Influence of Mosaic Shielding Drilling Fluid Filter Cake on the Cementing Quality of Second Interface and Improvement Method

-

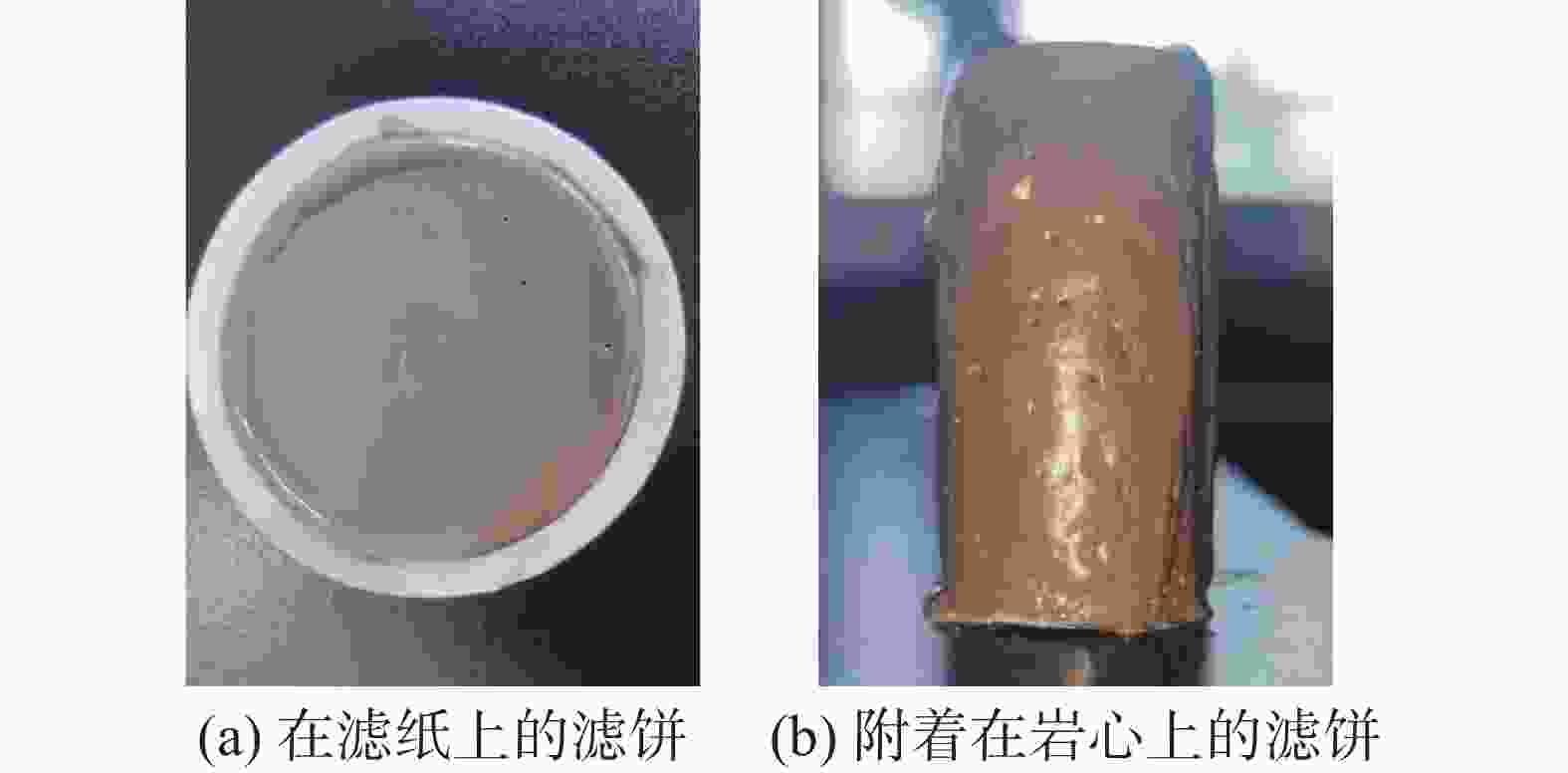

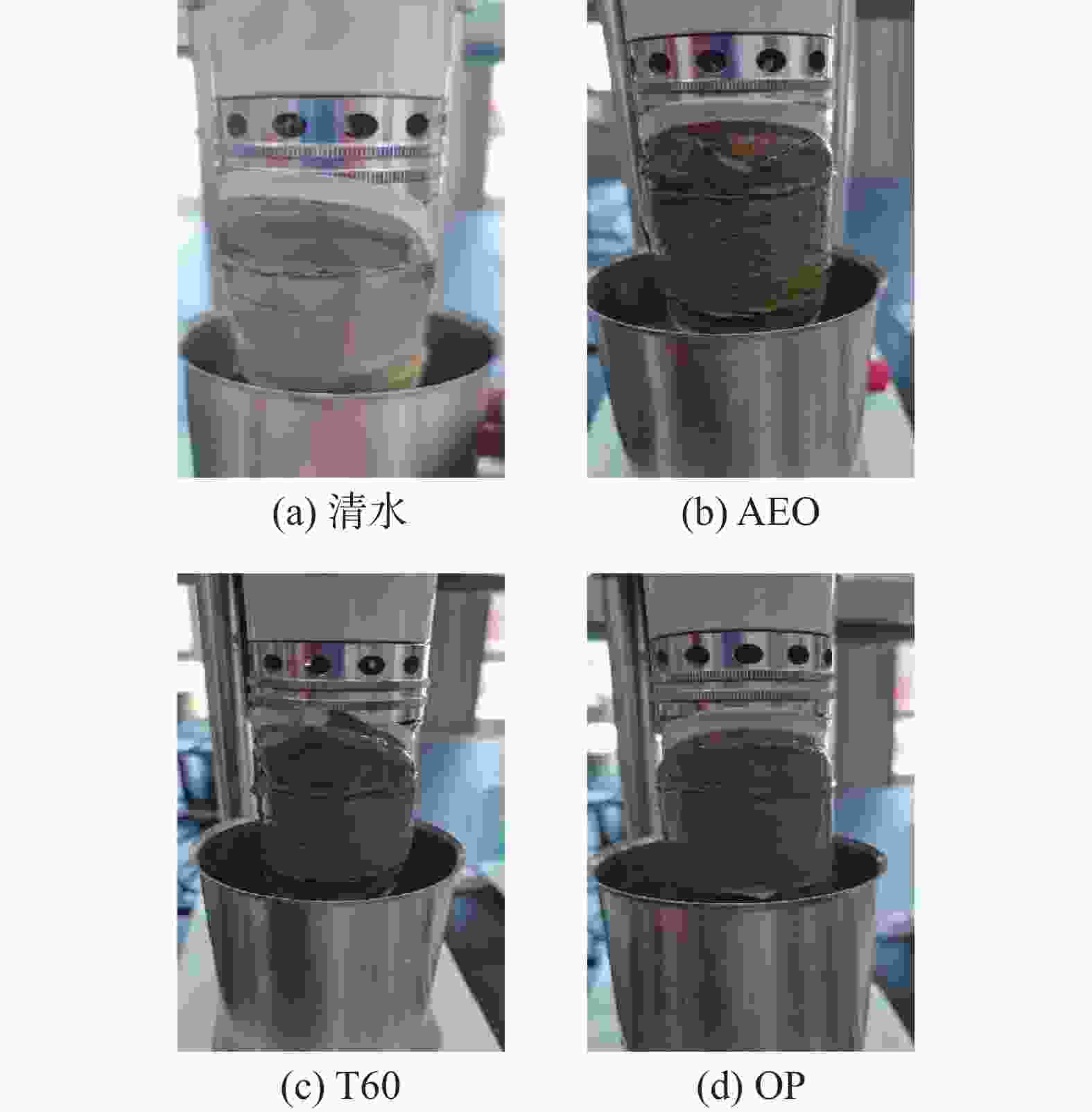

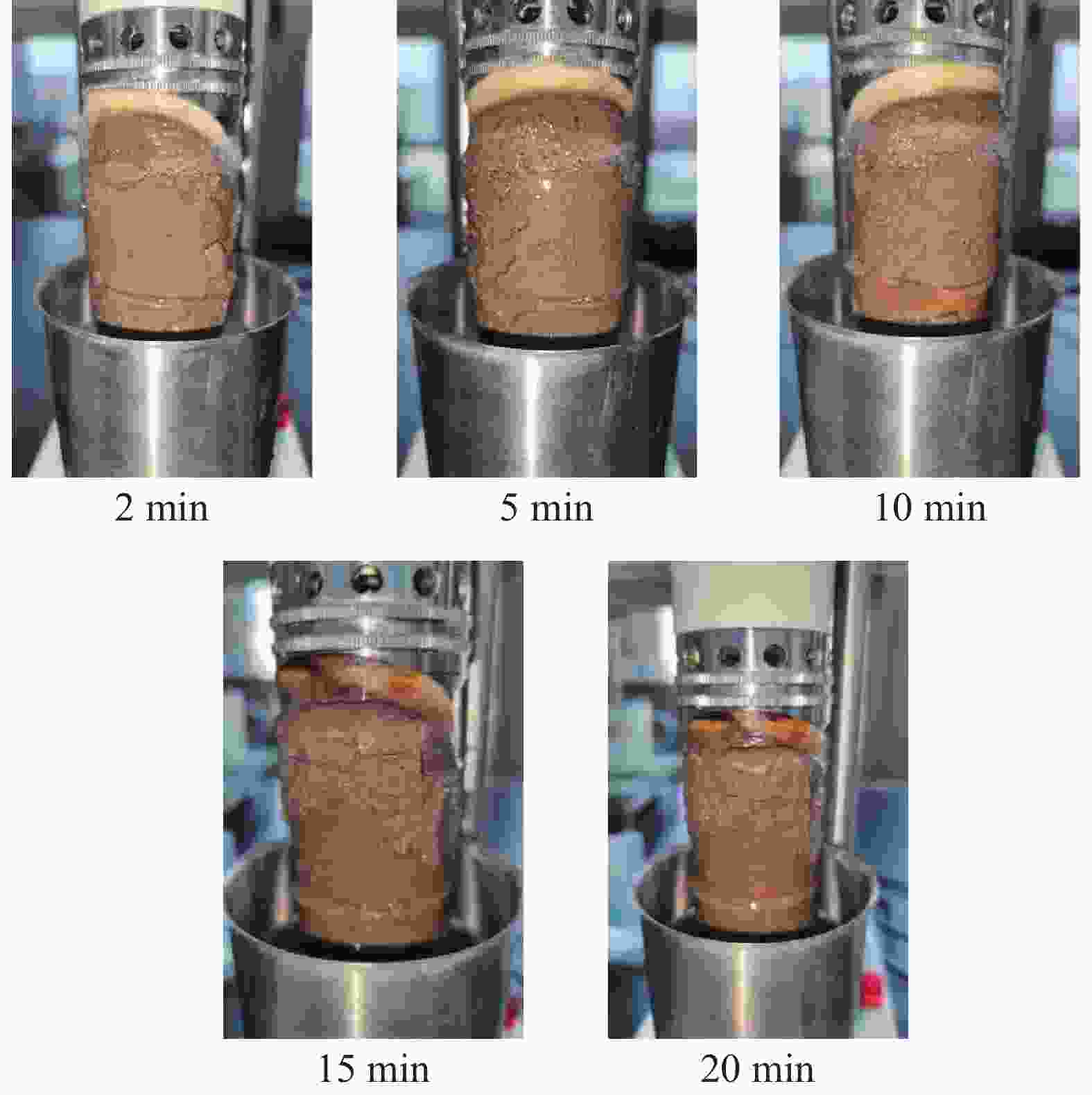

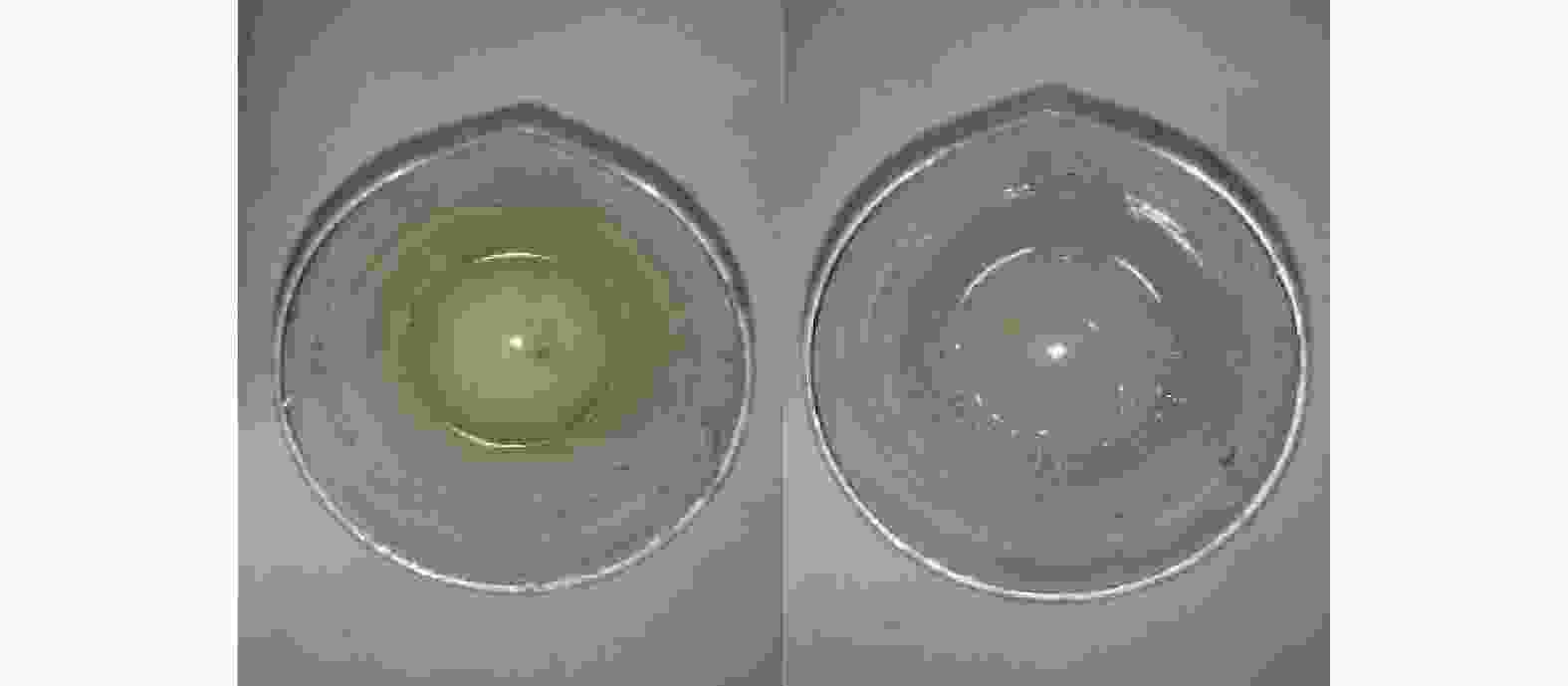

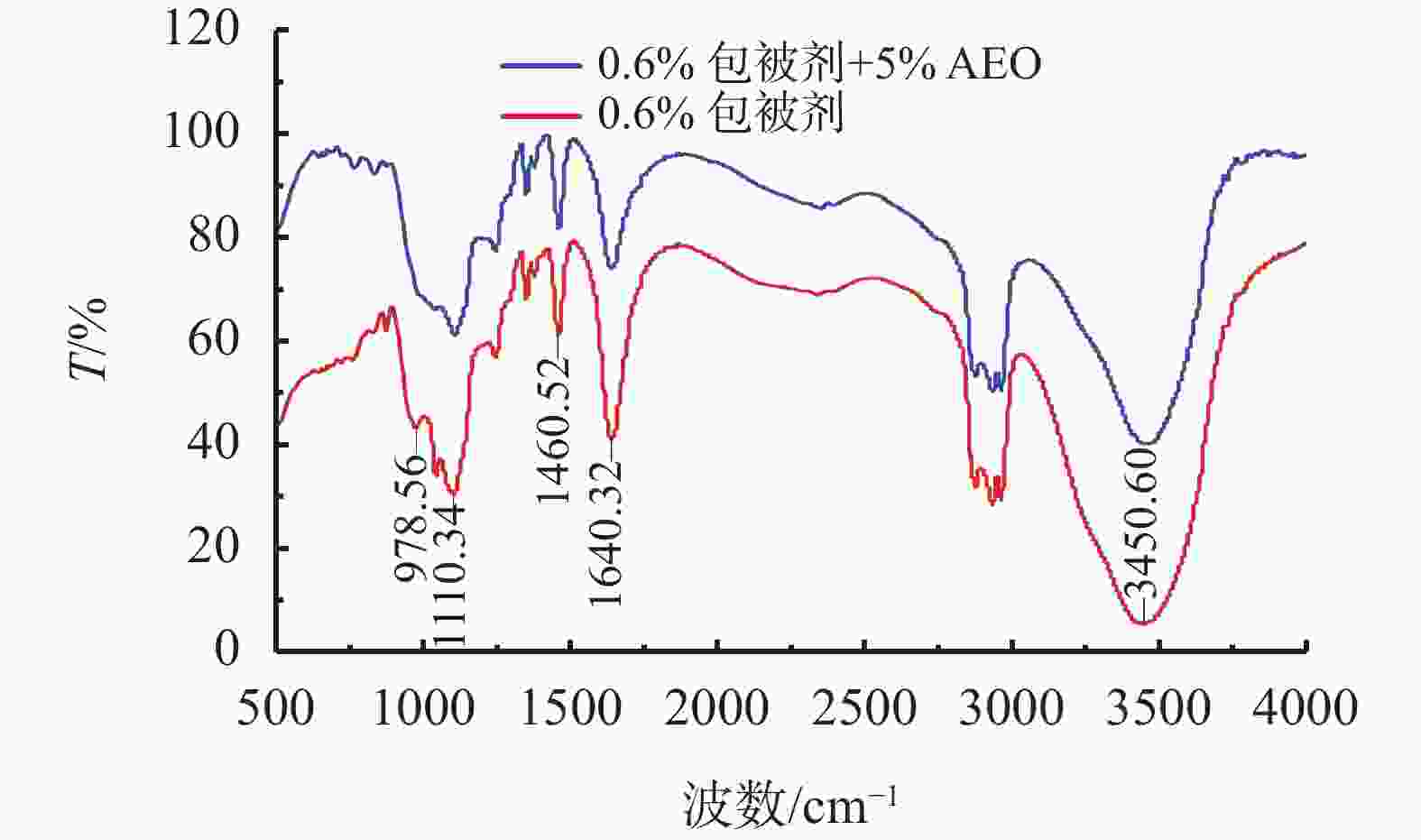

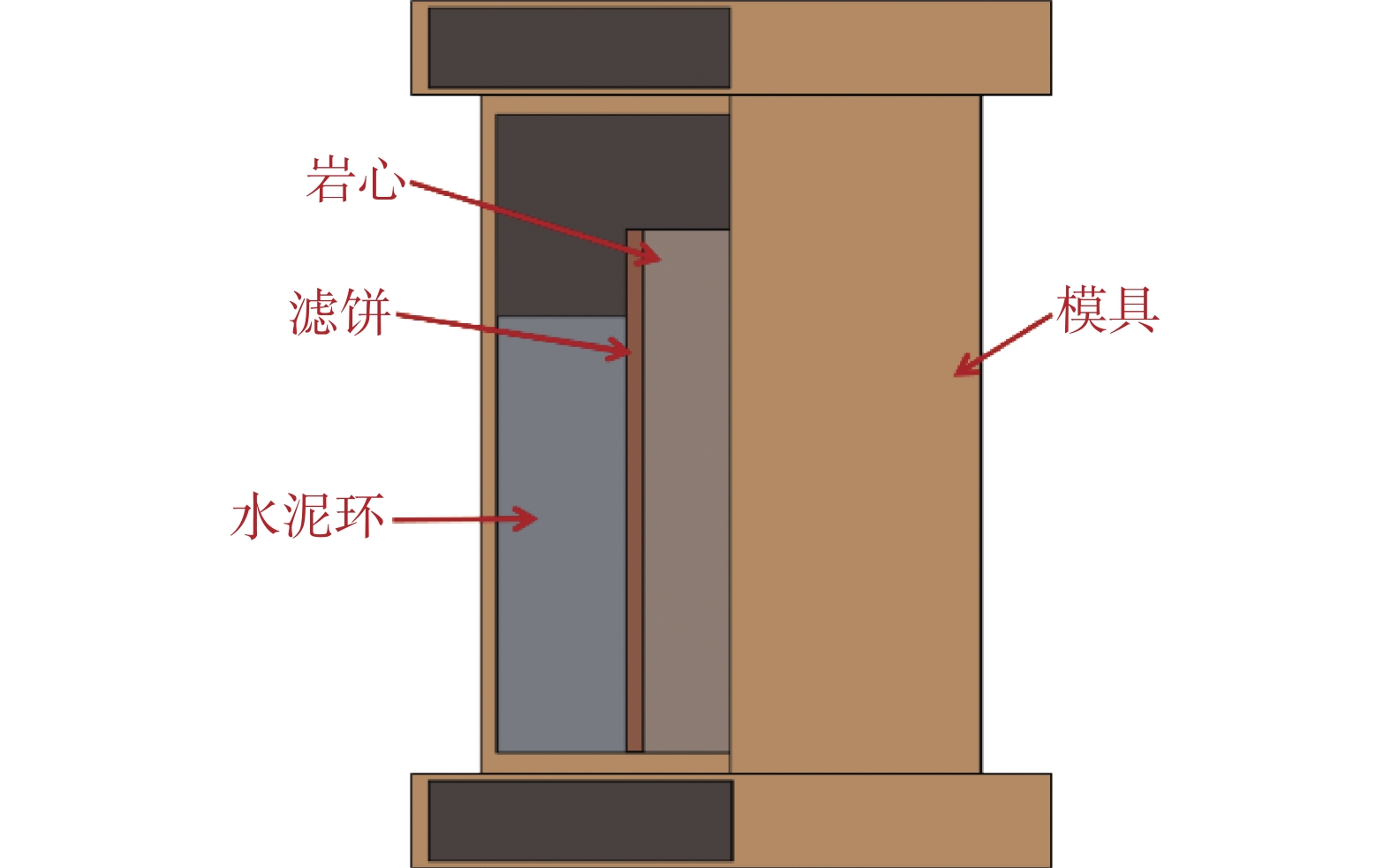

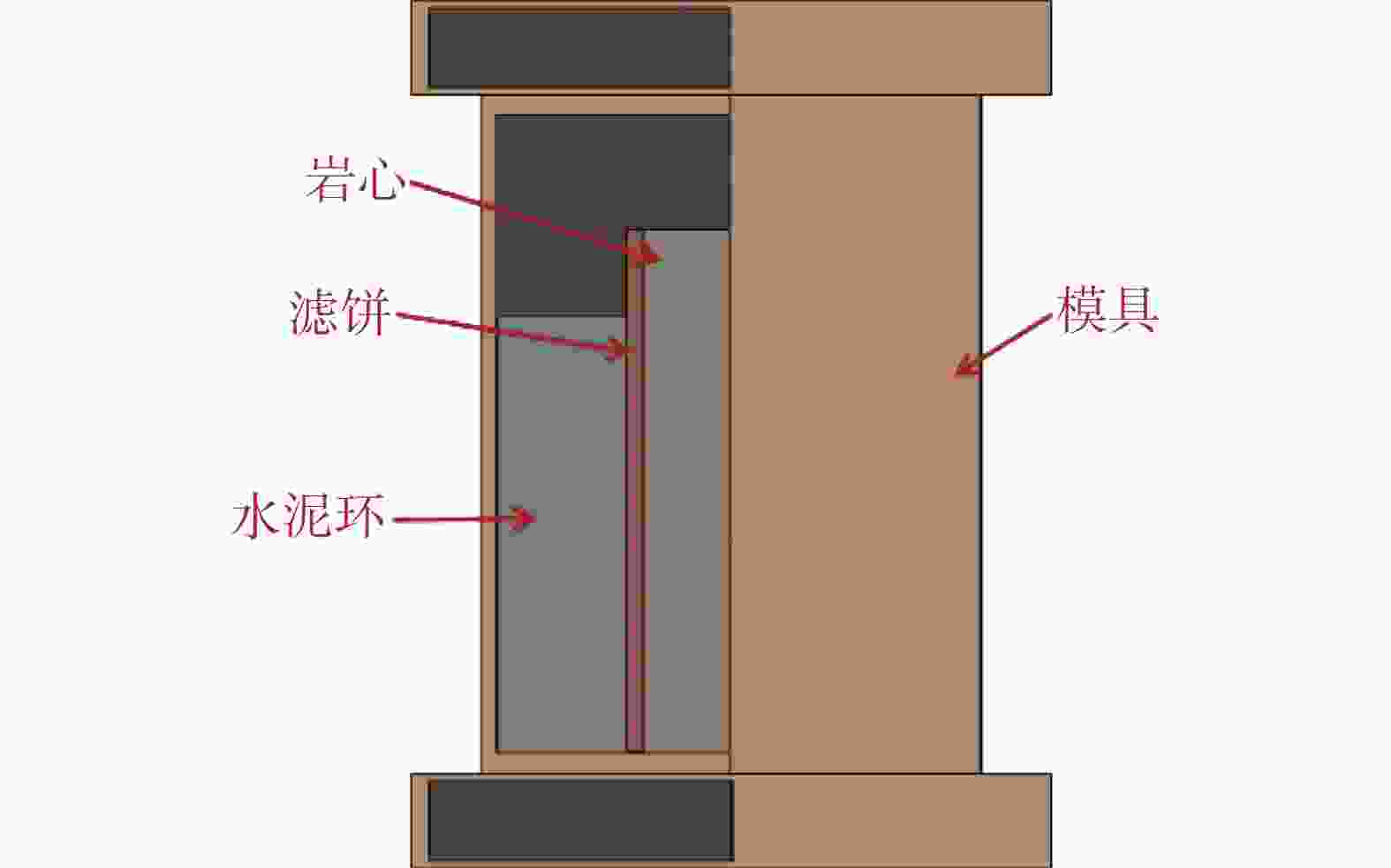

摘要: 固井质量的好坏是决定后期开采作业能否顺利进行的关键,钻井过程中形成的滤饼会影响固井二界面的胶结质量,因此通过固井二界面胶结强度的评价方法,分析镶嵌屏蔽钻井液滤饼对固井二界面胶结质量的影响,结合SEM和EDS进一步说明钻井液形成的虚滤饼因为其疏松的凝胶状态导致固井二界面质量降低。针对以上问题,选用脂肪醇聚氧乙烯醚(AEO)、脂肪酸山梨醇酐聚氧乙烯醚60(T60)、聚氧乙烯烷基酚醚(OP)3种渗透剂对镶嵌屏蔽钻井液滤饼进行冲洗,实验结果表明,AEO对镶嵌屏蔽钻井液滤饼的冲洗效果最好,滤饼通过AEO冲洗后,固井二界面胶结强度增大33.34%~166.67%,提高了固井二界面的胶结质量。Abstract: The quality of cementing is the key to decide whether the later mining operation can proceed smoothly. The filter cake formed during drilling will affect the cementing quality of the second interface. Therefore, this paper analyzes the influence of embedded shielding drilling fluid filter cake on the cementing quality of the second interface through the evaluation method of the cementing strength of the second interface. Combined with SEM and EDS, it further shows that the virtual filter cake formed by drilling fluid will reduce the cementing quality of the second interface because of its loose gel state. Aiming at the above problems, this paper selects AEO, T60 and OP as penetrant to flush the filter cake of embedded shielding drilling fluid. The experimental results show that AEO has the best flushing effect on the filter cake of embedded shielding drilling fluid. After the filter cake is flushed by AEO, the cementing strength of the second interface of cementing is increased by 33.34%~166.67%, which greatly improves the cementing quality of the second interface of cementing.

-

表 1 油井水泥化学组成

成分 含量/% 成分 含量/% 成分 含量/% CaO 62.070 Al2O3 3.608 K2O 0.675 SiO2 20.494 MgO 1.863 SO3 3.471 Fe2O3 4.071 Na2O 0.250 TiO2 0.262 表 2 不同样品的胶结强度结果

岩心 胶结强度/MPa 1 d 3 d 不含钻井液滤饼的岩心 2.10 4.18 附着钻井液滤饼的岩心冲洗前 0.21 0.84 附着钻井液滤饼的岩心冲洗后 0.56 1.12 -

[1] 薛锦华. 镶嵌屏蔽钻井液研究及评价[D]. 天津: 天津科技大学, 2015.XUE Jinhua. Research and evaluation of mosaic shielding drilling fluid system[D]. Tianjing: Tianjin University of Science and Technology, 2015. [2] THORSRUD A K, EKELI H NC C, et al. Application of novel downhole hydraulics software todrill safely and economically a north sea high-temperature/high-pressure exploration well [C]//Kuala Lumpur, Malaysia, IAD/SPE Asia Pacific Drilling Tech Conference, 2000, 9: 11-13. [3] 吕开河,乔伟刚,赵修太,等. 镶嵌屏蔽钻井液研究及应用[J]. 钻井液与完井液,2012,29(1):23-26. doi: 10.3969/j.issn.1001-5620.2012.01.007LYU Kaihe, QIAO Weigang, ZHAO Xiutai, et al. Study on research and application of mosaic and shielding drilling fluid system[J]. Drilling Fluid & Completion Fluid, 2012, 29(1):23-26. doi: 10.3969/j.issn.1001-5620.2012.01.007 [4] WANG F, TAN X, WANG R, et al. High temperature and high pressure rheological properties of high-density water-based driling fluids for deep wells[J]. PetroleumScience, 2012, 9(3):354-362. [5] 房恩楼,李浩然,张浩,等. 一种低温低密度可固化隔离液的研制与性能评价[J]. 钻井液与完井液,2020,37(1):86-92.FANG Enlou, LI Haoran, ZHANG Hao, et al. Development and performance evaluation of a low temperature low density solidifiable spacer fluid[J]. Drilling Fluid & Completion Fluid, 2020, 37(1):86-92. [6] 梅雨堃,李明,刘璐,等. 提高二界面胶结质量的矿渣钻井液滤饼可固化技术[J]. 钻井液与完井液,2016,33(1):68-72.MEI Yukun, LI Ming, LIU Lu, et al. Solidification of slag mud cake that improves cementation quality of the second bonding interface[J]. Drilling Fluid & Completion Fluid, 2016, 33(1):68-72. [7] 袁海平,王兆会,高宝奎,等. 固井过程中井壁虚泥饼的可冲刷性研究[J]. 钻井液与完井液,2015,32(2):67-71. doi: 10.3969/j.issn.1001-5620.2015.02.018YUAN Haiping, WANG Zhaohui, GAO Baokui, et al. Erodability of false filter cake on borehole wall during wellcementing[J]. Drilling Fluid & Completion Fluid, 2015, 32(2):67-71. doi: 10.3969/j.issn.1001-5620.2015.02.018 [8] 刘开强,赵殊勋,李炜,等. 提高固井第二界面质量的技术研究与应用[J]. 油田化学,2018,35(1):16-21.LIU Kaiqiang, ZHAO Shuxun, LI Wei, et al. Research and application on enhancing the cementing quality of second-interface technology[J]. Oilfield Chemistry, 2018, 35(1):16-21. [9] 李韶利,姚志翔,李志民,等. 基于油基钻井液下固井前置液的研究及应用[J]. 钻井液与完井液,2014,31(3):57-60. doi: 10.3969/j.issn.1001-5620.2014.03.015LI Shaoli, YAO Zhixiang, LI Zhimin, et al. Research and application of cementing ahead fluid in wells drilled with oil base drilling fluid[J]. Drilling Fluid & Completion Fluid, 2014, 31(3):57-60. doi: 10.3969/j.issn.1001-5620.2014.03.015 [10] HALE A H, COWAN K M, NAHM J J W. Conversion of emulsion mud to cement: US, 5358049[P]. 1994-10-125. [11] NAHM J J W, WYANT R E. Conversion of oil-base mud to oilmud-cement: US, US5476144 A[P]. 1995-01-17. [12] 顾军,杨卫华,秦文政,等. 固井二界面封隔能力评价方法研究[J]. 石油学报,2008(3):451-454. doi: 10.3321/j.issn:0253-2697.2008.03.028GU Jun, YANG Weihua, QIN Wenzheng, et al. Evaluation method for isolation ability of cement-formation interface[J]. Acta Petrolei Sinica, 2008(3):451-454. doi: 10.3321/j.issn:0253-2697.2008.03.028 [13] 武治强,许明标,刘书杰,等. 固井水泥环胶结质量检测与评价技术研究[J]. 重庆科技学院学报(自然科学版),2017,19(4):39-41,46.WU Zhiqiang, XU Mingbiao, LIU Shujie, et al. Study on testing method and evaluation technology of cement bond quality of well cementation[J]. Journal of Chongqing University of Science and Technology (Natural Sciences Edition) , 2017, 19(4):39-41,46. [14] 王广雷. 一种新型的固井二界面胶结质量评价方法[J]. 西部探矿工程,2020,32(9):89-91. doi: 10.3969/j.issn.1004-5716.2020.09.028WANG Guanglei. A new evaluation method of cementing quality at second interface of cementing[J]. West-China Exploration Engineering, 2020, 32(9):89-91. doi: 10.3969/j.issn.1004-5716.2020.09.028 [15] 顾军,秦文政. MTA方法固井二界面整体固化胶结实验[J]. 石油勘探与开发,2010,37(2):226-231. doi: 10.1016/S1876-3804(10)60028-6GU Jun, QIN Wenzheng. Experiments on integrated solidification and cementation of the cement-formation interface based on mud cake to agglomerated cake (MTA) method[J]. Petroleum Exploration and Development, 2010, 37(2):226-231. doi: 10.1016/S1876-3804(10)60028-6 [16] 周风山,赵明方,倪文学,等. 泥饼厚度影响因素研究[J]. 西安石油学院学报(自然科学版),1999(5):26-28.ZHOU Fengshan, ZHAO Mingfang, NI Wenxue, et al. A Study on the factors influencing the thickness of drilling fluid filter cake[J]. Journal of Xi'an Shiyou University(Natural Science Edition) , 1999(5):26-28. [17] 蒋官澄,史亚伟,贺垠博,等. 抗高温包被剂PAAND的研制与性能评价[J]. 油田化学,2018,35(2):197-202.JIANG Guancheng, SHI Yawei, HE Yinbo, et al. Preparation and characteristic of amphoteric polymer as a high temperature resistant coating agent[J]. Oilfield Chemistry, 2018, 35(2):197-202. [18] 康永. 油田用聚丙烯酰胺性能研究[J]. 橡塑技术与装备,2019,45(8):9-15.KANG Yong. Study on properties of polyacrylamide for oil field[J]. China Rubber/Plastics Technology and Equipment, 2019, 45(8):9-15. [19] 吴梅芬,薛静,陈晓楼. DMH化学冲洗液简介[J]. 钻井液与完井液,1992,9(5):59-62.WU Meifen, XUE Jing, CHEN Xiaolou. DMH washing fluid[J]. Drilling Fluid & Completion Fluid, 1992, 9(5):59-62. [20] 刘子帅. 冲洗隔离液体系研究[D]. 北京: 中国石油大学(北京), 2017.LIU Zishuai. Develop the study of the isolation liquid system[D]. Beijing: China University of Petroleum (Beijing) , 2017. [21] 柳洪华. 油基钻井液滤饼对二界面胶结强度的影响研究[D]. 成都: 西南石油大学, 2016.LIU Honghua. Study on the influence of oil-based drilling fluid filter cake on the bond strength of the second interface[D]. Chengdu: Southwest Petroleum University, 2016. [22] 陈小华,张福铭,赵琥,等. 油基钻井液用冲洗液PC–W31L的制备及性能研究[J]. 石油钻探技术,2019,47(2):81-86.CHEN Xiaohua, ZHANG Fuming, ZHAO Hu, et al. The development and properties of PC–W31L flushing fluid for oil-based drilling fluid[J]. Petroleum Drilling Techniques, 2019, 47(2):81-86. [23] 王翀,谢飞燕,刘爱萍,等. 油基钻井液用冲洗液BCS-020L研制及应用[J]. 石油钻采工艺,2013,35(6):36-39.WANG Chong, XIE Feiyan, LIU Aiping, et al. Research and application of flushing fluid BCS-020L for oil-based drilling fluid cleaning[J]. Oil Drilling & Production Technology, 2013, 35(6):36-39. [24] 陈大钧,王雪敏,吴永胜,等. 高密度高效冲洗液XM-1[J]. 钻井液与完井液,2015,32(3):70-72. doi: doi:10.3969/j.issn.1001-5620.2015.03.019CHEN Dajun, WANG Xuemin, WU Yongsheng, et al. High density flushing fluid XM-1[J]. Drilling Fluid & Completion Fluid, 2015, 32(3):70-72. doi: doi:10.3969/j.issn.1001-5620.2015.03.019 -

下载:

下载: