Study and Application of Dispersion Polymerization in Preparing PAM Filter Loss Reducer

-

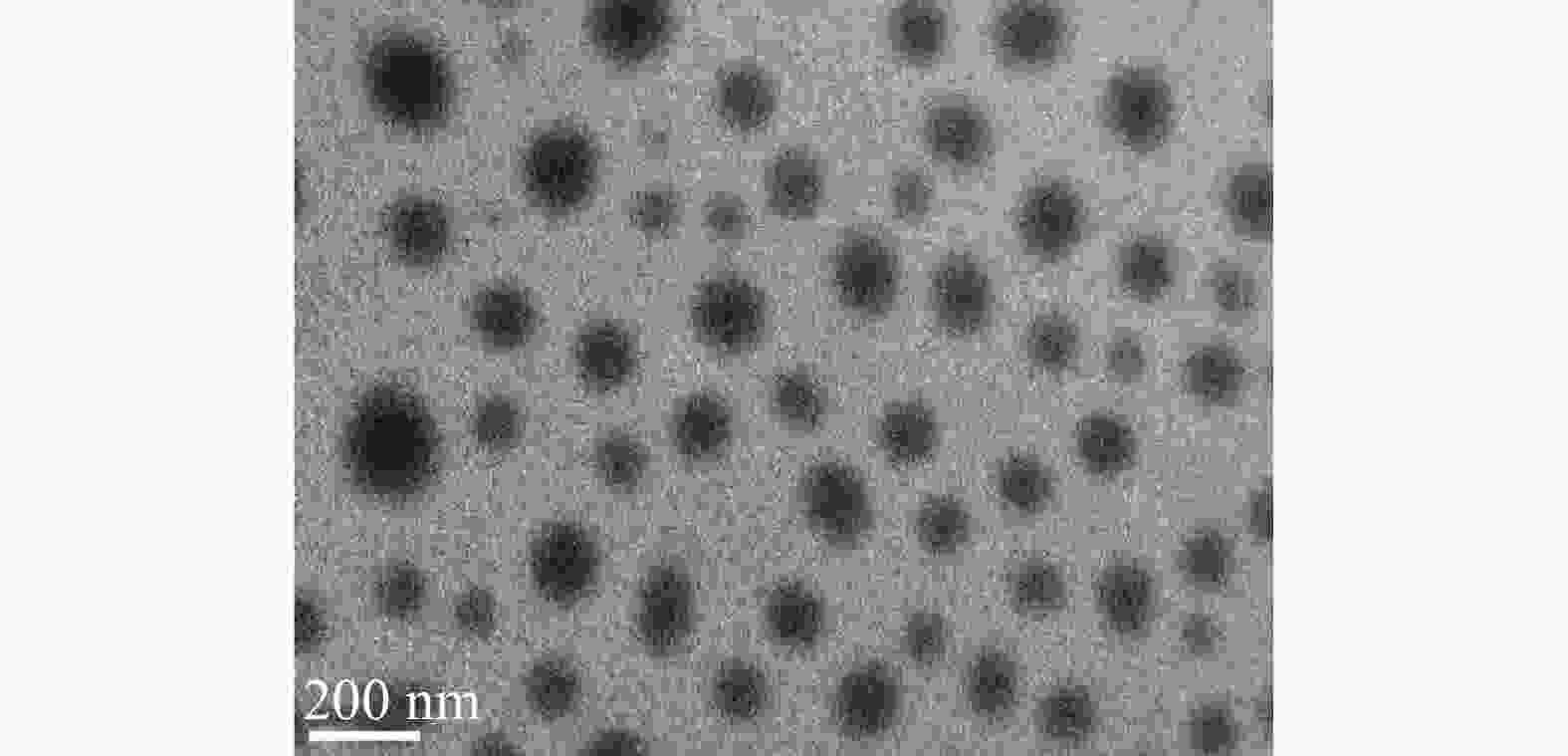

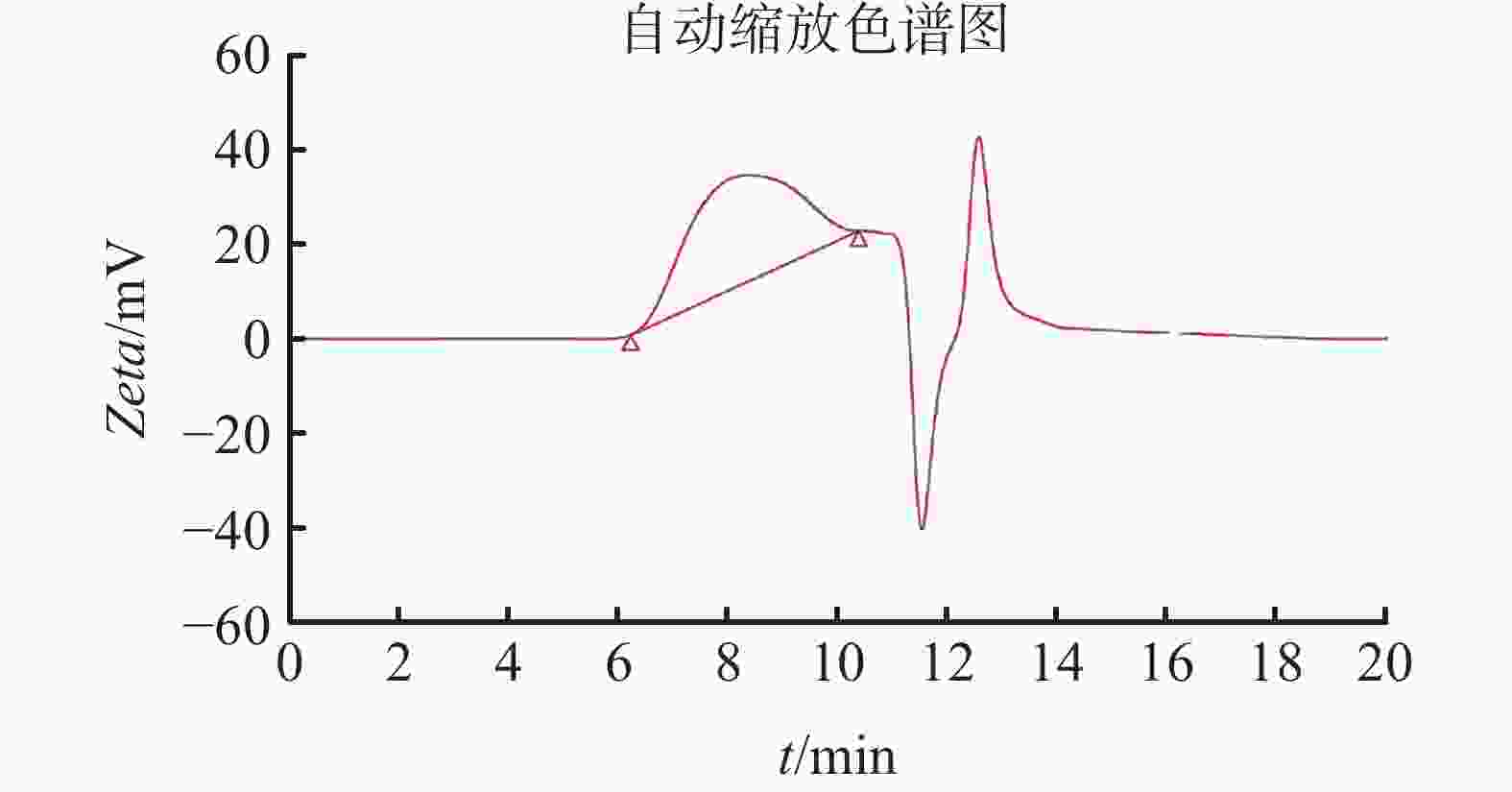

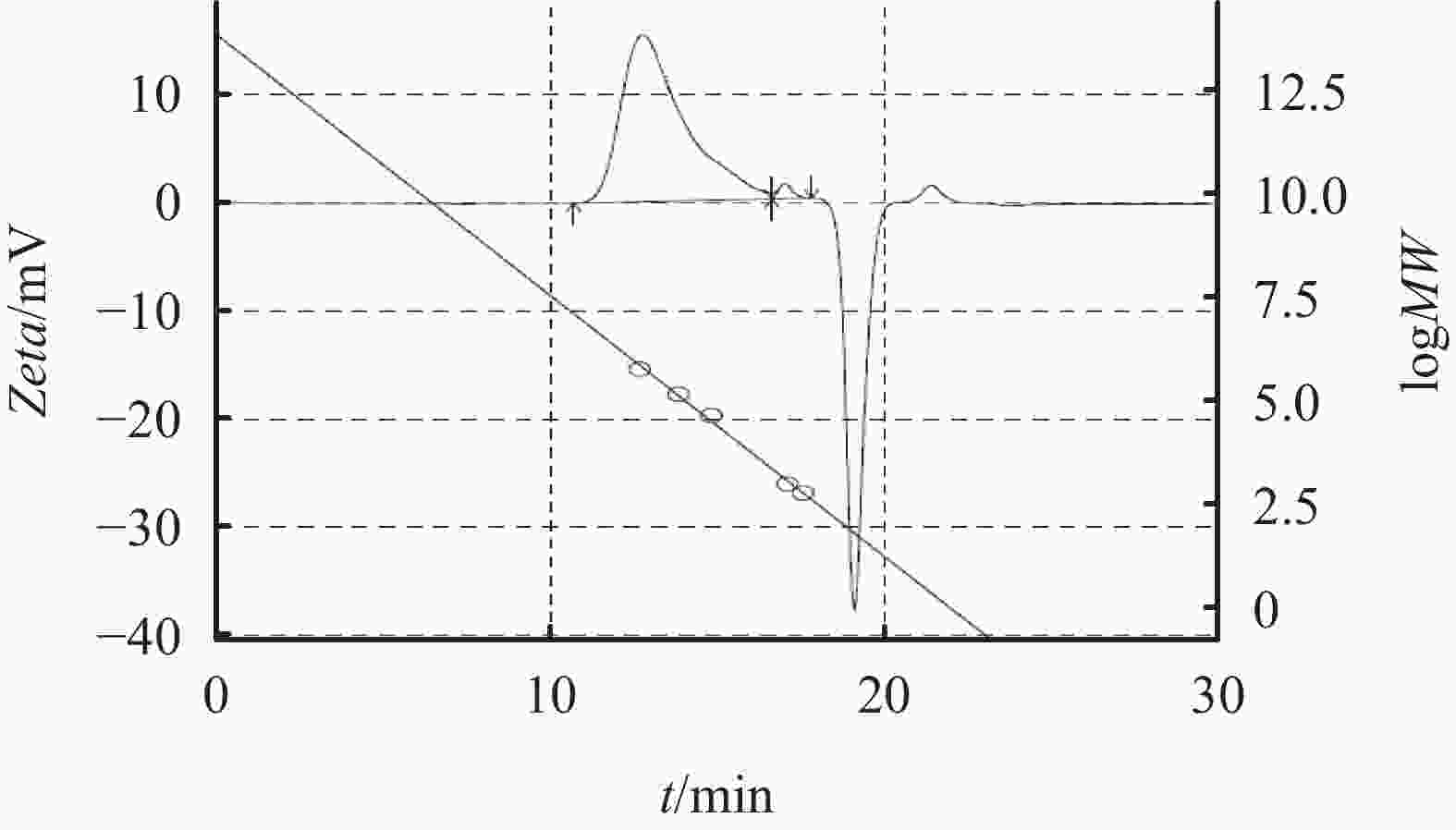

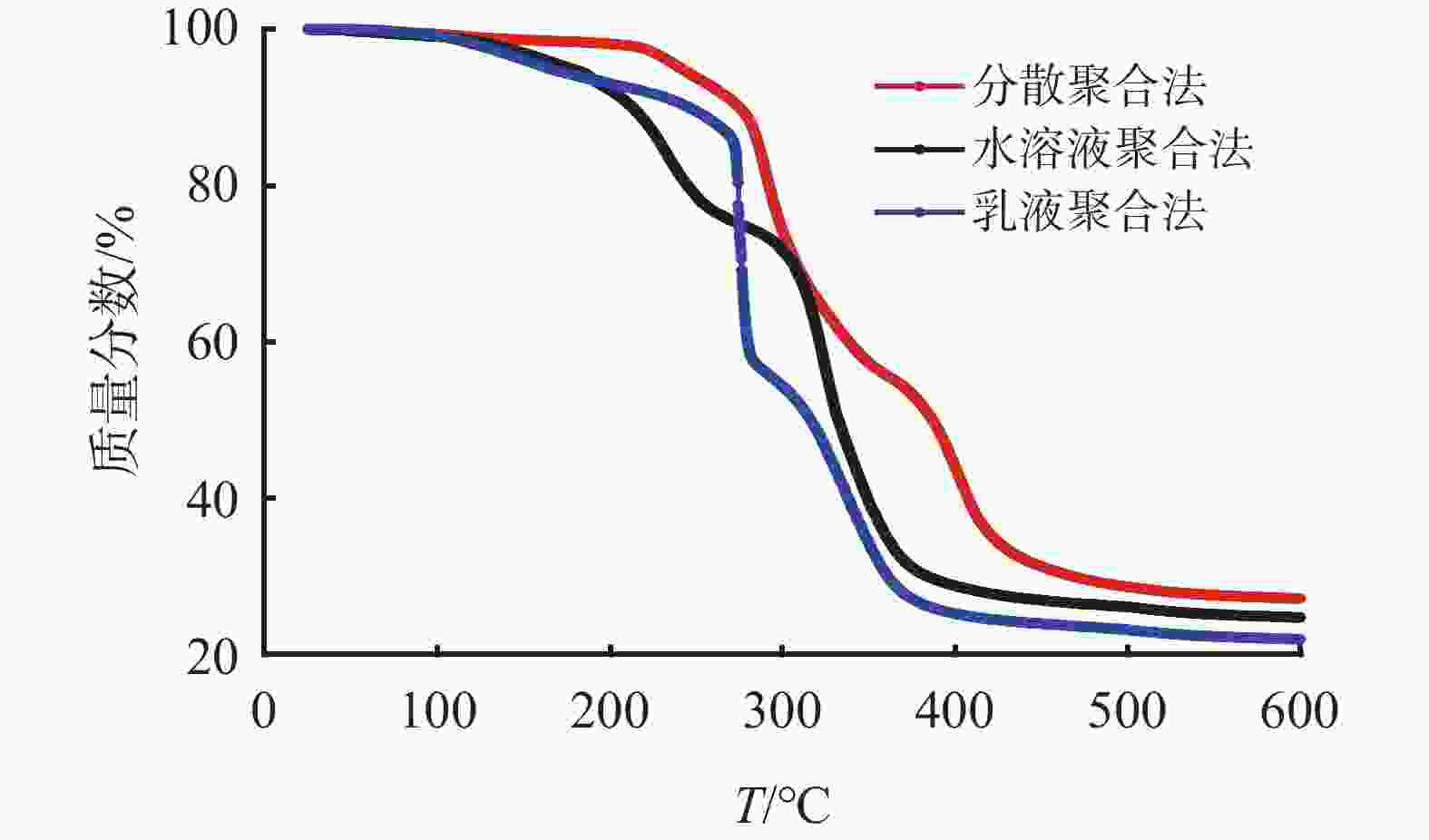

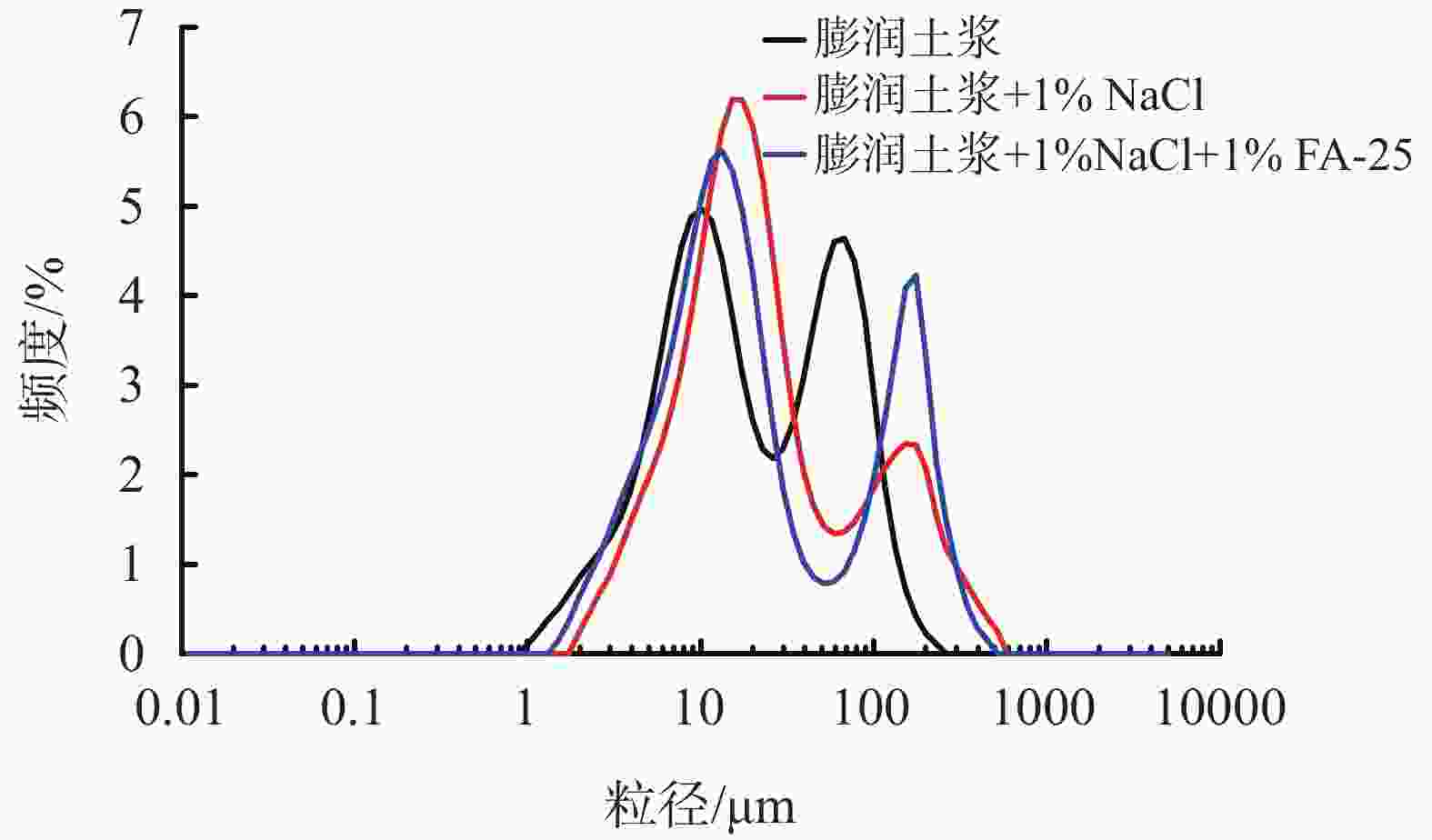

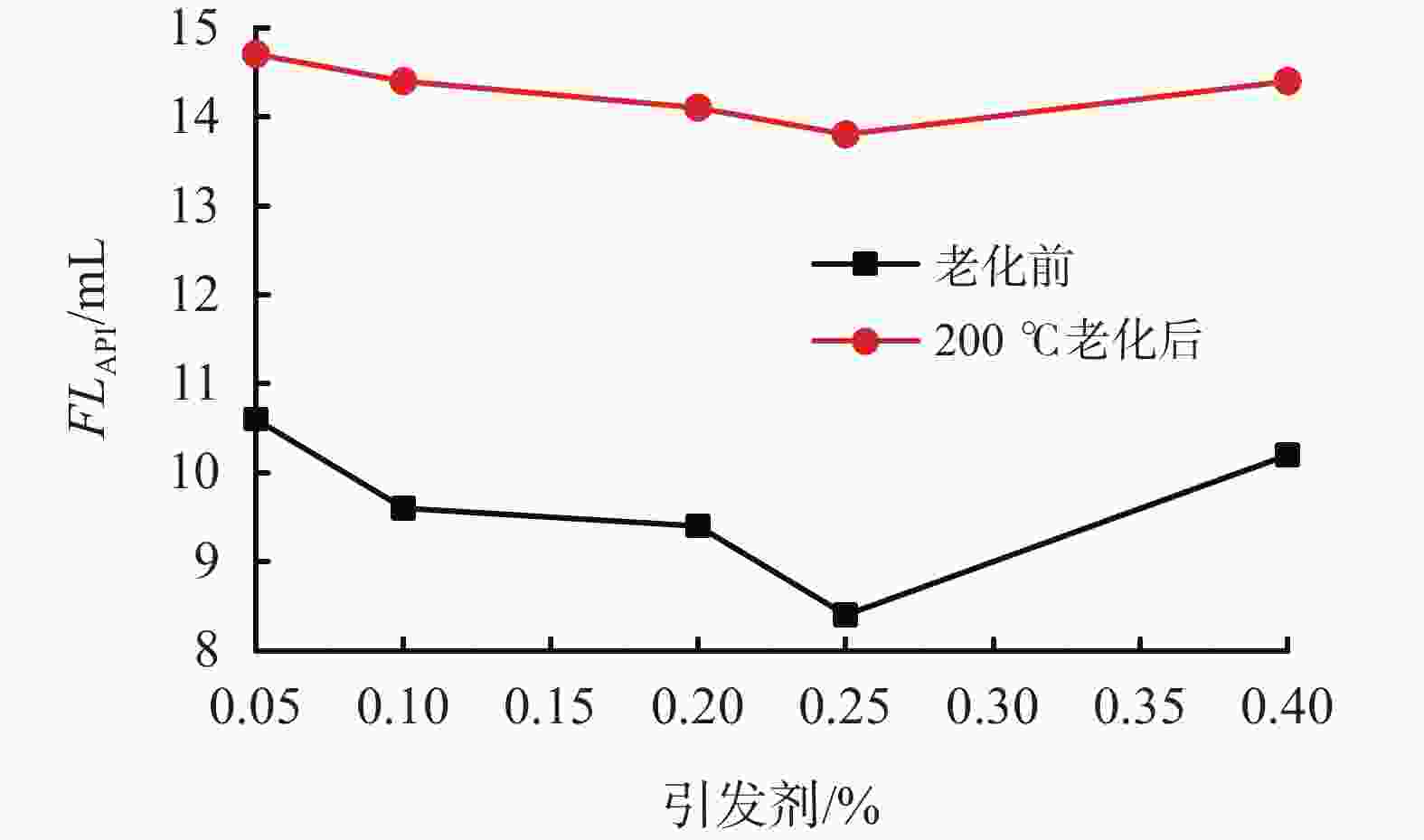

摘要: 以丙烯酰胺为单体,通过分散聚合法制备了一种聚丙烯酰胺微球降滤失剂,并与水溶液聚合法、反相乳液聚合法分别合成的聚丙烯酰胺降滤失剂进行了对比。通过优化引发剂加量等方法,合成了可溶解的聚丙烯酰胺微球降滤失剂FA-25。该方法合成过程无毒、环保,无需进行后处理。通过透射电镜分析、热重分析、粒径分析、凝胶色谱法分子量分析等手段,对FA-25进行了结构表征研究,结果表明FA-25为球形,尺寸在40~200 nm范围内,分子量可以达到104 928,初始热分解温度200 ℃。在膨润土浆中加入1% FA-25后能够将中压滤失量降至13.8 mL,优于水溶液合成的产品及反相乳液法制备的产品。此外,产品抗温性能良好,可以抵抗200 ℃的高温,具有良好的应用前景。Abstract: A microsphere polyacrylamide (PAM) filter loss reducer FA-25 has been developed with acrylamide monomer through dispersion polymerization. The filtration control performance of FA-25 and other PAMs made through aqueous polymerization and inverse emulsion polymerization was compared. The dispersion polymerization is nontoxic and environmentally friendly, and the product does not need any post-treatment. The product FA-25 was characterized through TEM analysis, TG analysis, particle size analysis and molecular weight analysis through gel chromatography. It was proved that the particles of FA-25 are in a shape of sphere, with particle sizes between 40 nm and 200 nm. The molecular weight of FA-25 is 104,928, and the initial thermal decomposition temperature is 200 ℃. A bentonite slurry treated with 1% FA-25 had its API filtration rate reduced to 13.8 mL, this proves that FA-25 has filtration control performance better than the PAMs made through water solution polymerization and inverse emulsion polymerization. FA-25 functions normally at temperatures up to 200 ℃. Good performance of FA-25 renders it good application prospect.

-

Key words:

- Microballoon /

- Filtrate reducer /

- Polyacrylamide

-

表 1 加入不同产品的膨润土浆200 ℃老化前后的性能

实验

方案实验

条件φ600 φ300 PV/

mPa·sYP/

PaYP/PV/

Pa/(mPa·s)FLAPI/

mL水溶液

聚合老化前 240 213 27 95.05 3.52 12.2 老化后 14 9 5 2.04 0.41 15.6 分散

聚合老化前 128 83 45 19.42 0.43 8.4 老化后 31 20 11 4.60 0.42 13.8 反相乳

液聚合老化前 29 25 4 10.73 2.68 22.8 老化后 10 5 5 0 0 25.0 注:膨润土浆中加入的不同产品的有效含量浓度均为1% 表 2 不同含量FA-25的膨润土浆在200 ℃老化前后性能

FA-25有效

含量/%反应

条件φ600 PV/

mPa·sYP/

PaYP/PV/

Pa/(mPa·s)FLAPI/

mL0.25 老化前 118 33 26.5720 0.8052 16.0 老化后 30 12 3.0660 0.2555 18.0 0.50 老化前 125 36 27.0830 0.7523 15.0 老化后 26 10 3.0660 0.3066 17.6 0.75 老化前 131 39 27.0830 0.6944 12.0 老化后 25 10 2.5550 0.2555 16.8 1.00 老化前 136 46 22.4840 0.4888 8.4 老化后 31 11 4.5990 0.4181 13.8 1.25 老化前 142 48 23.5060 0.4897 8.0 老化后 38 14 5.1100 0.3650 13.4 1.50 老化前 156 49 29.6380 0.6049 8.2 老化后 40 11 9.1980 0.8362 13.6 表 3 加入1%FA-25的膨润土浆在老化前后的性能

T老化/

℃φ600 φ300 PV/

mPa·sYP/

PaYP/PV/

Pa/(mPa·s)FLAPI/

mL150 62 36 26 5.1100 0.1965 9.2 180 32 23 9 7.1540 0.7949 11.6 200 31 20 11 4.5990 0.4181 13.8 220 25 14 11 1.5330 0.1394 19.2 -

[1] 刘朋飞,范雅珺,梁兵. 两端疏水聚丙烯酰胺的合成及疏水缔合性能[J]. 油田化学,2017,34(4):668-674,687.LIU Pengfei, FAN Yajun, LIANG Bing. Synthesis and hydrophobic association properties of hydrophobic polyacrylamide with two ends[J]. Oilfield Chemistry, 2017, 34(4):668-674,687. [2] 刘音,常青,于富美,等. 聚丙烯酰胺在油田生产中的应用[J]. 石油化工应用,2014,33(4):9-11. doi: 10.3969/j.issn.1673-5285.2014.04.003LIU Yin, CHANG Qing, YU Fumei, et al. Application of polyacrylamide in oilfield production[J]. Petrochemical Industry Application, 2014, 33(4):9-11. doi: 10.3969/j.issn.1673-5285.2014.04.003 [3] 鄢捷年. 钻井液工艺学[M]. 山东: 石油大学出版社, 2001: 348-360.YAN Jienian. Drilling fluid technology[M]. Shandong: University of Petroleum Press, 2001: 348-360. [4] GOU SHAOHUA, YIN TING, YAN LIWEI, et al. Water-soluble complexes of hydrophobically modified polymer and surface active imidazolium-based ionic liquids for enhancing oil recovery[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2015, 471:45-53. [5] ANA C LARA-CENICEROS, CLAUDIA RIVERA-VALLEJO, ENRIQUE J JIMÉNEZ-REGALADO. Synthesis and characterization of telechelic polymers obtained by micellar polymerization[J]. Polymer Bulletin, 2007, 59(4):499-508. doi: 10.1007/s00289-007-0792-7 [6] 夏景刚,史野,左洪国,等. 一种环保型抗高温钻井液技术[J]. 钻井液与完井液,2020,37(1):59-63.XIA Jinggang, SHI Ye, ZUO Hongguo, et al. An environment-friendly high temperature resistant drilling fluid technology[J]. Drilling Fluid & Completion Fluid, 2020, 37(1):59-63. [7] 黄维安,邱正松,曹杰,等. 钻井液用超高温抗盐聚合物降滤失剂的研制与评价[J]. 油田化学,2012,29(2):133-137,145.HUANG Weian, QIU Zhengsong, CAO Jie, et al. Development and evaluation of ultra high temperature salt resistant polymer fluid loss reducer for drilling fluid[J]. Oilfield Chemistry, 2012, 29(2):133-137,145. [8] PIERRE LEBRETON. Synthesis, characterization and associative properties of triblock and diblock perfluorinated poly(acrylamide)s[J]. Polymer Bulletin, 1999, 43(1):59-66. doi: 10.1007/s002890050533 [9] 孙维林, 胡靖邦, 林雅琴, 等. 聚丙烯酰胺在配浆黏土颗粒上的吸附试验研究[J]. 钻井液与完井液, 1989, 6(1): 45-50, 78.SUN Weilin, HU Jingbang, LIN Yaqin, et al. Experimental study on adsorption of polyacrylamide on slurry clay particles[J], Drilling Fluid & Completion Fluid, 1989, 6(1): 45-50,78. [10] 路福绥,侯万国,王果庭. 聚丙烯酰胺在溶液中的尺寸对其在膨润土上吸附量的影响[J]. 钻井液与完井液,1994,4(5):19-20.LU Fusui, HOU Wanguo, WANG Guoting. Effect of size of polyacrylamide in solution on its adsorption capacity on bentonite[J]. Drilling Fluid & Completion Fluid, 1994, 4(5):19-20. [11] 卜道露. 分散聚合法聚合物微球调剖剂的研究[D]. 成都理工大学, 2013.BU Daolu. Study on polymer microsphere profile control agent by dispersion polymerization[D]. Chengdu University of technology, 2013 [12] 李鑫. 聚丙烯酰胺(PAM)的合成方法研究进展[J]. 山东化工,2016,45(1):56-58. doi: 10.3969/j.issn.1008-021X.2016.01.018LI Xin. Research progress on synthetic methods of polyacrylamide (PAM)[J]. Shandong Chemical Industry, 2016, 45(1):56-58. doi: 10.3969/j.issn.1008-021X.2016.01.018 [13] PRADIP Y A. ATTIA D W. The adsorption of polyacrylamide flocculants on apatites[J]. Colloid and Polymer Science Kolloid-Zeitschrift & Zeitschrift für Polymere, 1980, 258(12):1343-1353. [14] 杨博,孙宾宾. 聚丙烯酰胺合成研究进展[J]. 当代化工,2017,46(2):286-288. doi: 10.3969/j.issn.1671-0460.2017.02.027YANG Bo, SUN Binbin. Progress in synthesis of polyacrylamide[J]. Contemporary Chemical Industry, 2017, 46(2):286-288. doi: 10.3969/j.issn.1671-0460.2017.02.027 [15] 宋武. 聚丙烯酰胺的合成及应用研究进展[J]. 中国石油和化工标准与质量,2018,38(15):189-190. doi: 10.3969/j.issn.1673-4076.2018.15.089SONG Wu. Progress in synthesis and application of polyacrylamide[J]. China Petroleum and Chemical Standard and Quality, 2018, 38(15):189-190. doi: 10.3969/j.issn.1673-4076.2018.15.089 [16] 赵鹏. 油田用聚丙烯酰胺的合成方法与应用[J]. 化工管理,2015(26):231. doi: 10.3969/j.issn.1008-4800.2015.26.193ZHAO Peng. Synthesis and application of polyacrylamide for oil field[J]. Chemical Enterprise Management, 2015(26):231. doi: 10.3969/j.issn.1008-4800.2015.26.193 [17] 吴蒙,邓生富,魏发林,等. 聚丙烯酰胺合成技术及其在油田开发中的应用[J]. 精细石油化工进展,2011,12(12):1-4. doi: 10.3969/j.issn.1009-8348.2011.12.001WU Meng, DENG Shengfu, WEI Falin, et al. Polyacrylamide synthesis technology and its application in oilfield development[J]. Advances in Fine Petrochemicals, 2011, 12(12):1-4. doi: 10.3969/j.issn.1009-8348.2011.12.001 [18] CORPART J M, CANDAU F. Formulation and polymerization of microemulsions containing a mixture of cationic and anionic monomers[J]. Colloid & Polymer Science, 1993, 271(11):1055-1067. [19] 单伟,张学佳,那荣喜,等. 聚丙烯酰胺生产技术及其应用[J]. 安徽化工,2010,36(1):13-17. doi: 10.3969/j.issn.1008-553X.2010.01.006SHAN Wei, ZHANG Xuejia, NA Rongxi, et al. Production technology and application of polyacrylamide[J]. Anhui Chemical Industry, 2010, 36(1):13-17. doi: 10.3969/j.issn.1008-553X.2010.01.006 [20] 钱伯章. 聚丙烯酰胺的生产技术与市场分析[J]. 化学工业,2010,28(Z1):15-19.QIAN Bozhang. Production technology and market analysis of polyacrylamide[J]. Chemical Industry, 2010, 28(Z1):15-19. [21] 刘建平,王雪芳,杨小敏. 高分子量聚丙烯酰胺的合成与应用进展[J]. 化学工程师,2010,24(8):26-28,46. doi: 10.3969/j.issn.1002-1124.2010.08.010LIU Jianping, WANG Xuefang, YANG Xiaomin. Progress in synthesis and application of high molecular weight polyacrylamide[J]. Chemical Engineer, 2010, 24(8):26-28,46. doi: 10.3969/j.issn.1002-1124.2010.08.010 [22] 杨桂英,刘温霞. 聚丙烯酰胺的制备及其应用研究[J]. 黑龙江造纸,2007(3):15-18. doi: 10.3969/j.issn.1673-0283.2007.03.006YANG Guiying, LIU Wenxia. Preparation and application of polyacrylamide[J]. Heilongjiang Pulp & Paper, 2007(3):15-18. doi: 10.3969/j.issn.1673-0283.2007.03.006 [23] 王志宏,李雷振. 一种耐温抗盐聚丙烯酰胺的制备与性能评价[J]. 化工管理,2018(2):6-7. doi: 10.3969/j.issn.1008-4800.2018.02.003WANG Zhihong, LI Leizhen. Preparation and performance evaluation of a temperature and salt resistant polyacrylamide[J]. Chemical Enterprise Management, 2018(2):6-7. doi: 10.3969/j.issn.1008-4800.2018.02.003 [24] 崔玉,张书香,杨金虎. 分散聚合法制备高分子量聚丙烯酰胺[J]. 济南大学学报(自然科学版),2002(4):327-328.CUI Yu, ZHANG Shuxiang, YANG Jinhu. Preparation of high molecular weight polyacrylamide by dispersion polymerization[J]. Journal of University of Jinan (Science and Technology) , 2002(4):327-328. -

下载:

下载: