High Density Clay-free Oil Based Drilling Fluid

-

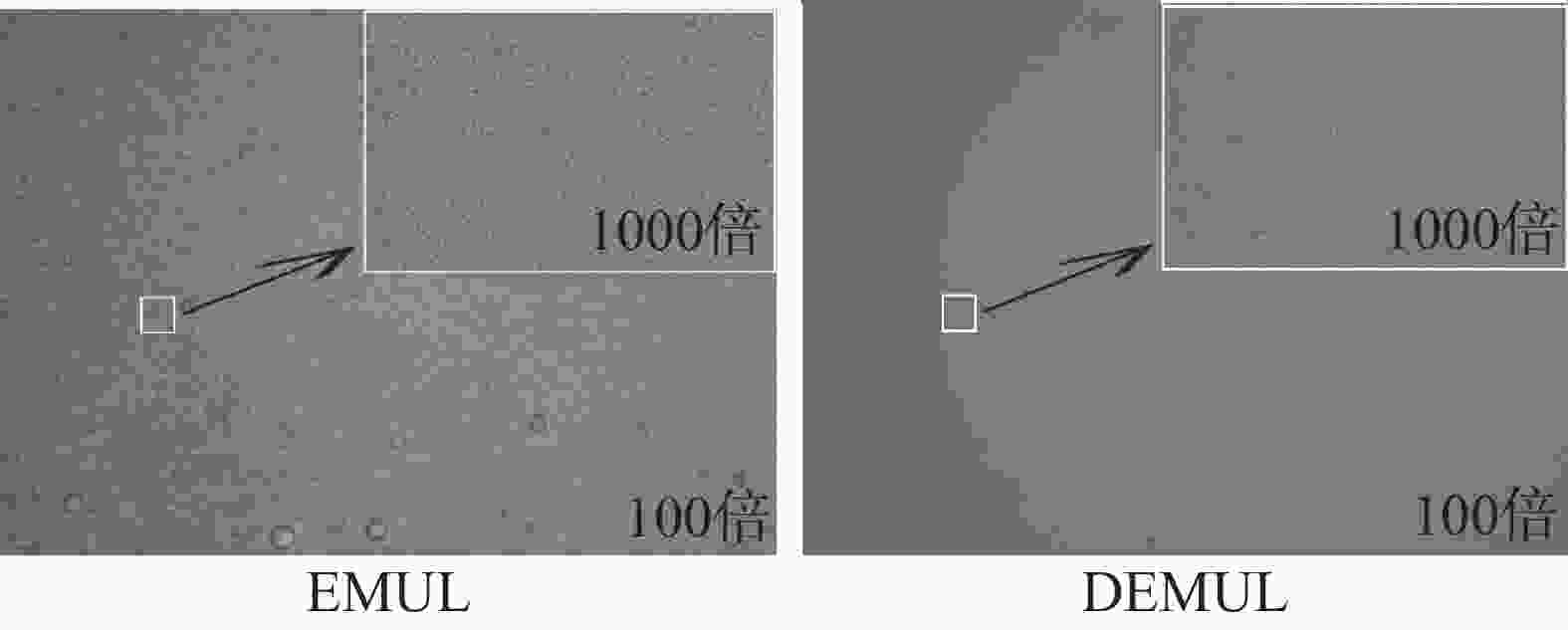

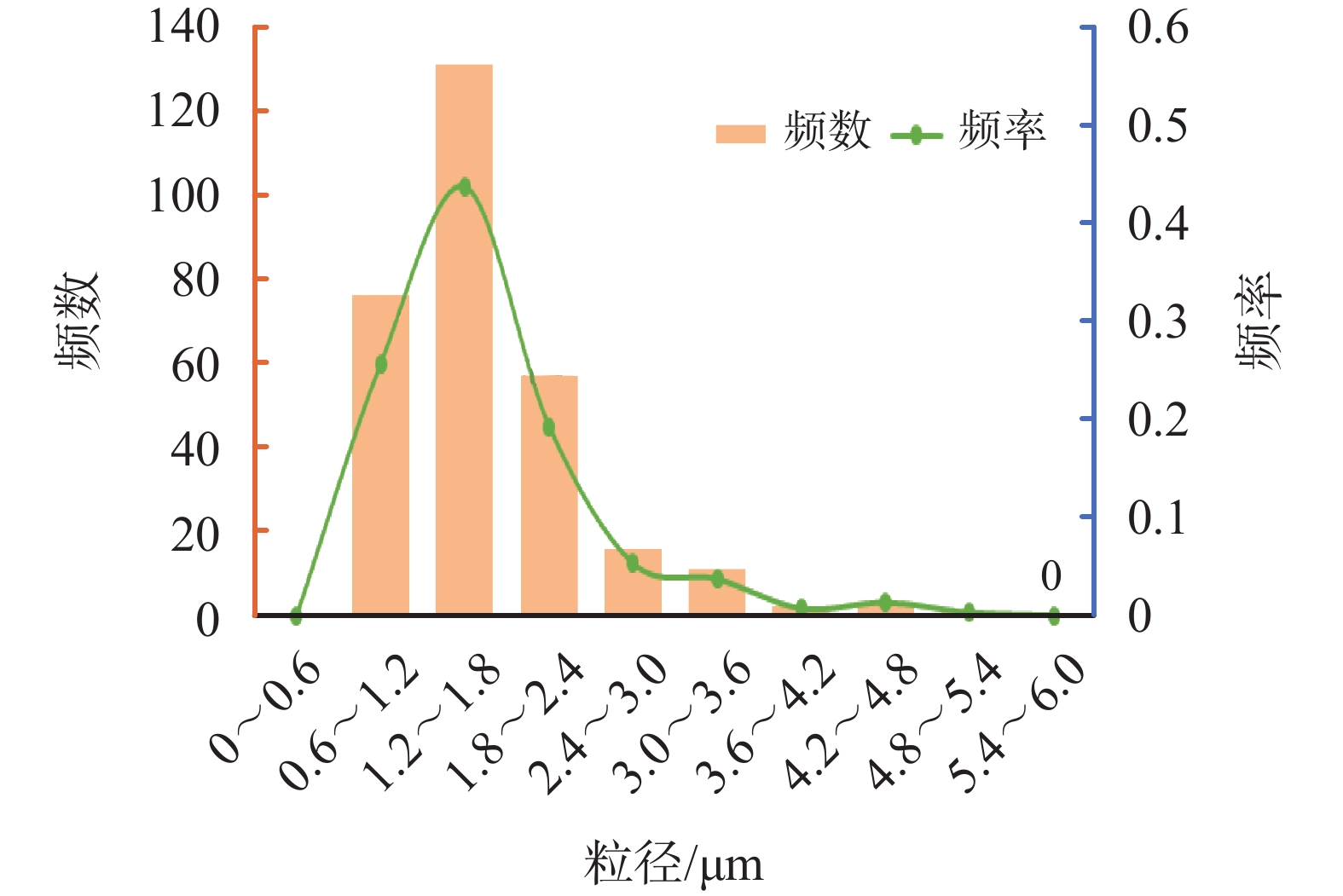

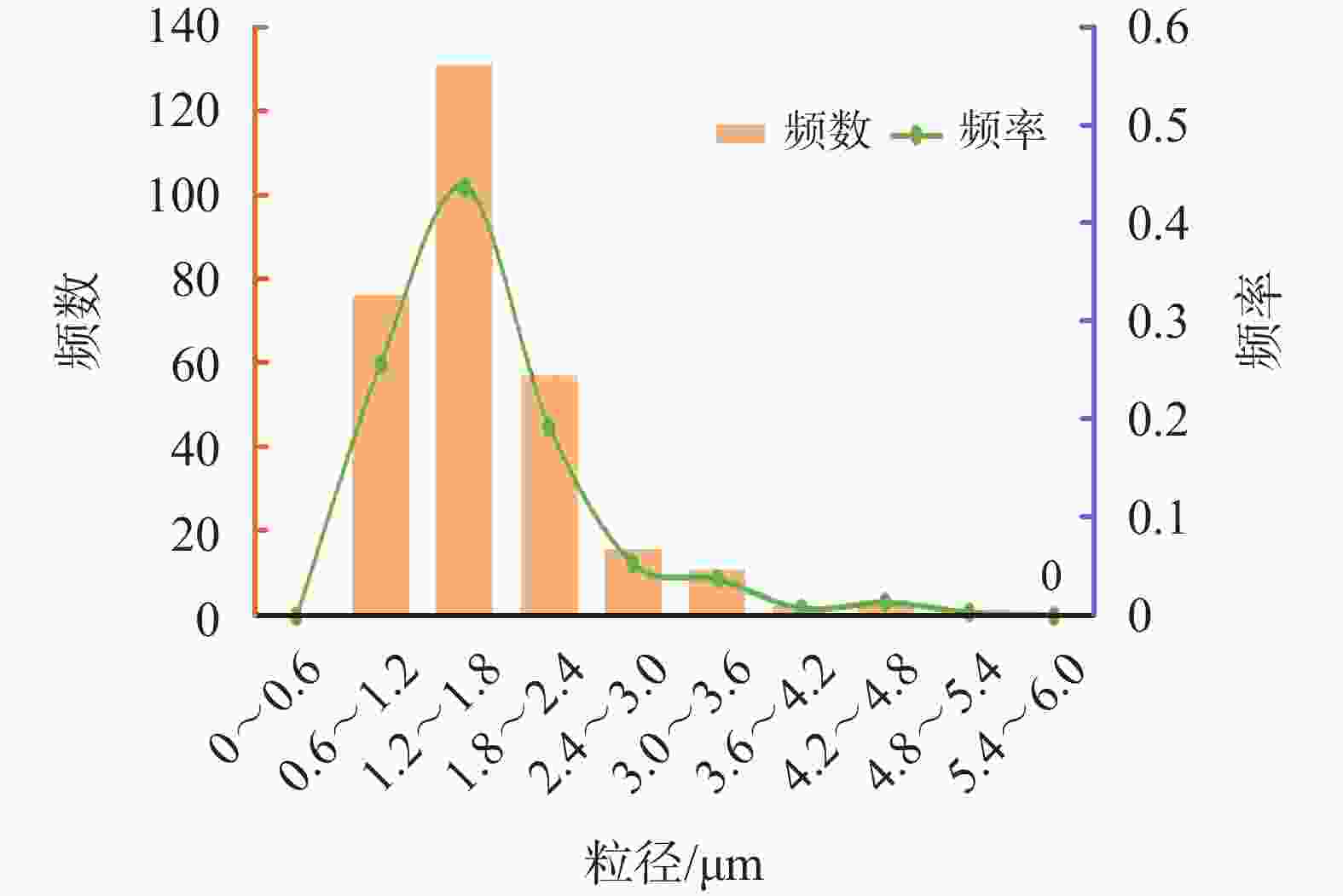

摘要: 高密度油基钻井液高温下重晶石易沉降,导致体系稳定性变差,传统方法采用高浓度有机土来解决,但其会引起钻井液黏度过高,造成ECD升高而引发井漏等复杂情况。针对以上问题,研发了一种具有强电稳定性能、增黏效果的小粒径乳化剂DEMUL,并开发了一种高密度无黏土相油基钻井液体系,通过加入DEMUL、苯乙烯-丁烯/丁二烯-苯乙烯嵌段共聚物(SEBS)与提切剂的协同作用,达到提高高密度油基钻井液的稳定性能,且配方简单、处理剂加量少。研究结果表明,该钻井液在200 ℃下老化160 h也能保持良好的流变性能,160 ℃恒温静置336 h后沉降因子为0.5074,表现出良好的稳定性,且具有良好的抑制性能和极压润滑性能。该钻井液体系在川渝页岩气某高密度水平井进行了应用,钻井过程中该体系流变性能稳定,携砂性能良好,抑制性能强,未出现井下复杂情况。Abstract: Barite in oil based drilling fluids at elevated temperatures is easy to sag, resulting in poor stability of the muds. Conventionally this is solved by adding more organophilic clay. High clay content in the mud results in high mud viscosity and high ECD, causing mud losses to happen. To deal with this problem, a small particle size emulsifier DEMUL with high electric stability and viscosifying property has been developed to formulate a high density clay-free oil based drilling fluid. The drilling fluid was treated with DEMUL, SEBS (a styrene-butene/butadiene-styrene block copolymer) and a gellant, the synergy of these additives helps improve the stability of the oil based drilling fluid. This drilling fluid has simple formulation, and each additive is added at a low concentration. Laboratory experiment showed that the oil based drilling fluid still retained good rheology after aging at 200 ℃ for 160 h. After standing still at 160 °C for 336 h, the settling factor of the drilling fluid was 0.5074, indicating that the drilling fluid had good stability. Furthermore, this drilling fluid also has good inhibitive capacity and extreme-pressure lubricity. This drilling fluid has been used in drilling the horizontal section of a high pressure shale gas well in Chuanyu area. During the whole drilling operation, the drilling fluid showed stable rheology, good sand carrying capacity and high inhibitive capacity, and no downhole trouble has ever been encountered.

-

Key words:

- Oil based drilling fluid /

- Emulsifier /

- Clay-free /

- Settling stabilityr /

- Inhibitive capacity /

- Rheological property

-

表 1 乳化剂DEMUL的加量对钻井液性能的影响

DEMUL/

%老化

条件AV/

mPa·sPV/

mPa·sYP/

Paφ6/φ3 ES/

VFLHTHP/

mL2.0 滚前 59 48 11 6/5 860 滚后 54 45 9 6/5 731 2.5 3.0 滚前 52 47 5 5/4 719 滚后 48 42 6 4/3 700 2.5 4.0 滚前 58 52 6 5/4 886 滚后 53 46 7 5/4 800 2.2 5.0 滚前 64 56 8 5/4 979 滚后 56 49 7 5/4 906 2.2 注:老化条件为:160 ℃、16 h,在65 ℃测定性能;DE

MUL的加量为2.0%时加入1.0%有机土表 2 聚合物SEBS与提切剂DEHEO对钻井液性能的影响

DEHEO/

%SEBS/

%热滚

条件AV/

mPa·sPV/

mPa·sYP/

Paφ6/φ3 ES/

VFLHTHP/

mL4.0 0 滚前 59 47 12 7/6 862 滚后 68 58 10 7/6 810 2.4 2.0 0.5 滚前 58 49 9 6/5 812 滚后 51 44 7 6/5 801 2.4 2.5 0.5 滚前 60 48 12 6/5 809 滚后 53 44 9 6/5 837 2.4 3.0 0.5 滚前 59 47 12 7/6 869 滚后 54 45 9 7/6 911 2.3 注:老化条件为:160 ℃、16 h,65 ℃下测定性能 表 3 高密度无黏土相油基钻井液的抗温性能

T老化/

℃t老化/

hAV/

mPa·sPV/

mPa·sYP/

Paφ6/φ3 ES/

VFLHTHP/

mL0 61 50 11 5/4 873 160 16 53 45 8 6/5 790 160 51 41 10 3/2 734 2.2 170 16 55 46 9 6/5 963 160 56 48 8 3/2 917 3.0 180 16 69 63 6 5/4 955 160 68 62 6 5/3 1100 3.6 200 16 66 61 5 4/3 1106 160 61 55 6 4/3 1164 4.4 表 4 乳化剂加量对高密度无土相油基钻井液性能的影响

t静置/

hAV/

mPa·sPV/

mPa·sYP/

Paφ6/φ3 ES/

VFLHTHP/

mL沉降

因子24 54 45 9 6/5 824 2.0 0.5042 72 53 44 9 5/4 763 2.2 0.5061 120 52 43 9 4/3 751 2.2 0.5073 240 54 44 10 3/2 592 3.0 0.5070 336 65 53 12 3/2 395 4.2 0.5074 表 5 高密度无黏土相油基钻井液的抗污染能力

侵污 AV/

mPa·sPV/

mPa·sYP/

Paφ6/φ3 ES/

VFLHTHP/

mL空白 53 45 8 6/5 786 2.2 5%钻屑 59 50 9 6/5 676 2.0 10%钻屑 59 49 10 6/5 684 1.8 10%水泥石粉 60 50 10 8/7 891 4.8 15%水泥石粉 72 58 14 10/8 866 6.4 10%CaCl2盐水 50 41 9 6/5 658 20%CaCl2盐水 67 54 13 14/12 590 表 6 龙马溪组现场钻井液主要性能

井段/

mFV/

sGel/

Pa/PaPV/

mPa·sYP/

PaFLHTHP/

mLES/

V固相含量/

%油水

比3500~4300 50~55 3~4.5/6~8 48~55 8~10 1.0~1.2 638~792 <50 79~83/17~21 4300~6100 55~64 4~5.0/7~10 50~60 9~11 1.0~1.5 766~974 <50 82~87/13~18 -

[1] 文华,陈毅,侯炼. 高温高密度无黏土相钻开液室内研究[J]. 河南科技,2015(1):124-126. doi: 10.3969/j.issn.1003-5168.2015.01.044WEN Hua, CHEN Yi, HOU Lian. Laboratory study of clay-Free high temperature and high density drilling fluid[J]. Journal of Henan Science and Technology, 2015(1):124-126. doi: 10.3969/j.issn.1003-5168.2015.01.044 [2] 蒋西平,周天辉,张勇. 无黏土相羟基酸盐钻井液[J]. 钻井液与完井液,2012,29(2):30-31. doi: 10.3969/j.issn.1001-5620.2012.02.010JIANG Xiping, ZHOU Tianhui, ZHANG Yong. Research on clay-free oxyacid salt drilling fluid[J]. Drilling Fluid & Completion Fluid, 2012, 29(2):30-31. doi: 10.3969/j.issn.1001-5620.2012.02.010 [3] 张立新,刘瑞. 高密度油基钻井液在阳101H3-6井长水平段的应用[J]. 钻探工程,2021,48(7):79-83.ZHANG Lixin, LIU Rui. Application of high-density oil-based drilling fluid in the long horizontal section of Well Yang 101H3-6[J]. Drilling Engineering, 2021, 48(7):79-83. [4] QIN Bobo, WANG Yidi, LUO Chunzhi, el at. Research on high temperature and high density white oil based drilling fluid and its application in well 201H7-6[J]. Open Journal of Yangtze Oil and Gas, 2019, 4(3):174-182. doi: 10.4236/ojogas.2019.43013 [5] 周峰,张华,李明宗,等. 强封堵型无土相油基钻井液在四川页岩气井水平段中的应用[J]. 钻采工艺,2016,39(3):106-109. doi: 10.3969/J.ISSN.1006-768X.2016.03.32ZHOU Feng, ZHANG Hua, LI Mingzong, et al. Application of strong sealing clay-free oil based drilling fluid in horizontal section of Sichuan shale gas reservoir[J]. Drilling process, 2016, 39(3):106-109. doi: 10.3969/J.ISSN.1006-768X.2016.03.32 [6] 张玉. 胜利油田钻井液油气层保护优化设计技术研究[D]. 中国石油大学(华东), 2018.ZHANG Yu. Optimal design of drilling fluid reservoir protection in Shengli Oilfield [D]. China University of Petroleum (East China), 2018. [7] 黄贤斌. 抗高温高性能无土相油基钻井液技术研究[D]. 中国石油大学(北京), 2017.HUANG Xianbin. High-temperature high-performance organoclay-free oil based drilling fluid technology research[D]. China University of Petroleum (Beijing), 2017. [8] 王燕,葛清晓,曾余祥. 无黏土高温高密度油基钻井液[J]. 科学技术创新,2019(30):48-49.WANG Yan, GE Qingxiao, ZENG Yuxiang. Clay free high temperature high density oil-based drilling fluid[J]. Science and Technology Innovation, 2019(30):48-49. [9] 孙金声,黄贤斌,蒋官澄,等. 无土相油基钻井液关键处理剂研制及体系性能评价[J]. 石油勘探与开发,2018,45(4):713-718.SUN Jinsheng, HUANG Xianbin, JIANG Guancheng, et al. Development of key additives for organoclay-free oil-based drilling mud and system performance evaluation[J]. Petroleum exploration and development, 2018, 45(4):713-718. [10] 蒋官澄,贺垠博,黄贤斌,等. 基于超分子技术的高密度无黏土油基钻井液体系[J]. 石油勘探与开发,2016,43(1):131-135. doi: 10.1016/S1876-3804(16)30015-5JIANG Guancheng, HE Yinbo, HUANG Xianbin, et al. A high-density organoclay-free oil base drilling fluid based on supramolecular chemistry[J]. Petroleum Exploration and Development, 2016, 43(1):131-135. doi: 10.1016/S1876-3804(16)30015-5 [11] 邢立江,张书会. SEBS共混物的力学性能研究[J]. 化学与生物工 程,2020,37(4):58-60.XING Lijiang, ZHANG Shuhui. Mechanical properties of SEBS blends[J]. Chemistry & Bioengineering, 2020, 37(4):58-60. [12] 邢立江,张书会. SIBS流变性能研究[J]. 化学与生物工程,2021,38(6):55-58. doi: 10.3969/j.issn.1672-5425.2021.06.011XING Lijiang, ZHANG Shuhui. Rheological property of SIBS[J]. Chemistry & Bioengineering, 2021, 38(6):55-58. doi: 10.3969/j.issn.1672-5425.2021.06.011 -

下载:

下载: