Drilling Fluid with Superior Plugging Performance Used in Deep Well Drilling in Manshen Block

-

摘要: 满深区块中深部地层断裂破碎,微裂缝发育,且黏土矿物含量高,组分差异大,硬脆性和水敏性泥页岩相互共存,钻井过程中易发生水力劈裂和水化不等速膨胀而导致的井壁失稳。为此,提出了“物理支撑+化学抑制封堵”防塌技术对策,并构建了多元协同防塌强封堵钻井液。室内评价表明:强封堵钻井液抗温达180 ℃;抗10%饱和盐水污染;T层和S层岩样滚动回收率高达89.36%和91.33%、膨胀率低至7.3%和4.2%;能有效封堵20~120目不同粒径石英砂间微孔隙。该钻井液在ManS5-H4井现场应用中性能稳定,流变性好,滤失量低,具有较好的抑制和防塌性能,解决了中深部地层阻卡、坍塌掉块和扩径等井壁失稳问题,井眼通畅规则,二、三开井段平均井径扩大率分别为4.28%和6.75%,返出岩屑代表性好,无钻井液事故发生,能满足复杂地层复杂工艺钻进需要,提高了钻井综合效益。Abstract: The deep formations drilled in the Manshen block are broken and full of microfractures. They have high clay contents with large differences in clay composition. Hard and brittle shales and water-sensitive shales are coexisting in the formations drilled. These formations easily lose their stability during drilling because of hydraulic splitting and difference in the speed of hydration. A technical measure named “physical support plus chemical inhibition and plugging” was presented and an anti-collapse drilling fluid with superior plugging capacity formulated to deal with the borehole wall instability problem. Laboratory study showed that the drilling fluid functioned normally at 180 ℃ and was able to resist contamination by 10% saltwater. Shale samples taken from the T layer and S layer were tested in the drilling fluid formulated. Hot rolling test gave percent cuttings recovery of 89.36% and 91.33% respectively, and expansion test gave rate of expansion of 7.3% and 4.2% respectively. This drilling fluid can plug the pores in cores made with quartz particles from 20 mesh to 120 mesh. In drilling the well ManS5-H4, the drilling fluid showed stable properties and had low filtration rate. It had good inhibitive capacity and collapse prevention performance. Tripping was smooth with no overpulls and resistance, the second and the third interval found average hole enlargement of 4.28% and 6.75% respectively. The cuttings returned to the shake shakers kept their original shakes and no downhole troubles were ever encountered. This drilling fluid has satisfied the needs of drilling the complex formations and saved the total cost of drilling.

-

Key words:

- Deep well /

- Plugging /

- Broken and fractured /

- Borehole wall stabilization /

- High pressure saltwater

-

满深区块位于塔里木盆地塔北与塔中两大隆起的鞍部[1],是塔里木油田深层油气勘探开发的重点新区。目的储层奥陶系碳酸盐岩顶面埋藏深度大于7000 m,是超深断控岩溶为主的碳酸盐岩油气藏。深井钻探需穿越多套地质层序,存在地温梯度高、岩性特殊多样、断裂破碎程度高和伴生高压盐水等诸多难点[2-4],对钻井液技术要求较高。前期部署的深探井上部地层施工顺畅,机械钻速较高;而中深部时有发生阻卡、坍塌掉块、扩径、卡钻和井漏等不同程度井壁失稳[5-14]。具体表现为三叠系、石炭系和志留系泥岩剥蚀掉块,二叠系火成岩漏失与垮塌,奥陶系桑塔木组泥岩坍塌与憋阻等。井壁失稳极易造成井眼不规则,甚至经反复划眼、倒划眼后上提下放时仍有挂卡显示,顶驱频繁憋停,严重滞缓了勘探与开发进程。由于各服务公司钻井液处理理念上的差异和对地层的认识不充分,此问题仍未能得到有效解决。针对该区块中深部地层井壁失稳难题,室内开展强封堵钻井液体系技术研究,该技术在现场应用中取得较好的应用效果。

1. 地层特点及钻井液技术对策

1.1 地层岩性及钻井液难点

由邻井资料可知:该区块发育多条走滑断裂,形成多个断控缝洞型碳酸盐岩圈闭。根据压力预测确定了四开井身结构,三个必封点分别对应封隔地表疏松地层、二叠系火成岩易漏地层及一间房组顶以上伴生高压盐水地层。

一开井段:钻遇第四系至新近系地层,岩性为泥岩、泥质粉砂岩和粉砂岩不等厚互层,易水化造浆,易形成虚厚泥饼,易造成泥包钻头和阻卡。

二开井段:钻遇新近系至石炭系地层,上部岩性为泥岩、泥质粉砂岩和粉砂岩不等厚互层,中部三叠系以含砾细砂岩与砂质小砂砾为主,间杂碳质泥岩;二叠系为凝灰岩及玄武岩;下部石炭系为泥岩、钙质粉砂岩与泥灰岩、灰岩略等厚互层。三叠系泥岩胶黏性强,易造成泥包;二叠系、石炭系微裂缝发育,易发生剥蚀性掉块,易造成阻卡、扩径和“糖葫芦”井眼。

三开井段:钻遇石炭系至奥陶系一间房顶地层,上部志留系为粉砂质泥岩与细砂岩、含沥青质细砂岩互层。中下部奥陶系铁热克阿瓦提组为细砂岩、粉砂岩、泥质粉砂岩、绿灰色泥岩不等厚互层;桑塔木组以泥灰岩、泥质灰岩为主,常发育侵入岩。铁热克阿瓦提组和桑塔木组存在破裂带,破碎程度高,且发育高压盐水层,地层承压能力低,易垮塌掉块,造成阻卡、憋钻,且伴生高压盐水易溢流污染浸泡井壁。

四开井段:钻遇奥陶系一间房组地层,岩性为亮晶、泥晶砂屑灰岩夹泥晶灰岩及生屑灰岩,地层缝洞发育,易漏、易溢流,且含H2S含量高,安全风险大。

1.2 井壁失稳机理分析

1.2.1 黏土矿物成分分析

取邻井中深部不同地层代表性岩样进行全岩X-射线衍射和黏土矿物成分分析,岩石矿物成分以石英和方解石为主,含少量斜长石,石英含量为31.2%~47%;黏土矿物含量在14.5%~63%,以伊利石和伊/蒙混层为主,局部富含高岭石和绿泥石。各地层组分占比差异大,T地层伊/蒙混层含量范围在74%~94%;P地层伊/蒙混层含量在50%~83%;C地层伊/蒙混层含量在16%~67%,局部含高岭石量达71%;D地层伊/蒙混层含量在18%~87%,局部含绿泥石量达46%~71%;S地层伊利石含量在24%~64%,伊/蒙混层含量在10%~56%;O地层伊利石含量在18%~54%,伊/蒙混层含量在17%~50%;地层具有潜在水化能力,且膨胀性存在较大差异。具体情况见表1。

表 1 满深区块各层段黏土矿物组分平均相对含量层

位样品数

(个)黏土矿物组份相对含量/% 混层比/% I K C I/S C/S I/S混层 C/S混层 J 8 15.60 65.90 11.40 7.10 25 T 7 7.80 6.30 7.30 78.60 75~100 P上 4 13.80 13.00 14.00 59.20 65~85 P下 5 13.60 7.80 6.20 61.40 11 50~65 C上 6 38.80 5.70 9.70 45.80 50~80 C下 5 16.60 54.40 8.80 20.20 15~25 D上 19 22.16 7.26 8.42 62.16 20~70 D下 8 18.25 7.62 53.75 20.38 15~30 S上 12 40.75 6.58 15.25 37.42 20 S中 6 27.67 10.50 14.30 20.20 27.33 20 20~30 S下 14 20.28 2.57 45.71 31.44 20 O 23 44.48 9.26 22.52 23.74 20 1.2.2 微观结构特征

取邻井中深部不同地层代表性岩样进行SEM电镜扫描分析,可以看出三叠系岩样结构松散,孔隙较发育,黏土矿物以伊蒙混层为主;石炭系岩样微裂缝和溶蚀孔隙发育,黏土矿物组分以伊利石和伊蒙混层为主;志留系岩样构造较疏松,微裂缝发育, 黏土矿物组分以伊蒙混层和伊利石为主;奥陶系桑塔木组岩样构造疏松,微裂缝、孔隙发育,黏土矿物组分以伊蒙混层和伊利石为主。

1.2.3 井壁失稳机理分析

结合地质特征、室内岩样矿物组分测试、电镜扫描结果及现场钻井情况中可知:满深区块中深部地质条件复杂,岩性多样,地层断裂破碎,微裂缝发育,外来液相侵入易造成井壁失稳,导致井漏、剥落掉块、阻卡和扩径等井下复杂,分析如下。

1)地层应力平衡破坏引起的井壁失稳。满深区块经历了加里东、海西、燕山、喜马拉雅等多期地质构造运动,地层存在倾角,当井眼被钻开后,原有应力平衡被破坏,根据剪切破裂理论模型,钻井液液柱压力不足以支撑时,井壁周围岩石所受应力超过岩石本身极限强度,发生力学失稳,产生剪切破坏造成剥落、坍塌等。

2)“水力劈裂”作用引起的井壁失稳。满深区块中深部地层岩石被压实,基岩致密,微裂缝或层理发育,在地应力或钻井液液柱压力作用下,钻井液的侵入将产生诱导裂缝,引起地层内部微裂缝的扩展。具体表现为对密度较敏感,易垮易漏。

3)水化膨胀作用引起井壁失稳。满深区块中深部地层的黏土矿物含量高,以伊利石和伊/蒙混层为主,局部富含高岭石和绿泥石,水敏性泥岩和硬脆性泥岩2种典型岩样相互共存,各矿物组分占比差异大,地层具有潜在的水化能力,且膨胀性存在较大差异。随着井深的增加,水化作用有所减弱,多属于弱膨胀、硬脆性泥岩[15-18]。 ①水敏性泥岩:水化作用造成岩石内膨胀压增加,改变了井周应力分布,减小了岩石的有效应力,同时使得岩石颗粒间胶结力减弱,岩石强度降低,坍塌压力增加;②硬脆性泥岩:岩石微裂缝发育,黏土矿物组分水化能力、水化速度和膨胀程度存在差异,诱发次生裂隙,加强水力劈裂作用,导致岩石剥蚀、崩塌、掉块。

1.3 钻井液技术对策

满深区块中深部地层岩石矿物组成,微观构造、孔渗性质等具有个体性和特殊性。现用聚磺体系在高温稳定性、流变性控制和抗污染性等方面有不错表现,而在化学抑制、化学封堵方面有所欠缺,不能完全满足钻井需要。将聚磺体系改造成KCl聚磺体系可使钻井液抑制性得到较大程度提高,但单一技术措施依旧无法改善井下情况,无法彻底根除井壁失稳问题。研究发现:水力劈裂和泥页岩水化不等速膨胀引起的井壁失稳是该区块中深部事故复杂较多的根本原因。除了满足合适的密度外,提高钻井液的抑制性和封堵性是提高井壁稳定性的技术关键。采用“物理支撑+化学抑制封堵”多元防塌技术对策,通过优选抑制剂、封堵防塌剂和抗温耐盐降滤失剂等关键处理剂,构建出适用于深井的强封堵钻井液体系,预期可降低井壁失稳可能性,达到减少井下复杂、提高钻井时效的目的。

2. 室内研究

2.1 强封堵钻井液体系配方

2.1.1 泥页岩抑制剂优选

取邻井T地层的代表性岩样,采用滚动回收率实验对其抑制性能进行评价,测得岩样在清水、5%KCl、2%NH4-HPAN-2、2%聚合醇、2%聚胺、0.3%IND30和2%硅酸钠中的滚动回收率分别为22.9%、56.70%、40.20%、36.50%、64.60%、71.16%、32.40%。由此可知,大分子聚合物IND30可以较好地包被抑制泥岩水化分散,其滚动回收率高达71.16%;KCl、聚胺滚动回收率分别为56.7%、64.6%,说明其抑制泥页岩水化分散效果也较好。考虑到流变性控制、成本和使用方便度等其他因素,优先选用KCl作为泥页岩抑制剂,辅助使用IND30和聚胺。KCl加量对钻井液性能的影响如表2所示。由表2可知,随着KCl加量的增加,钻井液的黏度、切力逐渐降低,滤失量逐渐增大,泥岩滚动回收率逐渐提高;当KCl加量为5%时,钻井液黏度、切力趋于稳定;当KCl加量为7%时,钻井液抑制泥岩水化分散和抑制膨胀能力最强。

表 2 KCl加量对钻井液性能的影响KCl/

%实验条件 回收率/

%ρ/

g·cm−3PV/

mPa∙sYP/

PaGel/

Pa/PaFLAPI/

mL0 常温 80.60 1.30 20 18.5 6.0/9.5 6.8 80 ℃×16 h 1.30 22 21.0 6.5/11.5 6.0 1 常温 87.60 1.32 15 19.0 5.5/6.5 8.0 80 ℃×16 h 1.32 18 21.0 5.5/6.5 6.8 3 常温 89.06 1.32 15 17.0 4.5/5.5 8.3 80 ℃×16 h 1.32 18 17.5 4.5/5.5 7.4 5 常温 94.06 1.32 15 17.0 4.0/5.0 8.6 80 ℃×16 h 1.32 17 17.5 3.5/4.5 7.8 7 常温 95.80 1.32 15 16.0 3.5/5.0 9.0 80 ℃×16 h 1.32 17 17.0 3.0/4.5 8.2 10 常温 93.84 1.32 15 16.0 3.5/4.5 10.4 80 ℃×16 h 1.32 18 16.0 3.0/4.5 9.6 注:配方:3%膨润土+0.3%Na2CO3+0.1%NaOH+0.6%

IND30+0.5%NH4-HPAN-2+0.5%THJN+加重剂;pH值为92.1.2 封堵防塌剂优选

结合前期研究成果,150 ℃时,SMP-1和SMP-2降滤失效果较差,SMP-3降滤失效果相对较好,且流变性控制较好;180 ℃时,SMP-1和SMP-2降滤失效果有所改善;SMP-3降滤失效果仍较好,故选用SMP-3作为主降滤失剂。以实验浆配方为基浆,分别加入不同封堵防塌剂,加重至钻井液密度为1.36 g/cm3,测试其老化后的性能,结果见表3。如表3所示,在150 ℃滚动16 h后,DYFT-2和FT-1A的中压滤失量、120 ℃和150 ℃高温高压滤失量相对较小,说明其封堵效果较好。SY-A01在120 ℃时高温高压滤失量小于15 mL,在井温120 ℃及以下时,也可以选用为封堵防塌剂。加入超细碳酸钙YX几乎不影响钻井液流变性,滤失量降低。

表 3 在基浆中加入不同防塌剂的性能(150 ℃、16 h)防塌剂 PV/

mPa·sYP/

PaGel/

Pa/PaFLAPI/

mLFLHTHP/mL 120 ℃ 150 ℃ 0 5 1.5 1.0/3.0 12.0 20.0 25.0 2%SY-A01 6 3.0 2.0/4.0 7.0 14.8 18.5 2%FT342 8 1.5 0.5/1.5 7.8 16.4 21.0 3% DYFT-2 8 5.0 1.5/5.0 4.4 13.6 17.0 2%FT103 6 1.0 0.5/2.5 7.6 17.6 26.0 3%FT-1 6 0.5 0.5/2.0 8.9 18.0 19.2 3%FT-1A 10 3.5 1.5/3.5 4.8 14.2 17.6 3%RLQ-2 8 2.0 0.5/3.0 7.2 15.5 19.0 2%YX 5 2.0 1.5/4.0 10.8 16.8 24.2 注:基浆为:5%膨润土浆+5%SMP-3+5%SPNH+7%KCl+

0.2%NaOH封堵防塌剂的优选复配性能评价实验见表4。由表4可以看出,在150 ℃滚动16 h后,DYFT-2和FT-1A复配使用可以降低中压滤失量和高温高压滤失量,说明复配后的封堵效果更好;加入超细碳酸钙YX、随钻堵漏剂SQD-98或DF-1,钻井液的黏度、切力略增,滤失量进一步降低,说明其粒径配比得到优化,封堵效果得到加强。

表 4 封堵防塌剂优选复配性能评价实验(150 ℃、16 h)防塌剂 PV/mPa·s YP/Pa Gel/(Pa/Pa) FLAPI/mL FLHTHP/mL 0 5 1.5 1.0/3.0 12.0 25.0 2%DYFT-2+2%FT-1A 9 2.5 2.5/5.0 6.8 17.2 2%DYFT-2+2%FT-1A +2%SYA01 10 2.5 2.5/6.5 5.5 15.6 2%DYFT-2+2%FT-1A +2%YX 9 4.5 2.5/6.5 4.0 14.8 2%DYFT-2+2%FT-1A+2%YX+2%SQD-98(细) 12 5.0 3.0/8.0 3.2 13.2 2%DYFT-2+2%FT-1A+2%YX+2%DF-1 9 5.0 3.0/7.0 3.6 14.2 注:FLHTHP在150 ℃测定 2.1.3 辅助降滤失剂优选

收集油田常用抗温耐盐降滤失剂,进行对比评价实验,结果见表5。由表5可以看出:在150 ℃滚动老化16 h后,XCD-LV可以增加基浆初终切力,但其滤失量相对较大,说明其抗温性较差;CMC-LV和PAC-LV可以增加基浆塑性黏度和动切力,同时滤失量较小,说明其抗温性和降滤失效果较好;当PAC-LV与KJAN、NH4-HPAN-2、JNF-3和TYJS-1复配使用时,可以达到维持相对低黏度、高切力;降低滤失量效果,说明复配后降滤失效果进一步加强。

表 5 降滤失剂优选性能评价实验(150 ℃、16 h)降滤失剂 PV/mPa·s YP/Pa Gel/(Pa/Pa) FLAPI/mL FLHTHP/mL 0 9 4.0 2.0/6.0 4.5 15.2 0.3%CMC-LV 15 6.0 1.5/7.0 2.8 14.6 0.5%XCD-LV 15 3.5 4.5/7.5 12.4 22.0 0.3%PAC-LV 21 7.0 1.5/9.0 2.2 13.8 0.5%Redul 18 5.0 1.0/8.5 2.3 14.0 0.3%PAC-LV+0.5%Redul 31 16.0 2.0/11.0 1.8 8.6 0.3%PAC-LV+2%KJAN 22 12.0 2.5/10.0 3.0 10.4 0.3%PAC-LV+0.5%NH4-HPAN-2 26 8.5 1.5/10.5 2.8 12.4 0.3%PAC-LV+2%JNF-3 18 5.0 1.5/8.5 2.0 9.2 0.3%PAC-LV+2%TYJS-1 16 5.0 1.5/6.5 2.4 9.8 注:基浆配方:5%膨润土浆+0.4%NaOH +3%SMP-3+3%SPNH +7%KCl +2% DYFT-2 +2%FT-1A +2%YX+2%润滑剂;钻井液密度为1.36 g/cm3;FLHTHP在150 ℃测定 2.1.4 强封堵钻井液配方的确定

通过大量的室内实验,进一步优化了抗温耐盐降滤失剂,封堵防塌剂和其他辅助处理剂加量配比,最终形成了强抑制强封堵钻井液的配方如下。

4%膨润土浆+0.4% NaOH+0.3%PAC-LV+3%SMP-3+3%SPNH+2%JNF-3( 或 PSC-2)+2%DYFT-2+2%FT-1A(或SY-A01)+2%YX +2% SQD-98+2%LE-5+7%KCl+重晶石

2.2 强封堵钻井液性能

为维护中深部地层井壁稳定,需提高钻井液的抑制和封堵防塌性能,以满足现场钻井需要。因此,主要评价强封堵钻井液的抗温性、抑制性、封堵性和抗污染性等指标以验证其适应性。

2.2.1 抗温性

根据前期部署探井地质和工程设计资料,满深区块井深约为8000 m,预计中深部地层温度为150 ℃,漏失当量密度最高为1.36 g/cm3,以此为依据来评价强封堵钻井液的抗温性,实验结果如表6所示。

表 6 强封堵钻井液抗温性能评价实验测试

条件PV/

mPa·sYP/

PaGel/

Pa/PaFLAPI/

mLFLHTHP/

mLpH 老化前 20 6.0 2.5/11.0 3.2 9 150 ℃、16 h 18 5.0 3.0/9.0 2.8 9.6 9 150 ℃、24 h 18 5.0 2.5/9.0 2.8 9.8 9 150 ℃、48 h 17 4.0 2.0/7.0 3.0 10.6 9 180 ℃、16 h 16 2.5 1.5/5.5 4.5 14.2 9 注:钻井液密度为1.36 g/cm3;FLHTHP在150 ℃测定 由表6可知,在150 ℃下,滚动老化前后相比黏度、切力略微下降,滤失量有所降低,说明老化后钻井液性能更趋于稳定,老化48 h后钻井液黏度、切力仍能维持较高程度,滤失量仍较低,说明其抗温性较好;在180 ℃下,黏度、切力有所降低,滤失量有所增加,钻井液仍能维持API滤失量小于5 mL,高温高压滤失量小于15 mL,说明其抗温性能满足180 ℃高温条件。

2.2.2 抑制性

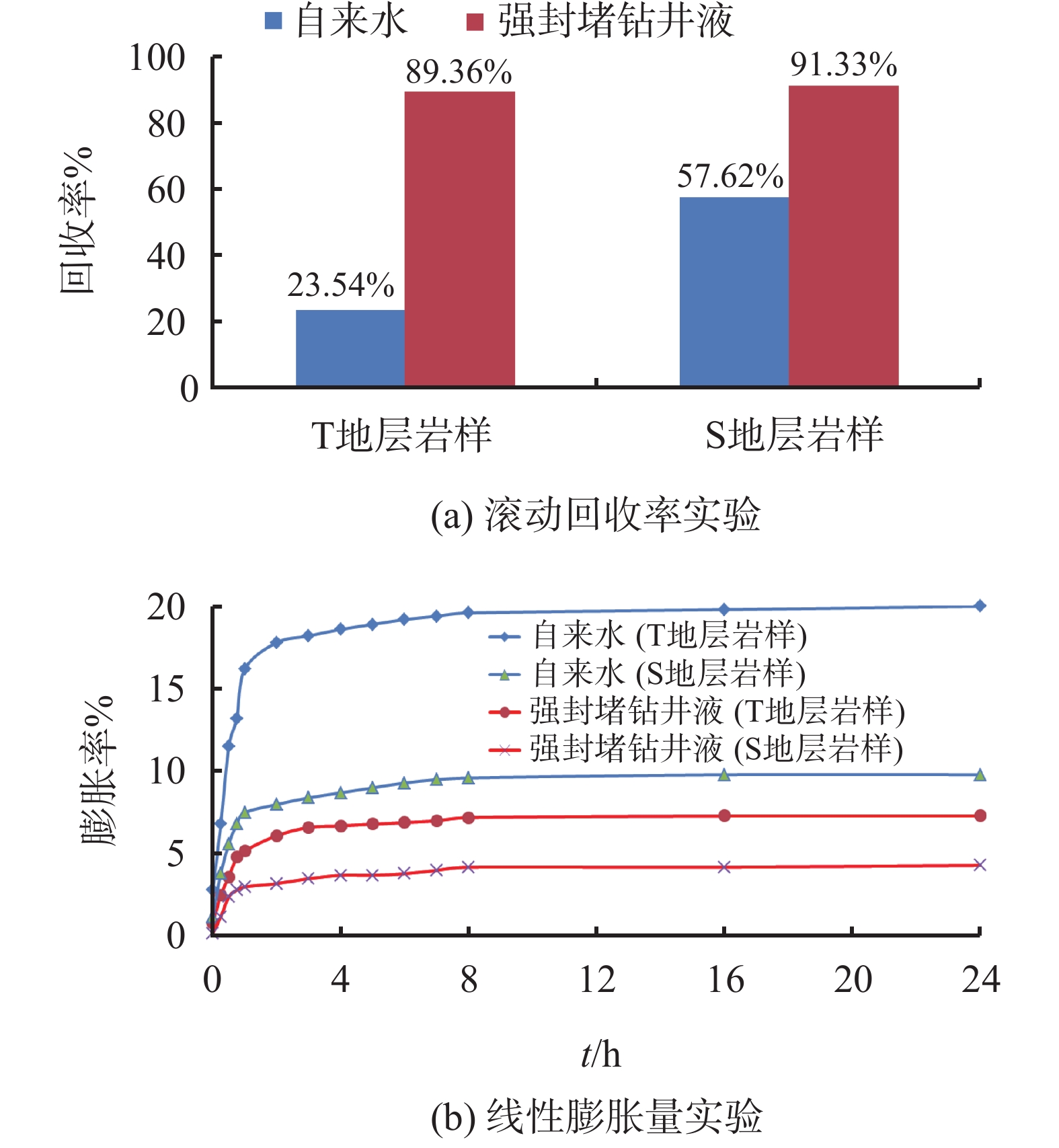

称取满深区块已钻井T,S地层代表性岩样做滚动回收实验和水化膨胀实验。T地层岩样滚动老化条件120 ℃×16 h,S地层岩样滚动老化条件140 ℃×16 h,结果见图1。由图1可知, 在强封堵钻井液中,T地层岩样滚动回收率为89.36%,S地层岩样滚动回收率为91.33%, T地层岩样膨胀率为7.3%,S地层岩样膨胀率为4.3%,均远优于自来水;说明钻井液抑制泥页岩水化膨胀能力强。

2.2.3 封堵性

采用高温高压可视型砂床滤失仪对强封堵钻井液封堵能力进行评价,用不同粒径石英砂模拟地层大小裂隙,结果见表7。由表7可以看出,在不同粒径砂床条件下,强封堵钻井液8 h侵入砂床的深度均较小,说明强封堵钻井液可以有效封堵不同砂粒间微裂隙,形成致密封堵层,阻止钻井液继续侵入,封堵效果较好。

表 7 强封堵钻井液钻井液砂床封堵性评价实验砂床粒径/目 砂床高度/cm P/MPa t/min 侵入深度/cm 20~40 30 0.7 480 4.9 40~80 30 0.7 480 4.2 80~100 30 0.7 480 3.4 100~120 30 0.7 480 2.6 2.2.4 抗盐水污染性

由调研资料知:奥陶系地层铁热克阿瓦提组和桑塔木组发育高压盐水,易溢流污染钻井液。化验返出盐水性能知,其氯离子含量较高,钙离子含量与淡水几乎一样,以此为依据,用饱和NaCl盐水模拟地层水对强封堵钻井液进行污染实验,结果见表8。由表8可以看出,强封堵钻井液在加入10%饱和盐水后,钻井液黏度、切力有所降低,滤失量有所增加,钻井液性能仍能维持较好;在加入15%饱和盐水后,钻井液密度,黏度、切力均有较大程度降低,滤失量增加较多,钻井液性能遭到一定程度破坏,需及时补加处理剂才能维护至较好,说明其抗盐水污染限为10%。

表 8 在强封堵钻井液中加入饱和盐水的抗盐水污染性能饱和盐水/

%ρ/

g·cm−3PV/

mPa·sYP/

PaGel/

Pa/PaFLAPI/

mLFLHTHP/

mLpH 0 1.36 18 5.0 3.0/9.0 2.8 9.5 9.0 5 1.35 17 5.0 3.0/8.0 3.0 11.8 9.0 10 1.33 14 3.5 2.0/5.5 3.8 14.6 8.5 15 1.28 12 3.0 1.0/3.0 5.2 19.8 8.0 20 1.25 11 1.0 0.5/1.0 5.8 22.4 8.0 3. 现场应用

ManS5-H4井是部署在满深区块满深5井区的一口超深水平井,目的层位为奥陶系一间房组。该井采用四开井身结构,一开采用Φ444.5 mm钻头开钻,钻进至井深1200 m中途完钻,下入Φ339.7 mm表层套管封固地表疏松地层;二开采用Φ311.2 mm钻头开钻,钻进至井深4830 m中途完钻,下入Φ244.5 mm技术套管封固二叠系易漏地层;三开采用Φ215.9 mm钻头开钻,钻进至井深7652 m中途完钻,下入Φ177.8 mm技术套管封固目的层顶部伴生高压盐水层;四开采用Φ152.4 mm钻头开钻,钻进至井深8116 m完钻,裸眼完井。

3.1 钻井液现场施工工艺

1)体系转换。钻进至三叠系后,在两循环周内均匀加入高浓度钾聚磺胶液,同时加入2%~3%沥青类防塌剂彻底转化为强封堵钻井液。随着井深的增加,预测井底温度达到120 ℃后,选用SMP-3作为酚醛树脂类处理剂,同时合理使用固控设备,有效清除劣质固相。造斜点后逐渐提高润滑剂含量,水平段维持含油量在4%~6%,确保钻井液具有良好的抗温、抗污染和润滑防卡能力。

2)密度控制。参照三压力剖面预测,根据地层压力监测和振动筛返砂情况合理调整钻井液密度范围,三叠系、二叠系、石炭系、泥盆系、志留系、奥陶系桑塔木组地层密度分别控制为1.25~1.27 g/cm3、1.27~1.28 g/cm3、1.28~1.3 g/cm3、1.33~1.35 g/cm3、1.33~1.36 g/cm3、1.36~1.40 g/cm3,确保在力学支撑上维持井壁稳定。

3)抑制性控制。维持井浆中KCl含量在7%左右。并监测K+含量,三叠系K+含量控制在25 000 mg/L以上,二叠系K+含量30 000 mg/L以上,志留系及以下地层K+含量20 000 mg/L以上。当发现岩屑黏软,及时补充KCl。也可向井浆中加入0.5%~2%聚胺进一步增强抑制性,加之前注意做好小型实验。

4)封堵性调控。将沥青类防塌剂、超细碳酸钙YX和随钻堵漏剂SQD-98复配使用加强封堵,并定期不断补充提高封堵效果。二叠系前加入3%沥青类防塌剂,进入二叠系提高至5%左右,同时补入2%超细碳酸钙YX,1-2%随钻堵漏剂SQD-98。随井深增加选用软化点匹配的沥青类防塌剂,三叠系、二叠系选用沥青软化点在115~125 ℃,石炭系、志留系选用125~135 ℃,奥陶系桑塔木组宜选用135 ℃以上。同时严格控制钻井液中压滤失量在5.0 mL以内,三叠系高温高压滤失量在12.0 mL以内,二叠系及以下地层高温高压滤失量在10.0 mL以内,减缓或避免泥页岩水化膨胀引起的井壁失稳。

3.2 钻井液应用效果分析

为了维护中深部地层井壁稳定,避免井下复杂,保障该井顺利钻进,在三叠系地层及以下井段(3500~8116 m)应用了强封堵防塌钻井液。其应用效果如下。

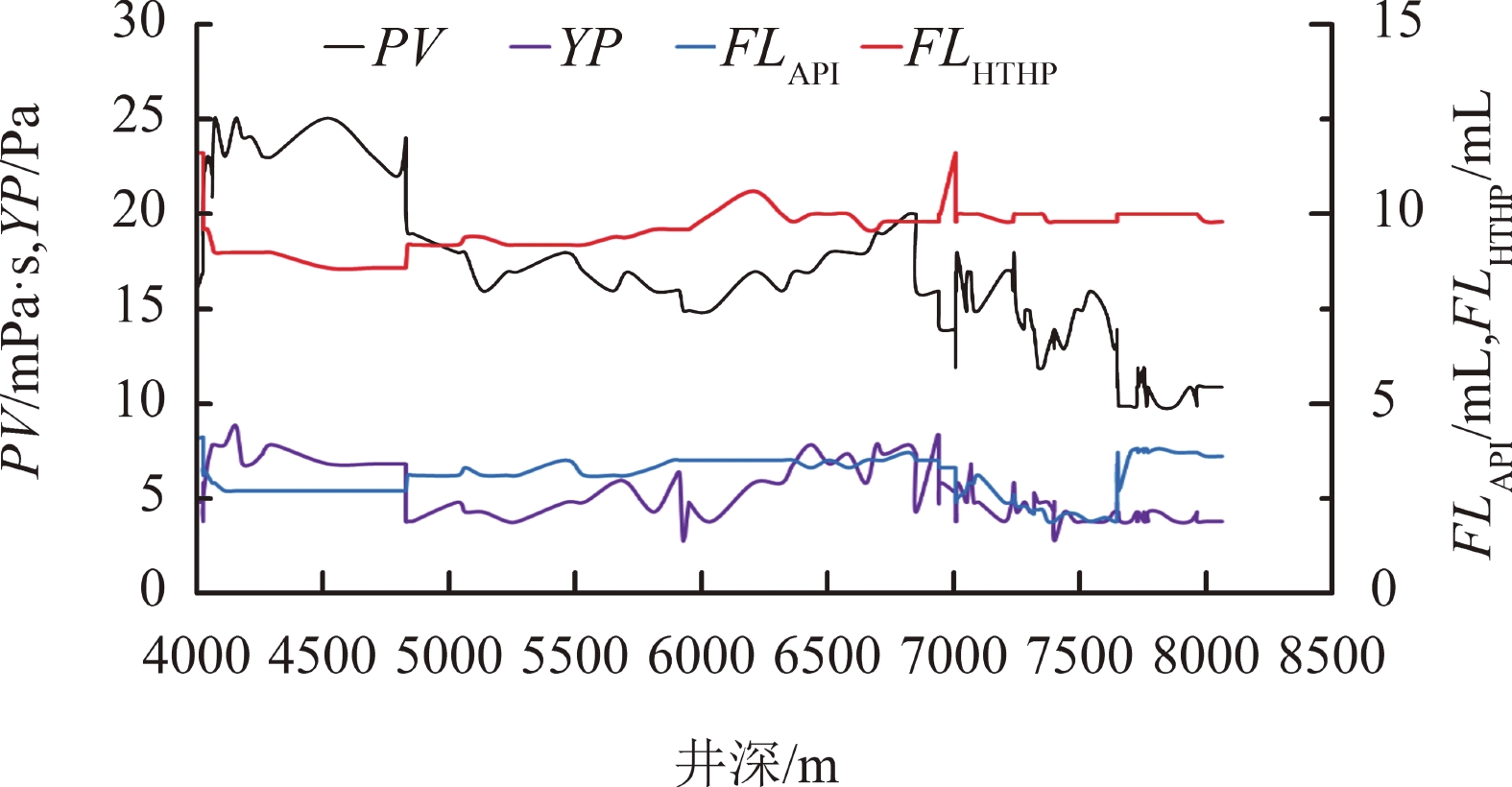

1)ManS5-H4实钻钻井液性能见图2。强封堵钻井液能适应井深和地层特点变化,性能稳定,流变性好,滤失量低,能满足该井中深部复杂地层复杂井眼轨迹钻井需求,无钻井液相关事故发生,电测、下套管等作业均一次性到位,应用效果较好。由图2可知:强封堵钻井液各开次性能稳定,动切力基本维持在5 Pa左右,中压滤失量小于5 mL,高温高压滤失量小于10 mL,能满足携岩返砂,清洁井眼钻井需求,岩屑规整代表性好。

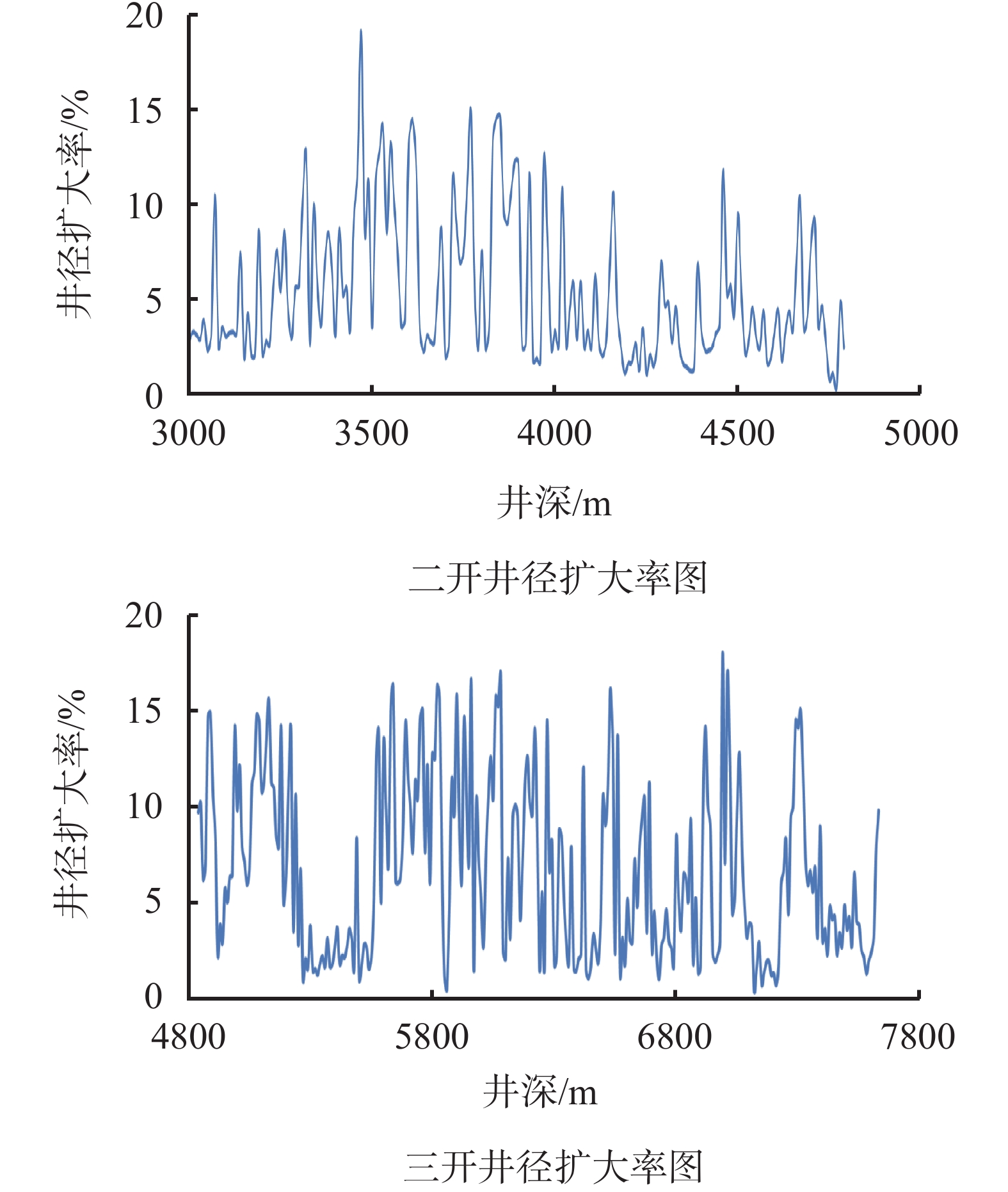

2)强封堵钻井液抑制性强,能有效抑制泥岩水化分散膨胀,降低水化不等速井壁失稳风险。如图3所示,该井井眼规则,井径扩大率较小,起下钻过程井眼通畅,无挂阻现象发生。井径扩大率能控制在钻井设计要求范围。二开井段井径平均扩大率为4.28%,三开井段井径平均扩大率为6.75%。

3)强封堵钻井液采用多元协同封堵防塌,将沥青类防塌剂、超细碳酸钙YX和随钻堵漏剂SQD-98复配使用,能封堵地层微裂缝间隙,在近井壁带形成致密封堵层,阻止钻井液固液相侵入地层,降低水力劈裂和水化不等速膨胀井壁失稳风险。同时也间接提高了地层的承压能力,在力学支撑上维持井壁稳定。该井三开井段使用钻井液密度最高为1.38 g/cm3,大于漏失压力当量密度1.36 g/cm3,钻进过程,无掉块现象发生,漏失量较邻井大幅降低。

4)强封堵钻井液抗盐水污染能力强。在奥陶系桑塔木组用1.38 g/cm3密度钻进至井深7011.31 m时遇高压盐水层,溢流盐水当量密度达1.43 g/cm3,氯离子含量高达120 000 mg/L,在关井压稳盐水过程中,井眼通畅,无垮塌掉块现象发生,钻具能轻松顺利起出,起下钻无挂卡现象。电测该井段最大井径扩大率为16.9%,溢流发生后现场变更为控压钻进工艺,在微溢情况下,钻井液流变性能保持稳定,能满足悬浮携岩,无垮塌现象发生,能满足复杂地层复杂工艺钻进需求。

4. 结论

1. 满深区块中深部地层黏土矿物含量高,组分差异大,具有潜在水化和膨胀性差异性,水力劈裂作用和水化膨胀不等速是造成井壁失稳的最直接原因,提高钻井液抑制性和加强封堵性是解决井壁失稳问题的技术关键。

2. 针对满深区块中深部地层岩性特点和钻井液技术难点,采用沥青类防塌剂、超细碳酸钙和随钻堵漏剂多元协同加强封堵防塌,构建了强封堵钻井液体系,经评价该体系钻井液抗温性达180 ℃、中压滤失量为3.0 mL,高温高压滤失量为10.6 mL/150 ℃、能封堵20~120目不同粒径石英砂间微孔隙。具有抗温性好,滤失量低,抑制性强和封堵性好等技术特点。

3. 强封堵钻井液体系在ManS5-H4井成功应用,解决了该井中深部地层阻卡、坍塌掉块和扩径等井壁失稳问题,钻井液施工过程中,井眼通畅,井径规则,岩屑代表性好,无钻井液事故发生,井下复杂大幅减少,能满足复杂地层复杂工艺钻进需要,提高了钻井综合效益,取得较好应用效果。

-

表 1 满深区块各层段黏土矿物组分平均相对含量

层

位样品数

(个)黏土矿物组份相对含量/% 混层比/% I K C I/S C/S I/S混层 C/S混层 J 8 15.60 65.90 11.40 7.10 25 T 7 7.80 6.30 7.30 78.60 75~100 P上 4 13.80 13.00 14.00 59.20 65~85 P下 5 13.60 7.80 6.20 61.40 11 50~65 C上 6 38.80 5.70 9.70 45.80 50~80 C下 5 16.60 54.40 8.80 20.20 15~25 D上 19 22.16 7.26 8.42 62.16 20~70 D下 8 18.25 7.62 53.75 20.38 15~30 S上 12 40.75 6.58 15.25 37.42 20 S中 6 27.67 10.50 14.30 20.20 27.33 20 20~30 S下 14 20.28 2.57 45.71 31.44 20 O 23 44.48 9.26 22.52 23.74 20 表 2 KCl加量对钻井液性能的影响

KCl/

%实验条件 回收率/

%ρ/

g·cm−3PV/

mPa∙sYP/

PaGel/

Pa/PaFLAPI/

mL0 常温 80.60 1.30 20 18.5 6.0/9.5 6.8 80 ℃×16 h 1.30 22 21.0 6.5/11.5 6.0 1 常温 87.60 1.32 15 19.0 5.5/6.5 8.0 80 ℃×16 h 1.32 18 21.0 5.5/6.5 6.8 3 常温 89.06 1.32 15 17.0 4.5/5.5 8.3 80 ℃×16 h 1.32 18 17.5 4.5/5.5 7.4 5 常温 94.06 1.32 15 17.0 4.0/5.0 8.6 80 ℃×16 h 1.32 17 17.5 3.5/4.5 7.8 7 常温 95.80 1.32 15 16.0 3.5/5.0 9.0 80 ℃×16 h 1.32 17 17.0 3.0/4.5 8.2 10 常温 93.84 1.32 15 16.0 3.5/4.5 10.4 80 ℃×16 h 1.32 18 16.0 3.0/4.5 9.6 注:配方:3%膨润土+0.3%Na2CO3+0.1%NaOH+0.6%

IND30+0.5%NH4-HPAN-2+0.5%THJN+加重剂;pH值为9表 3 在基浆中加入不同防塌剂的性能(150 ℃、16 h)

防塌剂 PV/

mPa·sYP/

PaGel/

Pa/PaFLAPI/

mLFLHTHP/mL 120 ℃ 150 ℃ 0 5 1.5 1.0/3.0 12.0 20.0 25.0 2%SY-A01 6 3.0 2.0/4.0 7.0 14.8 18.5 2%FT342 8 1.5 0.5/1.5 7.8 16.4 21.0 3% DYFT-2 8 5.0 1.5/5.0 4.4 13.6 17.0 2%FT103 6 1.0 0.5/2.5 7.6 17.6 26.0 3%FT-1 6 0.5 0.5/2.0 8.9 18.0 19.2 3%FT-1A 10 3.5 1.5/3.5 4.8 14.2 17.6 3%RLQ-2 8 2.0 0.5/3.0 7.2 15.5 19.0 2%YX 5 2.0 1.5/4.0 10.8 16.8 24.2 注:基浆为:5%膨润土浆+5%SMP-3+5%SPNH+7%KCl+

0.2%NaOH表 4 封堵防塌剂优选复配性能评价实验(150 ℃、16 h)

防塌剂 PV/mPa·s YP/Pa Gel/(Pa/Pa) FLAPI/mL FLHTHP/mL 0 5 1.5 1.0/3.0 12.0 25.0 2%DYFT-2+2%FT-1A 9 2.5 2.5/5.0 6.8 17.2 2%DYFT-2+2%FT-1A +2%SYA01 10 2.5 2.5/6.5 5.5 15.6 2%DYFT-2+2%FT-1A +2%YX 9 4.5 2.5/6.5 4.0 14.8 2%DYFT-2+2%FT-1A+2%YX+2%SQD-98(细) 12 5.0 3.0/8.0 3.2 13.2 2%DYFT-2+2%FT-1A+2%YX+2%DF-1 9 5.0 3.0/7.0 3.6 14.2 注:FLHTHP在150 ℃测定 表 5 降滤失剂优选性能评价实验(150 ℃、16 h)

降滤失剂 PV/mPa·s YP/Pa Gel/(Pa/Pa) FLAPI/mL FLHTHP/mL 0 9 4.0 2.0/6.0 4.5 15.2 0.3%CMC-LV 15 6.0 1.5/7.0 2.8 14.6 0.5%XCD-LV 15 3.5 4.5/7.5 12.4 22.0 0.3%PAC-LV 21 7.0 1.5/9.0 2.2 13.8 0.5%Redul 18 5.0 1.0/8.5 2.3 14.0 0.3%PAC-LV+0.5%Redul 31 16.0 2.0/11.0 1.8 8.6 0.3%PAC-LV+2%KJAN 22 12.0 2.5/10.0 3.0 10.4 0.3%PAC-LV+0.5%NH4-HPAN-2 26 8.5 1.5/10.5 2.8 12.4 0.3%PAC-LV+2%JNF-3 18 5.0 1.5/8.5 2.0 9.2 0.3%PAC-LV+2%TYJS-1 16 5.0 1.5/6.5 2.4 9.8 注:基浆配方:5%膨润土浆+0.4%NaOH +3%SMP-3+3%SPNH +7%KCl +2% DYFT-2 +2%FT-1A +2%YX+2%润滑剂;钻井液密度为1.36 g/cm3;FLHTHP在150 ℃测定 表 6 强封堵钻井液抗温性能评价实验

测试

条件PV/

mPa·sYP/

PaGel/

Pa/PaFLAPI/

mLFLHTHP/

mLpH 老化前 20 6.0 2.5/11.0 3.2 9 150 ℃、16 h 18 5.0 3.0/9.0 2.8 9.6 9 150 ℃、24 h 18 5.0 2.5/9.0 2.8 9.8 9 150 ℃、48 h 17 4.0 2.0/7.0 3.0 10.6 9 180 ℃、16 h 16 2.5 1.5/5.5 4.5 14.2 9 注:钻井液密度为1.36 g/cm3;FLHTHP在150 ℃测定 表 7 强封堵钻井液钻井液砂床封堵性评价实验

砂床粒径/目 砂床高度/cm P/MPa t/min 侵入深度/cm 20~40 30 0.7 480 4.9 40~80 30 0.7 480 4.2 80~100 30 0.7 480 3.4 100~120 30 0.7 480 2.6 表 8 在强封堵钻井液中加入饱和盐水的抗盐水污染性能

饱和盐水/

%ρ/

g·cm−3PV/

mPa·sYP/

PaGel/

Pa/PaFLAPI/

mLFLHTHP/

mLpH 0 1.36 18 5.0 3.0/9.0 2.8 9.5 9.0 5 1.35 17 5.0 3.0/8.0 3.0 11.8 9.0 10 1.33 14 3.5 2.0/5.5 3.8 14.6 8.5 15 1.28 12 3.0 1.0/3.0 5.2 19.8 8.0 20 1.25 11 1.0 0.5/1.0 5.8 22.4 8.0 -

[1] 杨海军,邓兴梁,张银涛,等. 塔里木盆地满深1井奥陶系超深断控碳酸盐岩油气藏勘探重大发现及意义[J]. 中国石油勘探,2020,25(3):13-23. doi: 10.3969/j.issn.1672-7703.2020.03.002YANG Haijun, DENG Xingliang, ZHANG Yintao, et al. Great discovery and its significance of exploration for ordovician ultra-deep fault-controlled carbonate reservoirs of well Manshen 1 in Tarim basin[J]. China Petroleum Exploration, 2020, 25(3):13-23. doi: 10.3969/j.issn.1672-7703.2020.03.002 [2] 袁国栋, 王鸿远, 陈宗琦, 等. 塔里木盆地满深1井超深井钻井关键技术[J]. 石油钻探技术, 2020, 48(4): 21-27.YUAN Guodong, WANG Hongyuan, CHEN Zongqi, et al. Key drilling technologies for the ultra-deep well Manshen 1 in the Tarim basin[J].Petroleum Drilling Techniques, 2020, 48(4): 21-27. [3] 吴柏志, 张怀兵. 满深1井碳酸盐岩地层自愈合水泥浆固井技术[J]. 石油钻探技术, 2021, 49(1): 67-73WU Bozhi, ZHANG Huaibing.Self-healing cementing technology in carbonate formation of Manshen 1 well[J]. Petroleum Drilling Techniques, 2021, 49(1): 67-73 [4] 翟科军,于洋,刘景涛,等. 顺北油气田火成岩侵入体覆盖区超深井优快钻井技术[J]. 石油钻探技术,2020,48(2):1-5. doi: 10.11911/syztjs.2020004ZHAI Kejun, YU Yang, LIU Jingtao, et al. Ultra-deep well drilling technology in the igneous invasion coverage area of the Shunbei oil and gas field[J]. Petroleum Drilling Techniques, 2020, 48(2):1-5. doi: 10.11911/syztjs.2020004 [5] 林永学, 王伟吉, 金军斌. 顺北油气田鹰1井超深井段钻井液关键技术[J]. 石油钻探技术, 2019, 47(3): 113-120.LIN Yongxue, WANG Weiji, JIN Junbin. Key drilling fluid technology in the ultra deep section of well Ying-1 in the Shunbei oil and gas field[J]. Petroleum Drilling Techniques, 2019, 47(3): 113-120. [6] 董小虎,李银婷. 塔里木盆地顺北区块二叠系井漏复杂的分析及对策[J]. 探矿工程(岩土钻掘工程),2020,47(2):59-62.DONG Xiaohu, LI Yinting. Analysis and countermeasures for complex Permian well leakage in the Shunbei block of Tarim basin[J]. Exploration Engineering ( Rock & Soil Drilling and Tunneling) , 2020, 47(2):59-62. [7] 于得水,徐泓,吴俢振,等. 满深1井奥陶系桑塔木组高性能防塌水基钻井液技术[J]. 石油钻探技术,2020,48(5):49-54. doi: 10.11911/syztjs.2020070YU Deshui, XU Hong, WU Xiuzhen, et al. High performance anti-collapse water-base drilling fluid technology of ordovician Santamu formation in well Manshen1[J]. Petroleum Drilling Techniques, 2020, 48(5):49-54. doi: 10.11911/syztjs.2020070 [8] 邱春阳,张翔宇,赵红香,等. 顺北区块深层井壁稳定钻井液技术[J]. 天然气勘探与开发,2021,44(2):81-86.QIU Chunyang, ZHANG Xiangyu, ZHAO Hongxiang, et al. Drilling-fluid system for deep borehole stability in Shunbei block, Tarim basin[J]. Natural Gas Exploration and Development, 2021, 44(2):81-86. [9] 李成,白杨,于洋,等. 顺北油田破碎地层井壁稳定钻井液技术[J]. 钻井液与完井液,2020,37(1):15-22.LI Cheng, BAI Yang, YU Yang, et al. Study and application of drilling fluid technology for stabilizing fractured formations in Shunbei oilfield[J]. Drilling Fluid & Completion Fluid, 2020, 37(1):15-22. [10] 陈修平,李双贵,于洋,等. 顺北油气田碳酸盐岩破碎性地层防塌钻井液技术[J]. 石油钻探技术,2020,48(2):12-16. doi: 10.11911/syztjs.2020005CHEN Xiuping,LI Shuanggui,YU Yang, et al. Anti-collapse drilling fluid technology for broken carbonate formation in Shunbei oil and gas field[J]. Petroleum Drilling Techniques, 2020, 48(2):12-16. doi: 10.11911/syztjs.2020005 [11] 金军斌. 塔里木盆地顺北区块超深井火成岩钻井液技术[J]. 石油钻探技术,2016,44(6):17-23.JIN Junbin. Drilling fluid technology for igneous rocks in ultra-deep wells in the Shunbei area, Tarim basin[J]. Petroleum Drilling Techniques, 2016, 44(6):17-23. [12] 谢俊, 司西强, 赵虎, 等. 顺北深井磺化钻井液起泡原因及解决思路[J]. 精细石油化工进展, 2019, 20(6): 1-6.XIE Jun, SI Xiqiang, ZHAO Hu, et al. Discussion on causes of sulfonated drilling fluid foaming and solution to this problem in deep wells of Shunbei oilfield[J]. Advances in Fine Petrochemicals, 2019, 20(6): 1-6. [13] 吴雄军,林永学,宋碧涛,等. 顺北油气田奥陶系破碎性地层油基钻井液技术[J]. 钻井液与完井液,2020,37(6):701-708. doi: 10.3969/j.issn.1001-5620.2020.06.004WU Xiongjun, LIN Yongxue, SONG Bitao, et al. Oil base drilling fluid technology for drilling broken ordovician formation in Shunbei block[J]. Drilling Fluid & Completion Fluid, 2020, 37(6):701-708. doi: 10.3969/j.issn.1001-5620.2020.06.004 [14] 黄维安,牛晓,沈青云,等. 塔河油田深侧钻井防塌钻井液技术[J]. 石油钻探技术,2016,44(2):51-57. doi: 10.11911/syztjs.201602009HUANG Weian, NIU Xiao, SHEN Qingyun, et al. Anti-sloughing dring fluid technology for deep sidetracking wells in the Tahe oilfield[J]. Petroleum Drilling Techniques, 2016, 44(2):51-57. doi: 10.11911/syztjs.201602009 [15] 胡广强,白彬珍,柯珂. 顺北区块辉绿岩井段井壁稳定性分析[J]. 中国海上油气,2017,29(5):119-125.HU Guangqiang, BAI Binzhen, KE Ke. Analysis on borehole instability mechanism of diabase in Shunbei block[J]. China Offshore Oil and Gas, 2017, 29(5):119-125. [16] 程善平,鄢家宇,曹鹏,等. 塔里木泛哈拉哈塘桑塔木组硬脆性泥岩井壁失稳机理及对策[J]. 钻采工艺,2018,41(5):23-25. doi: 10.3969/J.ISSN.1006-768X.2018.05.07CHENG Shanping, YAN Jiayu, CAO Peng, et al. study on instability mechanism of hardbrittle mudstone borehole wall at sangtamu group in halahatang block of tarim oilfield and countermeasures[J]. drilling & production technology, 2018, 41(5):23-25. doi: 10.3969/J.ISSN.1006-768X.2018.05.07 [17] 刘锋报,邵海波,周志世,等. 哈拉哈塘油田硬脆性泥页岩井壁失稳机理及对策[J]. 钻井液与完井液,2015,32(1):38-41. doi: 10.3969/j.issn.1001-5620.2015.01.10LIU Fengbao, SHAO Haibo, ZHOU Zhishi, et al. Mechanism and strategy to deal with borehole instability of hard and brittle shales in Halahatang oilfield.[J]. Drilling Fluid & Completion Fluid, 2015, 32(1):38-41. doi: 10.3969/j.issn.1001-5620.2015.01.10 [18] 范胜,宋碧涛,陈曾伟,等. 顺北5-8井志留系破裂性地层提高承压能力技术[J]. 钻井液与完井液,2019,36(4):431-436. doi: 10.3969/j.issn.1001-5620.2019.04.006FAN Sheng, SONG Bitao, CHEN Zengwei, et al. Technology for enhancing pressure bearing capacity of fractured silurian system in well Shunbei 5-8[J]. Drilling Fluid & Completion Fluid, 2019, 36(4):431-436. doi: 10.3969/j.issn.1001-5620.2019.04.006 期刊类型引用(3)

1. 罗玉财,喻化民,孙昊,于建涛,冯丹,刘飞. 冀中地区深层煤岩气水平井强封堵钻井液技术. 钻井液与完井液. 2025(02): 225-232 .  本站查看

本站查看2. 梁浩,贺刚,贺钦,刘政,邵平,罗宇峰. 超长水平段油基钻井液技术在威204H47-10井的应用. 石油化工应用. 2024(03): 18-23+33 .  百度学术

百度学术3. 王国辉,苏乐,赵燕博. 强封堵防塌型水基钻井液体系室内制备及其应用. 当代化工. 2024(05): 1162-1165+1169 .  百度学术

百度学术其他类型引用(0)

-

下载:

下载:

下载:

下载:

百度学术

百度学术