Application of Two-Stage Strengthened Bridging Technique in Well Nanpu27-Ping201

-

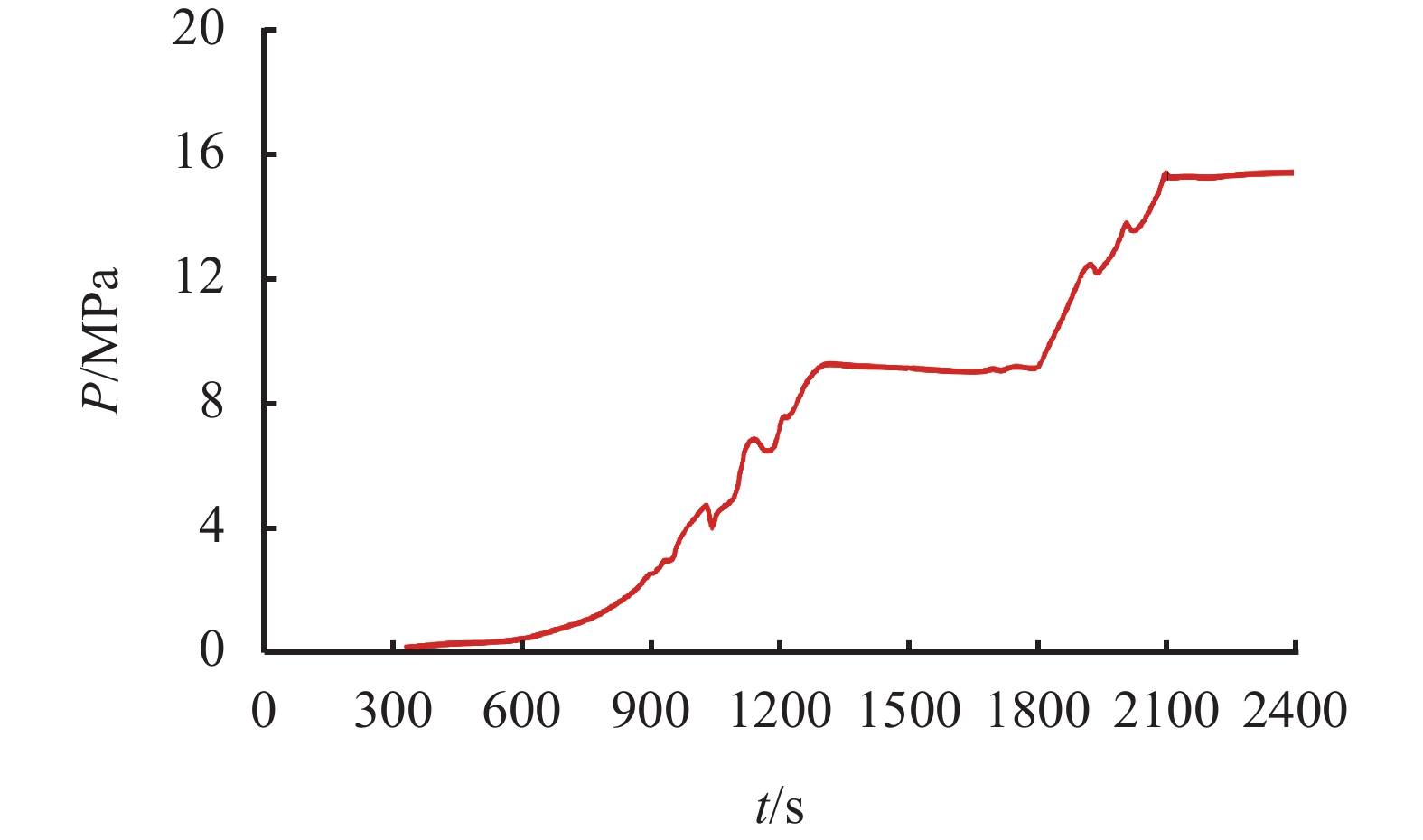

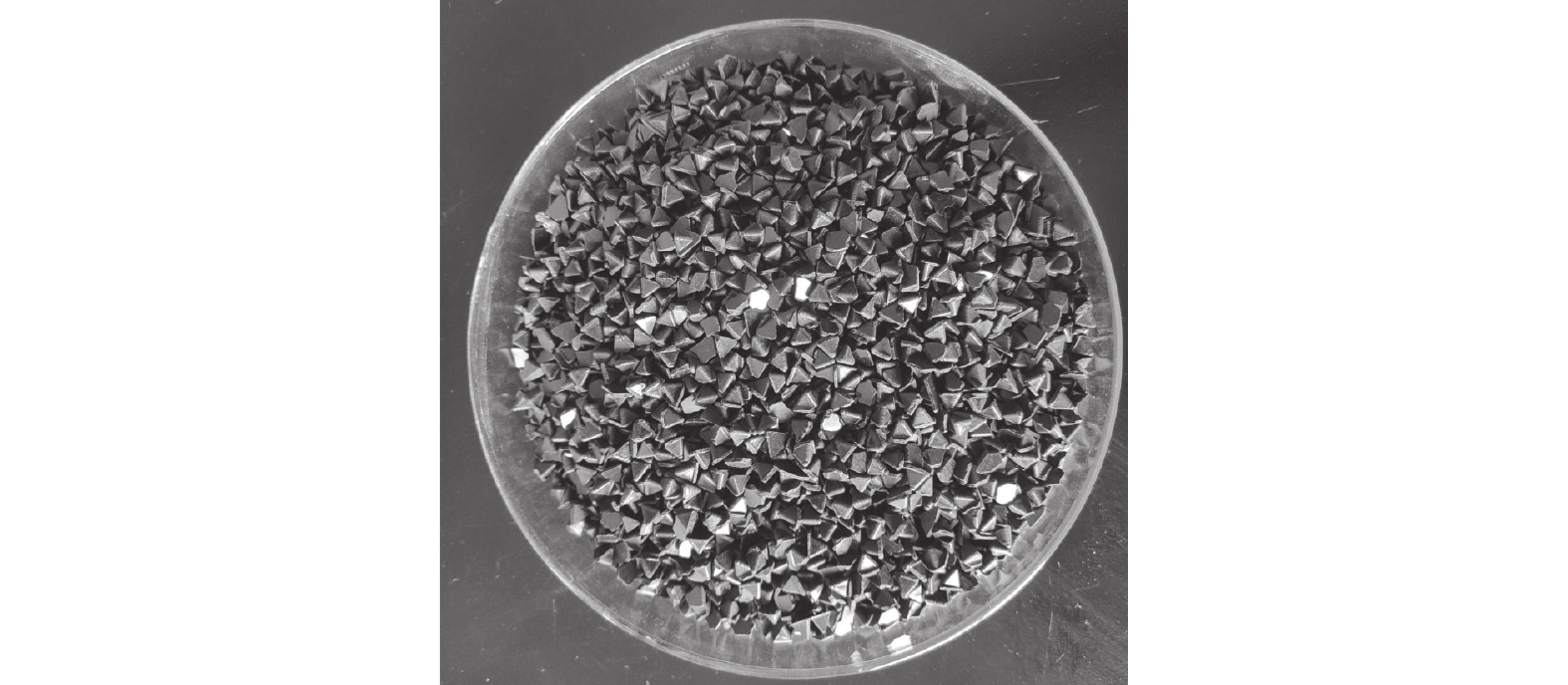

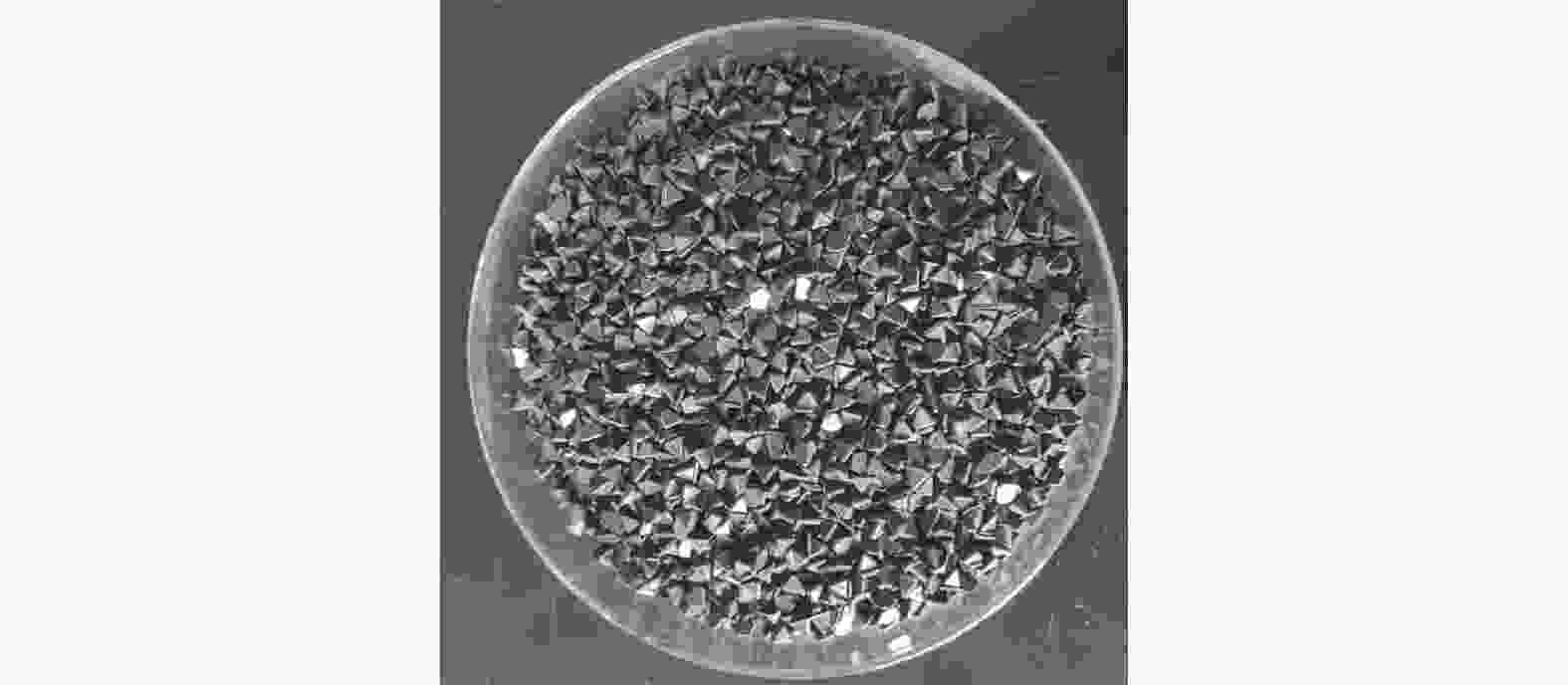

摘要: 冀东油田南堡2号构造2-27区块东三段发育多套火成岩,裂缝和孔洞发育,承压能力低,同井段深灰色泥岩坍塌压力高,安全密度窗口极窄,尤其是大斜度井垮塌与井漏矛盾异常突出,极易引发多重事故复杂。南堡27-平201井实钻过程中发生多次井漏,其中钻至井深4574 m发生钻井液失返后,进行2次桥接堵漏效果不佳,综合分析井下情况采用两段式桥堵增效技术,第一段堵漏浆以中细颗粒为主,辅助3%固结材料,实验结果显示加入固化剂后堵漏浆具备安全可泵性,堵塞层更致密,内摩擦力可提高6倍,第二段优选抗高温三角锥形树脂颗粒,充分发挥其易进入、易滞留、抗返排的特点,施工过程采取平推堵漏工艺,一次堵漏成功,后续施工未发生复漏。Abstract: Wells drilled in the Dongsan member of the 2-27 block, the 2nd Structure in Jidong Oilfield penetrate several sections of igneous rocks with fractures, vugs and low pressure-bearing capacity. In the same interval of the wells, there are dark gray colored shales with high collapse pressure and very narrow safe drilling window. In deviated well drilling, the coexistence of wellbore collapse and mud losses is frequently encountered, resulting in many downhole accidents. In the drilling operation of the well Nanpu27-Ping201, mud losses were encountered several times. One of the severe mud losses, lost circulation, took place when drilled to 4,574 m. Bridging method was tried twice without success in controlling the lost circulation. Based on the analysis of the downhole situations, it was decided to use the two-stage strengthened bridging method to cure the mud loss. In the first stage, the lost circulation control slurry was formulated mainly with fine and medium particles and 3% solidifying agent. Laboratory test results showed that when the solidifying agent was added, the lost circulation control slurry still has good pumpability, the particles pack much denser, and the internal friction of the slurry was increased by 6 times. In the second stage, a high temperature, high-temperature resin particles in triangular-cone shape were used to control the mud loss. The resin particles are easy to go into the channels through which the mud was lost, and are easy to be retained in the channels. If it is necessary, the resin particles are also easy to flow back. The lost circulation control slurry was pushed and squeezed into the channels and the mud loss was controlled in the first try. In subsequent drilling operation, no mud losses occurred again.

-

表 1 第一

段堵漏浆基浆的性能优化 配方 ρ/

g·cm−3FV/

s流动度/ cm 常温 120 ℃、16 h 1# 1.49 102 26.2 25.5 1#+堵漏材料 9.5 7.8 2# 1.49 78 33.5 35.0 2#+堵漏材料 22.0 20.5 3# 1.49 56 超测试玻璃边缘 超测试玻璃边缘 3#+堵漏材料 25.0 23.0 注:1#为南堡27-平201井现场浆;2#为1#基浆+10%胶液+

重晶石;3#为1#基浆+20%胶液+重晶石表 2 在桥接堵漏浆中加入不同加量固结材料对堵漏浆性能的影响

固结材料/

%流动度/cm 不同候堵时间的摩擦力/N 常温 120 ℃、16 h 0 h 1 h 3 h 5 h 0 26.0 24.5 3.0 3.0 2.6 2.2 1 23.8 22.2 4.4 7.6 8.0 8.2 2 22.0 20.5 7.2 10.8 11.4 11.8 3 19.1 17.5 10.6 15.0 15.4 15.8 5 9.8 6.5 注:桥接堵漏浆配方为:2#基浆+ 3%果壳(3~5 mm)+3%果壳(1~3 mm)+ 5%水化膨胀复合堵漏剂BZ-STAⅡ 型+

5%水化膨胀复合堵漏剂BZ-STAI型+3%随钻堵漏剂BZ-ACT+2%石棉纤维+2%贝壳粉表 3 针对5 mm裂缝配方优化实验结果

配方 配方 P突破/ MPa P返排/ MPa 4# 井浆+6%果壳(5~8 mm)+4%果壳(3~5 mm)+3%果壳(1~3 mm)+

7%BZ-STA Ⅱ型+5%BZ-STA Ⅰ型+3%BZ-ACT+2%石棉绒+

2%贝壳粉,总浓度32%9.52 1.5 5# 井浆+4%果壳(5~8 mm)+4%果壳(3~5 mm)+3%果壳(1~3 mm)+

7%BZ-STA Ⅱ型+5%BZ-STA I型+3%BZ-ACT+2%石棉绒+2%贝壳粉+

2%三角锥颗粒(6 mm),总浓度32%13.49 2.3 6# 井浆+4%果壳(5~8mm)+3%果壳(3~5 mm)+3%果壳(1~3 mm)+

7%BZ-STA Ⅱ型+5%BZ-STA I型+3%BZ-ACT+2%石棉绒+

2%贝壳粉+3%三角锥颗粒(6 mm),总浓度32%15.77 3.4 7# 井浆+3%果壳(5~8 mm)+3%果壳(3~5 mm)+3%果壳(1~3 mm)+

7%BZ-STA Ⅱ型+5%BZ-STA I型+3%BZ-ACT+2%石棉绒+

2%贝壳粉+4%三角锥颗粒(6 mm),总浓度32%15.82 3.5 -

[1] 李锦峰. 恶性漏失地层堵漏技术研究[J]. 探矿工程(岩土钻掘工程),2019,46(5):19-27.LI Jinfeng. The status and development direction of plugging technology for severe circulation loss formation[J]. Exploration Engineering (Rock & Soil Drilling and Tunneling) , 2019, 46(5):19-27. [2] 陈军,王先兵,刘松,等. 恶性井漏治理现状及展望[J]. 石油化工应用,2017,36(6):12-15.CHEN Jun, WANG Xianbing, LIU Song, et al. Serious lost circulation current situation and disposing prospects[J]. Petrochemical Industry Application, 2017, 36(6):12-15. [3] 韩立国. 新型随钻防漏堵漏钻井液技术研究 [J].钻采工艺, 2015, 38( 3) : 37-39, 42HAN Liguo. Study on new type of lost circulation additive[J]. Drilling & Production Technology, 2015, 38( 3) : 37-39, 42 [4] 王悦坚. 塔河油田恶性漏失堵漏与大幅度提高地层承压技术[J]. 钻井液与完井液,2013,30(4):33-36.WANG yuejian. Technology on mud lost control of severe lost circulation and improving formation pressure containment in Tahe oilfield[J]. Drilling Fluid & Completion Fluid, 2013, 30(4):33-36. [5] 孙金声,白英睿,程荣超,等. 裂缝性恶性井漏地层堵漏技术研究与展望[J]. 石油勘探与开发,2021,48(3):630-638.SUN Jinsheng, BAI Yingrui, CHENG Rongchao, et al. Research progress and prospect of plugging technologies for fractured formation with severe lost circulation[J]. Petroleum Exploration and Development, 2021, 48(3):630-638. [6] 李大奇, 刘四海, 康毅力, 等. 天然裂缝性地层钻井液漏失规律研究[J]. 西南石油大学学报(自然科学版),2016,38(3):101-106.LI Daqi, LIU Sihai, KANG Yili, et al. Dynamic behavior of drilling fluid leakage in naturally fractured formations[J]. Journal of Southwest Petroleum University (Natural Science Edition) , 2016, 38(3):101-106. [7] 邱元瑞,马海云,刘荣伟,等. 雷特堵漏技术在冀东油田NP13-1170 井的应用[J]. 石油地质与工程,2021,35(3):105-107.QIU Yuanrui, MA Haiyun, LIU Rongwei. Application of Leite plugging technology in well NP13-1170 of Jidong oilfield[J]. Petroleum Geology and Engineering, 2021, 35(3):105-107. [8] 邹和均,余丽彬,汪志强,等. 塔河油田托普区块二叠系高承压堵漏技术[J]. 钻井液与完井液,2011,28(4):78-80.ZOU Hejun, YU Libin, WANG Zhiqiang, et al. Research on technology of sealing under high pressure in Permian Tuofu block of Tahe oilfield[J]. Drilling Fluid & Completion Fluid, 2011, 28(4):78-80. [9] 黄达全,刘永存. 承压堵漏技术在AT5井的应用[J]. 钻井液与完井液,2007,24(4):78-80.HUANG Daquan,LIU Yongcun. Application of mud loss control under pressures technology in well AT5[J]. Drilling Fluid & Completion Fluid, 2007, 24(4):78-80. [10] 梁文利. 深层页岩气油基钻井液承压堵漏技术[J]. 钻井液与完井液,2018,35(3):37-41. doi: 10.3969/j.issn.1001-5620.2018.03.006LIANG Wenli. Enhancing pressure bearing capacity of formation to control mud losses in deep shale gas drilling with oil base drilling fluids[J]. Drilling Fluid & Completion Fluid, 2018, 35(3):37-41. doi: 10.3969/j.issn.1001-5620.2018.03.006 [11] 赵宏波,杨松,陈国飞,等. 分级堵漏技术在鄂尔多斯盆地东部的应用[J]. 钻井液与完井液,2021,38(5):583-592.ZHAO Hongbo, YANG Song, CHEN Guofei, et al. Study and application of mud loss control technique with graded lcms in theeast of Ordos basin[J]. Drilling Fluid & Completion Fluid, 2021, 38(5):583-592. -

下载:

下载: