Drilling Fluid with Superior Plugging Performance Used in Deep Well Drilling in Manshen Block

-

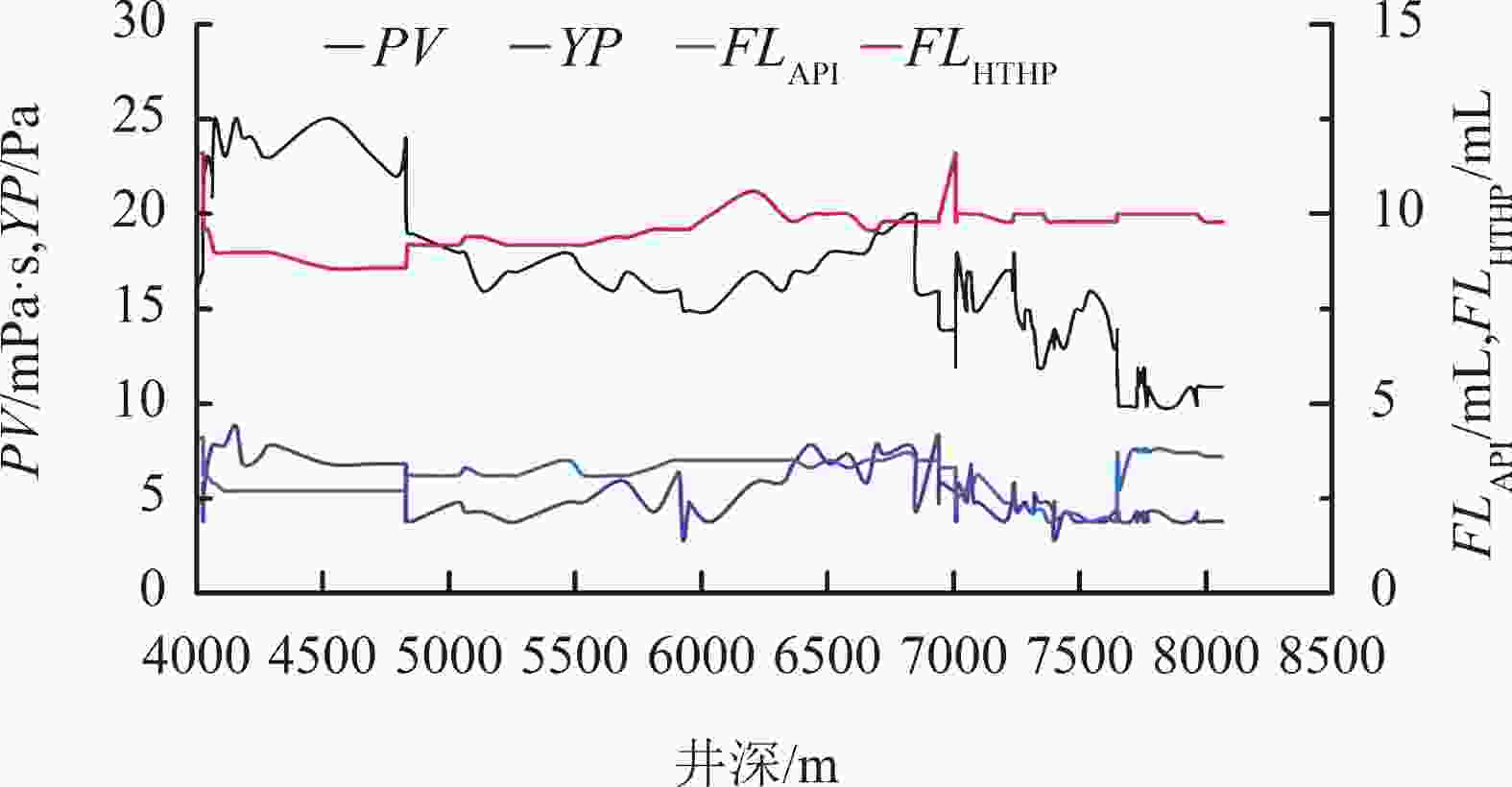

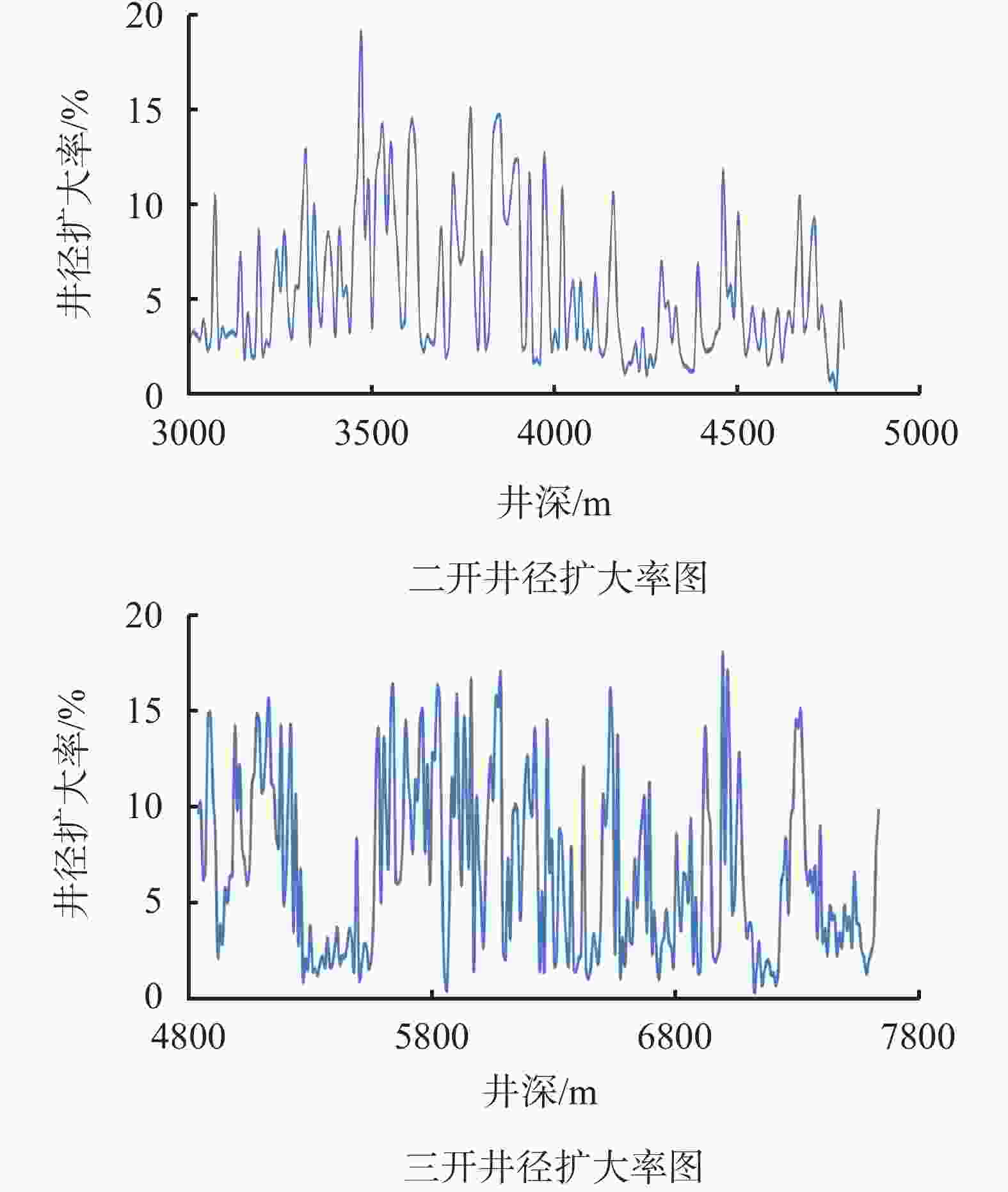

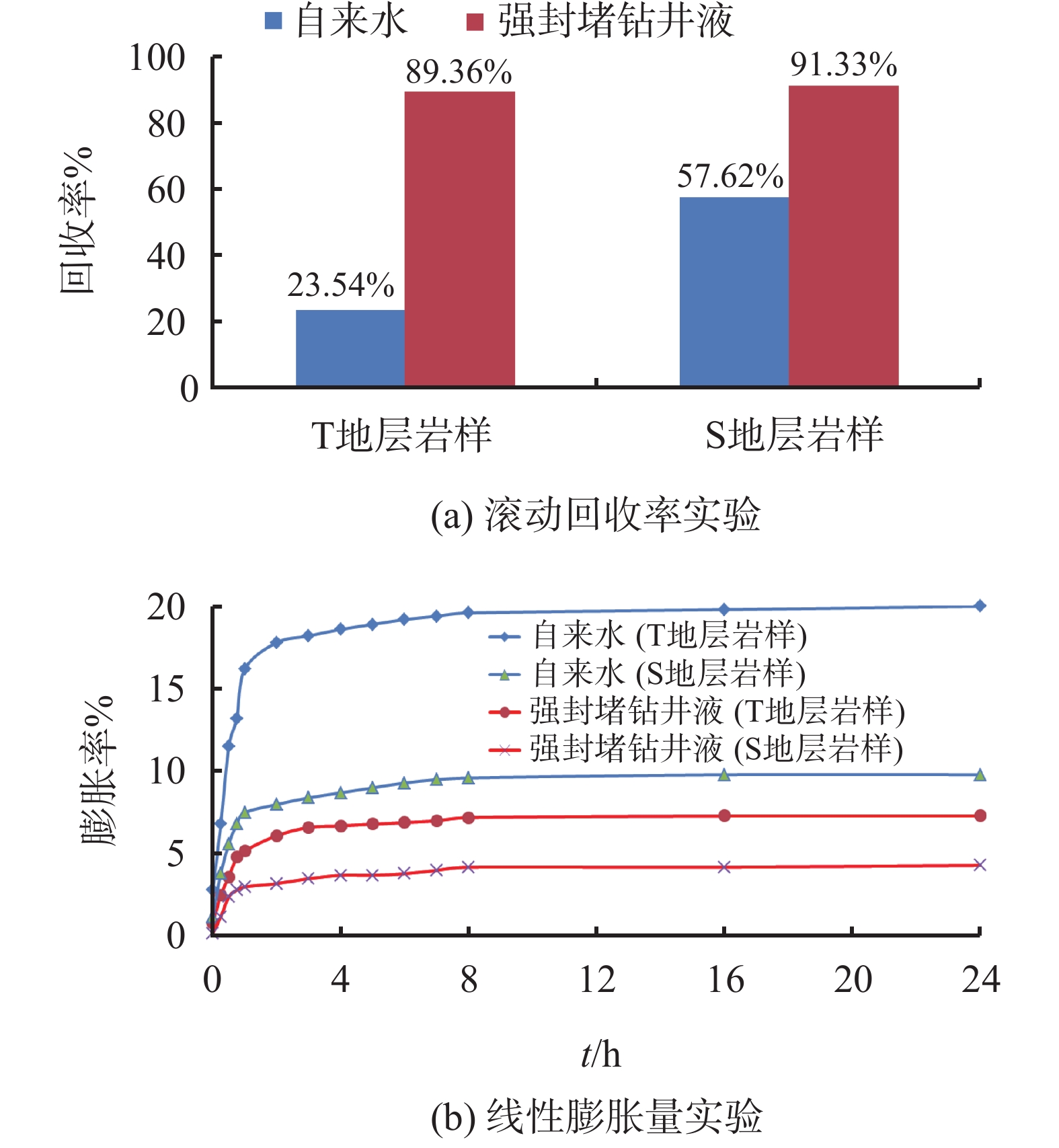

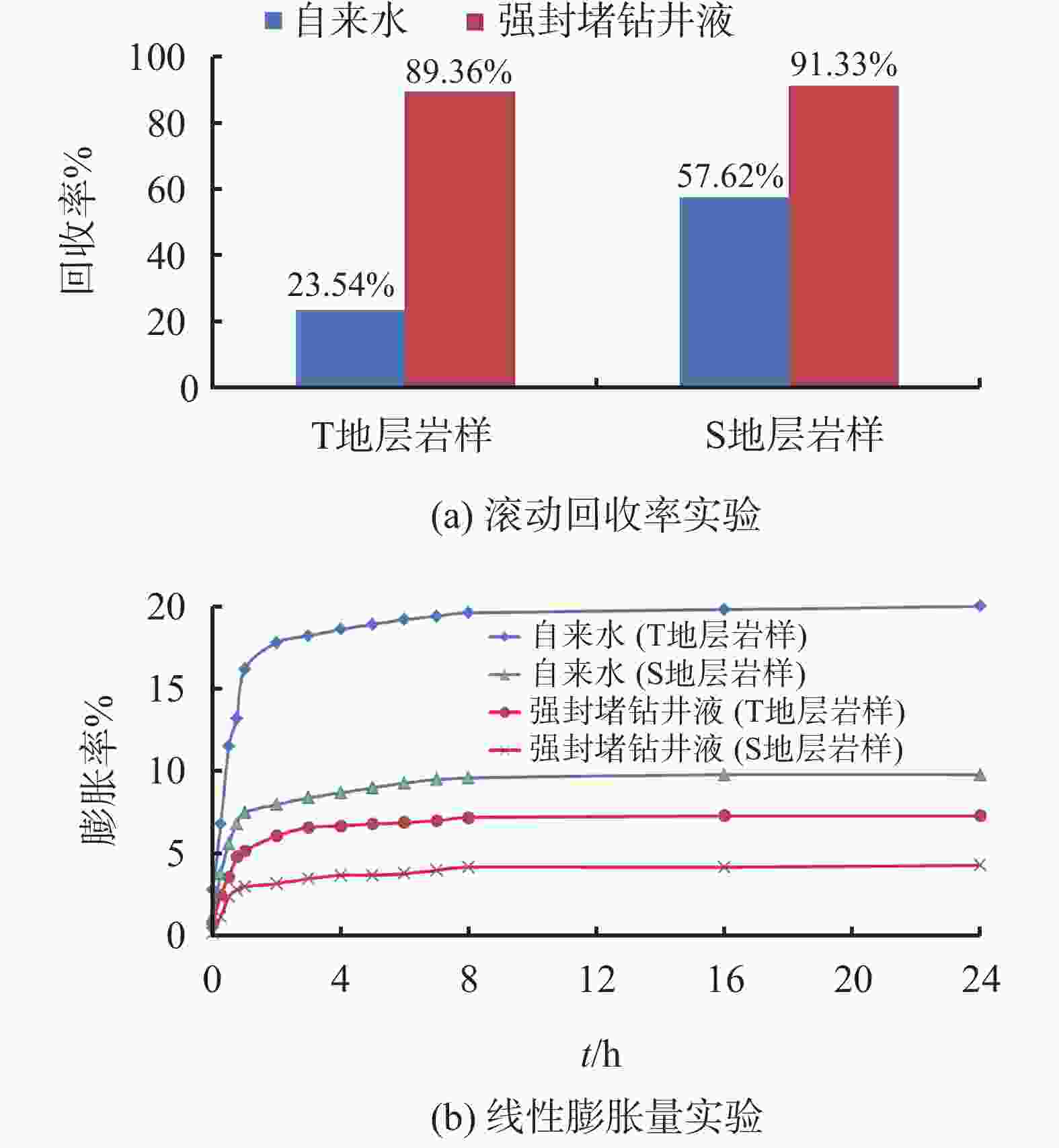

摘要: 满深区块中深部地层断裂破碎,微裂缝发育,且黏土矿物含量高,组分差异大,硬脆性和水敏性泥页岩相互共存,钻井过程中易发生水力劈裂和水化不等速膨胀而导致的井壁失稳。为此,提出了“物理支撑+化学抑制封堵”防塌技术对策,并构建了多元协同防塌强封堵钻井液。室内评价表明:强封堵钻井液抗温达180 ℃;抗10%饱和盐水污染;T层和S层岩样滚动回收率高达89.36%和91.33%、膨胀率低至7.3%和4.2%;能有效封堵20~120目不同粒径石英砂间微孔隙。该钻井液在ManS5-H4井现场应用中性能稳定,流变性好,滤失量低,具有较好的抑制和防塌性能,解决了中深部地层阻卡、坍塌掉块和扩径等井壁失稳问题,井眼通畅规则,二、三开井段平均井径扩大率分别为4.28%和6.75%,返出岩屑代表性好,无钻井液事故发生,能满足复杂地层复杂工艺钻进需要,提高了钻井综合效益。Abstract: The deep formations drilled in the Manshen block are broken and full of microfractures. They have high clay contents with large differences in clay composition. Hard and brittle shales and water-sensitive shales are coexisting in the formations drilled. These formations easily lose their stability during drilling because of hydraulic splitting and difference in the speed of hydration. A technical measure named “physical support plus chemical inhibition and plugging” was presented and an anti-collapse drilling fluid with superior plugging capacity formulated to deal with the borehole wall instability problem. Laboratory study showed that the drilling fluid functioned normally at 180 ℃ and was able to resist contamination by 10% saltwater. Shale samples taken from the T layer and S layer were tested in the drilling fluid formulated. Hot rolling test gave percent cuttings recovery of 89.36% and 91.33% respectively, and expansion test gave rate of expansion of 7.3% and 4.2% respectively. This drilling fluid can plug the pores in cores made with quartz particles from 20 mesh to 120 mesh. In drilling the well ManS5-H4, the drilling fluid showed stable properties and had low filtration rate. It had good inhibitive capacity and collapse prevention performance. Tripping was smooth with no overpulls and resistance, the second and the third interval found average hole enlargement of 4.28% and 6.75% respectively. The cuttings returned to the shake shakers kept their original shakes and no downhole troubles were ever encountered. This drilling fluid has satisfied the needs of drilling the complex formations and saved the total cost of drilling.

-

Key words:

- Deep well /

- Plugging /

- Broken and fractured /

- Borehole wall stabilization /

- High pressure saltwater

-

表 1 满深区块各层段黏土矿物组分平均相对含量

层

位样品数

(个)黏土矿物组份相对含量/% 混层比/% I K C I/S C/S I/S混层 C/S混层 J 8 15.60 65.90 11.40 7.10 25 T 7 7.80 6.30 7.30 78.60 75~100 P上 4 13.80 13.00 14.00 59.20 65~85 P下 5 13.60 7.80 6.20 61.40 11 50~65 C上 6 38.80 5.70 9.70 45.80 50~80 C下 5 16.60 54.40 8.80 20.20 15~25 D上 19 22.16 7.26 8.42 62.16 20~70 D下 8 18.25 7.62 53.75 20.38 15~30 S上 12 40.75 6.58 15.25 37.42 20 S中 6 27.67 10.50 14.30 20.20 27.33 20 20~30 S下 14 20.28 2.57 45.71 31.44 20 O 23 44.48 9.26 22.52 23.74 20 表 2 KCl加量对钻井液性能的影响

KCl/

%实验条件 回收率/

%ρ/

g·cm−3PV/

mPa∙sYP/

PaGel/

Pa/PaFLAPI/

mL0 常温 80.60 1.30 20 18.5 6.0/9.5 6.8 80 ℃×16 h 1.30 22 21.0 6.5/11.5 6.0 1 常温 87.60 1.32 15 19.0 5.5/6.5 8.0 80 ℃×16 h 1.32 18 21.0 5.5/6.5 6.8 3 常温 89.06 1.32 15 17.0 4.5/5.5 8.3 80 ℃×16 h 1.32 18 17.5 4.5/5.5 7.4 5 常温 94.06 1.32 15 17.0 4.0/5.0 8.6 80 ℃×16 h 1.32 17 17.5 3.5/4.5 7.8 7 常温 95.80 1.32 15 16.0 3.5/5.0 9.0 80 ℃×16 h 1.32 17 17.0 3.0/4.5 8.2 10 常温 93.84 1.32 15 16.0 3.5/4.5 10.4 80 ℃×16 h 1.32 18 16.0 3.0/4.5 9.6 注:配方:3%膨润土+0.3%Na2CO3+0.1%NaOH+0.6%

IND30+0.5%NH4-HPAN-2+0.5%THJN+加重剂;pH值为9表 3 在基浆中加入不同防塌剂的性能(150 ℃、16 h)

防塌剂 PV/

mPa·sYP/

PaGel/

Pa/PaFLAPI/

mLFLHTHP/mL 120 ℃ 150 ℃ 0 5 1.5 1.0/3.0 12.0 20.0 25.0 2%SY-A01 6 3.0 2.0/4.0 7.0 14.8 18.5 2%FT342 8 1.5 0.5/1.5 7.8 16.4 21.0 3% DYFT-2 8 5.0 1.5/5.0 4.4 13.6 17.0 2%FT103 6 1.0 0.5/2.5 7.6 17.6 26.0 3%FT-1 6 0.5 0.5/2.0 8.9 18.0 19.2 3%FT-1A 10 3.5 1.5/3.5 4.8 14.2 17.6 3%RLQ-2 8 2.0 0.5/3.0 7.2 15.5 19.0 2%YX 5 2.0 1.5/4.0 10.8 16.8 24.2 注:基浆为:5%膨润土浆+5%SMP-3+5%SPNH+7%KCl+

0.2%NaOH表 4 封堵防塌剂优选复配性能评价实验(150 ℃、16 h)

防塌剂 PV/mPa·s YP/Pa Gel/(Pa/Pa) FLAPI/mL FLHTHP/mL 0 5 1.5 1.0/3.0 12.0 25.0 2%DYFT-2+2%FT-1A 9 2.5 2.5/5.0 6.8 17.2 2%DYFT-2+2%FT-1A +2%SYA01 10 2.5 2.5/6.5 5.5 15.6 2%DYFT-2+2%FT-1A +2%YX 9 4.5 2.5/6.5 4.0 14.8 2%DYFT-2+2%FT-1A+2%YX+2%SQD-98(细) 12 5.0 3.0/8.0 3.2 13.2 2%DYFT-2+2%FT-1A+2%YX+2%DF-1 9 5.0 3.0/7.0 3.6 14.2 注:FLHTHP在150 ℃测定 表 5 降滤失剂优选性能评价实验(150 ℃、16 h)

降滤失剂 PV/mPa·s YP/Pa Gel/(Pa/Pa) FLAPI/mL FLHTHP/mL 0 9 4.0 2.0/6.0 4.5 15.2 0.3%CMC-LV 15 6.0 1.5/7.0 2.8 14.6 0.5%XCD-LV 15 3.5 4.5/7.5 12.4 22.0 0.3%PAC-LV 21 7.0 1.5/9.0 2.2 13.8 0.5%Redul 18 5.0 1.0/8.5 2.3 14.0 0.3%PAC-LV+0.5%Redul 31 16.0 2.0/11.0 1.8 8.6 0.3%PAC-LV+2%KJAN 22 12.0 2.5/10.0 3.0 10.4 0.3%PAC-LV+0.5%NH4-HPAN-2 26 8.5 1.5/10.5 2.8 12.4 0.3%PAC-LV+2%JNF-3 18 5.0 1.5/8.5 2.0 9.2 0.3%PAC-LV+2%TYJS-1 16 5.0 1.5/6.5 2.4 9.8 注:基浆配方:5%膨润土浆+0.4%NaOH +3%SMP-3+3%SPNH +7%KCl +2% DYFT-2 +2%FT-1A +2%YX+2%润滑剂;钻井液密度为1.36 g/cm3;FLHTHP在150 ℃测定 表 6 强封堵钻井液抗温性能评价实验

测试

条件PV/

mPa·sYP/

PaGel/

Pa/PaFLAPI/

mLFLHTHP/

mLpH 老化前 20 6.0 2.5/11.0 3.2 9 150 ℃、16 h 18 5.0 3.0/9.0 2.8 9.6 9 150 ℃、24 h 18 5.0 2.5/9.0 2.8 9.8 9 150 ℃、48 h 17 4.0 2.0/7.0 3.0 10.6 9 180 ℃、16 h 16 2.5 1.5/5.5 4.5 14.2 9 注:钻井液密度为1.36 g/cm3;FLHTHP在150 ℃测定 表 7 强封堵钻井液钻井液砂床封堵性评价实验

砂床粒径/目 砂床高度/cm P/MPa t/min 侵入深度/cm 20~40 30 0.7 480 4.9 40~80 30 0.7 480 4.2 80~100 30 0.7 480 3.4 100~120 30 0.7 480 2.6 表 8 在强封堵钻井液中加入饱和盐水的抗盐水污染性能

饱和盐水/

%ρ/

g·cm−3PV/

mPa·sYP/

PaGel/

Pa/PaFLAPI/

mLFLHTHP/

mLpH 0 1.36 18 5.0 3.0/9.0 2.8 9.5 9.0 5 1.35 17 5.0 3.0/8.0 3.0 11.8 9.0 10 1.33 14 3.5 2.0/5.5 3.8 14.6 8.5 15 1.28 12 3.0 1.0/3.0 5.2 19.8 8.0 20 1.25 11 1.0 0.5/1.0 5.8 22.4 8.0 -

[1] 杨海军,邓兴梁,张银涛,等. 塔里木盆地满深1井奥陶系超深断控碳酸盐岩油气藏勘探重大发现及意义[J]. 中国石油勘探,2020,25(3):13-23. doi: 10.3969/j.issn.1672-7703.2020.03.002YANG Haijun, DENG Xingliang, ZHANG Yintao, et al. Great discovery and its significance of exploration for ordovician ultra-deep fault-controlled carbonate reservoirs of well Manshen 1 in Tarim basin[J]. China Petroleum Exploration, 2020, 25(3):13-23. doi: 10.3969/j.issn.1672-7703.2020.03.002 [2] 袁国栋, 王鸿远, 陈宗琦, 等. 塔里木盆地满深1井超深井钻井关键技术[J]. 石油钻探技术, 2020, 48(4): 21-27.YUAN Guodong, WANG Hongyuan, CHEN Zongqi, et al. Key drilling technologies for the ultra-deep well Manshen 1 in the Tarim basin[J].Petroleum Drilling Techniques, 2020, 48(4): 21-27. [3] 吴柏志, 张怀兵. 满深1井碳酸盐岩地层自愈合水泥浆固井技术[J]. 石油钻探技术, 2021, 49(1): 67-73WU Bozhi, ZHANG Huaibing.Self-healing cementing technology in carbonate formation of Manshen 1 well[J]. Petroleum Drilling Techniques, 2021, 49(1): 67-73 [4] 翟科军,于洋,刘景涛,等. 顺北油气田火成岩侵入体覆盖区超深井优快钻井技术[J]. 石油钻探技术,2020,48(2):1-5. doi: 10.11911/syztjs.2020004ZHAI Kejun, YU Yang, LIU Jingtao, et al. Ultra-deep well drilling technology in the igneous invasion coverage area of the Shunbei oil and gas field[J]. Petroleum Drilling Techniques, 2020, 48(2):1-5. doi: 10.11911/syztjs.2020004 [5] 林永学, 王伟吉, 金军斌. 顺北油气田鹰1井超深井段钻井液关键技术[J]. 石油钻探技术, 2019, 47(3): 113-120.LIN Yongxue, WANG Weiji, JIN Junbin. Key drilling fluid technology in the ultra deep section of well Ying-1 in the Shunbei oil and gas field[J]. Petroleum Drilling Techniques, 2019, 47(3): 113-120. [6] 董小虎,李银婷. 塔里木盆地顺北区块二叠系井漏复杂的分析及对策[J]. 探矿工程(岩土钻掘工程),2020,47(2):59-62.DONG Xiaohu, LI Yinting. Analysis and countermeasures for complex Permian well leakage in the Shunbei block of Tarim basin[J]. Exploration Engineering ( Rock & Soil Drilling and Tunneling) , 2020, 47(2):59-62. [7] 于得水,徐泓,吴俢振,等. 满深1井奥陶系桑塔木组高性能防塌水基钻井液技术[J]. 石油钻探技术,2020,48(5):49-54. doi: 10.11911/syztjs.2020070YU Deshui, XU Hong, WU Xiuzhen, et al. High performance anti-collapse water-base drilling fluid technology of ordovician Santamu formation in well Manshen1[J]. Petroleum Drilling Techniques, 2020, 48(5):49-54. doi: 10.11911/syztjs.2020070 [8] 邱春阳,张翔宇,赵红香,等. 顺北区块深层井壁稳定钻井液技术[J]. 天然气勘探与开发,2021,44(2):81-86.QIU Chunyang, ZHANG Xiangyu, ZHAO Hongxiang, et al. Drilling-fluid system for deep borehole stability in Shunbei block, Tarim basin[J]. Natural Gas Exploration and Development, 2021, 44(2):81-86. [9] 李成,白杨,于洋,等. 顺北油田破碎地层井壁稳定钻井液技术[J]. 钻井液与完井液,2020,37(1):15-22.LI Cheng, BAI Yang, YU Yang, et al. Study and application of drilling fluid technology for stabilizing fractured formations in Shunbei oilfield[J]. Drilling Fluid & Completion Fluid, 2020, 37(1):15-22. [10] 陈修平,李双贵,于洋,等. 顺北油气田碳酸盐岩破碎性地层防塌钻井液技术[J]. 石油钻探技术,2020,48(2):12-16. doi: 10.11911/syztjs.2020005CHEN Xiuping,LI Shuanggui,YU Yang, et al. Anti-collapse drilling fluid technology for broken carbonate formation in Shunbei oil and gas field[J]. Petroleum Drilling Techniques, 2020, 48(2):12-16. doi: 10.11911/syztjs.2020005 [11] 金军斌. 塔里木盆地顺北区块超深井火成岩钻井液技术[J]. 石油钻探技术,2016,44(6):17-23.JIN Junbin. Drilling fluid technology for igneous rocks in ultra-deep wells in the Shunbei area, Tarim basin[J]. Petroleum Drilling Techniques, 2016, 44(6):17-23. [12] 谢俊, 司西强, 赵虎, 等. 顺北深井磺化钻井液起泡原因及解决思路[J]. 精细石油化工进展, 2019, 20(6): 1-6.XIE Jun, SI Xiqiang, ZHAO Hu, et al. Discussion on causes of sulfonated drilling fluid foaming and solution to this problem in deep wells of Shunbei oilfield[J]. Advances in Fine Petrochemicals, 2019, 20(6): 1-6. [13] 吴雄军,林永学,宋碧涛,等. 顺北油气田奥陶系破碎性地层油基钻井液技术[J]. 钻井液与完井液,2020,37(6):701-708. doi: 10.3969/j.issn.1001-5620.2020.06.004WU Xiongjun, LIN Yongxue, SONG Bitao, et al. Oil base drilling fluid technology for drilling broken ordovician formation in Shunbei block[J]. Drilling Fluid & Completion Fluid, 2020, 37(6):701-708. doi: 10.3969/j.issn.1001-5620.2020.06.004 [14] 黄维安,牛晓,沈青云,等. 塔河油田深侧钻井防塌钻井液技术[J]. 石油钻探技术,2016,44(2):51-57. doi: 10.11911/syztjs.201602009HUANG Weian, NIU Xiao, SHEN Qingyun, et al. Anti-sloughing dring fluid technology for deep sidetracking wells in the Tahe oilfield[J]. Petroleum Drilling Techniques, 2016, 44(2):51-57. doi: 10.11911/syztjs.201602009 [15] 胡广强,白彬珍,柯珂. 顺北区块辉绿岩井段井壁稳定性分析[J]. 中国海上油气,2017,29(5):119-125.HU Guangqiang, BAI Binzhen, KE Ke. Analysis on borehole instability mechanism of diabase in Shunbei block[J]. China Offshore Oil and Gas, 2017, 29(5):119-125. [16] 程善平,鄢家宇,曹鹏,等. 塔里木泛哈拉哈塘桑塔木组硬脆性泥岩井壁失稳机理及对策[J]. 钻采工艺,2018,41(5):23-25. doi: 10.3969/J.ISSN.1006-768X.2018.05.07CHENG Shanping, YAN Jiayu, CAO Peng, et al. study on instability mechanism of hardbrittle mudstone borehole wall at sangtamu group in halahatang block of tarim oilfield and countermeasures[J]. drilling & production technology, 2018, 41(5):23-25. doi: 10.3969/J.ISSN.1006-768X.2018.05.07 [17] 刘锋报,邵海波,周志世,等. 哈拉哈塘油田硬脆性泥页岩井壁失稳机理及对策[J]. 钻井液与完井液,2015,32(1):38-41. doi: 10.3969/j.issn.1001-5620.2015.01.10LIU Fengbao, SHAO Haibo, ZHOU Zhishi, et al. Mechanism and strategy to deal with borehole instability of hard and brittle shales in Halahatang oilfield.[J]. Drilling Fluid & Completion Fluid, 2015, 32(1):38-41. doi: 10.3969/j.issn.1001-5620.2015.01.10 [18] 范胜,宋碧涛,陈曾伟,等. 顺北5-8井志留系破裂性地层提高承压能力技术[J]. 钻井液与完井液,2019,36(4):431-436. doi: 10.3969/j.issn.1001-5620.2019.04.006FAN Sheng, SONG Bitao, CHEN Zengwei, et al. Technology for enhancing pressure bearing capacity of fractured silurian system in well Shunbei 5-8[J]. Drilling Fluid & Completion Fluid, 2019, 36(4):431-436. doi: 10.3969/j.issn.1001-5620.2019.04.006 -

下载:

下载: