Research and Application of Fracturing Flowback Fluid Reuse Technology in Sulige Gas Field

-

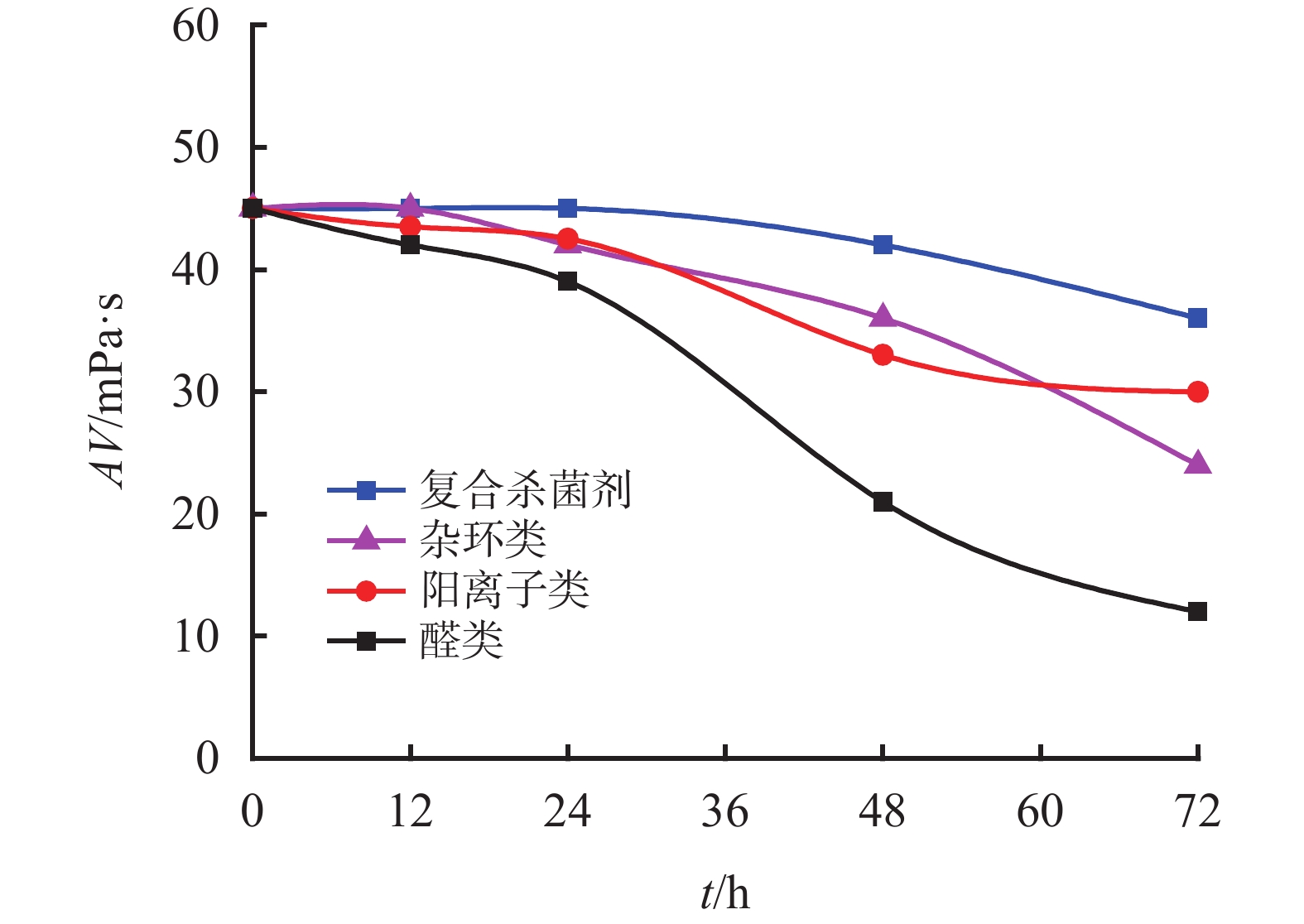

摘要: 根据苏里格气田压裂返排液的特点和回用配制压裂液对水质的要求,形成了一套以“预处理—混凝沉降—两级过滤—杀菌抑菌”为工艺路线的压裂返排液处理技术。经处理后的返排液固体悬浮物小于20 mg/L,钙、镁离子含量小于30 mg/L,化学需氧量低于100 mg/L,配制瓜胶压裂液72 h黏度下降率低于20%。处理后的返排液用于配制瓜胶压裂液和聚合物压裂液,其耐温耐剪切性、黏弹性、破胶液性能等各项指标均满足行业标准要求。现场可对各个模块和处理单元进行选择性组合实现快速处理和精细处理,速度为150~300 m3/d。近3年使用处理后的返排液配制压裂液超过3.6×104 m3,应用效果良好。Abstract: According to the characteristics of fracturing flowback fluid in Sulige gas field and the water quality requirement of treated flowback fluid used to prepare fracturing fluid, a series of treatment processes including pretreatment, coagulation & sedimentation, double filtration and sterilization & inhibition, had been established. After treatment, the suspended solid in the flowback fluid could be controlled to less than 20 mg/L, the content of calcium and magnesium ions is less than 30 mg/L, and the COD is also be reduced to lower than 100 mg/L. Viscosity decreasing rate of the guar gum fracturing fluid prepared by the treated water is less than 20% after 72 h. The treated water is used to prepare both guar gum based and polymer based fracturing fluid, whose temperature and shear resistance, viscoelasticity and gel-breaking properties could meet the requirements of the general industry standards. Both rapid and fine treatment within a treating speed of 150~300 m3/d can be realized by selectively combining each module and processing unit. In the last three years, more than 36,000 m3 fracturing fluid were prepared by using the treated flowback fluid and the field application effect is remarkable.

-

Key words:

- Fracturing flowback fluid /

- Reuse coagulation /

- Filtration /

- Sterilization

-

表 1 苏里格气田区块压裂返排液成分分析

项目 分析结果 桃7区块 苏5区块 苏59区块 外观 褐色至黑色液体 气味 有腐败气味 pH 6~8 总矿化度/

(mg·L−1)7570~9980 6890~13060 9080~14 910 Ca2+/(mg·L−1) 282~541 322~757 375~812 Mg2+/(mg·L−1) 60~122 88~216 79~225 COD/(mg·L−1) 2860~4490 2320~4680 1640~3570 固体悬浮物

含量/(mg·L−1)480~1150 330~1410 270~1340 细菌数/

(个·mL−1)>104 表 2 混凝沉降后上清液水质

项目 SS/

mg·L−1COD/

mg·L−1Ca2++Mg2+/

mg·L−1浊度/

NTU实测值 <150 <400 <30 <50 表 3 二级过滤前后返排液的水质

返排液 SS/

mg·L−1COD/

mg·L−1Ca2++Mg2+/

mg·L−1浊度/

NTU石英砂过滤后 <80 <250 <30 <5 滤袋过滤后 <20 <100 <30 <1 井水 40~60 80~150 <5 表 4 2种压裂液的破胶性能

项目 测试结果 瓜胶压裂液 聚合物压裂液 破胶时间/h 0.5~2可控 0.5~2可控 破胶液黏度/(mm2·s−1) 1~2 1~3 破胶液表面张力/(mN·m−1) 23~25 23~27 与煤油界面张力/(mN·m−1) 0.8~1.4 0.8~1.8 残渣含量/(mg·L−1) 300~450 220~350 -

[1] 韩卓,郭威,张太亮,等. 常规压裂返排液回注处理实验研究[J]. 石油与天然气化工,2014,43(1):108-112.HAN Zhuo, GUO Wei, ZHANG Tailiang, et al. Experimental study on reinjection treatment of unconventional fracturing flow-back fluid[J]. Chemical Engineering of Oil and Gas, 2014, 43(1):108-112. [2] 王佳,李俊华,雷珂,等. 压裂返排液处理技术研究进展[J]. 应用化工,2017,46(7):1414-1416,1423.WANG Jia, LI Junhua, LEI Ke, et al. Progresses in research of fracturing flowback fluids treatment technologies[J]. Applied Chemical Industry, 2017, 46(7):1414-1416,1423. [3] 路建萍,谢元,雷海,等. 压裂返排液的无害化处理技术研究[J]. 石油化工应用,2017,36(10):5-8,23.LU Jianping, XIE Yuan, LEI Hai, et al. A study on the harmless treatment technology of fracturing fluid flowback[J]. Petrochemical Industry Application, 2017, 36(10):5-8,23. [4] 韩洪晶,杨元林,王宝辉. 压裂返排液无害化处理的研究与现状[J]. 现代化工,2017,37(12):46-49.HAN Hongjing, YANG Yuanlin, WANG Baohui. Harmless treatment research status of hydraulic fracturing flowback fluid[J]. Modern Chemical Industry, 2017, 37(12):46-49. [5] 高树生,张文柯. 延长油田气井压裂返排液处理再利用技术研究[J]. 石化技术,2017,24(3):59-60.GAO Shusheng, ZHANG Wenke. Research on treatment and reutilization of gas well fracturing and flow-back fluids in Yanchang oilfield[J]. Petrochemical Industry Technology, 2017, 24(3):59-60. [6] 宋永亭,袁长忠,张守献,等. 滨37井工厂乳液缔合型压裂返排液回用处理技术应用[J]. 钻采工艺,2017,40(1):88-91,10.SONG Yongting, YUAN Changzhong, ZHANG Shouxian, et al. Treatment and recycling of returned factory emulsion associated fracturing fluid on well Bin 37[J]. Drilling & Production Technology, 2017, 40(1):88-91,10. [7] 马红,黄达全,李广环,等. 瓜胶压裂返排液重复利用的室内研究[J]. 钻井液与完井液,2017,34(4):122-126.MA Hong, HUANG Daquan, LI Guanghuan, et al. Laboratory study on recycling of flowback fluid of guar gun fracturing fluid[J]. Drilling Fluid & Completion Fluid, 2017, 34(4):122-126. [8] 于世虎,张晓虎,李倚云. 苏里格气田压裂返排液的处理及循环利用技术[J]. 化工环保,2019,39(3):360-366.YU Shihu, ZHANG Xiaohu, LI Yiyun. Treatment and recycling technology of fracturing flow-back fluid in Sulige gas field[J]. Environmental Protection of Chemical Industry, 2019, 39(3):360-366. [9] 俞音,蒋勇军,章媛媛,等. 压裂返排液回用技术中对干扰基液黏度影响因素的研究[J]. 石油化工应用,2019,38(3):28-33.YU Yin, JIANG Yongjun, ZHANG Yuanyuan, et al. Interference factor analysis of base fluid viscosity in fracturing flow-back fluid reuse technology[J]. Petrochemical Industry Application, 2019, 38(3):28-33. -

下载:

下载: