.3 10.3 4.4 注:实验配方为24%EDTA+4%ATS-5+10 mg/L ATS-6 表 4 不同交联剂浓度时压裂液交联时间和交联状态(基液pH值=10.50)

交联剂/

%交联时间/

s交联状态 1 h后交联状态 0.1 >180 拉丝 拉丝 0.2 150 弱交联 弱交联 0.3 120 交联良好 交联良好 0.4 100 交联良好 交联良好 0.5 30 交联 流动性差 0.6 10 交联 流动性差 表 5 不同pH值环境下压裂液的交联时间和交联状态(交联比为100 ∶ 0.3)

基液pH值 交联时间/s 交联状态 1 h后交联状态 7.00 8 交联良好 交联良好 9.11 20 交联良好 交联良好 10.25 60 交联良好 交联良好 12.79 100 可吐舌 交联良好 13.48 120 可吐舌 交联良好 -

[1] CHENG Y, BROWN K M, PRUD'HOMME R K. Characterization and intermolecular interactions of hydroxypropyl guar solutions[J]. Biomacromolecules, 2002, 3(3):456-461. doi: 10.1021/bm0156227 [2] GITTINGS M R, CIPELLETTI L, TRAPPE V, et al. The effect of solvent and ions on the structure and rheological properties of guar solutions[J]. J Phys Chem A, 2001, 105(40):9310-9315. doi: 10.1021/jp0121825 [3] KOTHAMASU R, DAS P, KONALE S. Effect of salt concentration on base-gel viscosity of different polymers used in stimulation fluid systems [C]. //SPE/EAGE European Unconventional Resources Conference and Exhibition. Society of Petroleum Engineers, 2014. [4] 林雪丽, 黄海燕, 赵启升, 等. 返排废液中无机盐离子对压裂液特性的影响[J]. 钻井液与完井液, 2013, 30(2): 73-76.LIN Xueli, HUANG Haiyan, ZHAO Qisheng, et al. Effect of inorganic ions in flow-back fliud on water-based fracturing fluid[J]. Drilling Fluid&Completion Fluid, 2013, 30(2): 73-76. [5] 蒋继辉, 冀忠伦, 赵敏, 等. 油田井场废水中无机盐对配制压裂液的影响[J]. 石油与天然气化工, 2013(2): 188-191.JIANG Jihui, JI Zhonglun, ZHAO Min, et al. Effects of inorganic salts in well site wastewater on preparation of Fracturing Fluid[J]. Chemical Engineering of Oil & Gas, 2013(2): 98-101. [6] 吴萌, 陈雁南, 李强, 等. 水中常见离子对水基压裂液性能影响的研究[J]. 石油化工应用, 2014, 33(8): 61-64, 75.WU Meng, CHEN Yannan, LI Qiang, et al. Study on the effect of common ions in water on the performance of water-based fracturing fluid[J]. Petrochemical Industry Application, 2014, 33(8): 61-64. [7] 林波,刘通义,陈光杰. 一种海水基清洁压裂液体系研究[J]. 油田化学,2015,32(3):336-340.LIN Bo LIU Tongyi, CHEN Guangjie. The formulation and properties of on a seawater-base clean fracturing fluid[J]. Oilfield Chemistry, 2015, 32(3):336-340. [8] 何乐,王世彬,郭建春,等. 海水中瓜尔胶溶胀性能研究[J]. 油田化学,2014,31(2):207-210.HE Le, WANG Shibin, GUO Jianchun, et al. Swelling performance of guar gum in seawater[J]. Oilfield Chemistry, 2014, 31(2):207-210. [9] 鲍文辉,王杏尊,郭布民,等. 高温海水基压裂液研究及应用[J]. 断块油气田,2017,24(3):434-436.BAO Wenhui, WANG Xingzun, GUO Bumin, et al. Research and application of high temperature seawater-based fracturing fluid[J]. Fault-Block Oil & Gas Field, 2017, 24(3):434-436. [10] 张大年,赵崇镇,范凌霄,等. 海水基植物胶压裂液体系快速制备及性能评价[J]. 中国海上油气,2016,28(6):95-98.ZHANG Danian, ZHAO Chongzhen, FAN Lingxiao, et al. Rapid preparation and performance evaluation of a seawater-based vegetable gum fracturing liquid[J]. China Offshore Oil and Gas, 2016, 28(6):95-98. [11] 魏杰. 高温海水基胍胶压裂液体系及其流变性研究[D]. 中国石油大学(北京), 2016.WEI Jie. Study on the fracturing fluid system of high temperature seawater-based and its rheological properties[D]. China University of Petroleum(Beijing), 2016. [12] 王所良,李勇,吴增智. 高温油藏用海水基压裂液研究进展[J]. 石油化工应用,2016,35(10):5-9. doi: 10.3969/j.issn.1673-5285.2016.10.002WANG Suoliang, LI Yong, WU Zengzhi. Review on seawater based fracturing fluids for high temperature reservoirs[J]. Petrochemical Industry Application, 2016, 35(10):5-9. doi: 10.3969/j.issn.1673-5285.2016.10.002 [13] 李阳,管保山,胥云,等. 高矿化度水压裂液螯合剂的研制[J]. 科学技术与工程,2016,16(14):175-180. doi: 10.3969/j.issn.1671-1815.2016.14.032LI Yang, GUAN Baoshan, XU Yun, et al. The research of complexant about using high salinity water for fracturing fluid[J]. Science Technology and Engineering, 2016, 16(14):175-180. doi: 10.3969/j.issn.1671-1815.2016.14.032 [14] 马兵,宋汉华,牛鑫,等. 环江油田抗高矿化度水质压裂液体系研究[J]. 石油与天然气化工,2011,40(6):602-606. doi: 10.3969/j.issn.1007-3426.2011.06.016MA Bing, SONG Hanhua, NIU Xin, et al. Research of fracturing fluid with high salinity resistance in Huanjiang oilfield[J]. Chemical Engineering of Oil & Gas, 2011, 40(6):602-606. doi: 10.3969/j.issn.1007-3426.2011.06.016 [15] 刘玉婷,管保山,刘萍,等. 压裂用螯合剂的开发及现场应用[J]. 化学试剂,2010,32(6):545-547. doi: 10.3969/j.issn.0258-3283.2010.06.018LIU Yuting, GUAN Baoshan, LIU Ping, et al. Research and field application of fracturing sequester[J]. Chemical Reagents, 2010, 32(6):545-547. doi: 10.3969/j.issn.0258-3283.2010.06.018 [16] BJ SERVICES COMPANY. Method for increasing the stability of water-based fracturing fluids: US 19920846688[P]. 1993-07-13. [17] 曾彬. 工业锅炉有机膦水化学技术研究[D]. 长沙理工大学, 2013.ZENG Bin. The research on organic phosphine treatment of water chemistry in industrial boilers[D]. Changsha University of Science & Technology, 2013. -

下载:

下载: