Effects of High Temperature Synthesized Calcium Silicate Hydrate on Hydration Process of Oil Well Cement

-

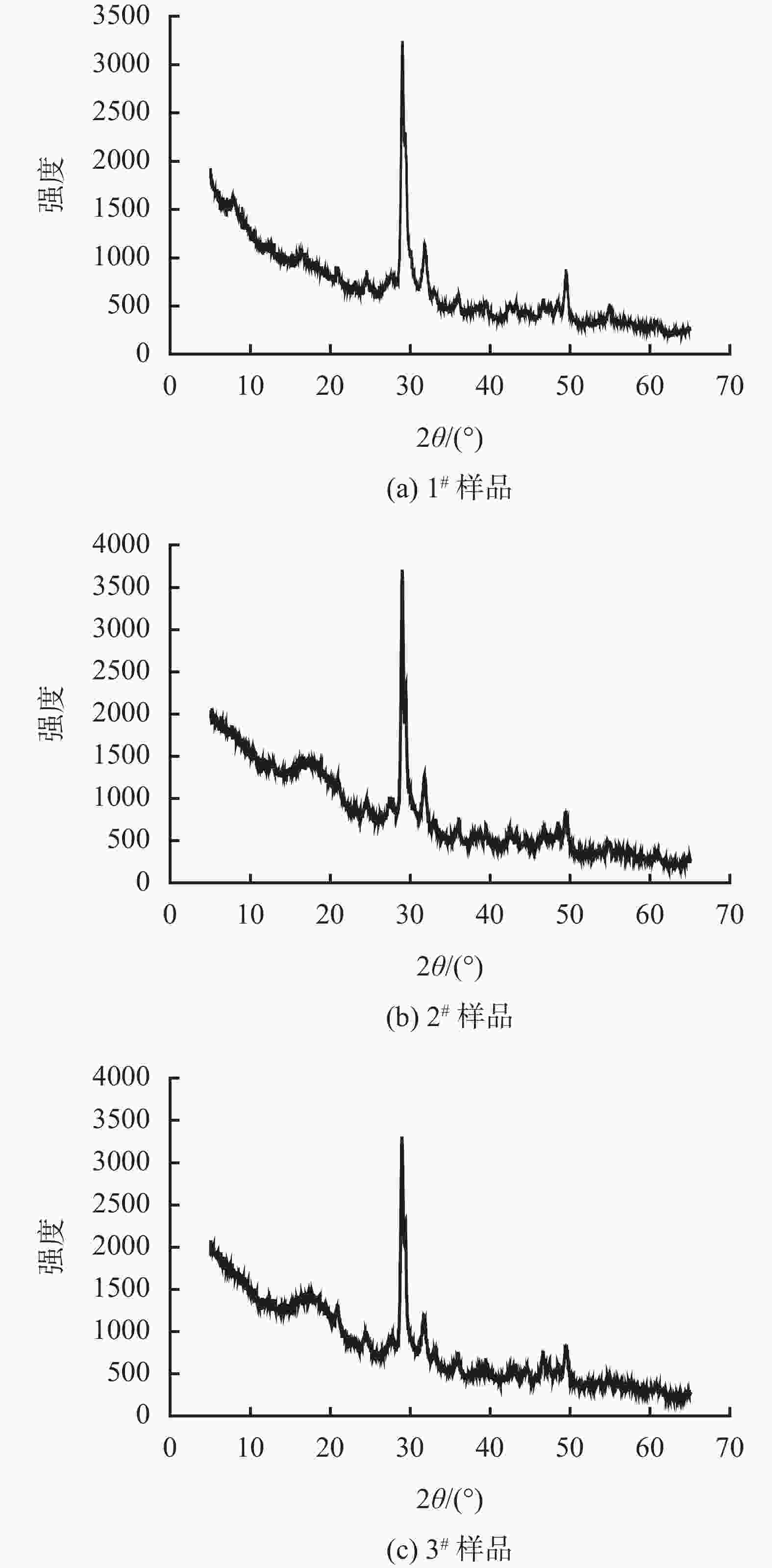

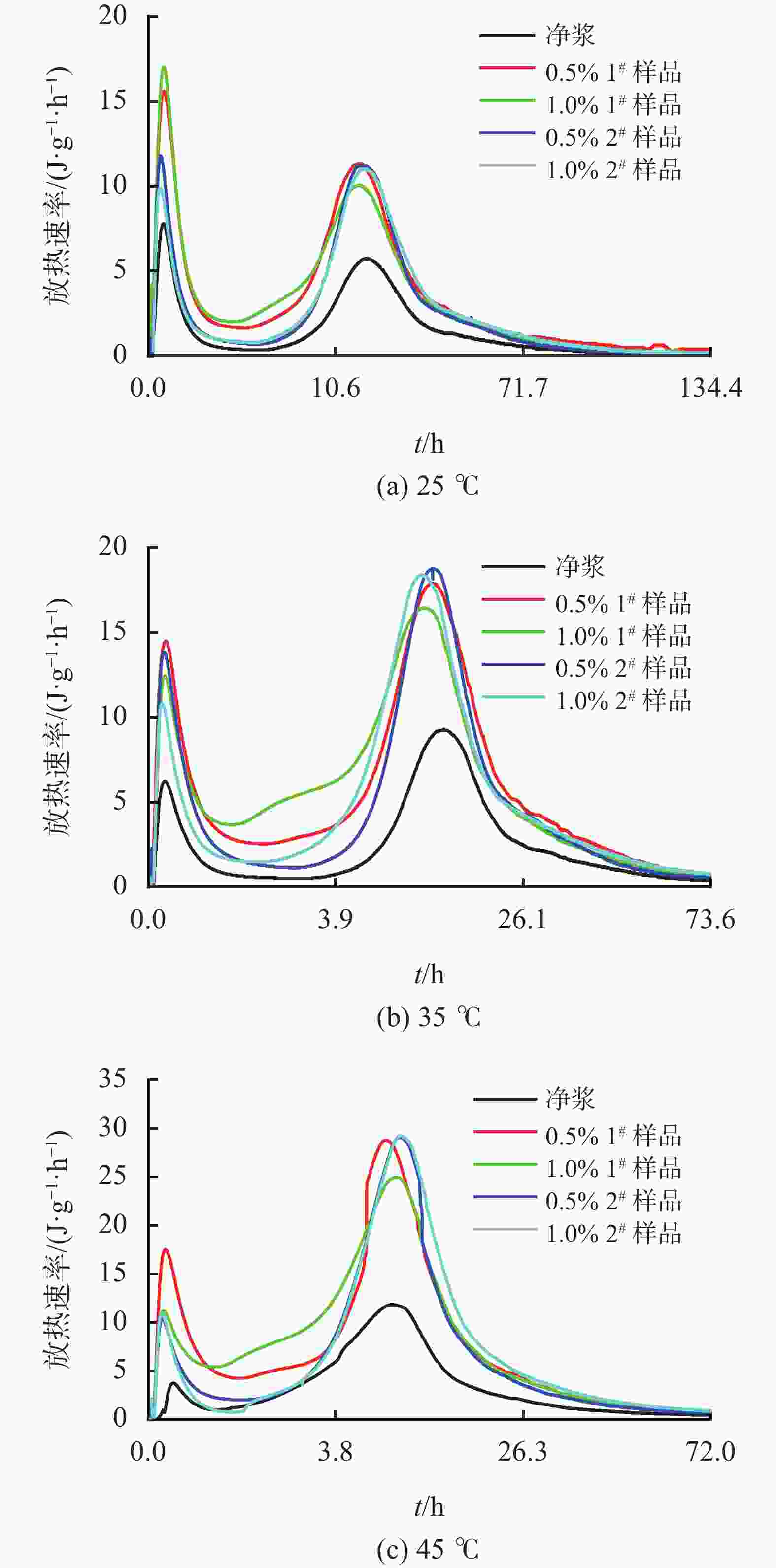

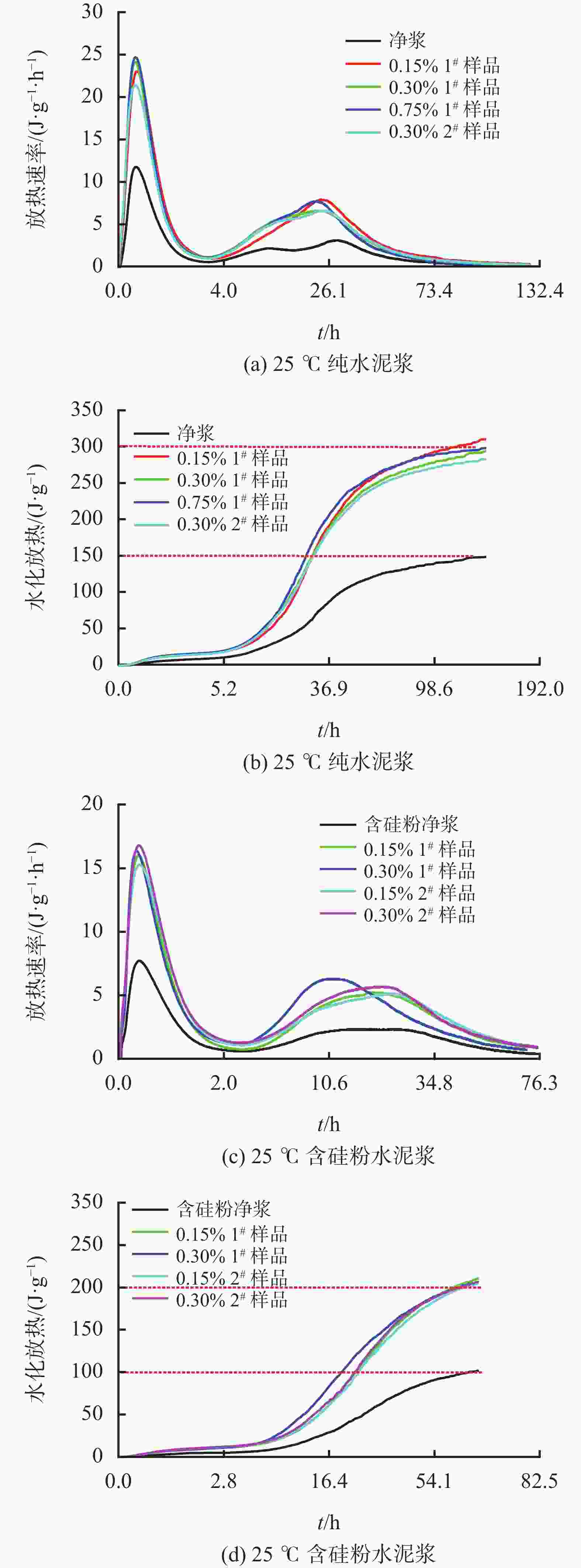

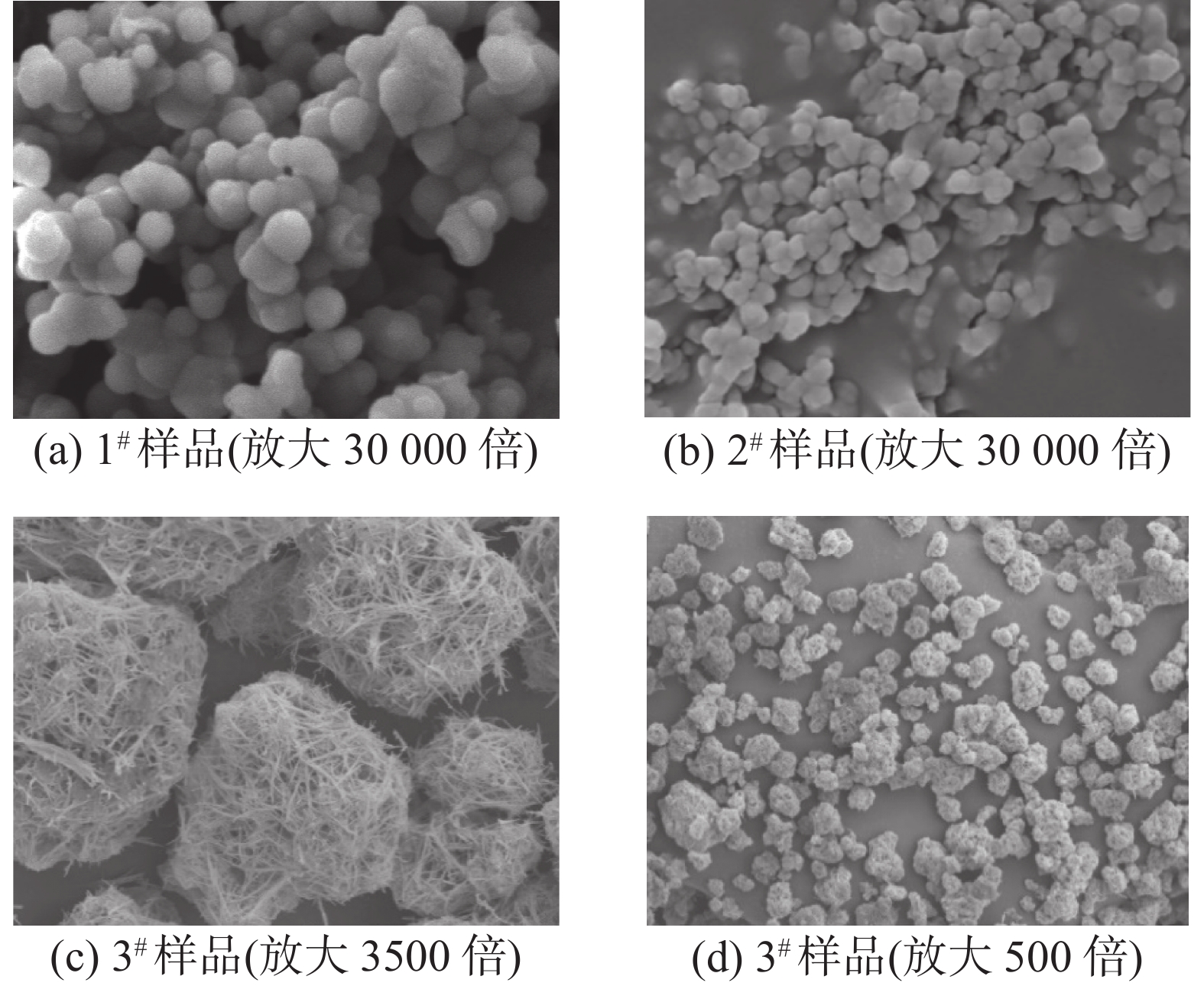

摘要: 以氧化钙、氢氧化钙、白炭黑等为主要原料,在160 ℃、80 MPa下,通过高温水热合成法合成了颗粒状水化硅酸钙晶体,并研究了其对油井水泥水化的影响。结果表明,合成的颗粒状水化硅酸钙晶体能使水泥水化放热量增加超过1倍,且能够显著加快水泥浆的放热速率;合成材料的粒径大小对水泥浆水化过程有一定影响,粒径为纳米级时水泥浆放热速率和总放热提高更为明显,一定加量下具有早强、增强水泥石强度的作用。研究表明水泥的钙硅比会影响水泥水化规律,相关机理需要进一步深入研究。Abstract: A granular crystalline calcium silicate hydrate has been synthesized through high temperature hydrothermal reaction at 160 ℃ and 80 MPa with CaO, Ca(OH)2 and white carbon black (a silica) as the major raw materials. Study on the effects of the synthesis product on the hydration process of oil well cement showed that the use of the synthesized calcium silicate hydrate caused the released heat of hydration of the cement to double, and was able to significantly accelerate the heat release process of the cement slurry. The particle sizes of the calcium silicate hydrate have some effects on the hydration process of the cement. When the particle size is in nano-scale, the rate of heat release and the total heat released of the cement slurry increase more obviously. By adding a specific amount of the calcium silicate hydrate into a cement slurry, the compressive strength of the set cement, the overall properties of the cement slurry and the set cement can all be improved. The study has shown that the ratio of SiO2/CaO of the cement affects its hydration process.

-

Key words:

- Oil well cement /

- Hydrothermal synthesis /

- Granular /

- Calcium silicate hydrate /

- Heat of hydration

-

表 1 合成样品的原料组成

样品 原料 催化剂 1# CaO、白炭黑 DZH-1 2# Ca(OH)2、白炭黑 DZH-1 3# CaO、白炭黑 DZH-2 表 2 1#样品对无硅粉中低温水泥浆性能的影响

样品 t稠化/min p48 h/MPa 30 ℃静胶凝

强度时间/h100 ℃ 120 ℃ 30 ℃ 120 ℃ 净浆 335 128 14.3 2.4 27 3%1#样品 325 110 18.4 6.3 17 表 3 1#和3#样品对纯水泥浆常压、加压养护强度的影响

样品 p48 h/MPa

(45 ℃、

常压)p48 h/MPa

(90 ℃、

常压)p48 h/MPa

(45 ℃、

10 MPa)p48 h/MPa

(90 ℃、

10 MPa)净浆 19.0 21.7 34.7 36.90 1%1#样品 20.8 26.0 3%1#样品 21.6 27.2 5%1#样品 22.3 26.9 40.6 42.70 10%1#样品 18.7 22.0 5%3#样品 13.5 14.6 19.6 20.55 表 4 1#样品对加硅粉水泥浆加压养护 强度的影响(150 ℃/10 MPa)

样品 p48 h/MPa P72 h/MPa 净浆 14.9 25.1 5%1#样品 17.5 26.4 10%1#样品 14.7 25.3 表 5 1#样品对加硅粉水泥浆水化进程中的作用

1#样品 60 ℃静胶凝

强度时间/ht稠化/min

(160 ℃)净浆 76 285 1% 63 275 2% 60 305 3% 40 321 4% 39 335 5% 60 340 3%+0.5%NaCl 48 3%+2.0%NaCl 53 表 6 3#样品对加硅粉水泥浆水化进程中的作用

3#样品/% t稠化/min

(150 ℃)30 ℃静胶凝

强度时间/h60 ℃静胶凝

强度时间/h0 370 200 76 5 380 196 96 -

[1] 彭小芹. 合成水化硅酸盐纳米粉体胶凝材料研究[D]. 重庆: 重庆大学, 2004.PENG Xiaoqin. Study on synthesized hydrated silicate as nano powder binding materials[D]. Chongqing: Chongqing University, 2004. [2] 余林岑. 水化硅酸钙的制备及其对水泥水化过程的影响[D]. 上海: 华东理工大学, 2018.YU Lincen. Preparation of calcium silicate (C—S—H) and the effect on the cement hydration process[D]. Shanghai: East China University of Science and Technology, 2018. [3] 石磊,马素花,李伟峰,等. C—S—H凝胶的水热合成及其性能研究[J]. 混凝土,2013(11):101-104. doi: 10.3969/j.issn.1002-3550.2013.11.027SHI Lei, MA Suhua, LI Weifeng, et al. Hydrothermal synthesis of C—S—H and its properties[J]. Concrete, 2013(11):101-104. doi: 10.3969/j.issn.1002-3550.2013.11.027 [4] 雷永胜,韩涛,王慧奇,等. 水热合成水化硅酸钙(C—S—H)的制备与表征[J]. 硅酸盐通报,2014,33(3):465-469.LEI Yongsheng, HAN Tao, WANG Huiqi, et al. Preparation and characterization of calcium silicate hydrate synthesized by the hydrothermal method[J]. Bulletin of the Chinese Ceramic Society, 2014, 33(3):465-469. [5] 金仁才,尹万云,裴立宅,等. 微孔硅酸钙的水热合成与表征[J]. 安徽工业大学学报(自然科学版),2010,27(4):366-369.JIN Rencai, YIN Wanyun, PEI Lizhai, et al. Hydrothermal synthesis and characterizations of microporous calcium silicate[J]. Journal of Anhui University of Technology (Natural Science) , 2010, 27(4):366-369. [6] ROUZBEH SHAHSAVARI, SUNG HOON HWANG. Size and shape-controlled synthesis of calcium silicate particles enables self-assembly and enhanced mechanical and durability properties[J]. Langmuir, 2018, 34(40):12154-12166. doi: 10.1021/acs.langmuir.8b00917 [7] 王同友,符军放,赵琥. 纳米级水化硅酸钙晶种作为油井水泥促凝剂的研究[J]. 钻井液与完井液,2017,34(3):68-71. doi: 10.3969/j.issn.1001-5620.2017.03.013WANG Tongyou, FU Junfang, ZHAO Hu. Study on nano calcium silicate hydrate used as oil well cement accelerator[J]. Drilling Fluid & Completion Fluid, 2017, 34(3):68-71. doi: 10.3969/j.issn.1001-5620.2017.03.013 [8] 彭小芹,兰聪,王淑萍,等. 水化硅酸钙粉体对水泥水化反应过程及机理的影响[J]. 建筑材料学报,2015,18(2):195-201. doi: 10.3969/j.issn.1007-9629.2015.02.003PENG Xiaoqin, LAN Cong, WANG Shuping, et al. Effects of the C—S—H powder on the hydration process and mechanism of cement[J]. Journal of Building Materials, 2015, 18(2):195-201. doi: 10.3969/j.issn.1007-9629.2015.02.003 [9] 杨巧. 水热合成C—S—H超细粉体微观结构分析及接触硬化机理初探[D]. 重庆: 重庆大学, 2008.YANG Qiao. Analysis on microstructure and primary exploring of contact hardening mechanism of C—S—H superfine powder made with hydrothermal synthesis[D]. Chongqing: Chongqing University, 2008. [10] 黄德样. 新型晶核型早强剂的性能与早强机理研究[D]. 安徽建筑大学, 2015.HUANG Dexiang. Performance and mechanism of new crystal nucleus based hardening accelerator[D]. Anhui Jianzhu University, 2015. [11] 张明昌. 固井工艺技术[M]. 北京: 中国石化出版社, 2017: 510.ZHANG Mingchang. Cementing technology[M]. Beijing: China Petrochemical Press, 2017: 510. -

下载:

下载: