Preparation and Application of Fluid Loss Additive GT-1 for High Temperature Cementing Slurry

-

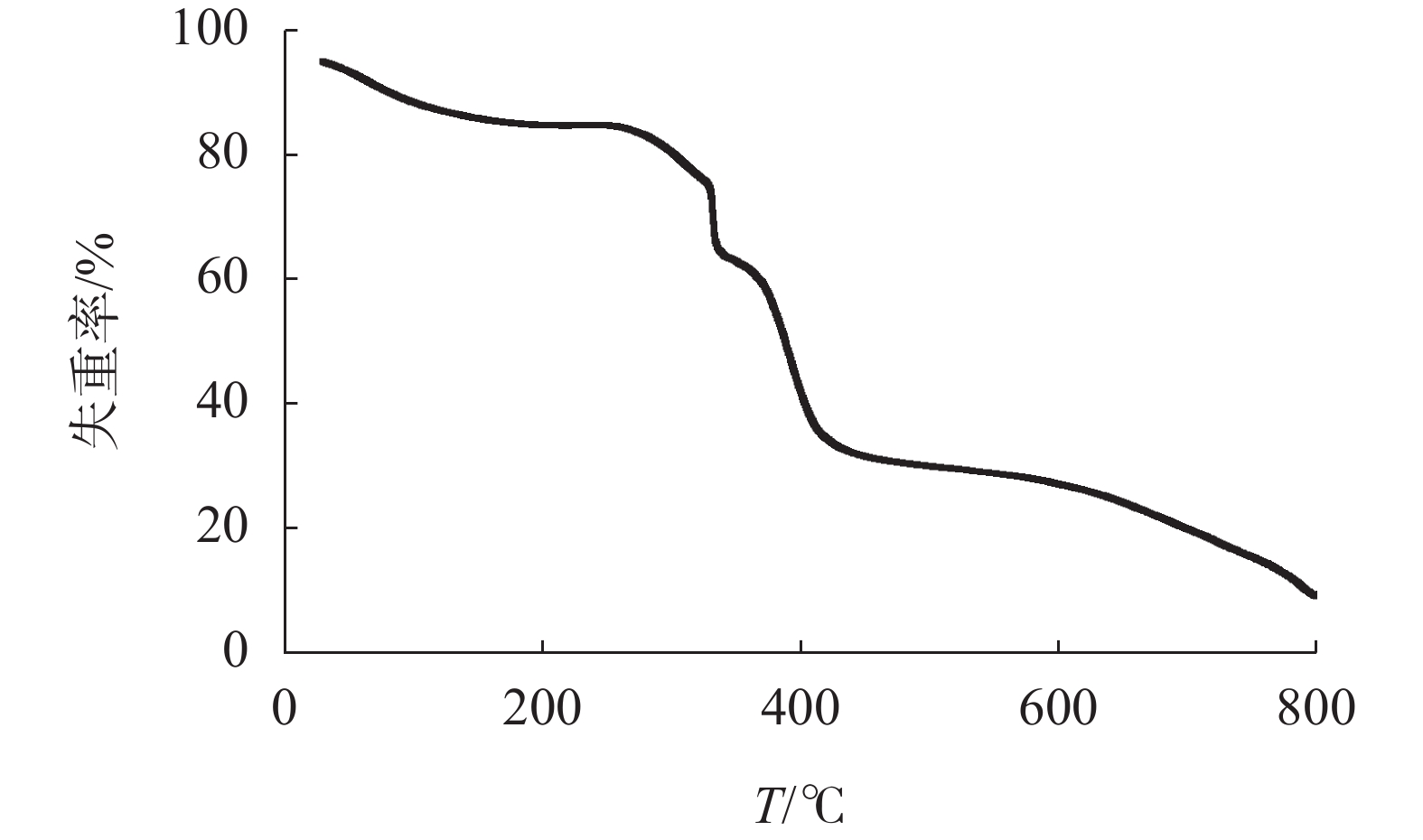

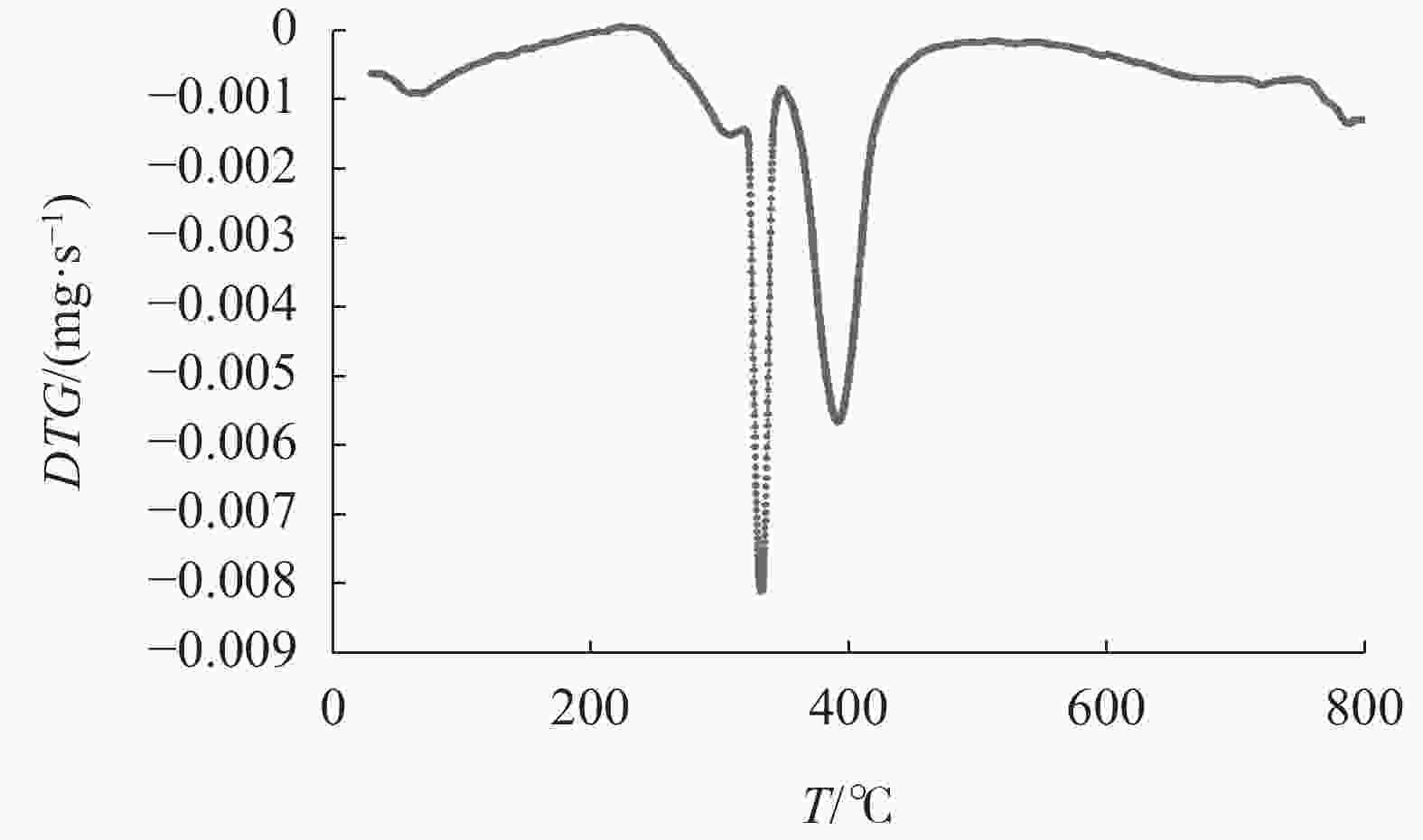

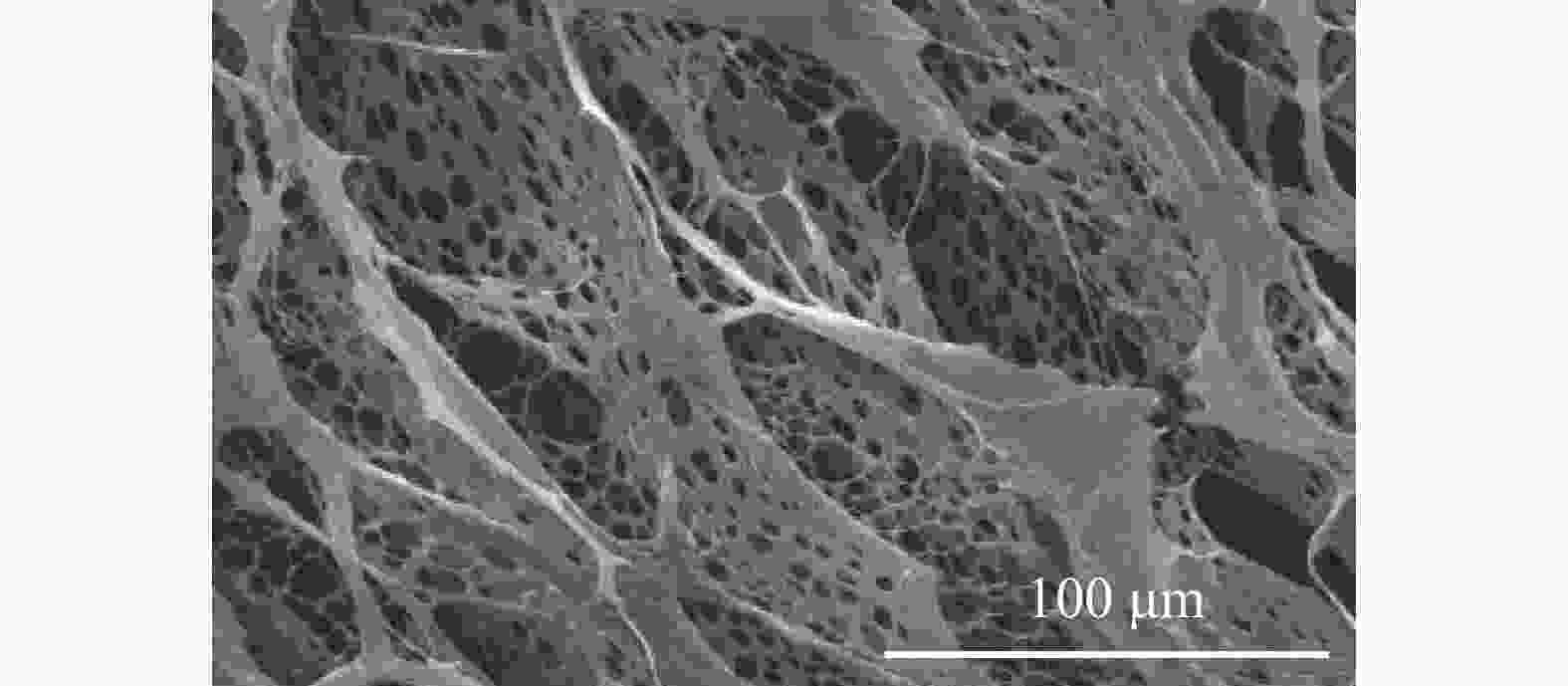

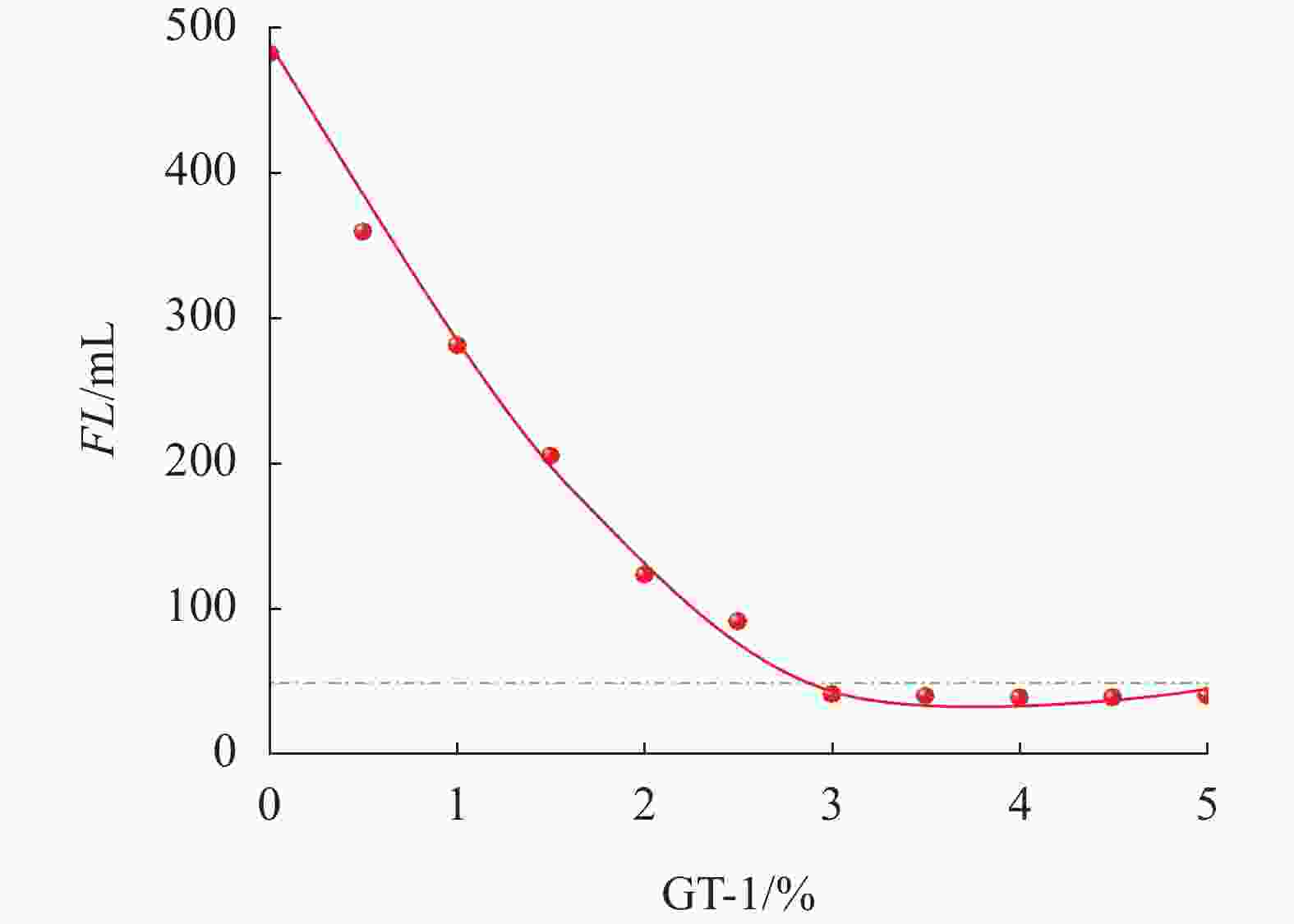

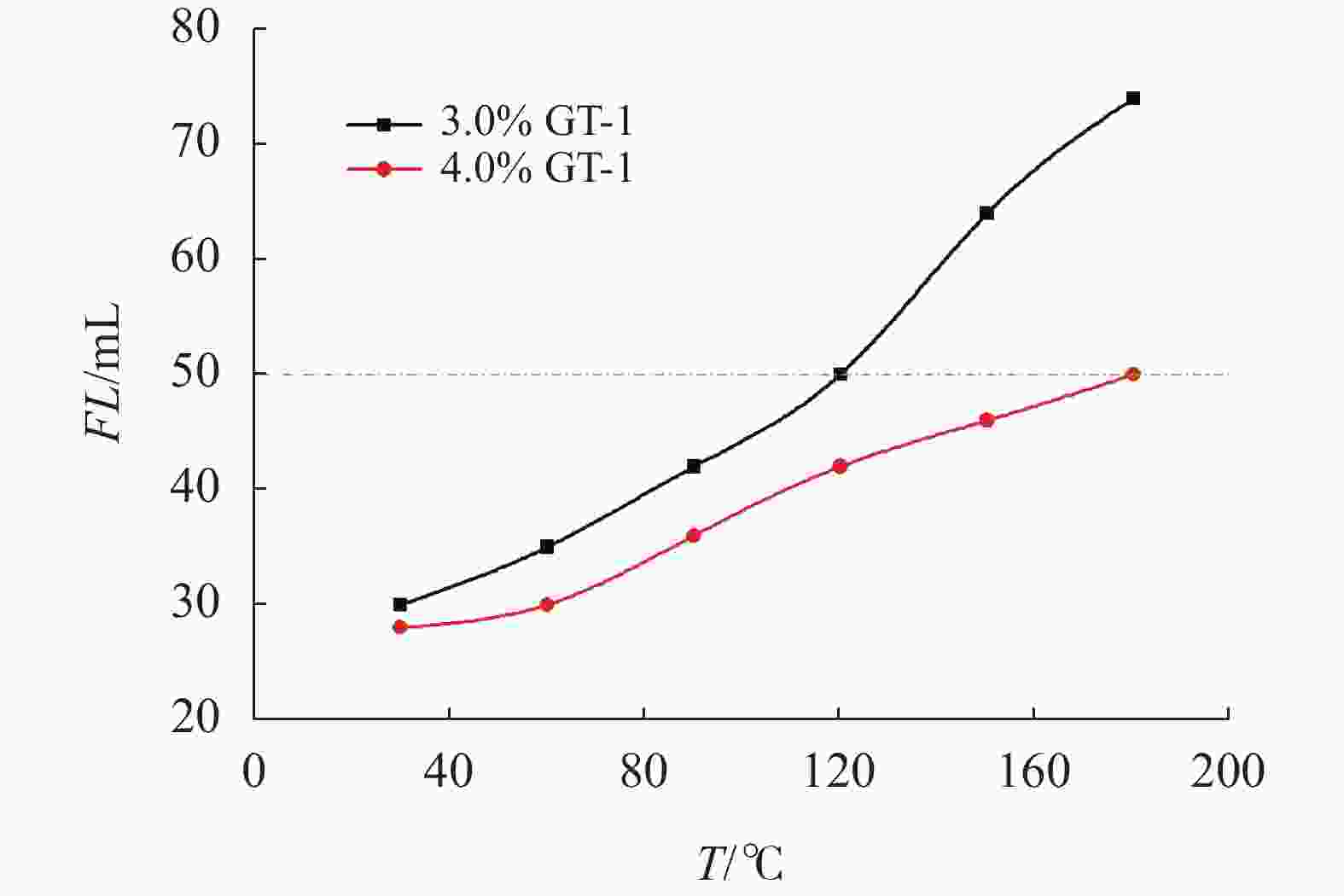

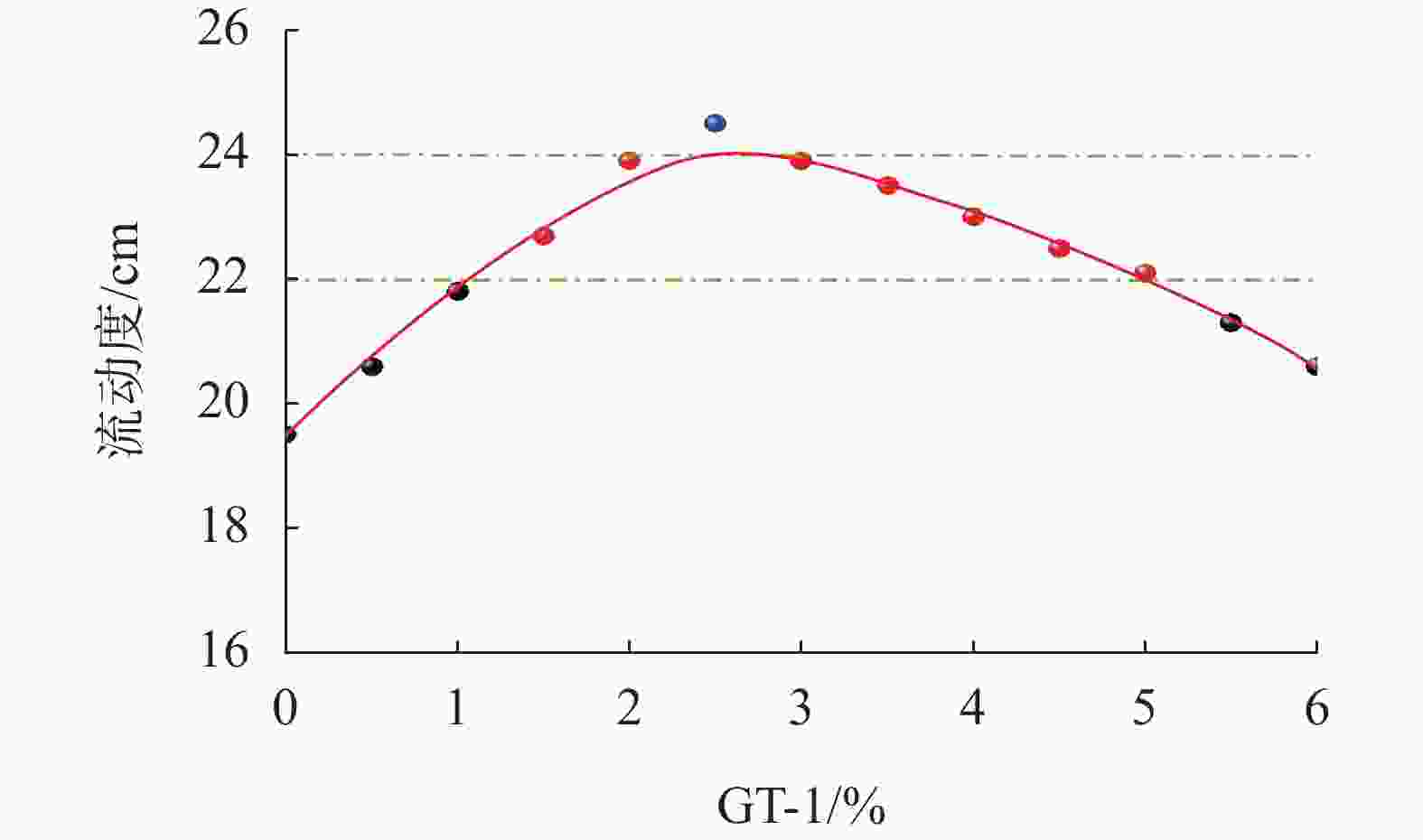

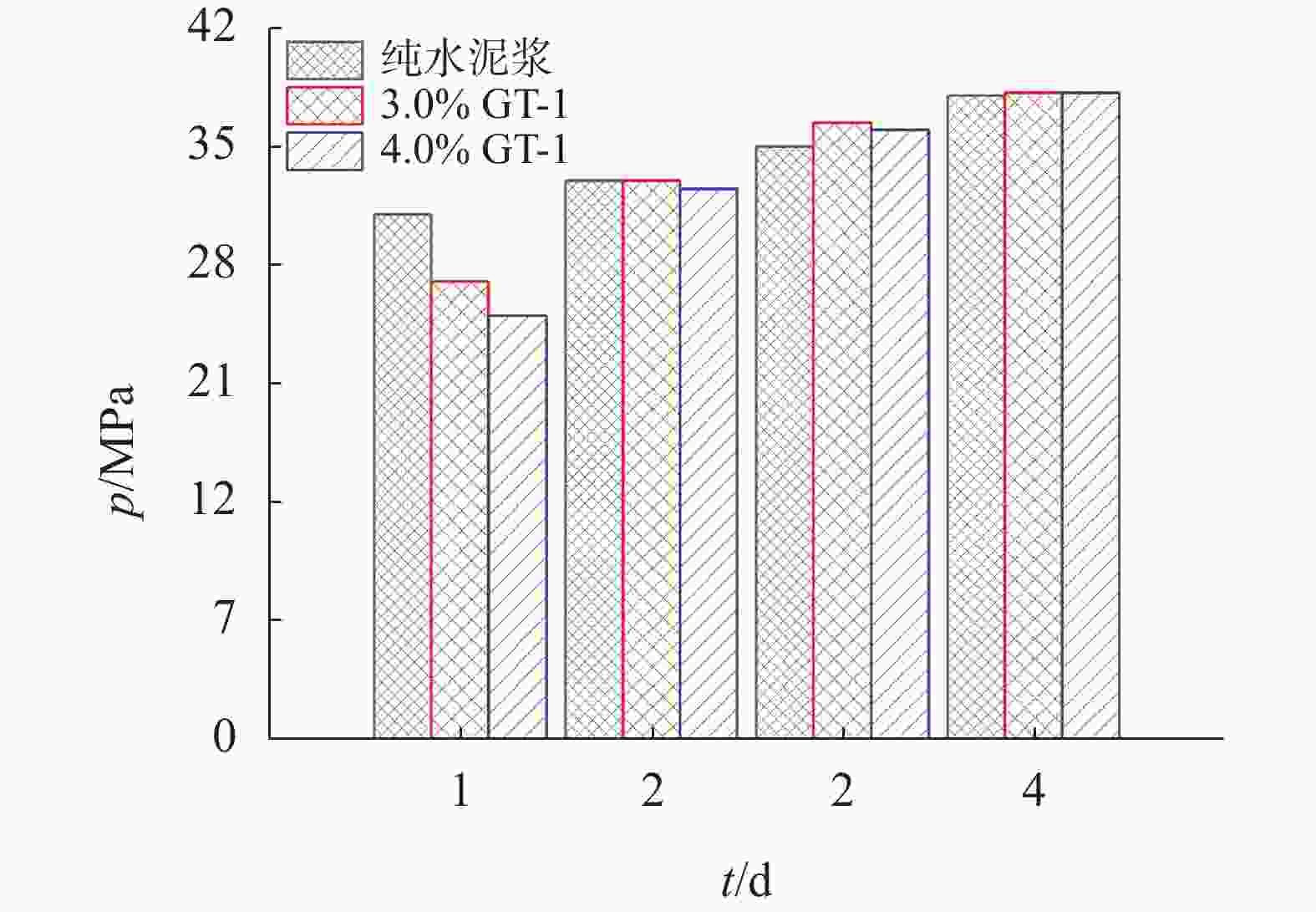

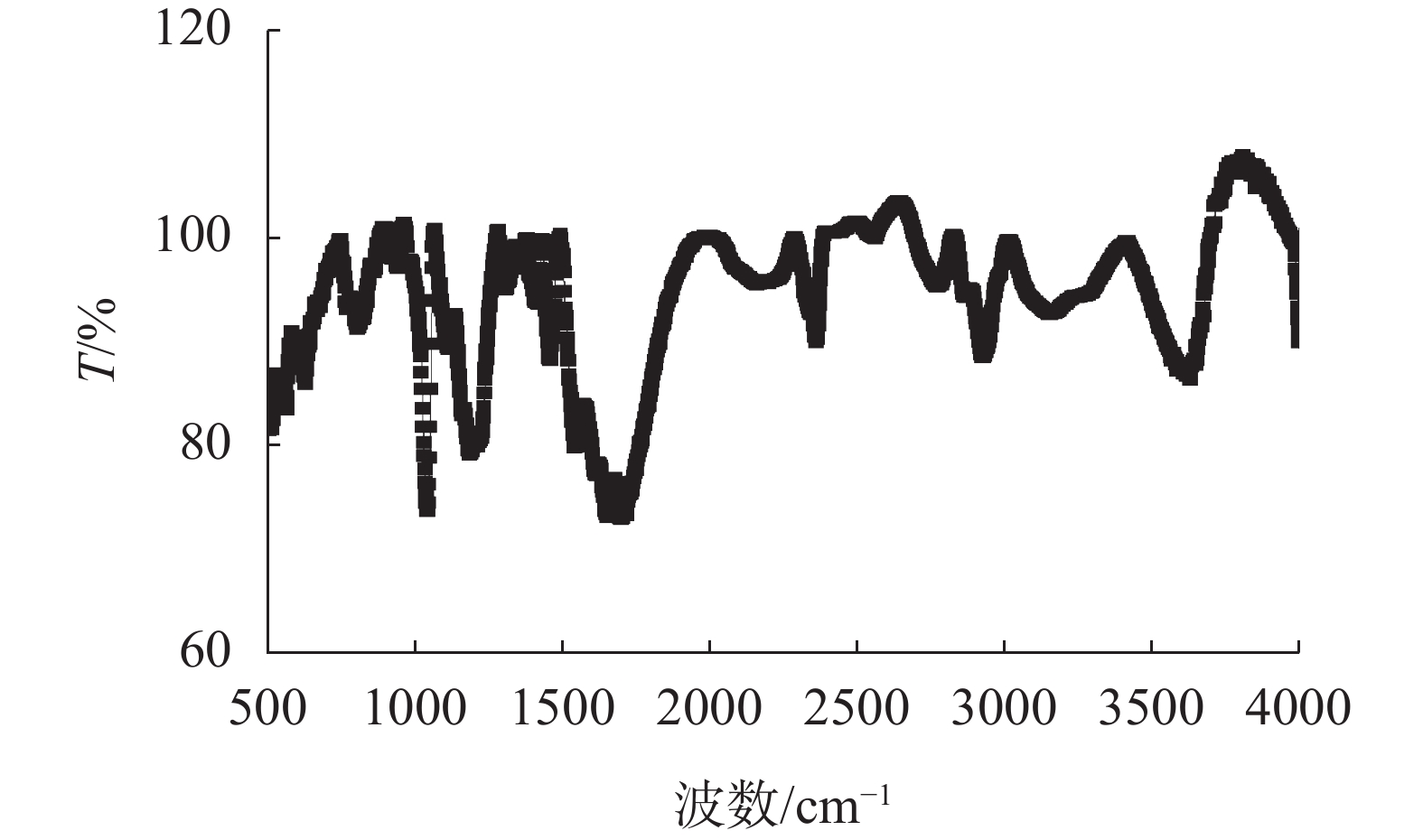

摘要: 随着油气勘探向深井、超深井方向的不断发展,固井作业对其工作液体系及外加剂提出了更高要求。针对目前降失水剂耐温、抗盐性能不足、适应温度范围窄、且与其他外加剂相容性差等问题,基于分子结构设计思想并结合功能单体优选,以2-丙烯酰胺基-2-甲基丙磺酸(AMPS)、丙烯酰胺(AM)、对苯乙烯磺酸钠(SSS)、纳米二氧化硅等为原料制备了高温固井水泥浆用降失水剂GT-1。采用红外光谱、凝胶色谱、热综合及扫描电镜等分析方法研究了其化学结构、分子量、热稳定性及水溶液微观形貌。并对GT-1的失水性能、耐温性能、抗盐性能及所配制水泥浆体系的流变性能、抗压强度和稠化性能进行了研究。结果表明,降失水剂GT-1化学结构符合预期设计,重均相对分子质量为138 431,热稳定性优良,且其水溶液呈现规整的空间网状结构;同时,降失水剂GT-1耐温、抗盐性能突出,能够控制水泥浆失水量,且所配制水泥浆工程性能良好,满足固井施工需求,具有较好的应用前景。Abstract: In exploration of deep and ultra-deep buried oil and gas resources, well cementing operation has long imposed more rigorous requirements on cement slurries and additives. Filter loss reducers commonly used in cement slurries, for example, have some shortages such as poor high-temperature and salt resistance, narrow temperature range in which the filter loss reducers can work, as well ss poor compatibility with other additives. To solve these problems, a high temperature filter loss reducer GT-1 was developed based on the design of molecular structure and the selection of functional monomers, with raw materials such as 2-acrylamido-2-methylpropane sulfonic acid (AMPS), acrylamide (AM), sodium p-styrene sulfonate (SSS) and nano silica. Using IR, gel chromatography, simultaneous thermal analyzer and SEM, the filtration control, high temperature resistance and salt resistance of GT-1, as well as GT-1’s effect on the rheology of cement slurry, the compressive strength of set cement and consistency of cement slurry were studied. The study showed that the chemical structure of GT-1 meets the requirements previously planned. The weight average molecular weight of GT-1 is 138,431, and GT-1 has excellent thermal stability. A regular spatial network structure can be measured in GT-1’s water solution. Good high temperature and salt resistance of GT-1 makes it suitable for controlling the filtration rate of cement slurry. Cement slurries formulated with GT-1 have good engineering performance which satisfies the needs of well cementing.

-

表 1 因素水平表

水平 A B C D m(AMPS)∶m(AM)∶m(SSS) T/℃ 引发剂/% t/h 1 2.5∶2∶1 60 0.25 2.5 2 2∶2∶1 65 0.20 3.0 3 2∶1∶1 70 0.15 3.5 表 2 正交实验设计及结果

因素 A B C D FLAPI/mL 1 2.5∶2∶1 60 0.25 2.5 350 2 2.5∶2∶1 65 0.20 3.0 320 3 2.5∶2∶1 70 0.15 3.5 290 4 2.0∶2∶1 60 0.20 3.5 305 5 2.0∶2∶1 65 0.15 2.5 300 6 2.0∶2∶1 70 0.25 3.0 295 7 2.0∶1∶1 60 0.15 3.0 335 8 2.0∶1∶1 65 0.25 3.5 325 9 2.0∶1∶1 70 0.20 2.5 340 K1 320.000 330.000 323.333 330.000 K2 300.000 315.000 321.667 316.667 K3 333.333 308.333 308.333 306.667 R 33.333 21.667 15.000 23.333 表 3 不同NaCl加量下水泥浆的失水量

GT-1/% NaCl/% T/℃ FL/mL 3.0 18 90 112 4.0 18 90 68 5.0 18 90 42 4.0 36 90 107 5.0 36 90 85 6.0 36 90 69 -

[1] WU X. Research on integrated planning method of offshore oil and gas exploration and development[J]. International Journal of Geosciences, 2020, 11(7):483-491. doi: 10.4236/ijg.2020.117024 [2] LEI Q, YUN X U, YANG Z, et al. Progress and development directions of stimulation techniques for ultra-deep oil and gas reservoirs[J]. Petroleum Exploration and Development, 2021, 48(1):221-231. doi: 10.1016/S1876-3804(21)60018-6 [3] 秦伟堂,张宏军,郑成胜,等. 国内外油井水泥降失水剂概述[J]. 钻井液与完井液,2005,22(2):54-58. doi: 10.3969/j.issn.1001-5620.2005.02.016QIN Weitang, ZHANG Hongjun, ZHENG Chengsheng, et al. Overview of oil well cement fluid loss additive at home and abroad[J]. Drilling Fluid & Completion Fluid, 2005, 22(2):54-58. doi: 10.3969/j.issn.1001-5620.2005.02.016 [4] 郭锦棠,周贤明,靳建洲,等. 抗高温耐盐AMPS/AM/AA降失水剂的合成及其性能表征[J]. 石油学报,2011,32(3):470-473. doi: 10.7623/syxb201103014GUO Jintang, ZHOU Xianming, JIN Jianzhou, et al. Synthesis and characterization of high temperature and salt resistant AMPS / AM / AA fluid loss additive[J]. Acta Petrolei Sinica, 2011, 32(3):470-473. doi: 10.7623/syxb201103014 [5] 张科,王展旭,孙伟. AMPS多元聚合物固井降失水剂的合成与应用性能评价[J]. 青岛科技大学学报(自然科学版),2004,25(6):500-502.ZHANG Ke, WANG Zhanxu, SUN Wei. Synthesis and application performance evaluation of AMPS multicomponent polymer cementing fluid loss additive[J]. Journal of Qingdao University of science and Technology(Natural Science Edition) , 2004, 25(6):500-502. [6] 严思明,杨圣月,张红丹,等. 抗高温油井水泥缓凝剂HL-1的合成与性能[J]. 油田化学,2015,32(3):317-321.YAN Siming, YANG Shengyue, ZHANG Hongdan, et al. Synthesis and properties of high temperature resistant oil well cement retarder HL-1[J]. Oilfield Chemistry, 2015, 32(3):317-321. [7] 宋芳, 徐兴华, 刘锐可. 一种钻井液用抗高温降失水剂及其制备方法: CN106398661A[P]. 2017-02-15.SONG Fang, XU Xinghua, LIU Ruike. The invention relates to a high temperature fluid loss reducer for drilling fluid and a preparation method thereof: CN106398661A[P]. 2017-02-15. [8] 李皋,付强,余杭航,等. 四元共聚抗高温抗盐油井水泥浆降失水剂的合成[J]. 天然气工业,2018,38(12):96-101. doi: 10.3787/j.issn.1000-0976.2018.12.011LI Gao, FU Qiang, YU Hanghang, et al. Synthesis of quaternary copolymer high temperature and salt resistant oil well cement slurry fluid loss additive[J]. Natural Gas Industry, 2018, 38(12):96-101. doi: 10.3787/j.issn.1000-0976.2018.12.011 [9] 刘飞,刘学鹏,曾德智. 油井水泥浆抗高温抗盐降失水剂合成及性能研究[J]. 化学研究与应用,2016,28(8):1075-1079. doi: 10.3969/j.issn.1004-1656.2016.08.005LIU Fei, LIU Xuepeng, ZENG Dezhi. Study on synthesis and properties of high temperature and salt resistant fluid loss reducer for oil well cement slurry[J]. Chemical Research and Application, 2016, 28(8):1075-1079. doi: 10.3969/j.issn.1004-1656.2016.08.005 [10] WANG H, LI M, ZHENG Y, et al. Function synergy of cross-linked cationic PVA polymer to AMPS-type fluid loss additive used for cement-based material[J]. International Journal of Polymer Science, 2020(7):1-15. [11] 郭锦棠,刘振兴,何军,等. 新型耐温抗盐降失水剂LX-1的研制与性能评价[J]. 天津大学学报:自然科学与工程技术版,2021,54(3):318-323.GUO Jintang, LIIU Zhenxing, HE Jun, et al. Development and evaluation of a new type of temperature reducing agent LX-1[J]. Journal of Tianjin University(Science and Technology) , 2021, 54(3):318-323. [12] 张瑞,霍锦华,彭志刚,等. 钻井液降滤失剂PAAS的制备及性能[J]. 精细化工,2017,34(5):569-575.ZHANG Rui, HUO Jinhua, PENG Zhigang, et al. Preparation and properties of drilling fluid filtrate reducer PAAS[J]. Fine Chemicals, 2017, 34(5):569-575. [13] 李晓岚,国安平,孙举. 三元共聚物油井水泥降失水剂的室内研究[J]. 钻井液与完井液,2013,30(1):56-59. doi: 10.3969/j.issn.1001-5620.2013.01.015LI Xiaolan, GUO Anping, SUN Ju. Laboratory study on terpolymer oil well cement fluid loss additive[J]. Drilling Fluid & Completion Fluid, 2013, 30(1):56-59. doi: 10.3969/j.issn.1001-5620.2013.01.015 [14] 于小荣. 大温差两性离子缓凝剂的制备及在低密度水泥浆中的应用[D]. 成都: 西南石油大学, 2017.YU Xiaorong. Preparation of zwitterionic retarder with large temperature difference and its application in low density cement slurry[D]. Chengdu: Southwest Petroleum University, 2017. [15] 郭锦棠,骆成,余前峰,等. 抗盐降失水剂HTF-110L的研制及性能评价[J]. 天津大学学报:自然科学与工程技术版,2015,48(10):901-907.GUO Jintang, LUO Cheng, YU Qianfeng, et al. Development and performance evaluation of salt resistant fluid loss additive HTF-110L[J]. Journal of Tianjin University(Science and Technology) , 2015, 48(10):901-907. [16] 张健,彭志刚,邹长军,等. 聚合物基纳米SiO2复合微球固井降失水剂的合成及表征[J]. 硅酸盐学报,2017,45(11):1649-1657.ZHANG Jian, PENG Zhigang, ZOU Changjun, et al. Synthesis and characterization of polymer based nano SiO2 composite microsphere cementing fluid loss additive[J]. Journal of the Chinese Ceramic Society, 2017, 45(11):1649-1657. [17] MING S, CHEN G, WU Z, et al. Effective dispersion of aqueous clay suspension using carboxylated nanofibrillated cellulose as dispersant[J]. RSC Advances, 2016, 6(44):37330-37336. doi: 10.1039/C6RA03935A [18] 孔德玉,杜祥飞,杨杨,等. 纳米二氧化硅团聚特性对水泥水化硬化性能的影响[J]. 硅酸盐学报,2012,40(11):1599-1606.KONG Deyu, DU Xiangfei, YANG Yang, et al. Effect of agglomeration characteristics of nano silica on hydration and hardening properties of cement[J]. Journal of the Chinese Ceramic Society, 2012, 40(11):1599-1606. [19] FLORES I, SOBOLEVO R, TORRES-MARTINEZ R M, et al. Performance of cement systems with nano-SiO2 particles produced by using the sol-gel method[J]. Transportation Research Record:Journal of the Transportation Research Board, 2010, 2141(1):10-14. doi: 10.3141/2141-03 -

下载:

下载: