Factors Affecting Measurement of Polyether Amine Content and Elimination Thereof

-

摘要: 胺基聚醚作为一种高效抑制剂在钻井液中使用越来越多,但对其在钻井液中的游离含量却无法进行检测,导致配制维护钻井液时确定加量没有依据。研究了胺基聚醚含量测定方法,考察发现钻井液常用处理剂如氢氧化钠、羧甲基纤维素钠盐、磺化酚醛树脂、水解聚丙烯酰胺钾盐等使测定结果高出理论值,研究了干扰因素消除方法。在钻井液中进行验证,测定结果表明,该方法偏差不大于10%,能够较好地满足现场应用。Abstract: Polyether amine is a highly effective shale inhibitor which are more and more widely used in drilling fluids. Since there are no methods of determining the free content of the polyether amine in a drilling fluid, there is no basis for determining the amount of polyether amine when maintaining the properties of the drilling fluid. In laboratory studies, the methods of determining the content of polyether amine in drilling fluids were investigated. It was found that the common drilling fluid additives, such as caustic soda, sodium carboxy methyl cellulose, sulfonated methyl phenolic resin and potassium salts of hydrolyzed polyacrylamide make the measurement results higher than the theoretical value. A method was found able to eliminate the factors interfering the determination of the polyether amine concentration. In verifying the new method in laboratory experiment, it was found that it gave results with errors ≤10%, satisfying the needs of field application.

-

Key words:

- Polyether amine /

- Free content /

- Additive /

- Interfere /

- Measurement method

-

表 1 处理剂对胺基聚醚含量的影响程度

处理剂 加量/% 偏差/% 处理剂 加量/% 偏差/% NaOH 0.50 +80.0 LV-CMC 1.5 +23 Na2CO3 0.24 +30.0 SMP 3.0 +16 聚合醇 5.00 +2.0 SMC 3.0 +25 铵盐 2.00 +8.5 大钾 0.5 +21 表 2 不同处理剂在20 g/L D230水溶液中的总胺值测定

NaOH/

%实测值/

g·L−1理论值/

g·L−1碳酸钠/

%实测值/

g·L−1理论值/

g·L−10 20.0 20 0 20.0 20 0.1 22.9 20 0.06 23.2 20 0.2 26.1 20 0.18 25.3 20 0.5 35.0 20 0.24 26.1 20 聚合醇/

%实测值/

g·L−1理论值/

g·L−1铵盐/

%实测值/

g·L−1理论值/

g·L−10 20.0 20 0 20.00 20 1 20.3 20 1.0 20.80 20 3 20.3 20 1.5 21.37 20 5 20.4 20 2.0 21.71 20 LV-CMC/

%实测值/

g·L−1理论值/

g·L−1SMP/

%实测值/

g·L−1理论值/

g·L−10 19.9 20 0 20.06 20 0.5 21.4 20 1 20.44 20 1 22.6 20 2 21.59 20 1.5 24.6 20 3 23.27 20 SMC/

%实测值/

g·L−1理论值/

g·L−1大钾/

%实测值/

g·L−1理论值/

g·L−10 20.06 20 0 20.00 20 1 21.20 20 0.1 21.05 20 2 23.11 20 0.3 22.11 20 3 24.91 20 0.5 24.21 20 表 3 处理剂在异丙醇中的溶解性

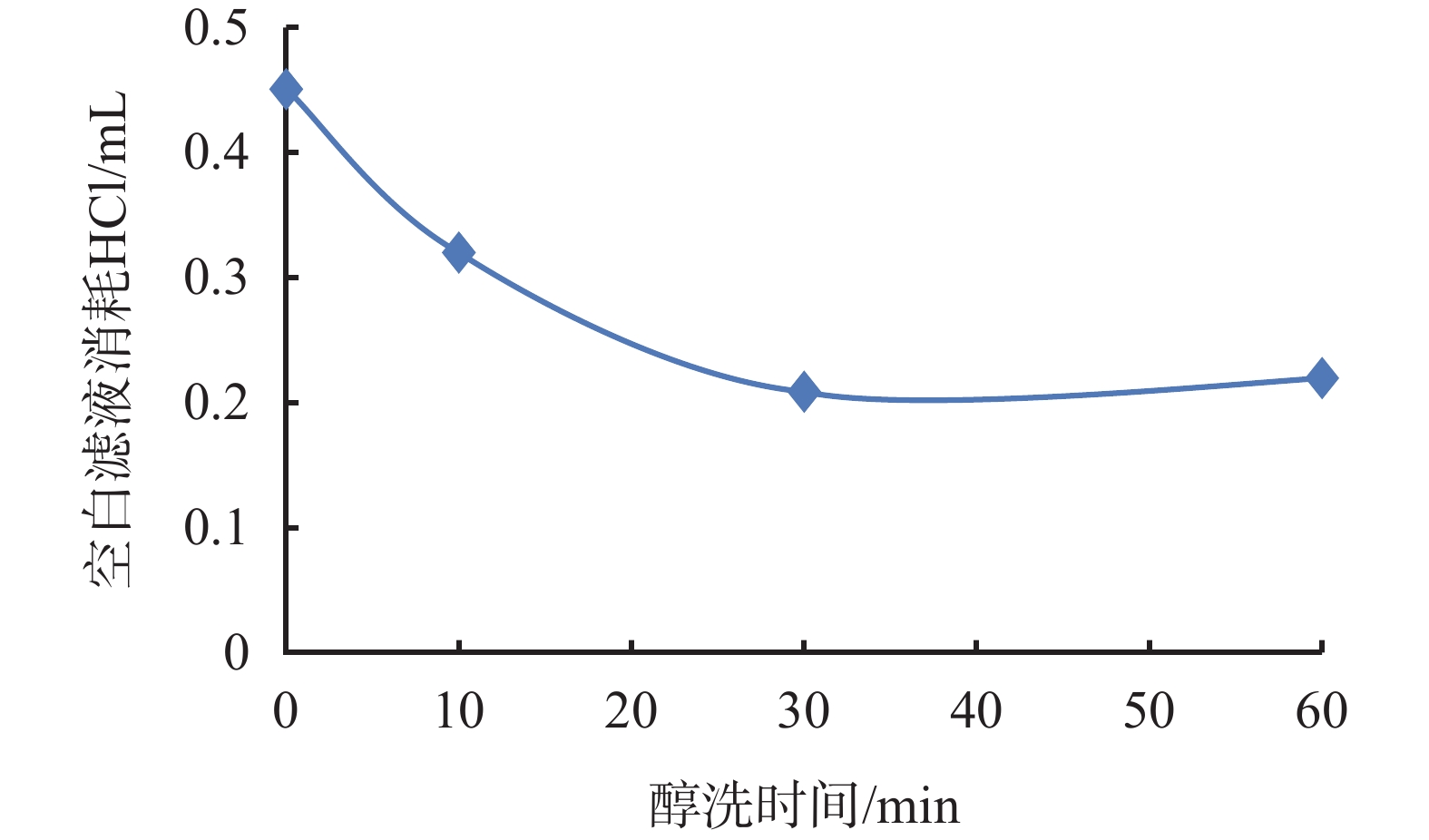

处理剂 醇洗

现象溶解性 处理剂 醇洗

现象溶解性 D230 无 易溶 SMP 絮状沉淀 不溶 NaOH 白色沉淀 不溶 SMC 黑色絮状沉淀 不溶 Na2CO3 白色沉淀 不溶 大钾 少量溶解 不溶 LV-CMC 白色沉淀 不溶 铵盐 浅褐色浑浊 微溶 表 4 不同处理剂在钻井液中的醇洗效果

处理剂 理论值/

g·L−1醇洗前/

g·L−1醇洗后/

g·L−1洗后偏差/

%0.24%Na2CO3 20.0 26.1 21.0 5.0 1.5%LV-CMC 20.0 24.6 21.5 7.5 3%SMC 20.0 24.9 20.9 4.7 3%SMP 20.0 23.3 21.2 5.9 0.5%大钾 20.0 24.2 21.4 6.9 2%铵盐 20.0 21.7 20.8 4.0 表 5 不同钻井液滤液中的胺基聚醚含量测定结果

试液 消耗盐酸体积/

mLD230/

g·L−1偏差/

%水溶液 6.50 20.0 聚合物钻井液 6.74 20.7 3.7 聚磺钻井液 7.11 21.9 9.4 饱和盐水钻井液 6.76 20.8 4.0 聚合物氯化钾钻井液 7.09 21.8 9.1 -

[1] 王荐,舒福昌,吴彬,等. 强抑制聚胺钻井液体系室内研究[J]. 油田化学,2007,24(4):296-300. doi: 10.3969/j.issn.1000-4092.2007.04.002WANG Jian, SHU Fuchang, WU Bin, et al. Laboratory study on strong inhibition polyamine drilling fluid system[J]. Oilfield Chemistry, 2007, 24(4):296-300. doi: 10.3969/j.issn.1000-4092.2007.04.002 [2] 马雷,韩洪伟,李渊. 新型改性聚胺聚合物钻井液体系室内研究[J]. 石油天然气学报(江汉石油学院学报),2010,32(4):336-338.MA Lei, HAN Hongwei, LI Yuan. Laboratory study on new modified polyamine polymer drilling fluid system[J]. Journal of Petroleum and Natural Gas Technology, 2010, 32(4):336-338. [3] 张洪伟,左凤江,贾东民,等. 新型强抑制胺基钻井液技术的研究[J]. 钻井液与完井液,2011,28(1):14-17. doi: 10.3969/j.issn.1001-5620.2011.01.005ZHANG Hongwei, ZUO Fengjiang, JIA Dongmin, et al. Research on new strong inhibition technology of amine based drilling fluid[J]. Drilling Fluid & Completion Fluid, 2011, 28(1):14-17. doi: 10.3969/j.issn.1001-5620.2011.01.005 [4] 王中华. 关于聚胺和“聚胺”钻井液的几点认识[J]. 中外能源,2012,17(11):36-42.WANG Zhonghua. Some understandings on polyamine and "polyamine" drilling fluid[J]. Chinese & Foreign Energy, 2012, 17(11):36-42. [5] 张金龙. 端氨基聚醚的合成[J]. 聚氨酯工业,2011,26(5):40-42. doi: 10.3969/j.issn.1005-1902.2011.05.012ZHANG Jinlong. Synthesis of amino-terminated polyethers[J]. Polyurethane Industry, 2011, 26(5):40-42. doi: 10.3969/j.issn.1005-1902.2011.05.012 [6] 陈明亮,崔长伟,张丽君,等. 端氨基聚醚的合成[J]. 化学推进剂与高分子材料,2013,11(3):56-59.CHEN Mingliang, CUI Changwei, ZHANG Lijun, et al. Synthesis of amino-terminated polyethers[J]. Chemical Propellants and Polymer Materials, 2013, 11(3):56-59. [7] 苏秀纯,李洪俊,代礼杨,等. 强抑制性钻井液用有机胺抑制剂的性能研究[J]. 钻井液与完井液,2011,28(2):32-35. doi: 10.3969/j.issn.1001-5620.2011.02.009SU Xiuchun, LI Hongjun, DAI Liyang, et al. Study on the performance of organic amine inhibitor for strong inhibitory drilling fluid[J]. Drilling Fluid & Completion Fluid, 2011, 28(2):32-35. doi: 10.3969/j.issn.1001-5620.2011.02.009 [8] 钟汉毅,黄维安,林永学,等. 新型聚胺页岩抑制剂性能评价[J]. 石油钻探技术,2011,39(6):44-48. doi: 10.3969/j.issn.1001-0890.2011.06.011ZHONG Hanyi, HUANG Wei'an, LIN Yongxue, et al. Performance evaluation of new polyamine shale inhibitor[J]. Petroleum Drilling Techniques, 2011, 39(6):44-48. doi: 10.3969/j.issn.1001-0890.2011.06.011 [9] 钟汉毅,邱正松,黄维安,等. 新型聚胺页岩水化抑制剂的研制及应用[J]. 西安石油大学学报(自然科学版),2013,28(2):72-77.ZHONG Hanyi, QIU Zhengsong, HUANG Wei'an, et al. Development and application of novel polyamine shale hydration inhibitor[J]. Journal of Xi'an Shiyou University (Natural Science Edition) , 2013, 28(2):72-77. [10] 邱正松,钟汉毅,黄维安. 新型聚胺页岩抑制剂特性及作用机理[J]. 石油学报,2011,32(4):678-682. doi: 10.7623/syxb201104017QIU Zhengsong, ZHONG Hanyi, HUANG Wei'an. Characteristics and action mechanism of novel polyamine shale inhibitor[J]. Acta Petrolei Sinica, 2011, 32(4):678-682. doi: 10.7623/syxb201104017 [11] 郭文宇,彭波,操卫平,等. 钻井液用低聚胺类页岩抑制剂的结构与性能[J]. 钻井液与完井液,2015,32(1):26-29. doi: 10.3969/j.issn.1001-5620.2015.01.007GUO Wenyu, PENG Bo, CAO Weiping, et al. Structure and performance of oligomeric amine shale inhibitors for drilling fluids[J]. Drilling Fluid & Completion Fluid, 2015, 32(1):26-29. doi: 10.3969/j.issn.1001-5620.2015.01.007 [12] 宋碧涛,陈雪艳,谭敏,等. 硅钼酸光度法定量测定钻井液中的聚醚多元醇含量[J]. 油田化学,2014,31(4):610-614.SONG Bitao, CHEN Xueyan, TAN Min, et al. Quantitative determination of polyether polyols in drilling fluid by silicomolybdate photometric method[J]. Oilfield Chemistry, 2014, 31(4):610-614. [13] 张妍,蓝强,薛玉志,等. 硅酸盐钻井液中二氧化硅有效含量快速测定方法研究[J]. 石油钻探技术,2009,37(5):39-42. doi: 10.3969/j.issn.1001-0890.2009.05.009ZHANG Yan, LAN Qiang, XUE Yuzhi, et al. Research on rapid determination method of silica effective content in silicate drilling fluid[J]. Petroleum Drilling Techniques, 2009, 37(5):39-42. doi: 10.3969/j.issn.1001-0890.2009.05.009 [14] 王立志. 硫酸铝—聚合物钻井液中硫酸铝含量的测定方法[J]. 油田化学,1995,12(3):276-277.WANG Lizhi. Determination method of aluminum sulfate content in aluminum sulphate-polymer drilling fluid[J]. Oil Field Chemistry, 1995, 12(3):276-277. [15] 郑小平,刘毅,靳三江,等. 现场钻井液PHPA含量测定[J]. 钻井液与完井液,2002,19(5):51. doi: 10.3969/j.issn.1001-5620.2002.05.019ZHENG Xiaoping, LIU Yi, JIN Sanjiang, et al. Field measurement of PHPA in drilling fluid[J]. Drilling Fluid & Completion Fluid, 2002, 19(5):51. doi: 10.3969/j.issn.1001-5620.2002.05.019 [16] 靳三江,陈升,王学军,等. 现场钻井液K+含量测定[J]. 钻井液与完井液,2002,19(3):13. doi: 10.3969/j.issn.1001-5620.2002.03.019JIN Sanjiang, CHEN Sheng, WANG Xuejun, et al. Field determination of K+ content in drilling fluid[J]. Drilling Fluid & Completion Fluid, 2002, 19(3):13. doi: 10.3969/j.issn.1001-5620.2002.03.019 [17] 郭建华, 马文英, 刘晓燕, 等 . 聚胺抑制剂的测定方法及最佳用量的确定[J].钻井液与完井液, 2016, 33(3): 35-40.GUO Jianhua, MA Wenying, LIU Xiaoyan, et al. Ploya mine shale inhibitor content measurement and determination of optimum dosage[J]. Drilling Fluid & Completion Fluid , 2016, 33(3): 35-40. -

下载:

下载: