Experimental Research on Prediction and Prevention of Scaling in Lingshui 25-1 Gas Reservoir

-

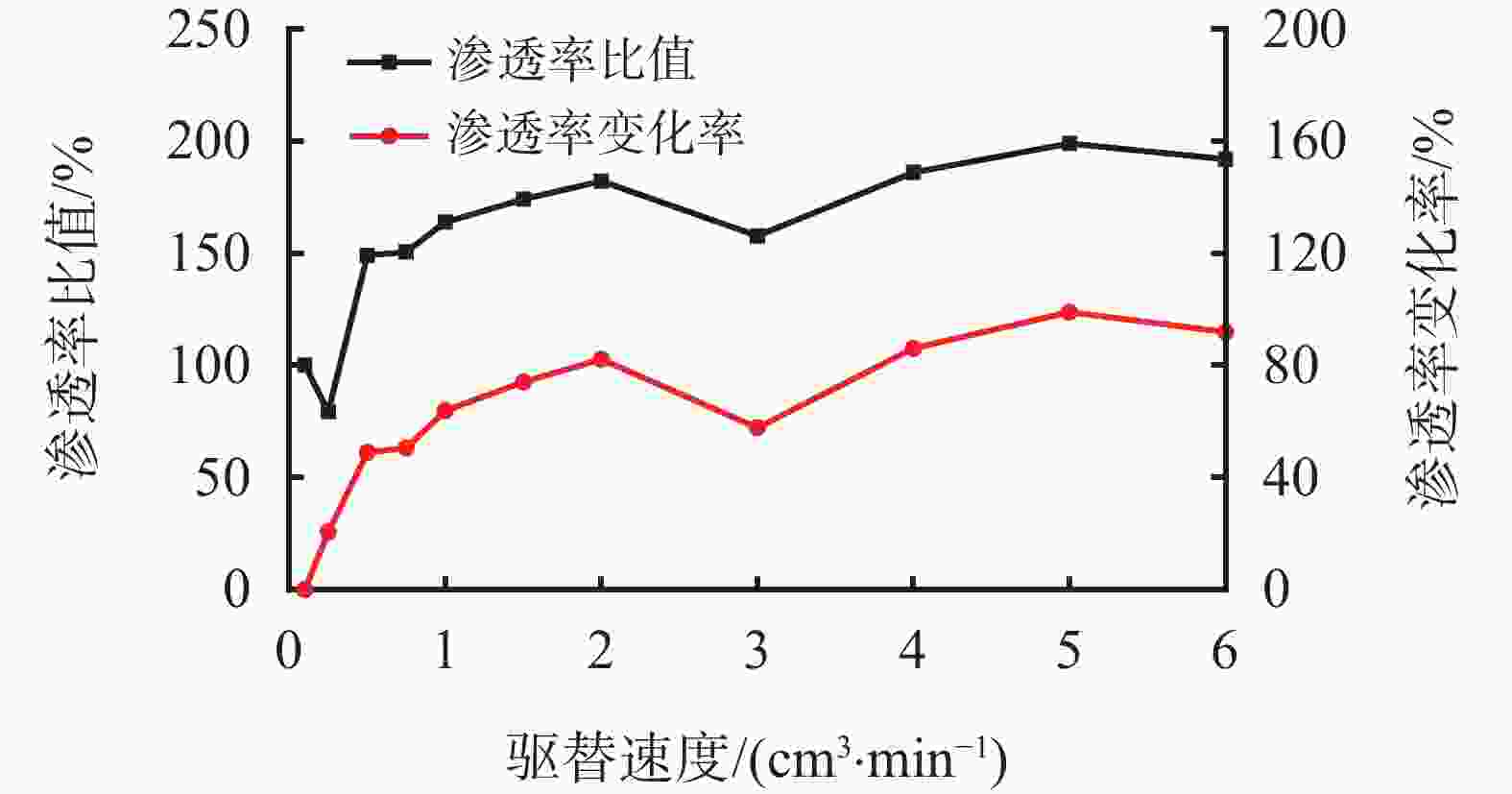

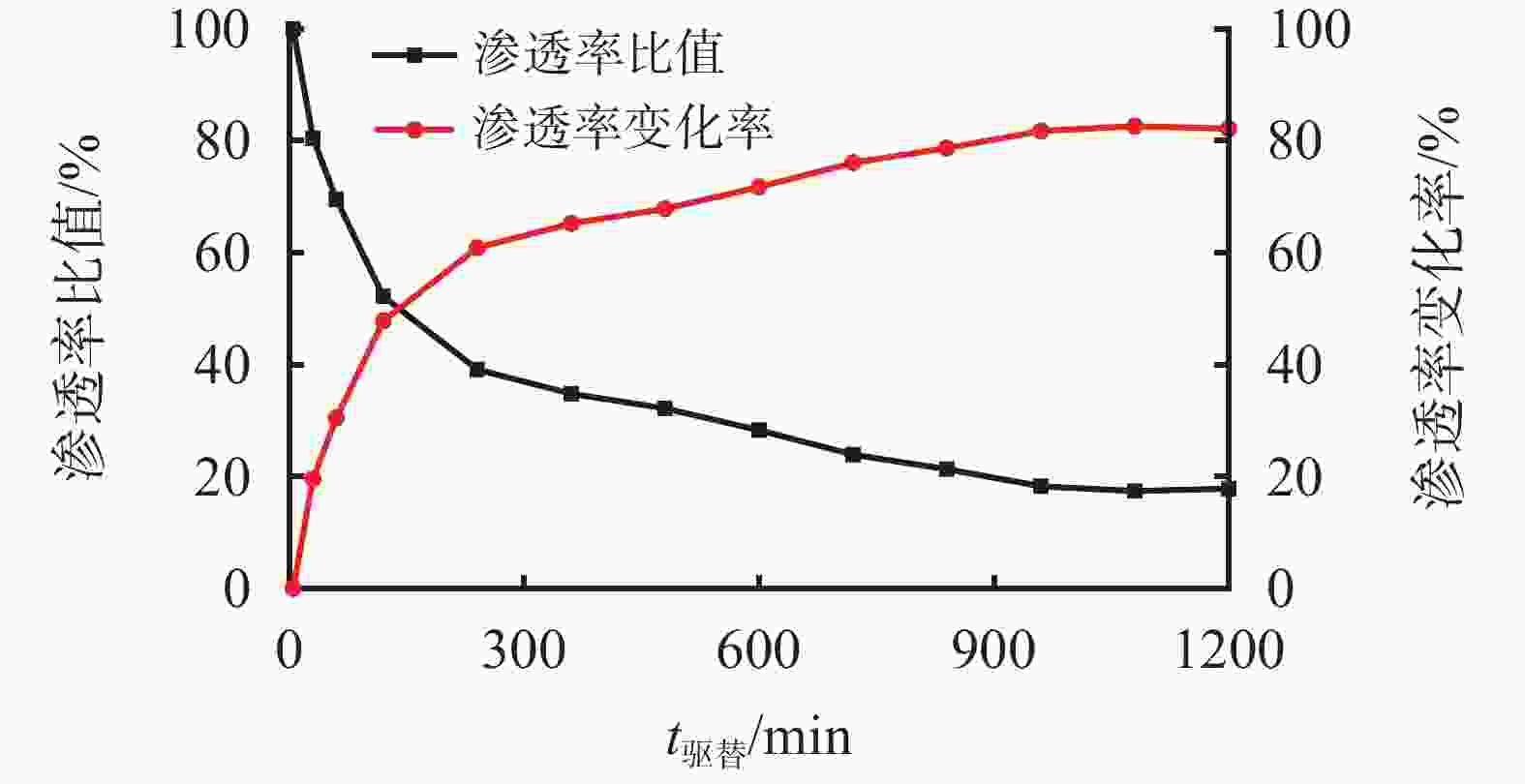

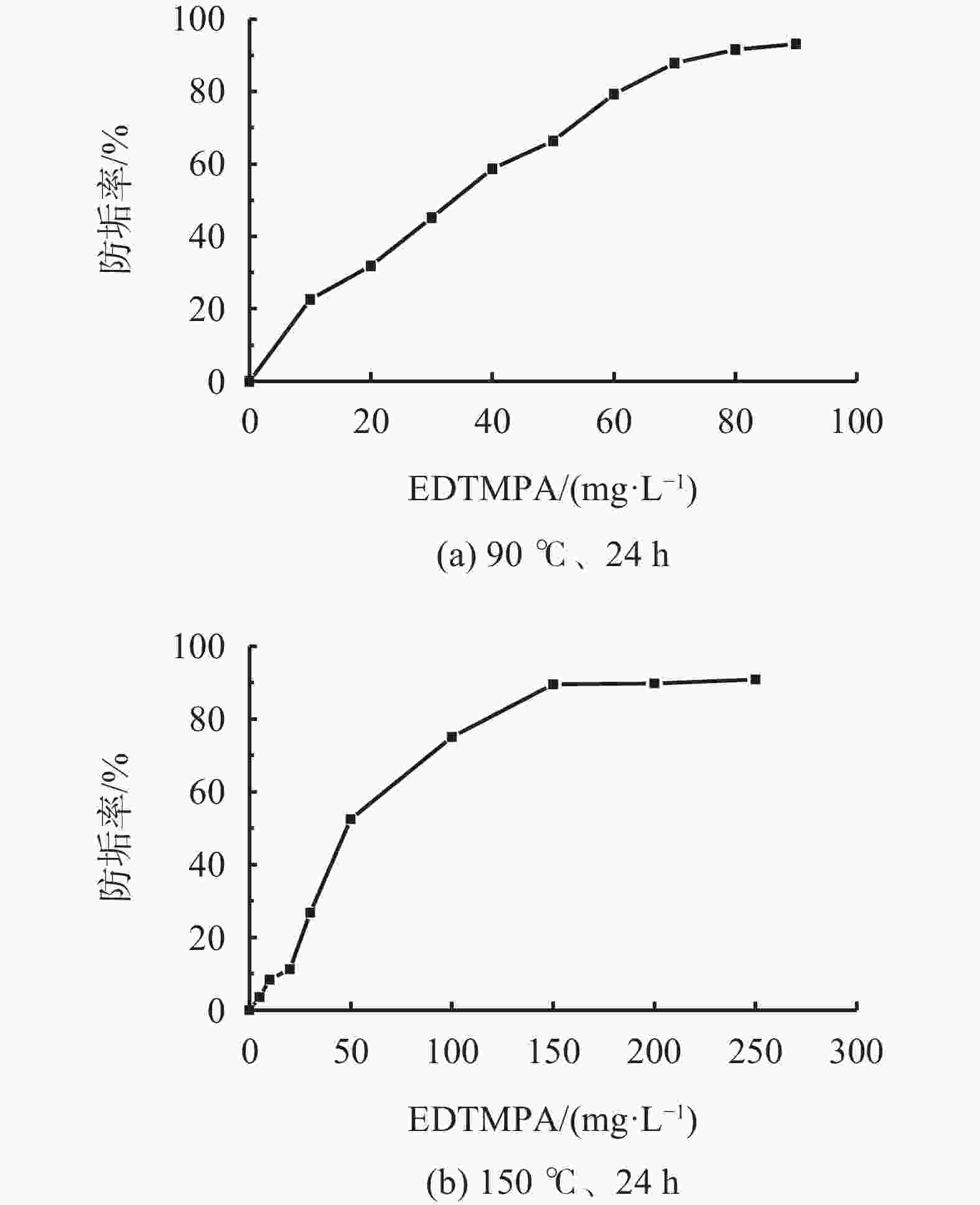

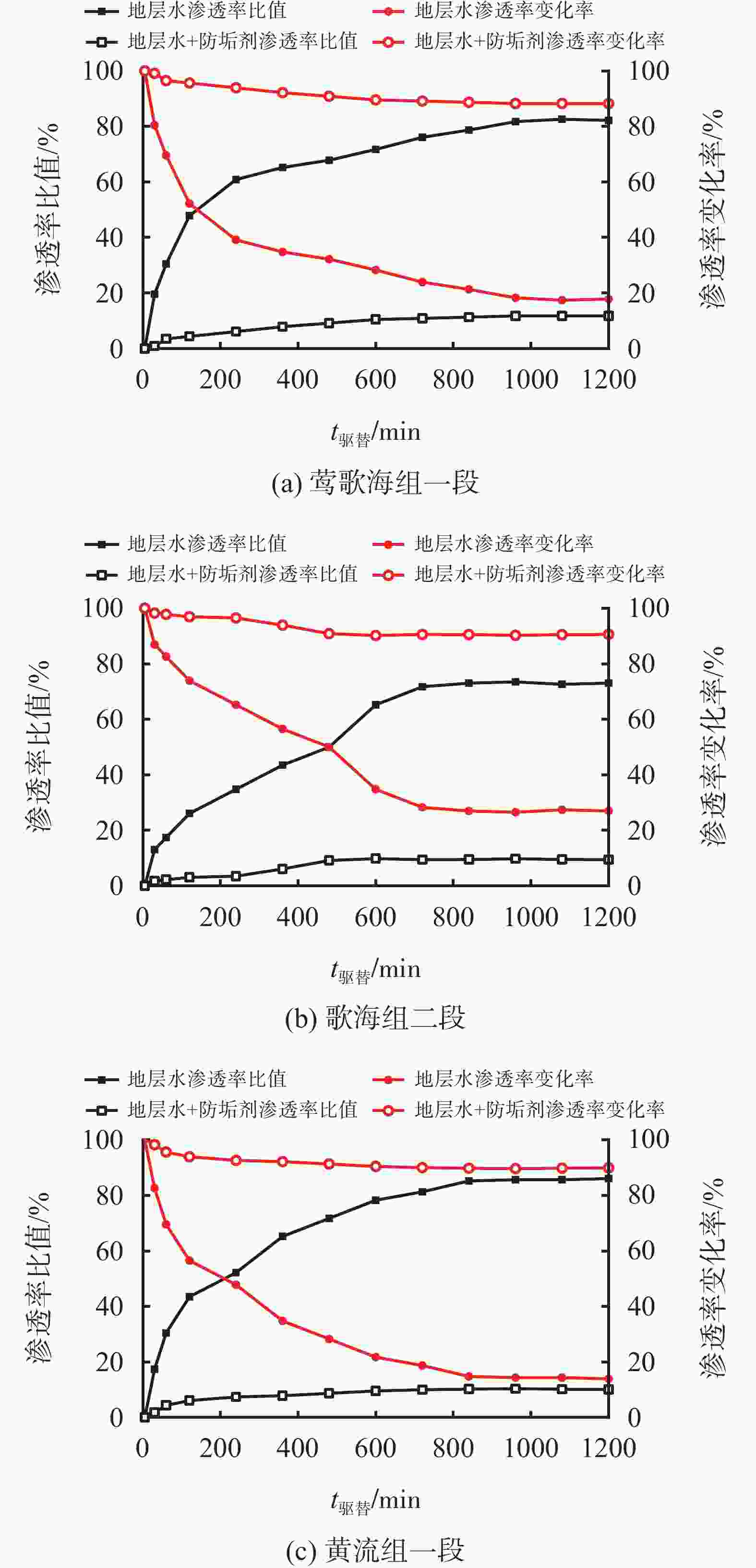

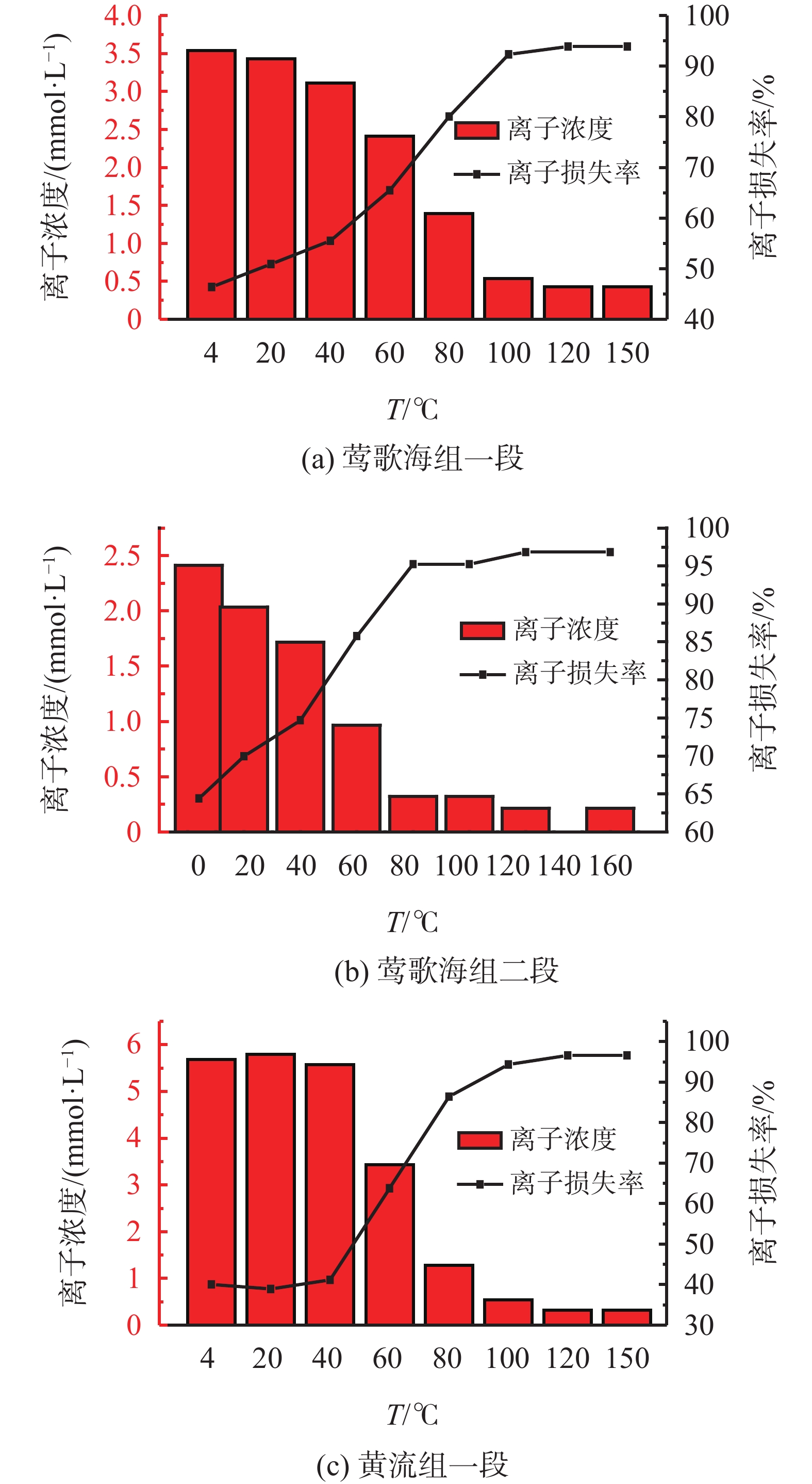

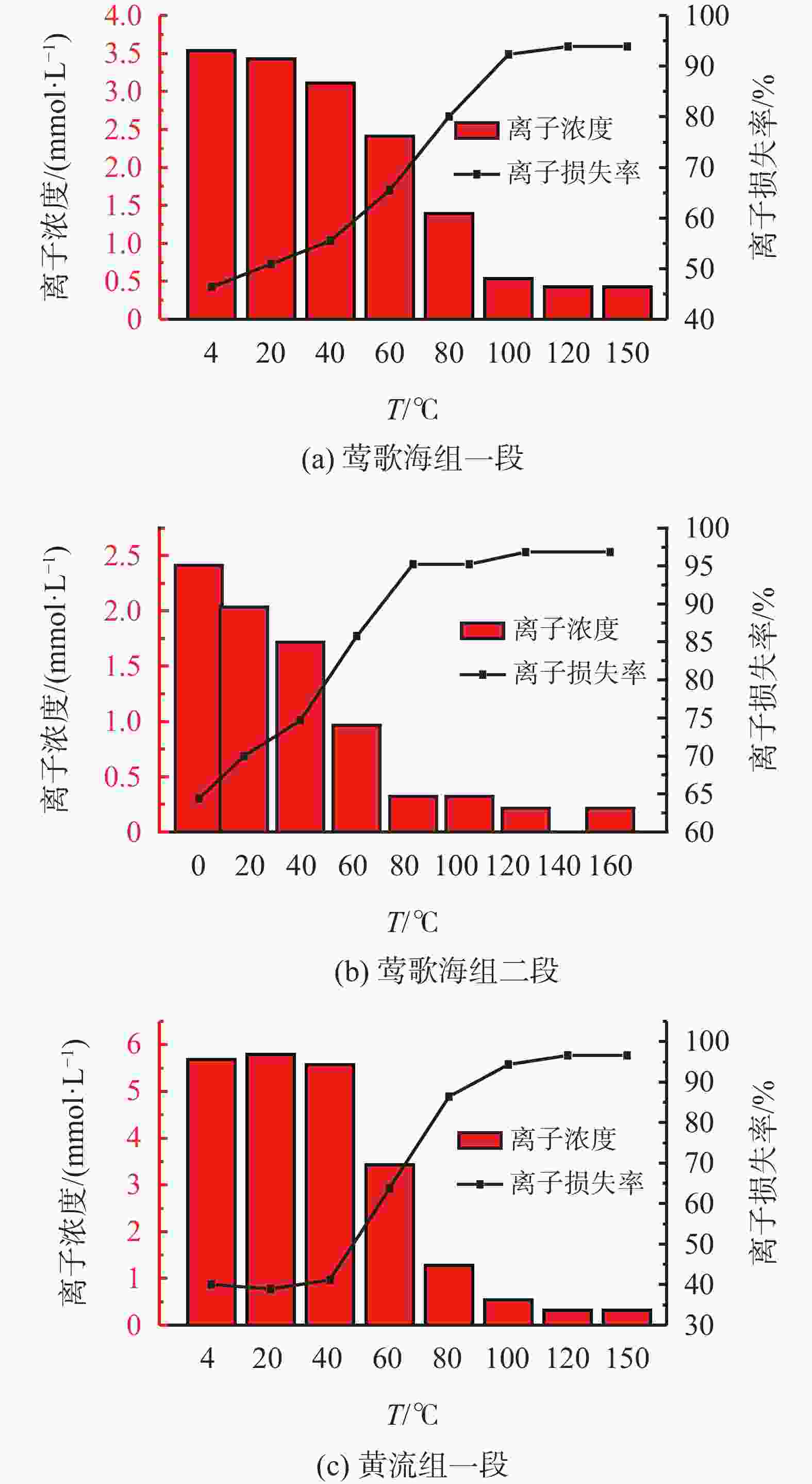

摘要: 为解决陵水25-1气田地层水矿化度高,结垢严重的问题,通过结垢趋势计算与实验评价,分析了陵水25-1气田的结垢风险,建立了附着系数等结垢程度定量化评价指标,开展其影响规律实验研究,并优选了具有良好阻垢效果的防垢剂。结果表明,陵水25-1气田在地层温度和压力下,存在严重的结垢风险。岩心流动实验表明,垢样附着系数较小,易随流体产生运移,临界流速为0.25 cm3/min,随着驱替时间的增加,岩心渗透率逐渐降低,并在1200 min左右达到平衡,渗透率变化率最大为82.17%,随着温度的升高将会加剧地层水的结垢趋势,最大渗透率变化率为81.86%;优选的防垢剂乙二胺四亚甲基膦酸通过强金属螯合与晶格畸变作用,对陵水25-1气田不同层位地层水的静态及动态防垢效果均大于85%,具有良好的防垢效果。Abstract: In order to solve the prominent problems of high salinity and serious scaling of formation water in Lingshui 25-1 gas field, through the scaling trend calculation and experimental evaluation, the scaling risk of Lingshui 25-1 gas field is analyzed, the quantitative evaluation indexes of scaling degree such as adhesion coefficient are established, the experimental research on its influence law is carried out, and the scale inhibitor with good scale inhibition effect is optimized. The results show that there is a serious scaling risk in Lingshui 25-1 gas field under the conditions of formation temperature and pressure. The core test results show that the scale sample has a small adhesion coefficient and is easy to migrate with the fluid. The critical flow rate is 0.25 cm3/min. with the increase of displacement time, the core permeability gradually decreases and reaches equilibrium at about 1200 min. the maximum permeability change rate is 82.17%. With the increase of temperature, the scaling trend of formation water will be exacerbated, and the maximum permeability change rate is 81.86%; The preferred scale inhibitor ethylenediamine tetramethylene phosphonic acid (EDTMPA) has a good scale prevention effect on the static and dynamic scale prevention of formation water in different layers of Lingshui 25-1 gas field through strong metal chelation and lattice distortion.

-

Key words:

- Permeability /

- Scale inhibitor /

- Mineralization degree /

- Scaling mechanism

-

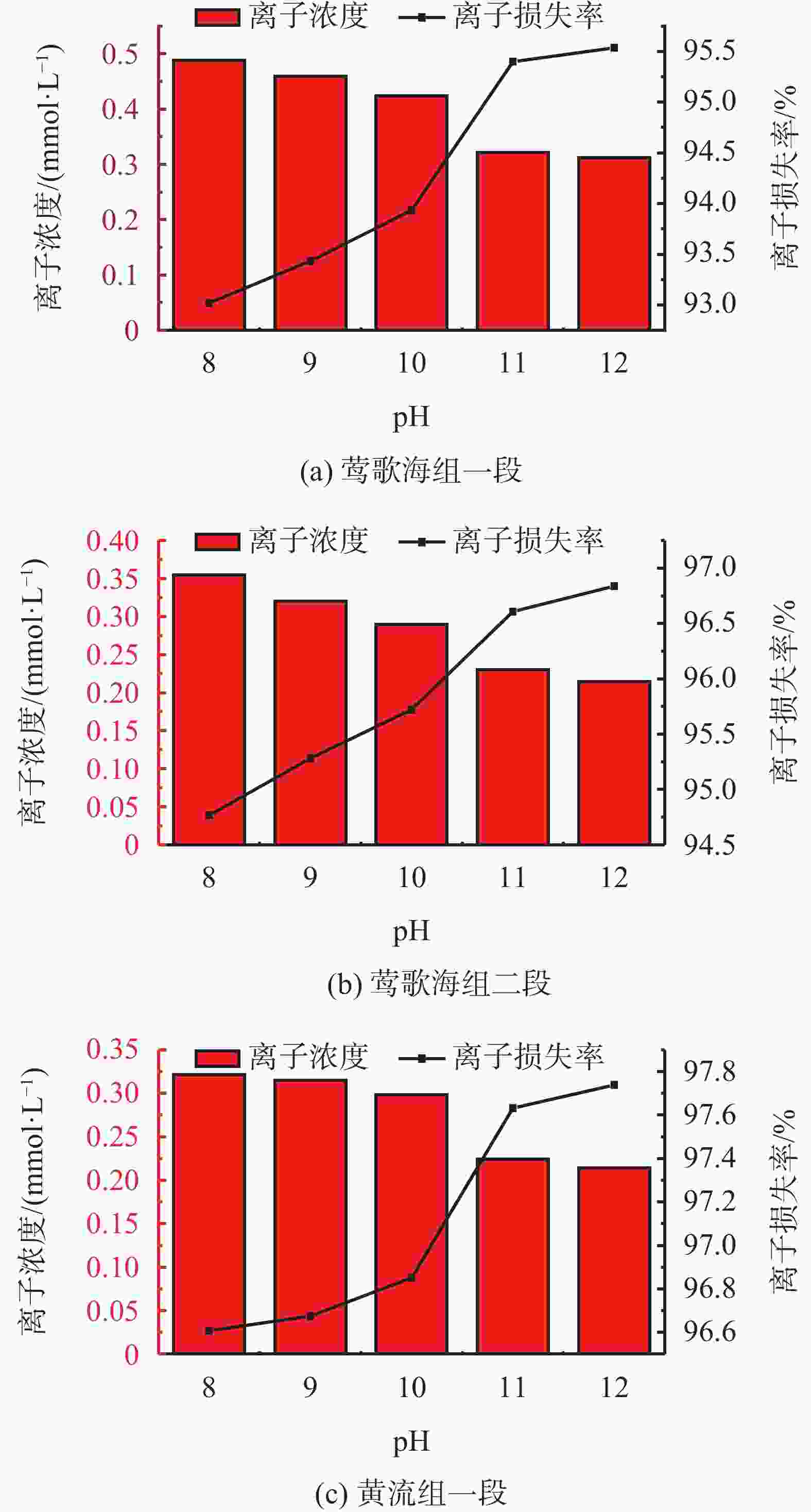

表 1 陵水25-1气田井不同地层水的离子含量分析

井号 地层 地层水离子含量/(mg·L−1) 总矿化度/

(mg·L−1)水型 pH值 阳离子 阴离子 K++ Na+ Ca2+ Mg2+ Cl− SO42− HCO3− CO32− LS22-1-1 莺歌海组 8076 1868 105 15 200 4.88 1596 0 26 850 CaCl2 7.27 LS17-2-4 莺歌海组 10 458 55 5 14 582 204 2370 111 27 785 NaHCO3 8.62 LS25-1-2 莺歌海组一段 14 813 143 82 20 709 1986 3026 379 41 138 NaHCO3 8.85 莺歌海组二段 14 910 197 45 19 921 2411 5057 220 42 761 NaHCO3 8.71 黄流组一段 13 115 131 149 17 610 2499 3901 244 37 649 NaHCO3 8.75 表 2 陵水25-1气田地层水碳酸钙结垢趋势预测

井号 地层 饱和指数SI LS22-1-1 莺歌海组 3.57 LS17-2-4 莺歌海组 0.54 LS25-1-2 莺歌海组一段 1.61 莺歌海组二段 1.03 黄流组一段 1.48 表 3 地层温度、压力下硫酸钙结垢趋势计算

井号 地层 饱和指数SI CaSO4·2H2O CaSO4·1/2H2O CaSO4 LS22-1-1 莺歌海组 −0.51 −0.48 0.20 LS17-2-4 莺歌海组 0.43 0.53 1.37 LS25-1-2 莺歌海组一段 0.42 0.54 1.50 莺歌海组二段 0.56 0.69 1.64 黄流组一段 0.37 0.51 1.50 表 4 陵水25-1地层水防垢剂优选实验结果(150 ℃/24 h)

样品 外观 防垢率/% 样品 外观 防垢率/% 空白 0 JXL-201 琥珀色透

明液体10.1 ATMP 橙色透

明液体33.2 PC191T 黄色透

明液体35.6 JH-622 白色透

明液体44.3 KBei-214 淡黄色透

明液体46.0 XT-607B 琥珀色透

明液体58.6 TS-310 黄色透

明液体16.8 EDTMPA 白色粉末 89.6 KY-308 无色或浅

黄色液体53.7 -

[1] 唐咸弟,李中,郭永宾,等. 陵水17-2气田深水钻井液性能控制指标体系研究[J]. 化学与生物工程,2019,36(12):44-47.TANG Xiandi, LI Zhong, GUO Yongbin, et al. Study on performance control index system of deepwater drilling fluid in Lingshui 17-2 gas field[J]. Chemical and Biological Engineering, 2019, 36(12):44-47. [2] 王雪峰,李林,王国雨,等. 南海深水盆地油气地质特征及勘探方向[J]. 海洋地质前沿,2021,37(1):1-10.WANG Xuefeng, LI Lin, WANG Guoyu, et al. Petroleum geological characteristics and exploration direction of deep-water basins in the South China Sea[J]. Marine Geological Frontier, 2021, 37(1):1-10. [3] 赵梓涵. 油田结垢预测及防垢技术的研究进展[J]. 辽宁石油化工大学学报,2018,38(5):19-23.ZHAO Zihan. Research progress of oilfield scaling prediction and scale prevention technology[J]. Journal of Liaoning University of Petrochemical Technology, 2018, 38(5):19-23. [4] 魏凯,何荣华,李国锋. 鄂尔多斯盆地大牛地气田气井结垢机理及除垢技术[J]. 天然气勘探与开发,2018,41(4):62-68.WEI Kai, HE Ronghua, LI Guofeng. Scaling mechanism and descaling technology of gas wells in Daniudi gas field, Ordos Basin[J]. Natural Gas Exploration and Development, 2018, 41(4):62-68. [5] 瓮子文,谢国松,李勇. 油田结垢和化学除垢剂的应用[J]. 化学工程师,2020,50(3):61-65.WENG Ziwen, XIE Guosong, LI Yong. Oilfield scaling and application of chemical descaling agent[J]. Chemical Engineer, 2020, 50(3):61-65. [6] S HAMID, O DE JESUS, C JACINTO, et al. A practical method of predicting calcium carbon-ate scale formation in well completions[J]. SPE Prod, 2016, 31(1):1-11. [7] 米思丞. 渤中28-2南油田注水结垢机理及防垢、除垢方法研究[D]. 西南石油大学, 2015.MI Sicheng. Study on scaling mechanism and scale prevention and removal methods of water injection in Bozhong 28-2 South oilfield [D]. Southwest Petroleum University, 2015. [8] 曾丽瑶. 硫酸钙结垢影响因素及化学阻垢剂合成[D]. 西南石油大学, 2018.ZENG Liyao. Influencing factors of calcium sulfate scaling and synthesis of chemical scale inhibitor [D]. Southwest Petroleum University, 2018. [9] JORDAN M M, WILLIAMS H, LINARES-SAMANIEGO S , et al. New insights on the impact of high temperature conditions (176 ℃) on carbonate and sulphate scale dissolver performance[C]//SPE International Oilfield Scale Conference and Exhibition. OnePetro, 2014. [10] 路建萍,冯虎强,刘聪,等. 一种高效多功能型阻垢剂的性能评价[J]. 化学工程师,2016,30(7):14-17.LU Jianping, FENG Huqiang, LIU Cong, et al. Performance evaluation of an efficient multifunctional scale inhibitor[J]. Chemical engineer, 2016, 30(7):14-17. [11] 赵晓洋,唐静,刘伟,等. 乙二胺四乙酸和乙二胺四亚甲基麟酸清除铁垢性能的量子化学计算[J]. 华南师范大学学报(自然科学版),2020,52(3):35-41.ZHAO Xiaoyang, TANG Jing, LIU Wei, et al. Quantum chemical calculation of iron scale removal performance of ethylenediamine tetraacetic acid and ethylenediamine tetramethyllin acid[J]. Journal of South China Normal University (Natural Science Edition) , 2020, 52(3):35-41. -

下载:

下载: