Preparation of a High Molecular Weight Polymer Thickening Agent and Its Use in Fracturing Fluids

-

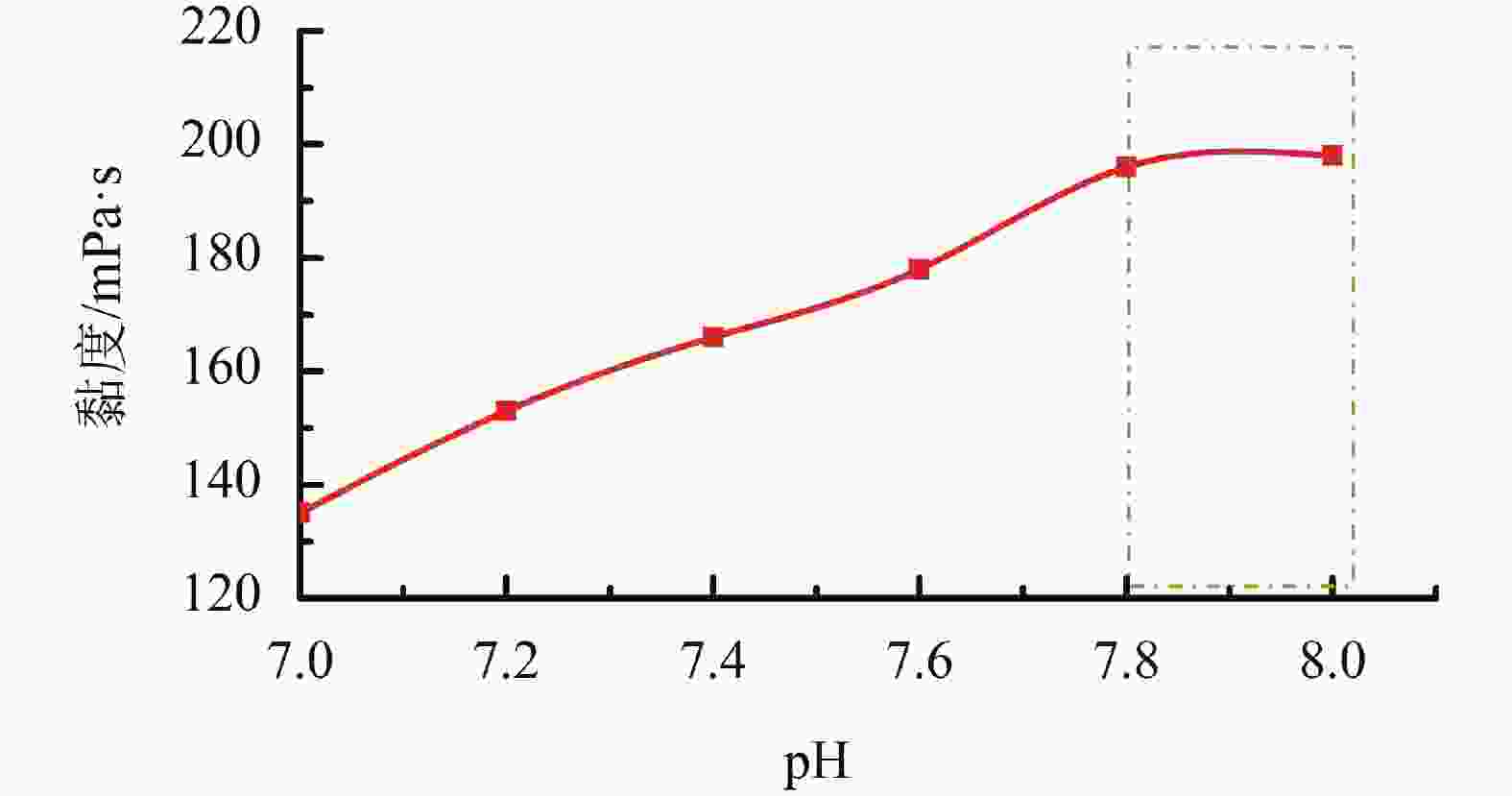

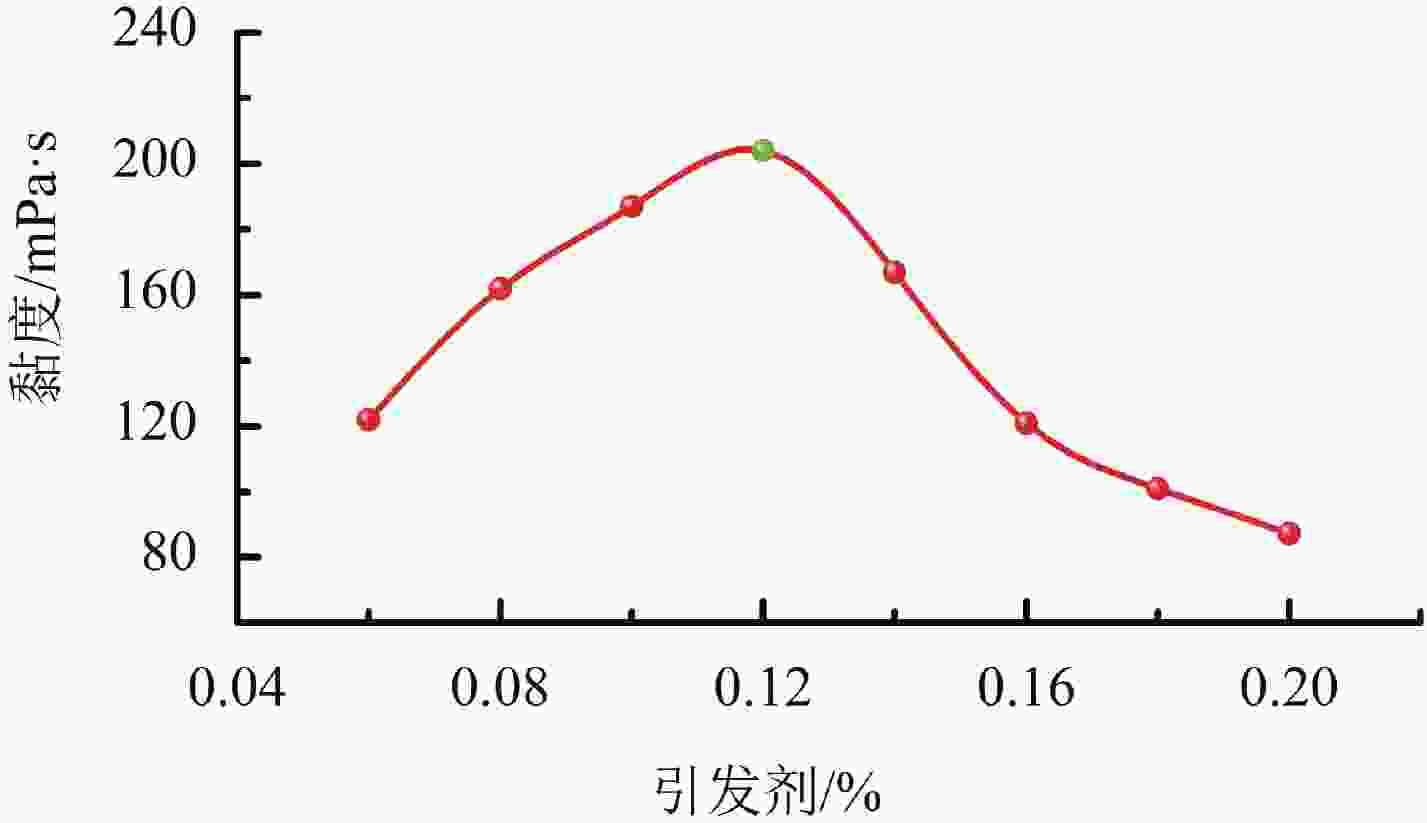

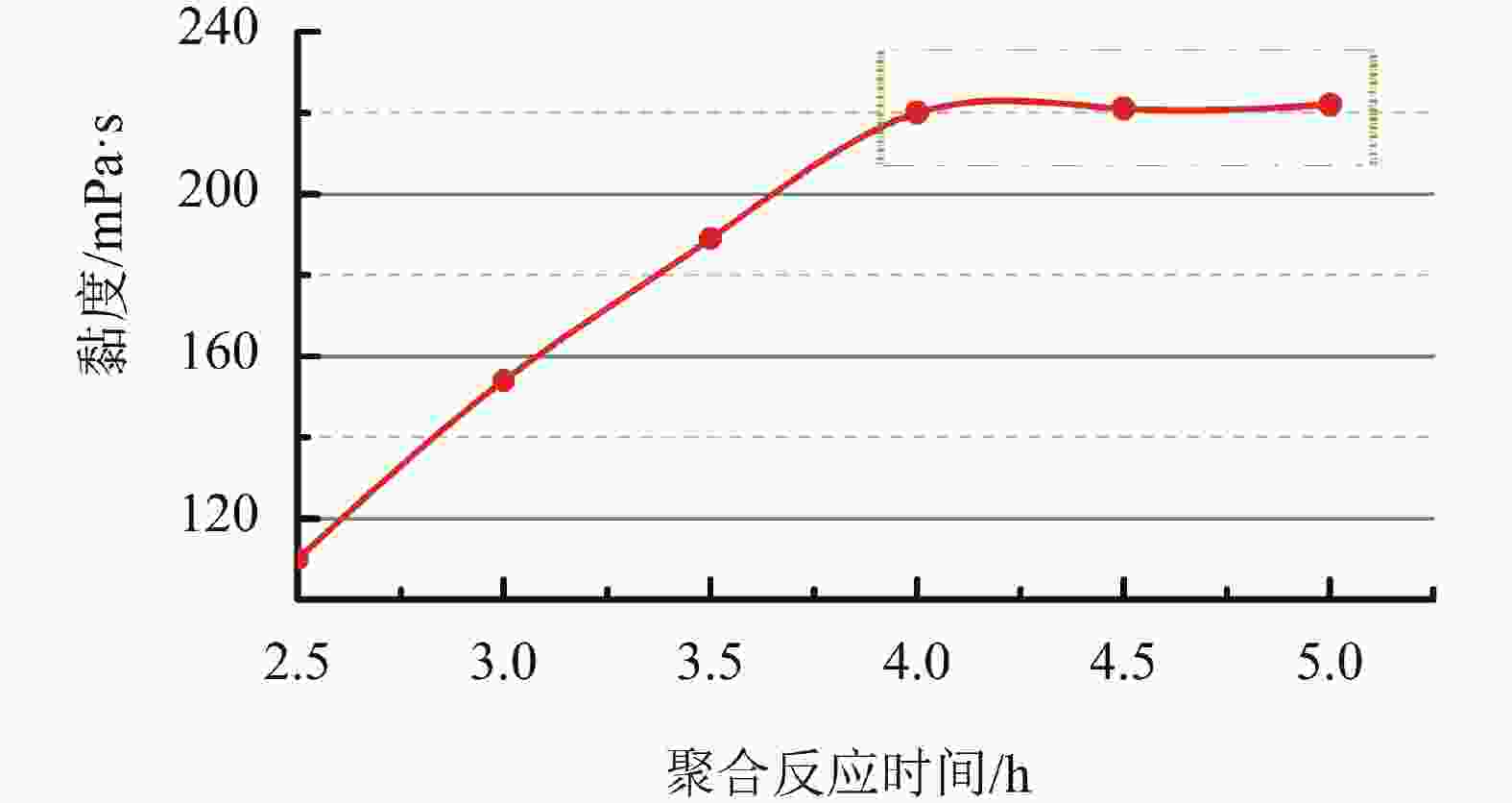

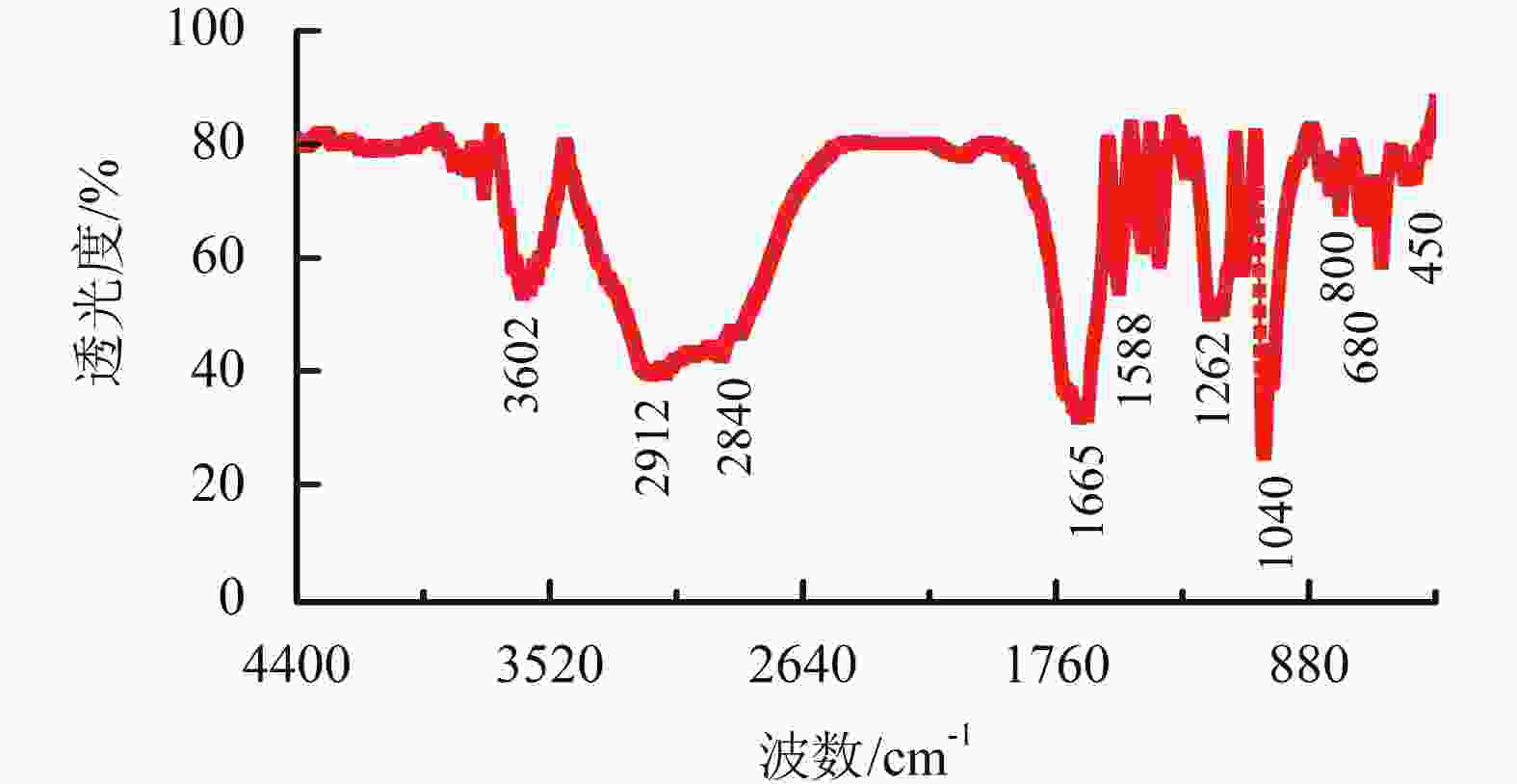

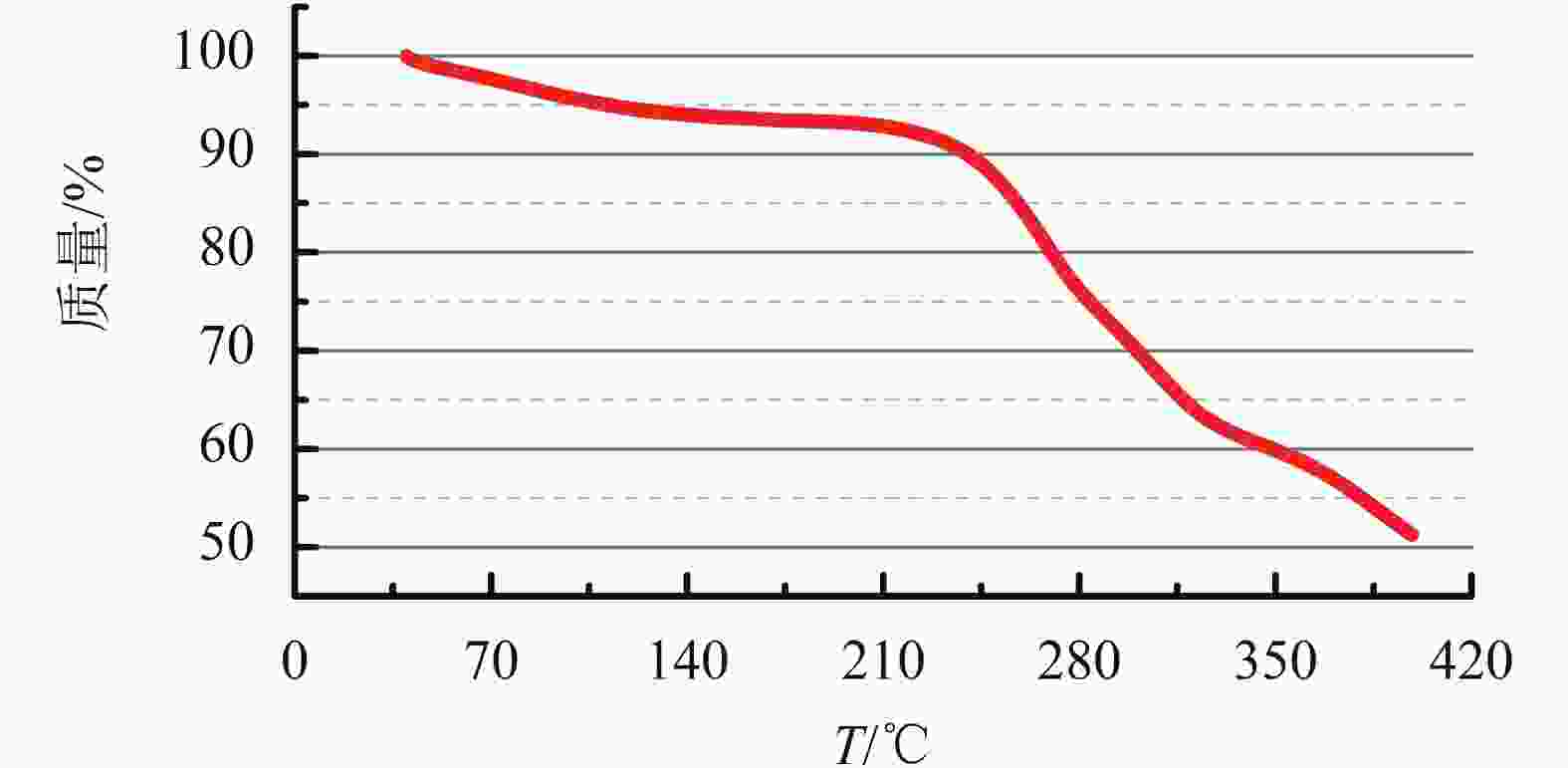

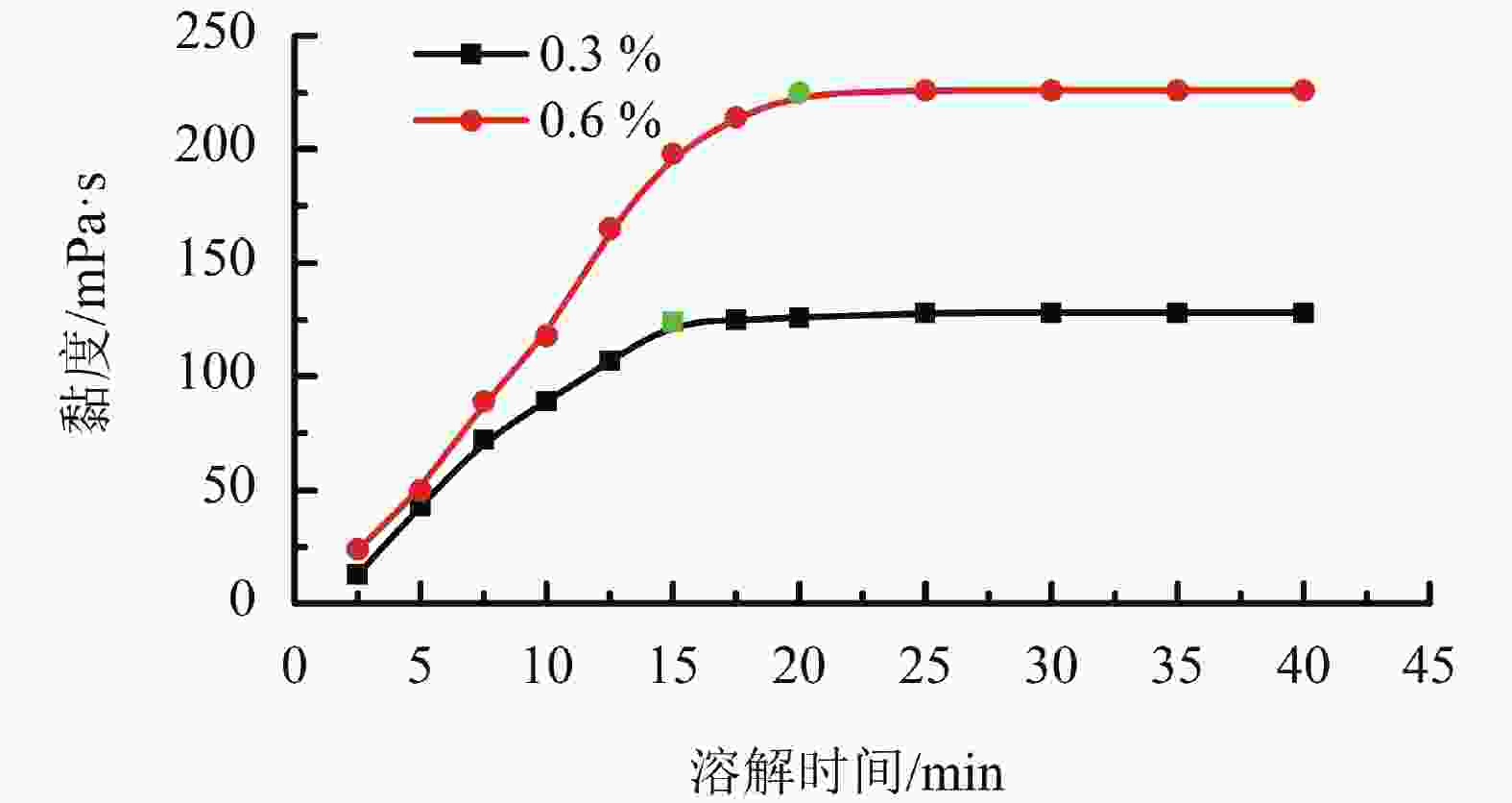

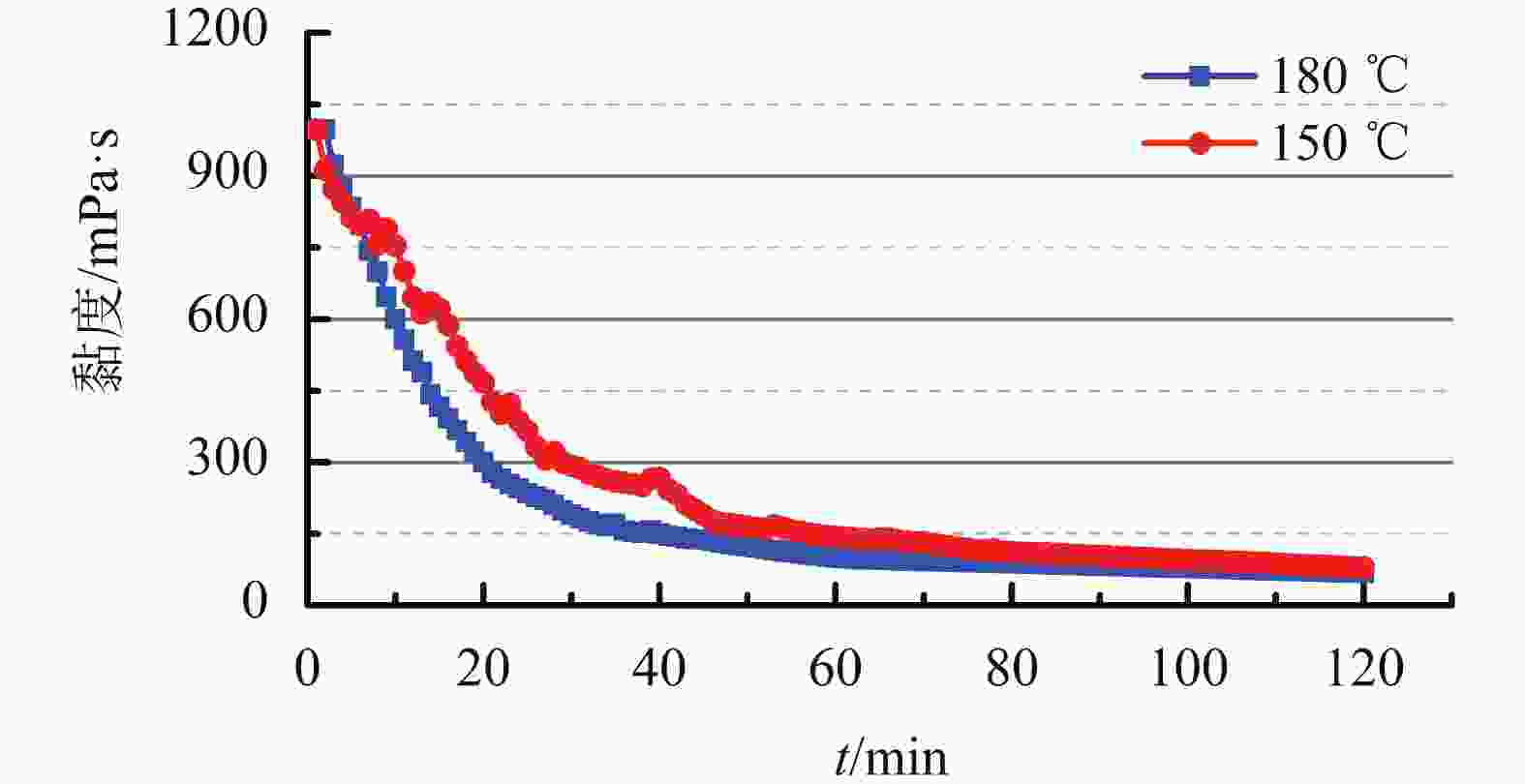

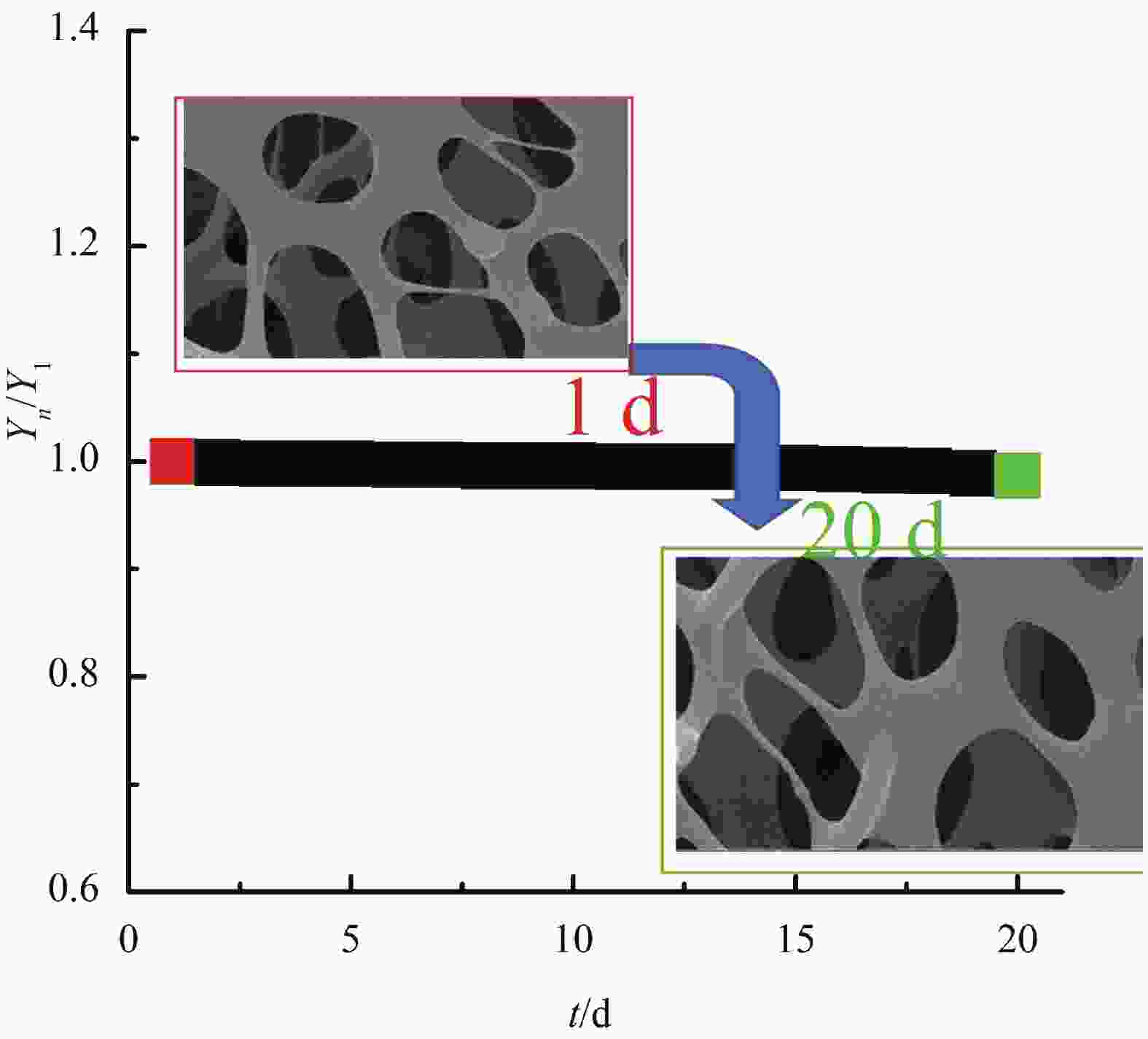

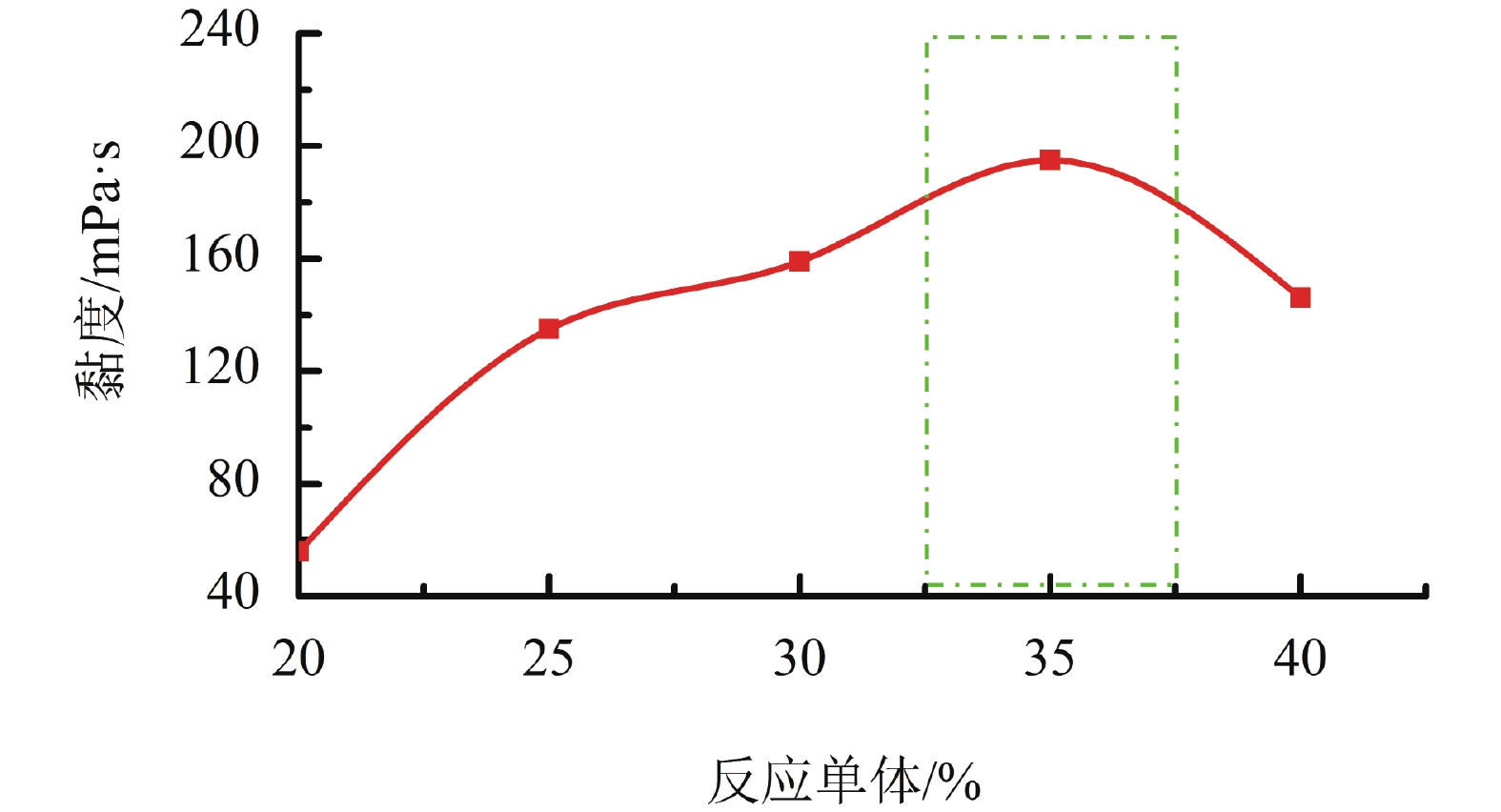

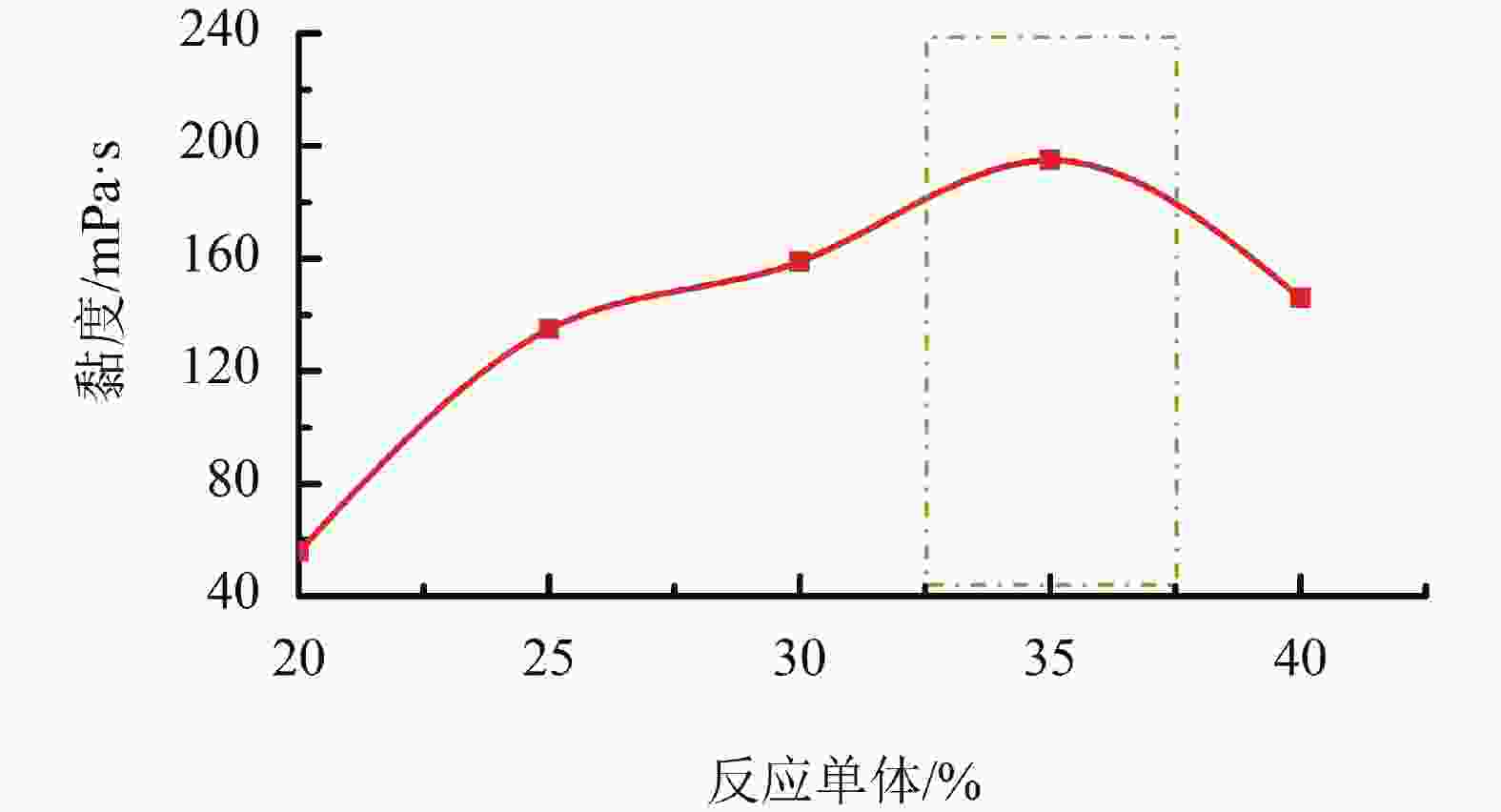

摘要: 以2-丙烯酰胺基-2-甲基丙磺酸(AMPS)、丙烯酰胺(AM)、对苯乙烯磺酸钠(SSS)和二甲基二烯丙基氯化铵(DMDAAC)为聚合单体,通过水溶液聚合法制备了高分子聚合物压裂液稠化剂FTW-1,与有机锆交联剂交联,考察了聚合反应温度、体系酸碱度、反应时间、单体浓度、引发剂加量等对高分子聚合物稠化剂FTW-1性能的影响,利用FTIR、TG等方法对高分子聚合物稠化剂FTW-1进行了表征。结果显示,高分子聚合物稠化剂最佳合成工艺为单体质量浓度为35%,pH值为7.8~8.0,引发剂加量为0.12%,反应温度为50 ℃,反应时间为4 h。红外及热重分析显示,该高分子聚合物稠化剂FTW-1分子结构符合预期设计,黏均分子量约为1.8×106,具有良好的热稳定性,可满足180 ℃施工需求。同时,也开展了压裂液性能,诸如溶解性能、增稠和交联性能、耐温耐剪切性能、抗微生物降解性能、破胶性能等的研究,结果表明压裂液各项性能均满足相关行业标准要求。Abstract: A high molecular weight polymer thickening agent, FTW-1, for fracturing fluids has been developed through water solution polymerization using 2-acrylamido-2-methylpropane sulfonic acid (AMPS), acrylamide (AM), sodium p-styrenesulfonate (SSS) and dimethyl diallyl ammonium chloride (DMDAAC) as polymerization monomers. Several factors, such as the reaction temperature, the pH of the reaction system, reaction time, concentrations of monomers, as well as the concentration of the initiator, were studied for their effects on the performance of FTW-1. The molecular structure of FTW-1 was characterized with FTIR, TG etc. It was found that the optimum conditions for the polymerization reaction are as follows: the mass concentration of the monomers = 35%, the pH of the reaction system = 7.8-8.0, the concentration of the initiator = 0.12%, the reaction temperature = 50 ℃, and the reaction time = 4 h. FTIR and TG analyses showed that the molecular structure of the reaction product FTW-1 meets the expectations. The viscosity average molecular weight of FTW-1 is 1.8 × 106. FTW-1 has good thermal stability; it satisfies the need of operation at 180 ℃. Studies on the performance of the FTW-1 treated fracturing fluids showed that the solubility, thickening and crosslinking performance, high temperature and shearing resistance, resistance to biodegradation, as well as gel breaking capacity of FTW-1 all meet the requirements of relevant industrial standards.

-

表 1 反应单体浓度对FTW-1状态的影响

反应单体质量浓度/% 性能特征 20 软、极易流动 25 较软、极易流动 30 较软、易流动 35 软硬适中、不沾壁、弹性良好 40 较硬、难以取料 表 2 聚合体系pH值对FTW-1状态的影响

pH 性能特征 5 软、极易流动 6 较软、极易流动 7 软硬适中、略微沾壁、弹性良好 8 软硬适中、不沾壁、弹性良好 9 不引发 10 不引发 表 3 高分子聚合物稠化剂FTW-1压裂液破胶性能

基液质量

浓度/%破胶剂/

g·L−1破胶时间/h

(95 ℃)破胶液黏度/

mPa·s残渣含/

mg·L−10.3 0.4 3.5 5.0 3.45 0.6 4.0 5.5 3.82 0.3 0.5 3.0 4.0 2.89 0.6 3.5 4.5 3.07 -

[1] 邹才能,杨智,王红岩,等. “进源找油”: 论四川盆地非常规陆相大型页岩油气田[J]. 地质学报,2019,93(7):1551-1562.ZOU Caineng, YANG Zhi, WANG Hongyan, et al. Exploring petroleum inside source kitchen jurassic unconventional continental giant shale oil and gas field in Sichuan basin, China[J]. Acta Geologica Sinica, 2019, 93(7):1551-1562. [2] EPELLE, EI, GEROGIORGIS, DI. A review of technological advances and open challenges for oil and gas drilling systems engineering[J]. AIChE Journal, 2020, 66(4):1-27. [3] 薛明宇,程远方,闫传梁,等. 页岩气藏水平井多级水力压裂方法优选[J]. 大庆石油地质与开发,2020,39(6):155-162.XUE Mingyu, CHENG Yuanfang, YAN Chuanliang, et al. Optimization of multistage hydraulic fracturing method for horizontal wells in shale gas reservoir[J]. Petroleum Geology & Oilfield Development in Daqing, 2020, 39(6):155-162. [4] ALMUBARAK T, NG J, HA NASR〦L〥In, et al. Influence of zirconium crosslinker chemical structure and polymer choice on the performance of crosslinked fracturing fluids[J]. The Canadian Journal of Chemical Engineering, 2021:1-7. [5] 李江银. 新型压裂液稠化增粘剂的研制[J]. 南方农机,2020(5):123.LI Jiangyin. Development of a new thickener for fracturing fluid[J]. China Southern Agricultural Machinery, 2020(5):123. [6] 汤鲁馨,张晓琪,罗炎生,等. 四元聚合物溶液及其压裂液流变性能[J]. 油田化学,2021,38(2):235-246.TANG Luxing, ZHANG Xiaoqi, LUO Yansheng, et al. Rheological properties of quaternary polymer solution and its fracturing fluid[J]. Oilfield Chemistry, 2021, 38 (2) :235-246. [7] 戴秀兰,刘通义,魏俊,等. 加重压裂液用聚合物稠化剂合成及性能[J]. 钻井液与完井液,2019,36(6):766-770.DAI Xiulan, LIU Tongyi, WEI Jun, et al. Synthesis and performance of a polymeric thickening agent for weighted fracturing fluids[J]. Drilling Fluid & Completion Fluid, 2019, 36(6):766-770. [8] 李斌,彭欢,李晓龙. 合成聚合物压裂液稠化剂的研究进展[J]. 广州化工,2015,43(4):33-35.LI Bin, PENG Huan, LI Xiaolong. Research progress of thickener for synthetic polymer fracturing fluid[J]. Guangzhou Chemical Industry, 2015, 43(4):33-35. [9] 马喜平,杨立,张蒙,等. 疏水聚合物压裂液稠化剂PDAM-16的合成与评价[J]. 化学研究与应用,2017,9(29):100-107.MA Xiping, YANG Li, ZHANG Meng, et al. Synthesis and evaluation of hydrophobic polymer fracturing fluid thickener PDAM-16[J]. Chemical Research and Application, 2017, 9(29):100-107. [10] 丁瑜,伍才辉,辜思曼. AM/AMPSNa-瓜尔胶接枝共聚物的合成及其在压裂液中的应用[J]. 石油化工,2020,49(10):985-991.DING Yu, WU Caihui, GU Siman. Synthesis of AM/ AMPSNa-guar gum graft copolymer and its application in fracturing fluid[J]. Petrochemical Technology, 2020, 49(10):985-991. [11] 张菅,尹海亮,刘新亮,等. 耐温耐盐P(AM-AMPS-St-AA)共聚物压裂液稠化剂的合成与性能[J]. 油田化学,2016,33(2):215-219.ZHANG Jian, YIN Hailiang, LIU Xinliang, et al. Synthesis and properties of temperature and salt resistant P (AM-AMPS-St-AA) copolymer fracturing fluid thickener [J]. Oilfield Chemistry, 2016, 33(2):215-219. [12] 许可,侯宗锋,常进,等. 耐245 ℃超高温压裂液稠化剂的制备与性能分析[J]. 应用化工,2020,49(12):3031-3033.XU Ke, HOU Zongfeng, CHANG Jin, et al. Research and performance analysis of 245 ℃ ultra-high temperature fracturing liquid thickener[J]. Applied Chemical Industry, 2020, 49(12):3031-3033. [13] 郑勇,孙立君,彭志刚,等. 抗盐抗高温强抑制性降滤失剂SN-K的合成与评价[J]. 精细化工,2017,34(2):220-226.ZHENG Yong, SUN Lijun, PENG Zhigang, et al. Synthesis and evaluation of salt resistant, high temperature resistant and strong inhibitory fluid loss reducer SN-K[J]. Fine Chemicals, 2017, 34(2):220-226. [14] 孙立君,郑勇,彭志刚,等. 有机/无机复合型降滤失剂LJ-1的合成及性能评价[J]. 精细化工,2017,7(34):111-117.SUN Lijun, ZHENG Yong, PENG Zhigang, et al. Synthesis and performance evaluation of organic / inorganic composite fluid loss reducer LJ-1[J]. Fine Chemicals, 2017, 7(34):111-117. [15] WU YM, SUN DJ, ZHANG BQ, et al. Properties of high-temperature drilling fluids incorporating disodium itaconate/acrylamide/sodium 2-acrylamido-2-methylpropanesulfonate terpolymers as fluid-loss reducers[J]. Journal of Applied Polymer Science, 2002, 83(14):3068-3075. [16] 李波,于慧,邵秀梅. 二甲基二烯丙基氯化铵及其聚合物的红外光谱研究[J]. 分析试验室,2002,21(2):41-43.LI Bo, YU Hui, SHAO Xiumei. Infrared spectra of dimethyl diallyl ammonium chloride and its polymers[J]. Chinese Journal of Analysis Laboratory, 2002, 21(2):41-43. -

下载:

下载: