The Synthesis and Evaluation of a High Temperature Nano Micro-Spherical Polymer Plugging Agent

-

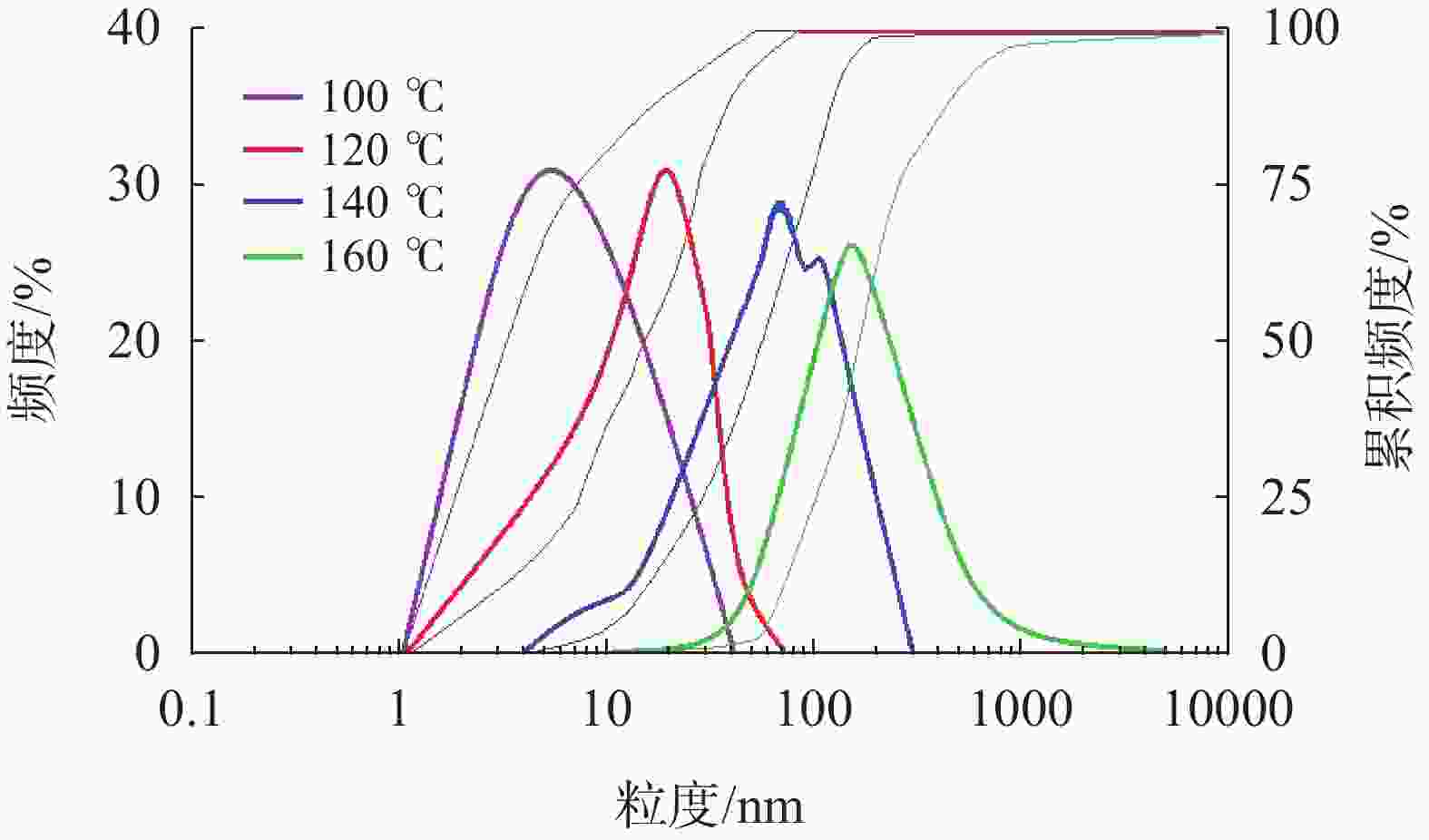

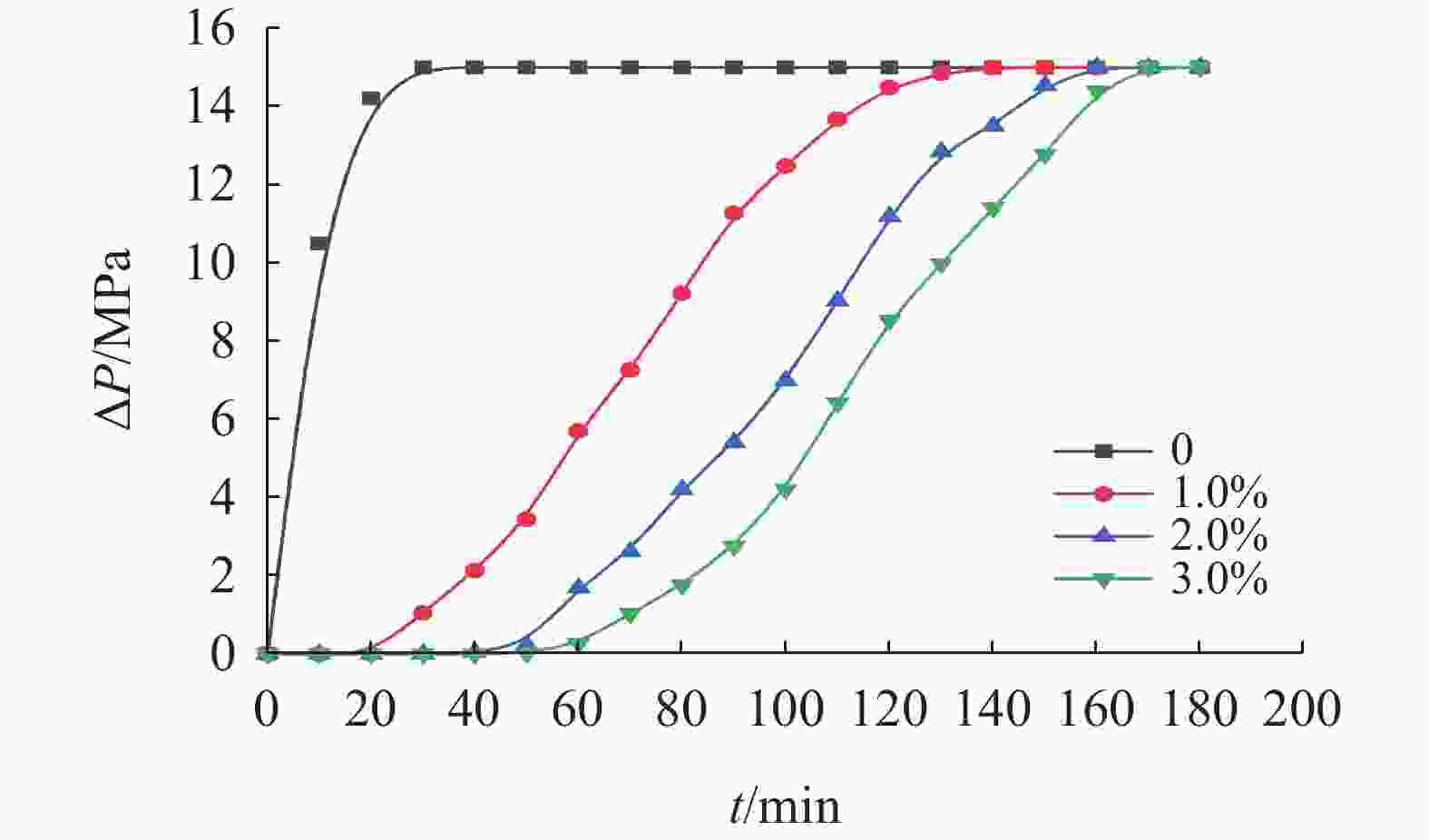

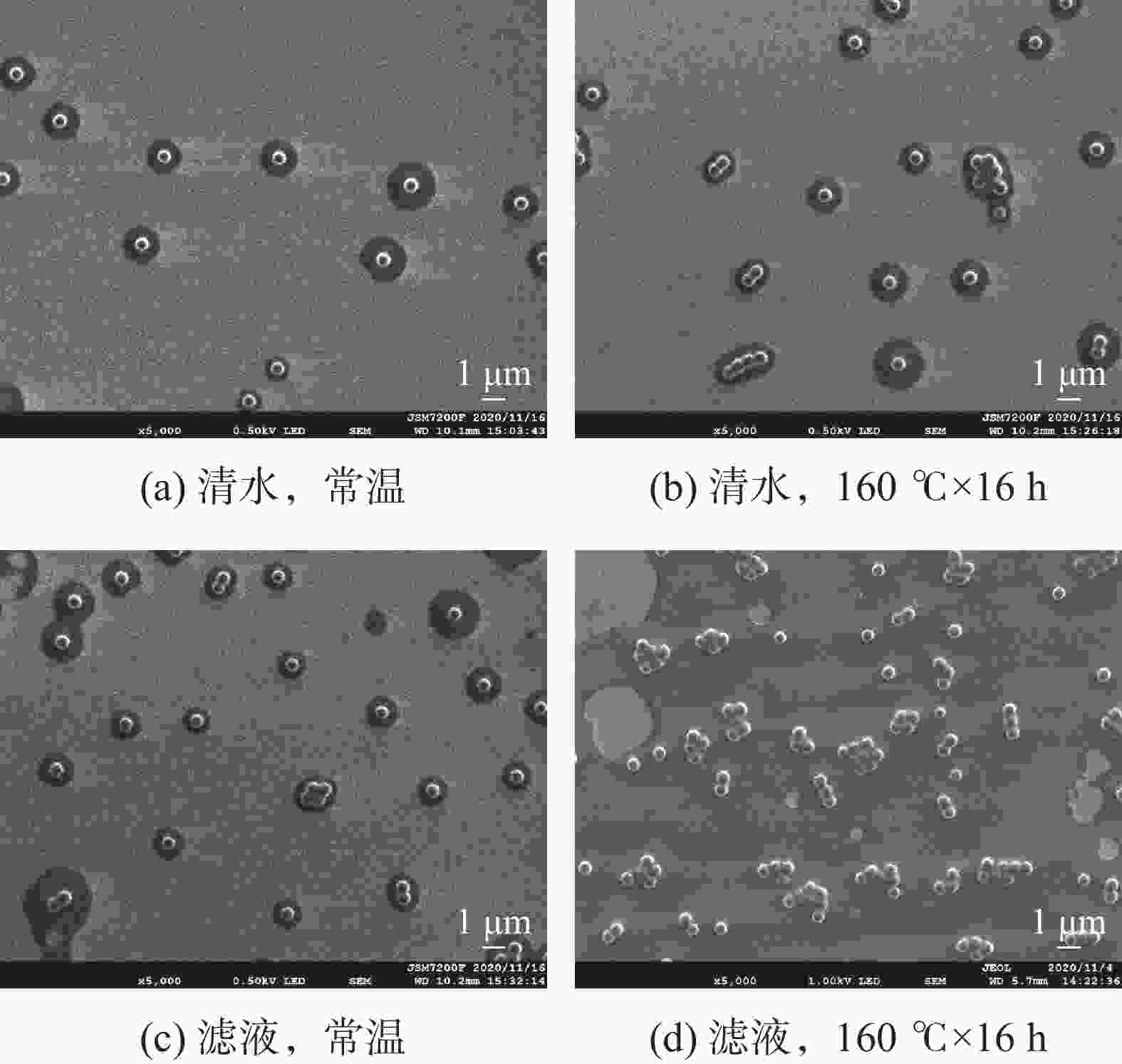

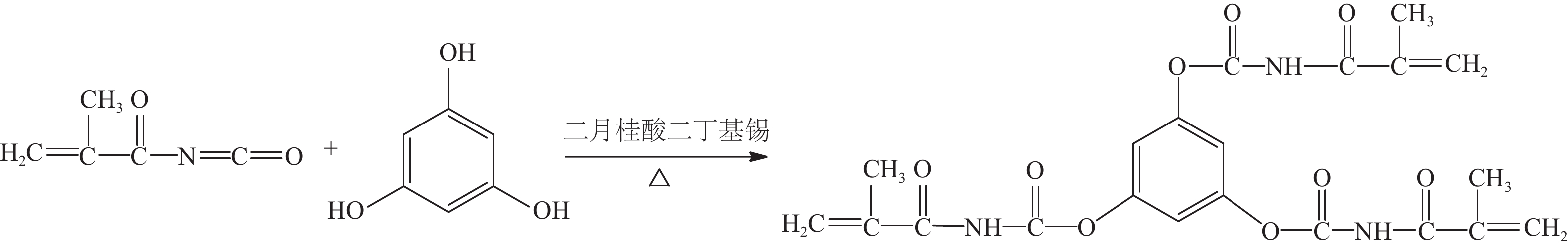

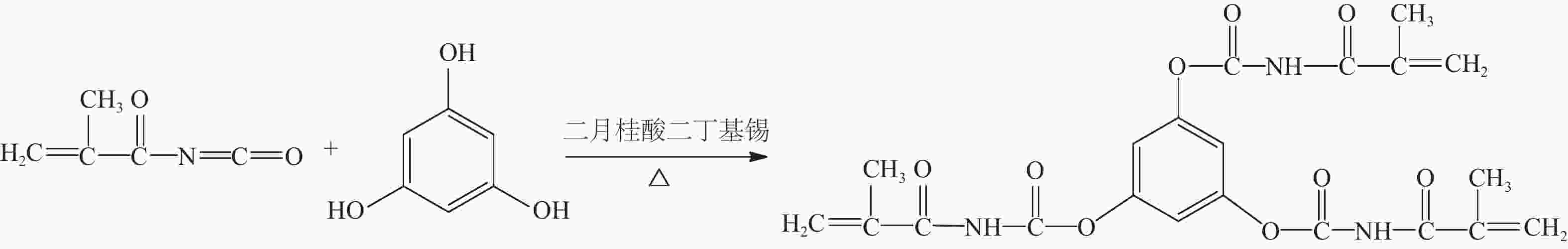

摘要: 针对目前钻井用柔性封堵剂抗温性弱的问题,开展了抗高温聚合物纳米微球封堵剂的研究。以丙烯酰胺(AM)、对苯乙烯磺酸钠(SSS)、丙烯酸钠(AAS)、丙烯酸十三氟辛酯(TEAC)和1,3,5-三(甲基丙烯酰胺基甲酸酯)苯(B-TMAC)为原料,偶氮异丁氰基甲酰胺(CABN)为引发剂,十二烷基硫醇(TDDM)为分子量调节剂,通过自由基胶束聚合法合成了聚合物纳米微球OPTB。通过正交实验确定了最佳合成条件:反应温度105 ℃、反应时间20 h、反应单体浓度7.5%、CABN浓度0.4%和TDDM浓度1.5%。借助核磁共振光谱仪(1H-NMR)进行了分子结构表征。OPTB的钻井液性能测试结果显示,OPTB对钻井液的流变性能影响较小,滤失造壁性能显著。高温老化后,OPTB的粒径仍呈单分散状态。OPTB的加量达到3.0%时,对纳微米孔隙的封堵率高达90.84%,且可有效减慢井筒内液柱压力向地层传递的速度。采用扫描电镜(ESEM)观测了160 ℃老化16 h前后的OPTB的微观形貌,结果显示 OPTB颗粒呈球形,粒径较均一,高温作用仍有部分颗粒仍保持单分散状态。Abstract: A nano micro-spherical polymer plugging agent OPTB was developed to try to replace the flexible plugging agents presently in use, which have the shortage of low thermal stability. OTPB is a high temperature plugging agent and is synthesized through free radical micellar polymerization with several raw materials such as acrylamide (AM), sodium p-styrene sulfonate (SSS), sodium acrylate (AAS), 1H,1H,2H,2H-perfluorooctyl acrylate (TEAC) and 1,3,5-tris(methacrylamido) benzene (B-TMAC). The polymerization used 1-((cyano-1-methylethyl) azo) formamide as the initiator, and dodecyl mercaptan (TDDM) as the molecular weight regulator. The optimum synthesis conditions were determined through orthogonal experiment, as follows: reaction temperature = 105 ℃, reaction time = 20 h, concentration of the monomeric raw materials = 7.5%, concentration of CABN = 0.4%, and concentration of TDDM = 1.5%. The molecular structure of OPTB was characterized with 1H-NMR. Experiment on the properties of the drilling fluid treated with OPTB showed that OPTB has little effect on the rheology of the drilling fluid, and the quality of the mud cake was significantly improved. After aging at high temperature, the particle size of OPTB is still in a monodisperse state. At a concentration of 3.0%, 90.84% of the nanometer-sized and micron-sized pores can be plugged by OPTB, and this plugging effect can effectively slow down the transmission of the pressure of the fluid column in the wellbore into the formations. The micromorphology of OPTB before and after aging at 160 ℃ for 16 h observed under SEM showed that the particles of OPTB are spherical with narrow size distribution. At elevated temperatures, part of the OPTB particles is still in monodisperse state.

-

表 1 L16(45)正交实验

水平 A B C D E 反应温

度/℃反应时

间/h反应单体

浓度/%CABN

浓度/%TDDM

浓度/%1 100 8 5.0 0.2 0.5 2 105 12 7.5 0.4 1.0 3 110 16 10.0 0.6 1.5 4 115 20 12.5 0.8 2.0 表 2 L16(45)正交实验结果

实验号 A B C D E 封堵率/% 1# 100 8 5.0 0.2 0.01 87.5 2# 100 12 7.5 0.4 0.02 88.2 3# 100 16 10.0 0.6 0.03 90.3 4# 100 20 12.5 0.8 0.04 91.2 5# 105 8 7.5 0.6 0.04 90.5 6# 105 12 5.0 0.8 0.03 95.0 7# 105 16 12.5 0.2 0.02 93.2 8# 105 20 10.0 0.4 0.01 91.7 9# 110 8 10.0 0.8 0.02 91.4 10# 110 12 12.5 0.6 0.01 84.2 11# 110 16 5.0 0.4 0.04 92.2 12# 110 20 7.5 0.2 0.03 95.8 13# 115 8 12.5 0.4 0.03 95.5 14# 115 12 10.0 0.2 0.04 87.4 15# 115 16 7.5 0.8 0.01 89.9 16# 115 20 5.0 0.6 0.02 87.0 均值1 89.300 91.225 90.425 90.975 88.325 均值2 92.600 88.700 91.100 91.900 89.950 均值3 90.900 91.400 90.200 88.000 94.150 均值4 89.950 91.425 91.025 91.875 90.325 极差(R) 3.300 2.725 0.900 3.900 5.825 表 3 钻井液流变性能及滤失性能测试结果

OPTB/

%T老化/

℃AV/

mPa·sPV/

mPa·sYP/

PaFLAPI/

mLFLHTHP/

mL0 100 16.0 11.0 5.0 12.6 32.0 120 16.0 11.0 5.0 13.0 32.6 140 15.5 11.0 4.5 14.4 35.0 160 14.5 10.0 4.5 16.8 40.0 180 12.0 8.0 4.0 18.8 60.4 1.0 100 17.5 12.0 5.5 9.2 23.4 120 17.0 12.0 5.0 9.2 24.0 140 16.0 11.0 5.0 9.6 24.8 160 15.0 10.0 5.0 11.8 27.2 180 11.5 8.0 3.5 18.6 58.4 2.0 100 17.5 12.0 5.5 8.6 20.2 120 16.5 11.0 5.5 8.8 21.6 140 16.5 11.0 5.5 9.0 22.4 160 15.5 11.0 4.5 10.8 24.0 180 11.5 8.0 3.5 18.4 58.0 3.0 100 18.5 13.0 5.5 8.0 19.6 120 17.5 12.0 5.5 8.2 20.8 140 17.0 12.0 5.0 8.6 22.0 160 16.0 11.0 5.0 10.0 23.4 180 12.0 8.0 4.0 18.0 57.6 注:磺化钻井液体系:4.0%预水化膨润土浆+0.3%PAC-

HV+1.0%SMC+1.0%SMP-I+1.0%SPNH表 4 OPTB对模拟纳微米孔隙地层封堵率的测试结果

OPTB/

%T老化/

℃平均流量/

cm2·s−1渗透率/

10−2 mD封堵率/

%1.0 100 0.1512 39.26 89.84 120 0.2089 54.24 85.96 140 0.3455 89.70 76.79 160 0.4718 122.49 68.30 2.0 100 0.0875 22.72 94.12 120 0.1372 35.62 90.78 140 0.1598 41.49 89.26 160 0.1917 49.77 87.12 3.0 100 0.0500 12.98 96.64 120 0.0916 23.78 93.85 140 0.1251 32.48 91.59 160 0.1364 35.41 90.84 注: 模拟纳微米级孔隙地层的渗透率为386.4×10−2 mD,

磺化钻井液的流量为1.4883 cm2·s−1 -

[1] 闫丽丽,李丛俊,张志磊,等. 基于页岩气“水替油”的高性能水基钻井液技术[J]. 钻井液与完井液,2015,32(5):1-6.YAN Lili, LI Congjun, ZHANG Zhilei, et al. High performance water base drilling fluid for shale gas drilling[J]. Drilling Fluid & Completion Fluid, 2015, 32(5):1-6. [2] 孟英峰,刘厚彬,余安然,等. 深层脆性页岩水平井裸眼完井井壁稳定性研究[J]. 西南石油大学学报(自然科学版),2019,41(6):51-59.MENG Yingfeng, LIU Houbin, YU Anran, et al. Borehole completion stability of deep brittle shale horizontal wells[J]. Journal of Southwest Petroleum University (Science & Technology Edition) , 2019, 41(6):51-59. [3] 温航,陈勉,金衍,等. 硬脆性泥页岩斜井段井壁稳定力学耦合研究[J]. 石油勘探与开发,2019,41(6):748-754.WEN Hang, CHEN Mian, JIN Yan, et al. A chemo-mechanical coupling model of deviated borehole stability in hard brittle shale[J]. Petroleum Exploration and Development, 2019, 41(6):748-754. [4] 陶士先,胡继良,纪卫军. 水敏性地层钻探用接枝淀粉聚合物泥浆体系研究[J]. 地质与勘探,2012,48(5):1029-1033.TAO Shixian, HU Jiliang, JI Weijun. Study of the grafted starch-polymer mud system used for drilling in water-sensitive strata[J]. Geology and Exploration, 2012, 48(5):1029-1033. [5] 何振奎. 页岩水平井斜井段强抑制强封堵水基钻井液技术[J]. 钻井液与完井液,2013,30(2):43-46. doi: 10.3969/j.issn.1001-5620.2013.02.013HE Zhenkui. Strong hibition and sealing water based drilling fluid technology for deviated section of shale horizontal[J]. Drilling Fluid & Completion Fluid, 2013, 30(2):43-46. doi: 10.3969/j.issn.1001-5620.2013.02.013 [6] 罗霄,都伟超,蒲晓林,等. 抗高温有机硅-胺类抑制剂的研制与性能研究[J]. 油田化学,2016,33(4):575-579.LUO Xiao, DU Weichao, PU Xiaolin, et al. Preparation and performance of high-temperature tolerant organosilicon-amine inhibitor for drilling fluid[J]. Oilfield Chemistry, 2016, 33(4):575-579. [7] 邱正松,钟汉毅,黄维安. 新型聚胺页岩抑制剂特性及作用机理[J]. 石油学报,2011,32(4):678-682. doi: 10.7623/syxb201104017QIU Zhengsong, ZHONG Hanyi, HUANG Weian. Properties and mechanism of a new polyamine shale inhibitor[J]. Acta Petrolei Sinica, 2011, 32(4):678-682. doi: 10.7623/syxb201104017 [8] 褚奇,李涛,王栋,等. 龙凤山气田强抑制封堵型防塌钻井液技术[J]. 钻井液与完井液,2016,33(5):35-40.CHU Qi, LI Tao, WANG Dong, et al. Plugging inhibitive drilling fluid used in Longfengshan gas field[J]. Drilling Fluid & Completion Fluid, 2016, 33(5):35-40. [9] 褚奇,孔勇,杨帆,等. 多苯基芳基硅烷偶联剂改性纳米SiO2封堵剂[J]. 断块油气田,2017,24(2):281-284.CHU Qi, KONG Yong, YANG Fan, et al. Nano-silica dioxide plugging agent modified by polyphenyl aryl silanes coupling agent[J]. Fault-Block Oil & Gas Field, 2017, 24(2):281-284. [10] 马成云,宋碧涛,徐同台,等. 钻井液用纳米封堵剂研究进展[J]. 钻井液与完井液,2017,34(1):1-8. doi: 10.3969/j.issn.1001-5620.2017.01.001MA Chengyun, SONG Bitao, XU Tongtai, et al. Progresses in studying drilling fluid nano material plugging agents[J]. Drilling Fluid & Completion Fluid, 2017, 34(1):1-8. doi: 10.3969/j.issn.1001-5620.2017.01.001 [11] 于洪江,拓丹,熊迅宇. 成膜性纳米微乳液封堵剂的制备与评价[J]. 应用化工,2018,47(1):92-95. doi: 10.3969/j.issn.1671-3206.2018.01.023YU Hongjiang, TUO Dan, XIONG Xunyu. Preparation and evaluation of film-forming nano microemulsion plugging agent[J]. Applied Chemical Industry, 2018, 47(1):92-95. doi: 10.3969/j.issn.1671-3206.2018.01.023 [12] 向朝纲,蒲晓林,陈勇. 新型封堵剂FDJ-EF封堵特性及作用机理[J]. 断块油气田,2012,19(2):249-252.XIANG Chaogang, PU Xiaolin, CHEN Yong. Characteristics of novel sealing agent FDJ-EF and its sealing mechanism[J]. Fault-Block Oil & Gas Field, 2012, 19(2):249-252. [13] GB/T 16783-1997, 水基钻井液现场测试程序[S].GB/T 16783-1997, Water-based drilling fluid field test procedure[S]. [14] 刘洋洋,邓明毅,谢刚,等. 基于压力传递的钻井液纳米封堵剂研究与应用[J]. 钻井液与完井液,2017,34(6):24-28. doi: 10.3969/j.issn.1001-5620.2017.06.005LIU Yangyang, DENG Mingyi, XIE Gang, et al. Study and application of a drilling fluid plugging agent based on pressure transfer inhibition[J]. Drilling Fluid & Completion Fluid, 2017, 34(6):24-28. doi: 10.3969/j.issn.1001-5620.2017.06.005 -

下载:

下载: