Study on Relationship between Rheology of HPAM Solution and Friction Reduction

-

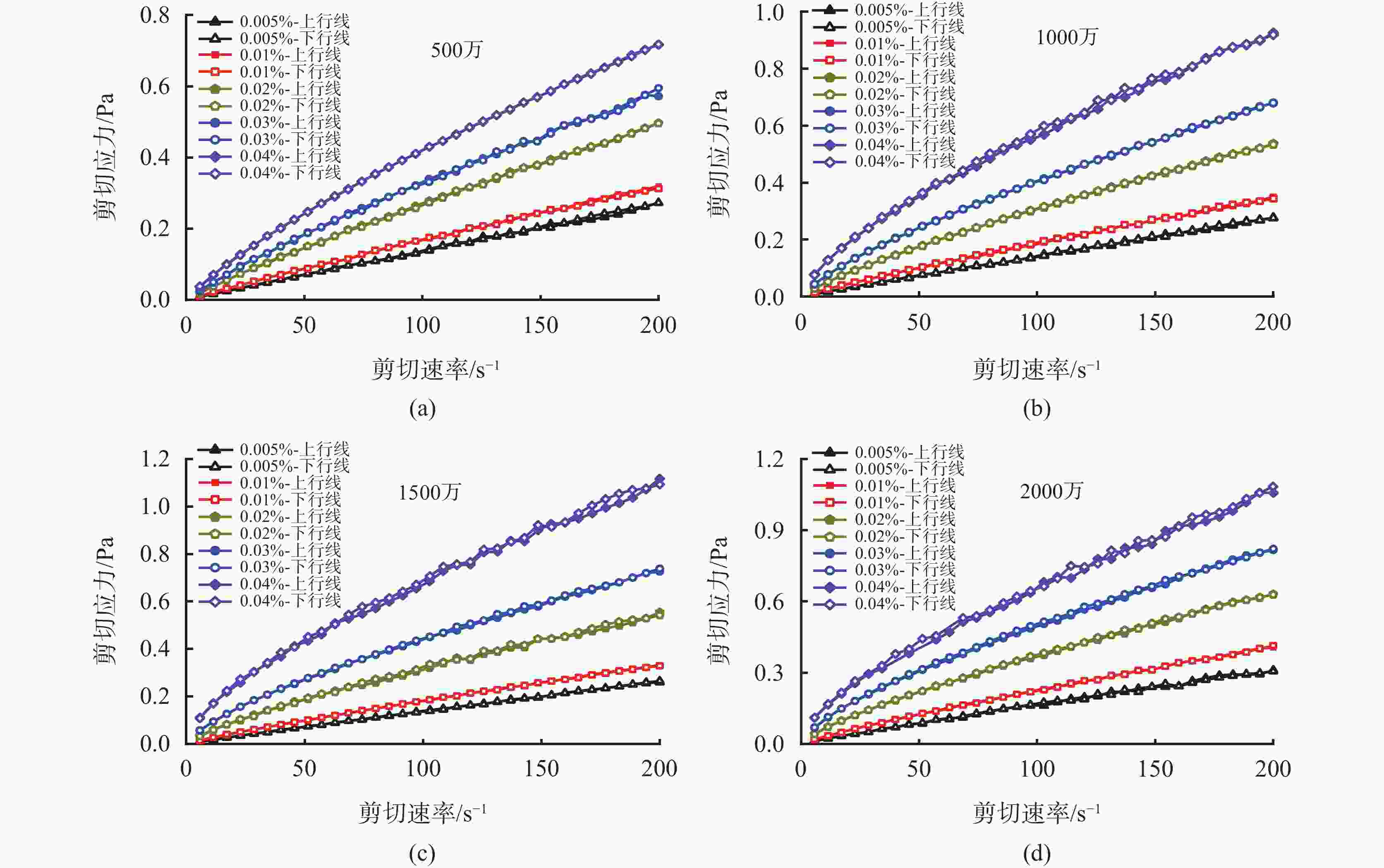

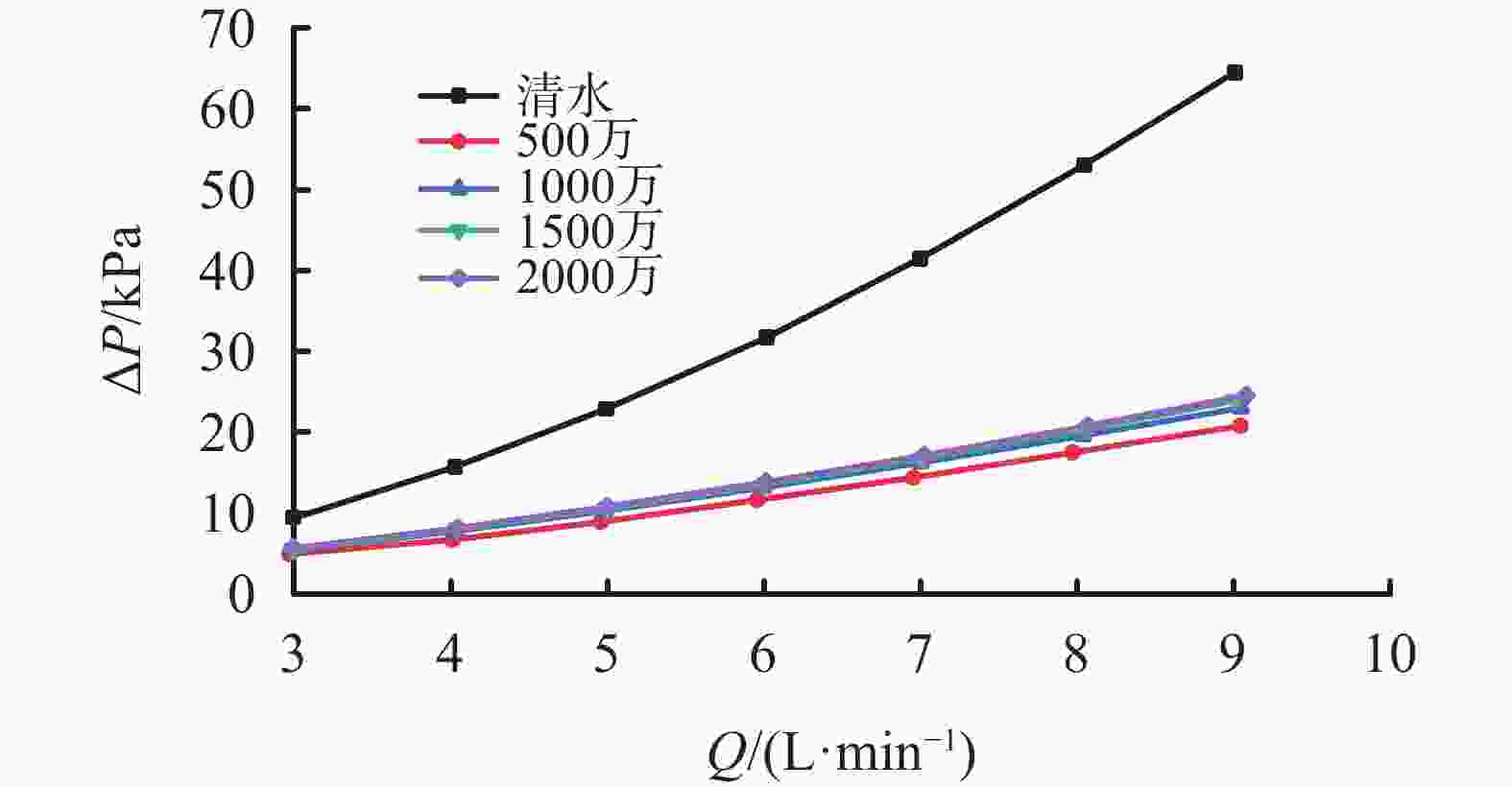

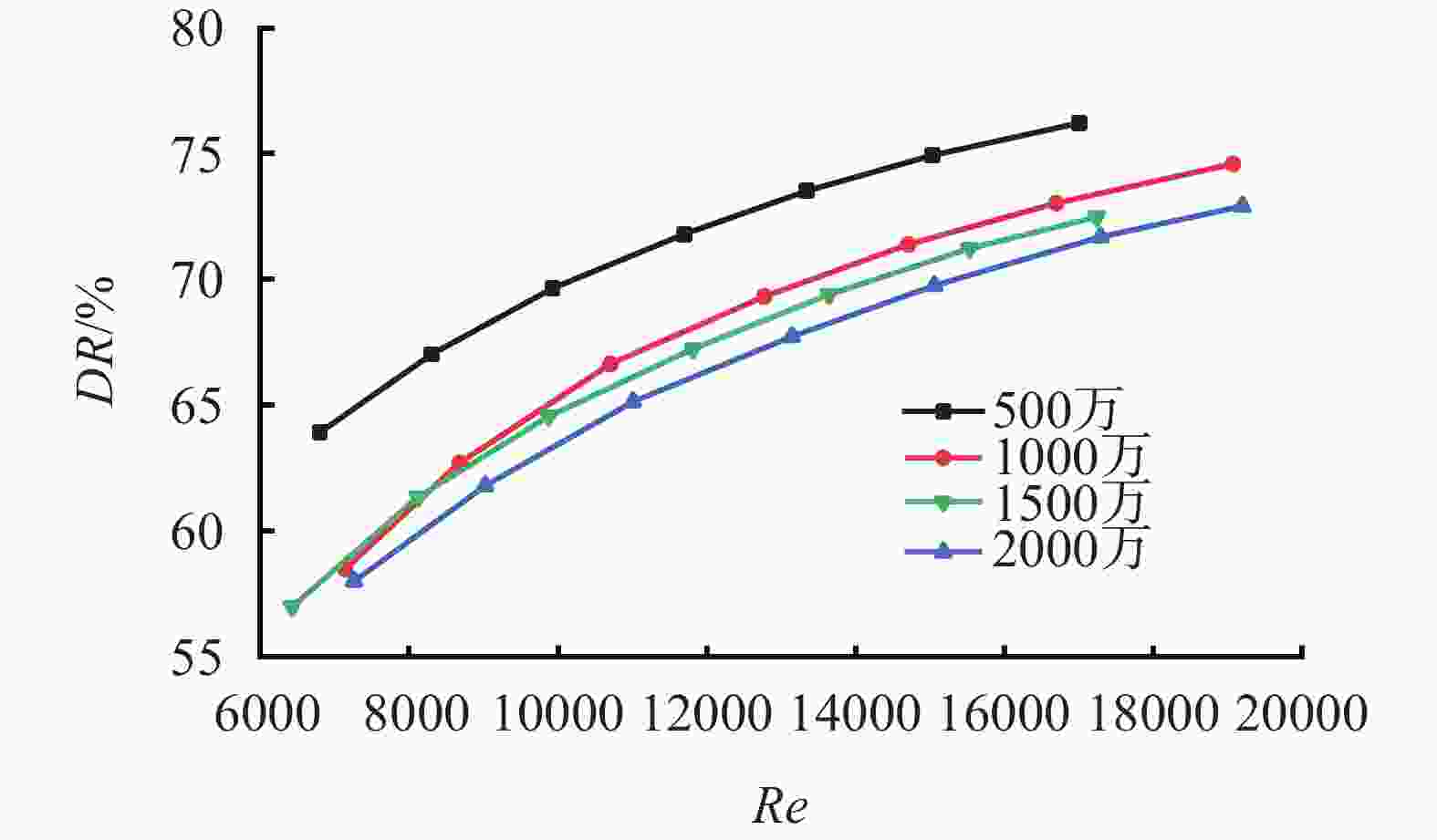

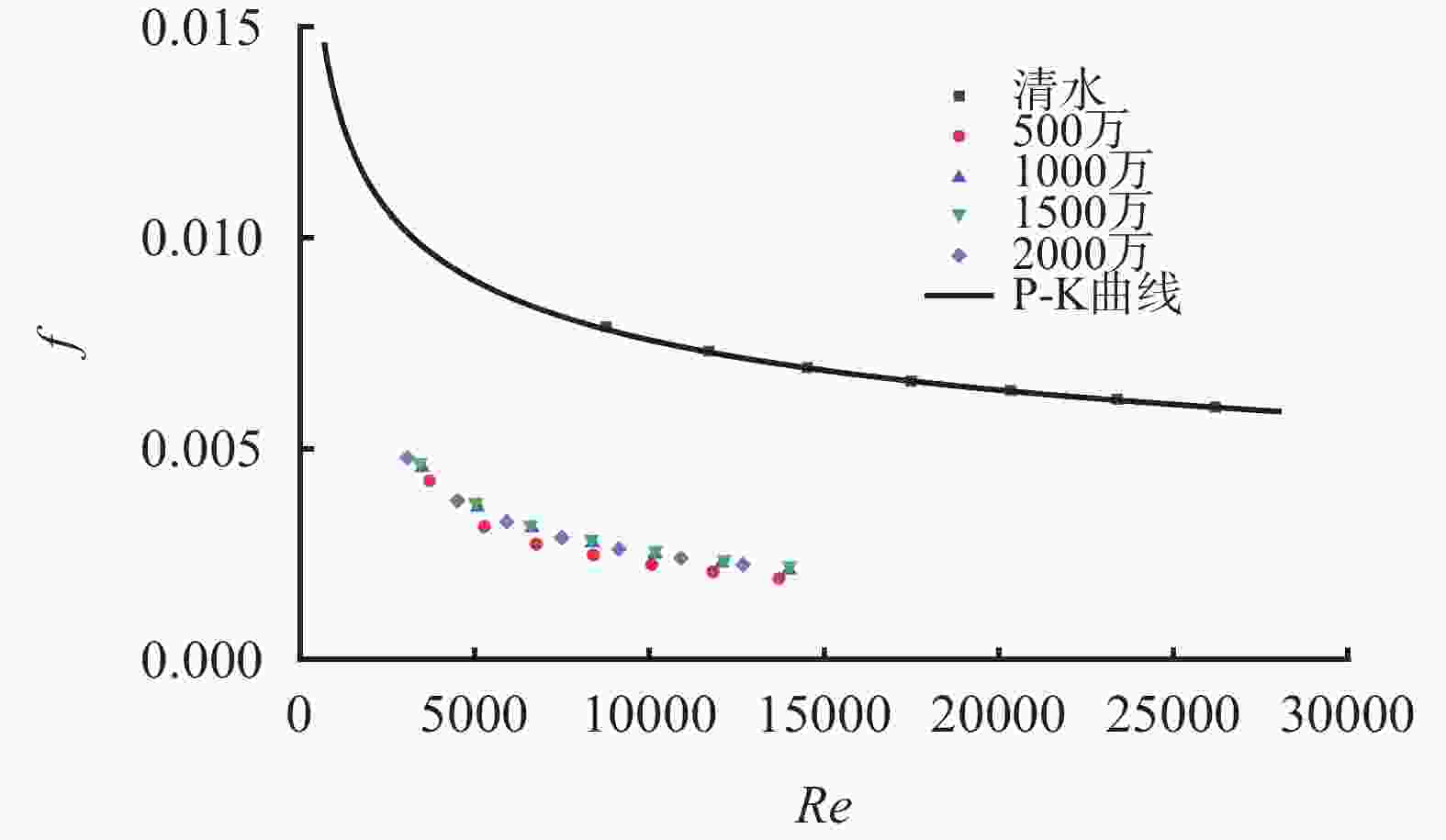

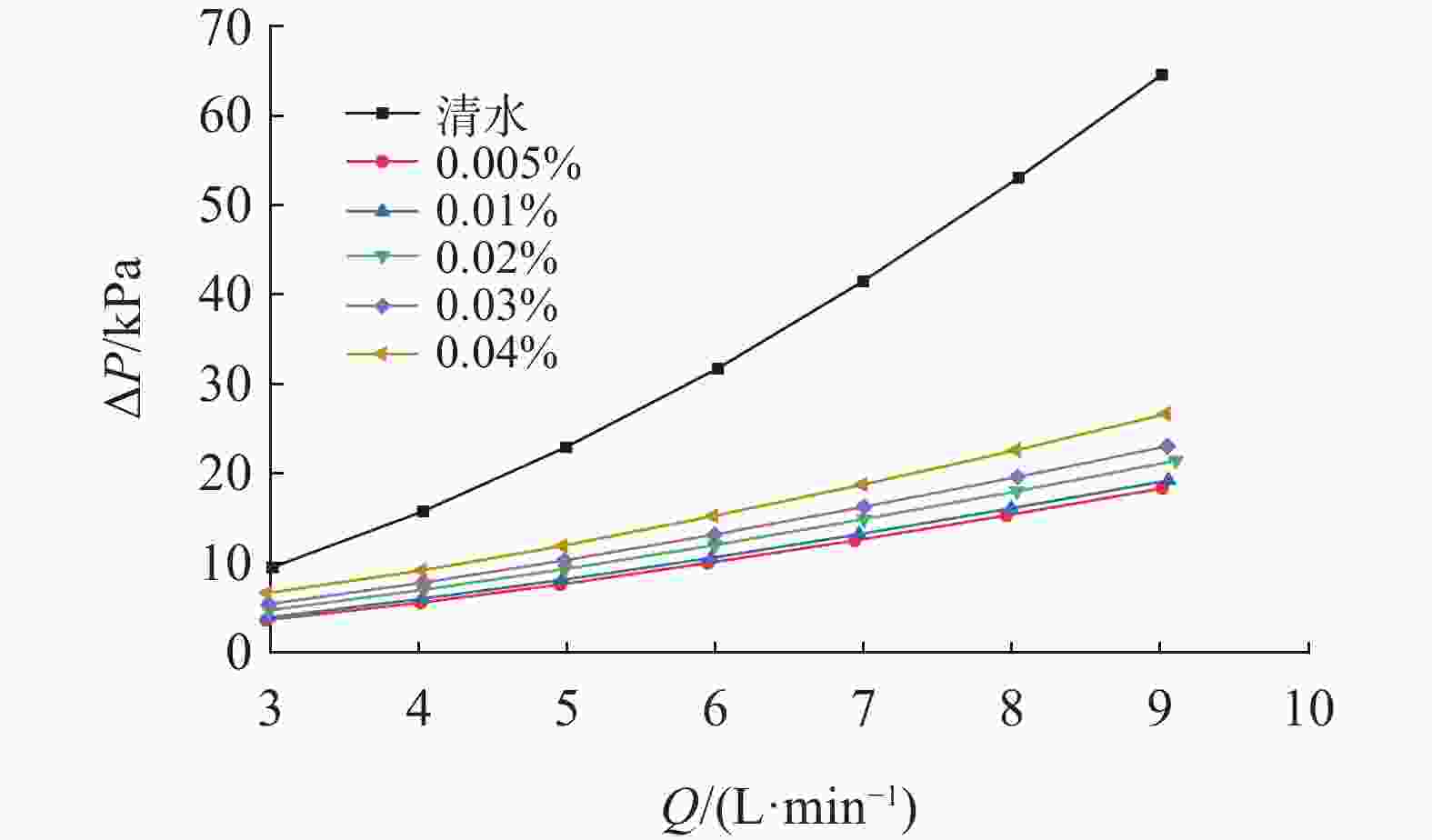

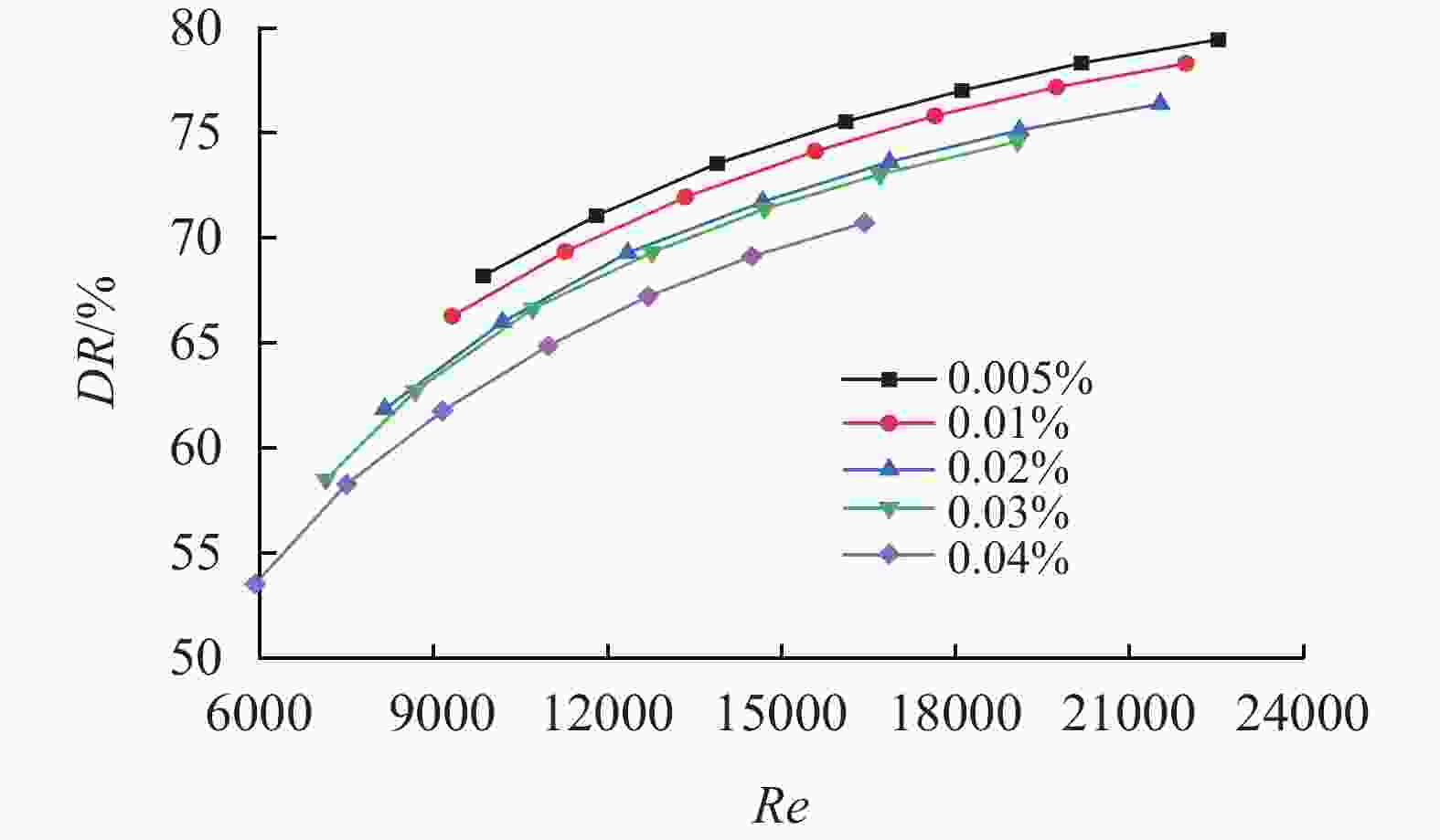

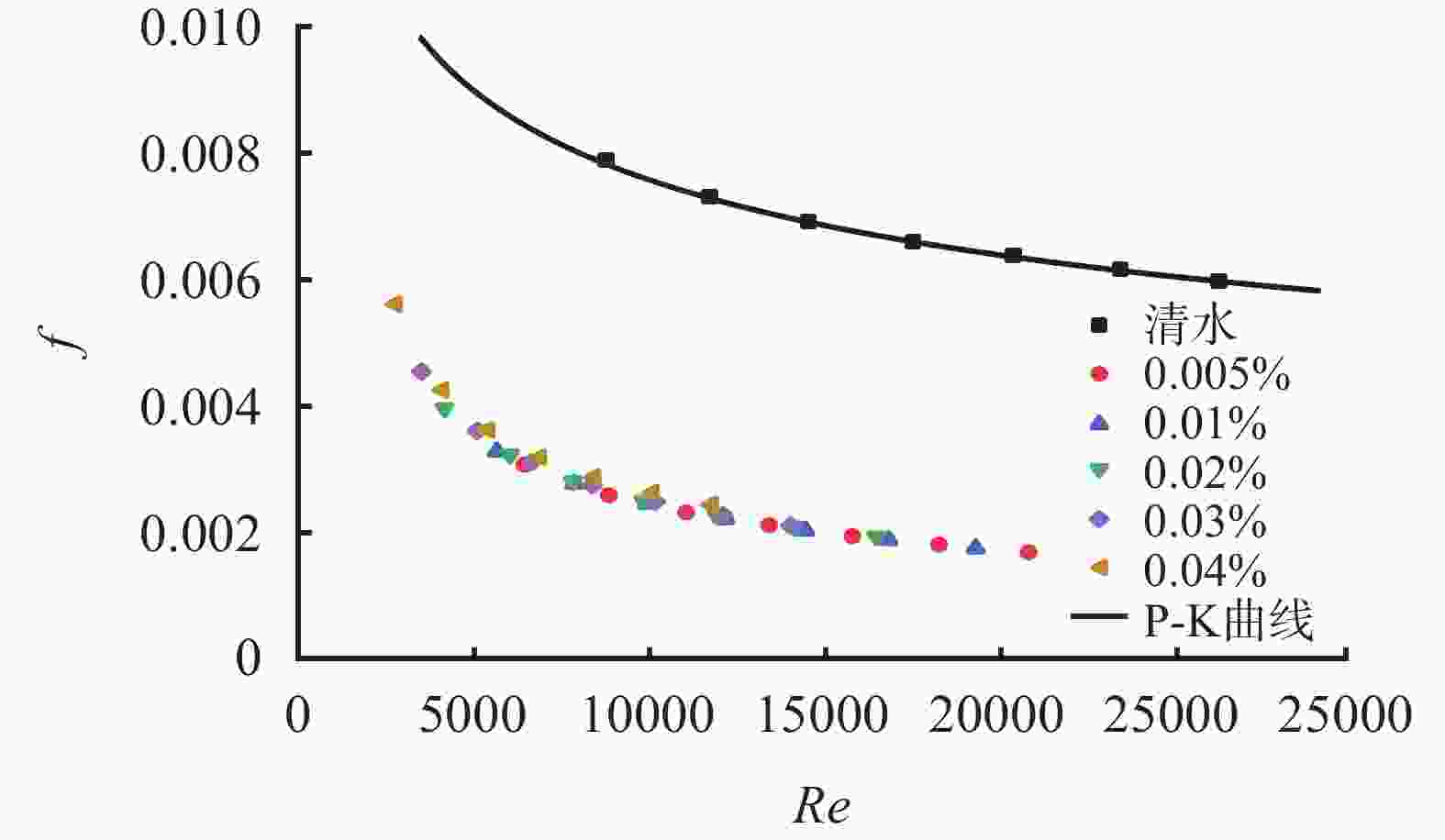

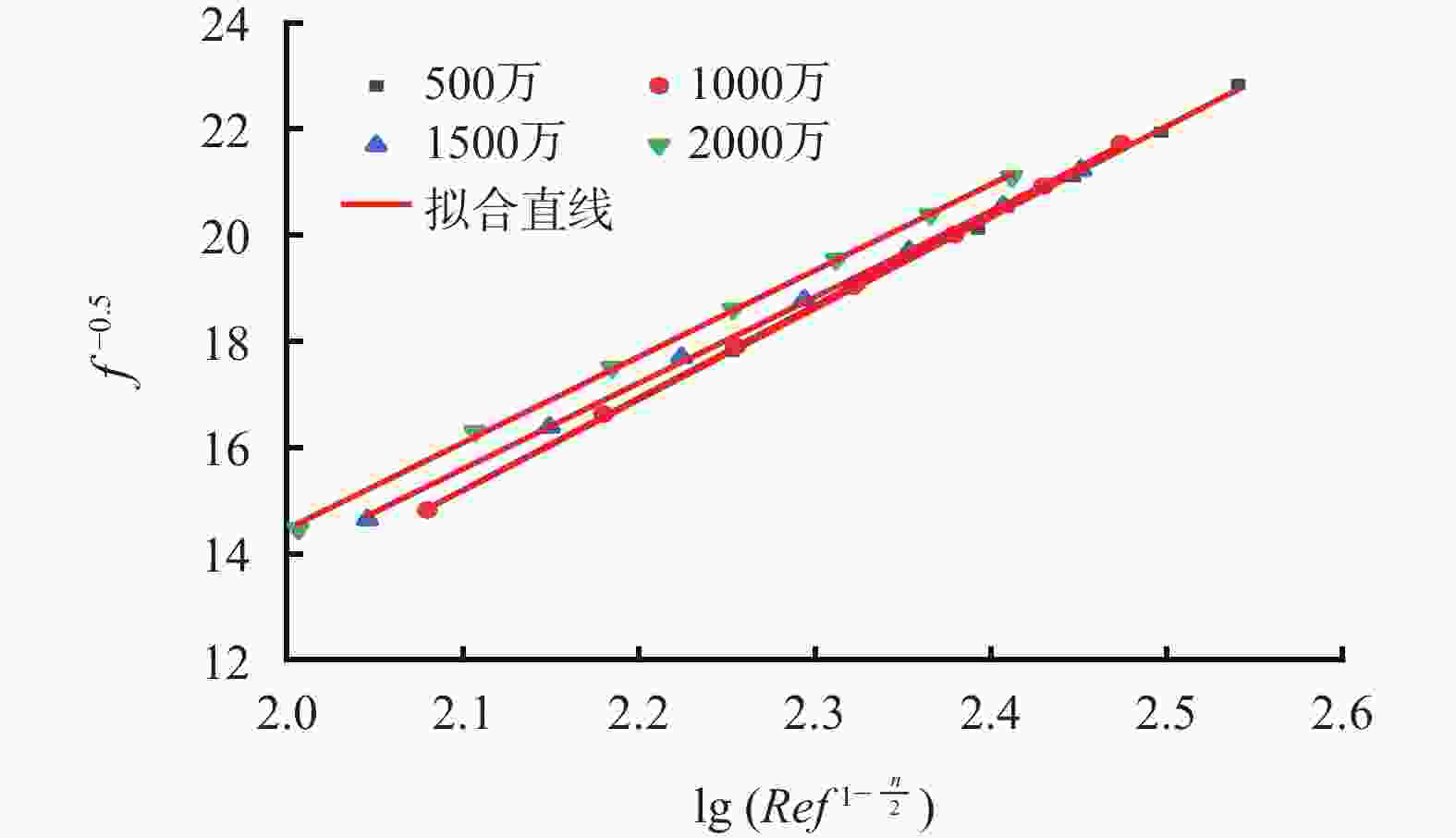

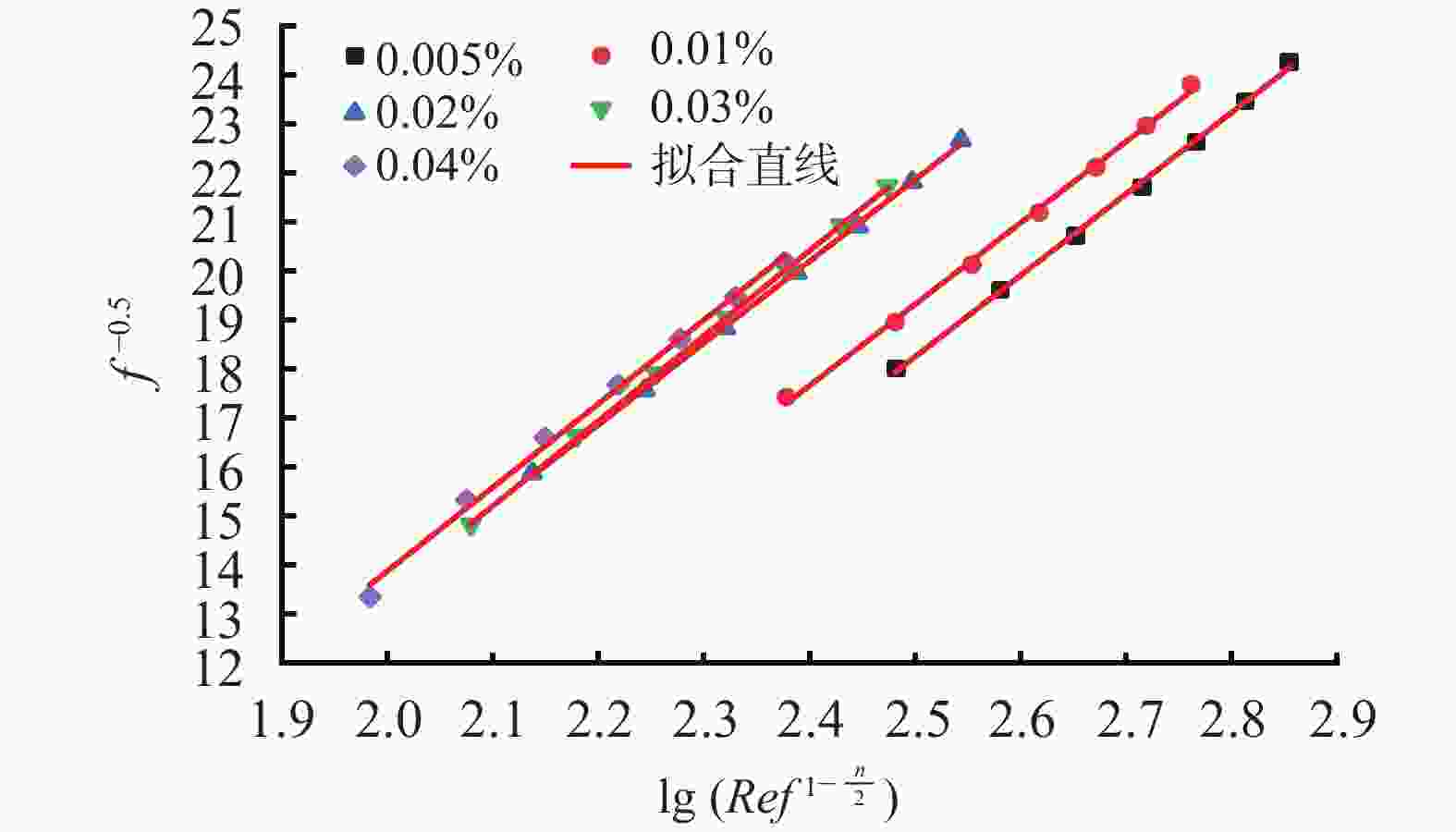

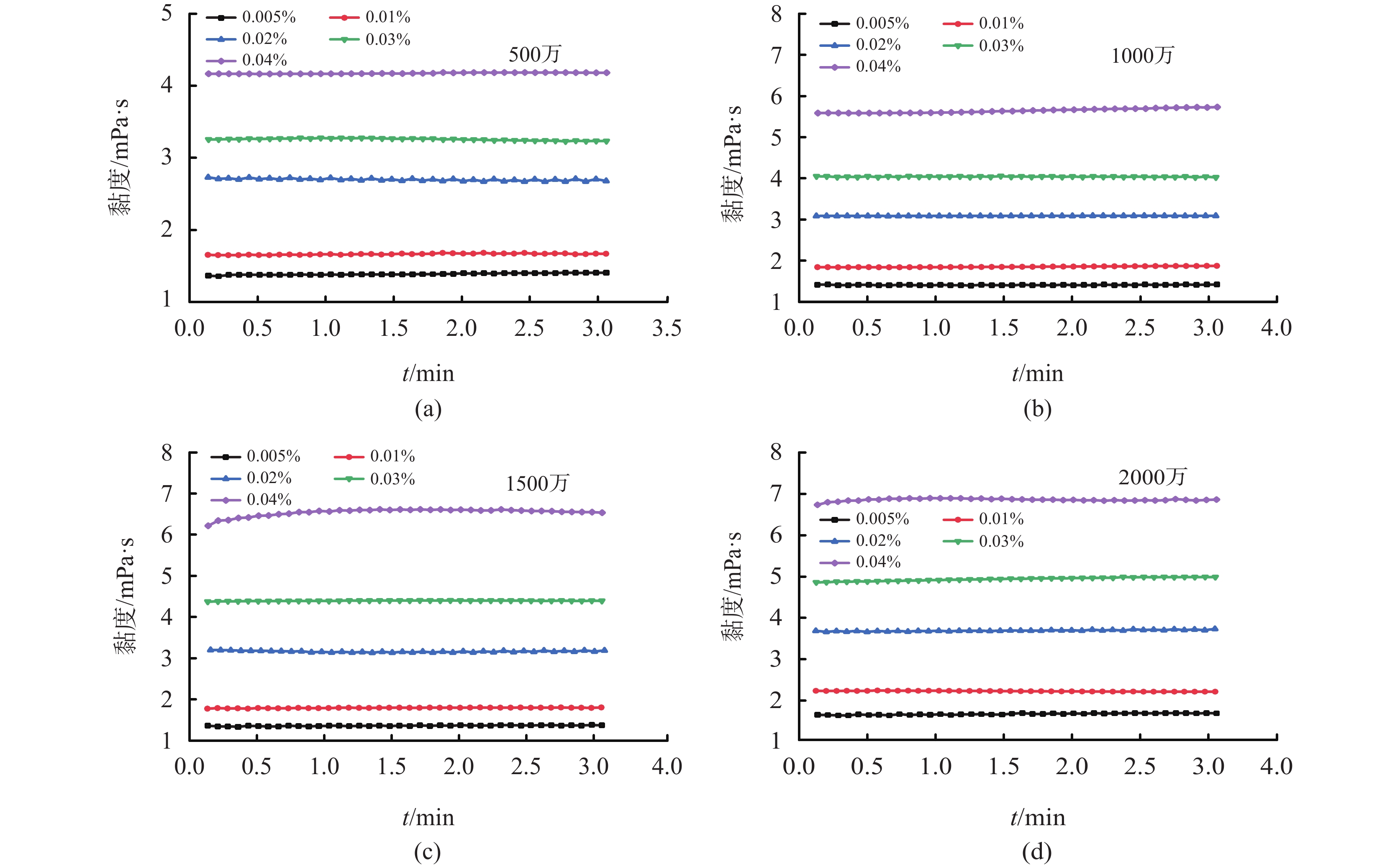

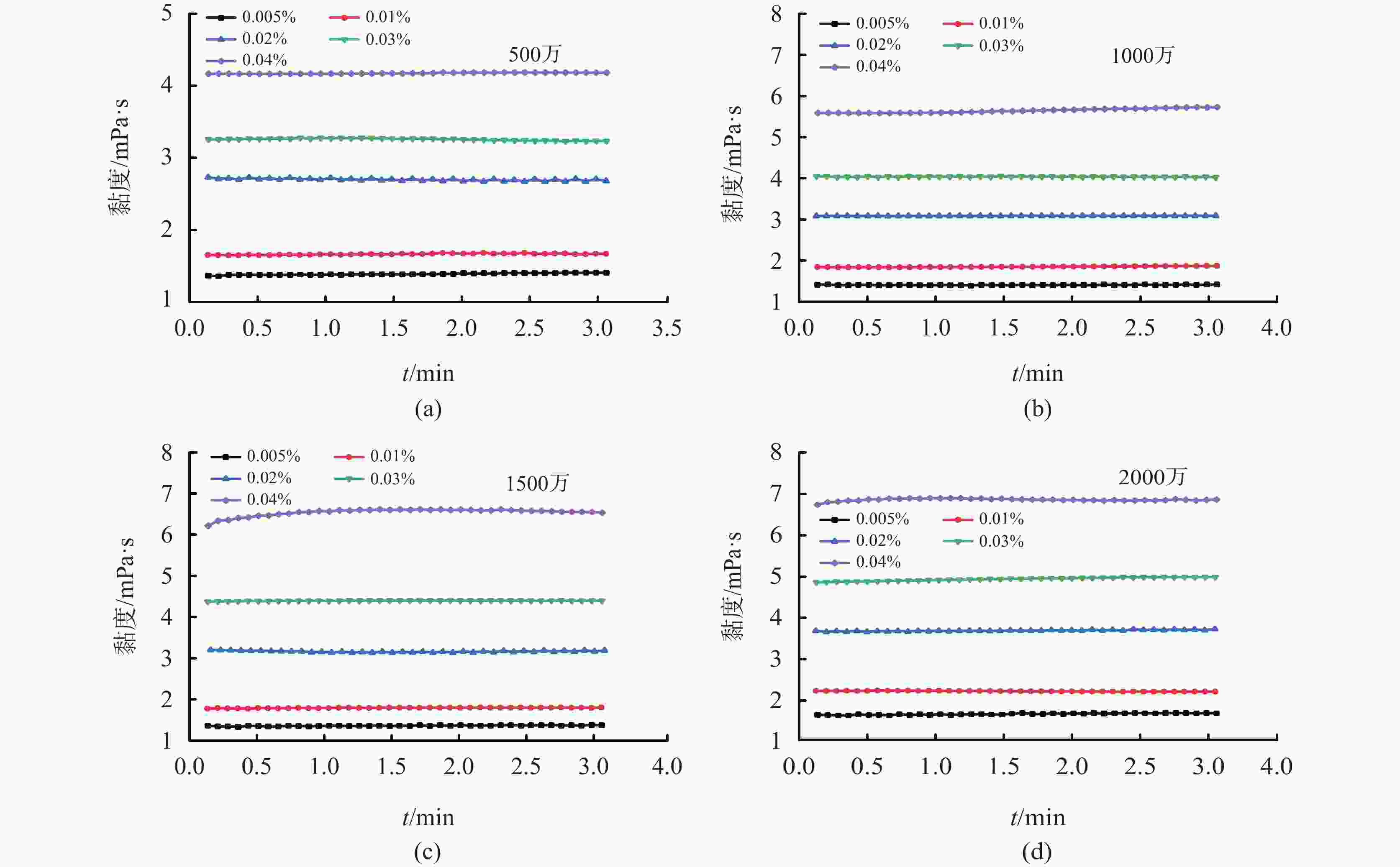

摘要: 通过研究不同浓度、不同分子量的HPAM溶液的流变及摩阻性能,建立了一个聚合物溶液摩阻系数方程。测试了5种不同浓度、4种不同分子量的HPAM溶液的稳态剪切黏度、触变性、流动曲线等流变性能;并分别测试其在管内径为0.77 cm,流量为3~9 L/min的压差数据,计算得摩阻系数数据,分析了聚合物分子量、聚合物浓度等对溶液减阻的影响,建立了聚合物溶液摩阻系数f和广义雷诺数Re及聚合物溶液流型参数n之间的摩阻系数方程。Abstract: An equation describing the friction of polymer solutions was developed through the studies on the rheology and friction of HPAM solutions of different concentrations and molecular weights of HPAM. HPAM solutions formulated with five different HPAM concentrations and HPAM with four different molecular weights were measured for their steady-state shear viscosity, thixotropy and flow curves. The friction data of the HPAM solutions were calculated by measuring the differential pressures of these solutions in a pipe with inner diameter of 0.77 cm at flow rates ranging between 3 L/min and 9 L/min. The effects of the molecular weight and concentration of the polymer on friction reduction of solution were analyzed. Based on these studies, a friction coefficient equation describing the relationship among the friction coefficient f, the generalized Reynolds number Re and the flow pattern index n of the polymer solutions was established.

-

Key words:

- HPAM /

- Rheology /

- Friction reduction performance /

- Friction model

-

表 1 不同浓度HPAM溶液流动曲线幂律模型拟合参数

黏均分子量 浓度/% K/Pa·sn n R 500万 0.005 1.732 0.9557 0.9705 0.01 2.235 0.9334 0.9850 0.02 5.114 0.8631 0.9969 0.03 7.188 0.8252 0.9966 0.04 11.83 0.7732 0.9996 1000万 0.005 1.858 0.9437 0.9878 0.01 2.985 0.8937 0.9976 0.02 9.619 0.7663 0.9959 0.03 12.82 0.7492 0.9997 0.04 22.20 0.7015 0.9984 1500万 0.005 3.195 0.8761 0.9978 0.01 4.113 0.8614 0.9695 0.02 8.925 0.7786 0.9930 0.03 15.76 0.7223 0.9989 0.04 29.99 0.6791 0.9979 2000万 0.005 2.564 0.9074 0.9527 0.01 4.257 0.8578 0.9977 0.02 10.62 0.7732 0.9979 0.03 17.50 0.7230 0.9980 0.04 27.70 0.6842 0.9969 表 2 不同分子量HPAM溶液的

$ {f}^{-0.5} $ 与$ \mathrm{l}\mathrm{g}\left(Re{f}^{1-\frac{n}{2}}\right) $ 的线性函数拟合参数黏均分子量 K/Pa·sn n $ \frac{4}{{n}^{0.75}}+{\xi }_{1} $ $ {\xi }_{1} $ $ \frac{0.4}{{n}^{1.2}}+{\xi }_{2} $ $ {\xi }_{2} $ R 500万 7.188 0.8252 17.15 12.53 20.82 20.32 0.9992 1000万 12.82 0.7492 17.37 12.40 21.27 20.70 0.9999 1500万 15.76 0.7223 16.19 11.08 18.39 17.80 0.9997 2000万 17.50 0.7230 16.22 11.12 17.97 17.38 0.9996 表 3 不同浓度HPAM的

$ {f}^{-0.5} $ 与$ \mathrm{l}\mathrm{g}\left(Re{f}^{1-\frac{n}{2}}\right) $ 的线性函数拟合参数浓度/% K n $ \frac{4}{{n}^{0.75}}+{\xi }_{1} $ $ {\xi }_{1} $ $ \frac{0.4}{{n}^{1.2}}+{\xi }_{2} $ $ {\xi }_{2} $ R 0.005 1.858 0.9437 16.62 12.44 23.31 22.88 0.9993 0.01 2.985 0.8937 16.62 12.27 22.22 21.76 0.9990 0.02 9.619 0.7663 16.68 11.80 19.84 19.29 0.9998 0.03 12.82 0.7492 17.37 12.40 21.27 20.70 0.9999 0.04 22.20 0.7015 17.08 11.86 20.29 19.68 0.9980 -

[1] 陈昊, 毕凯琳, 张军, 等. 非常规油气开采压裂用减阻剂研究进展[J]. 油田化学, 2021, 38(2): 347-359.CHEN Hao, BI Kailin, ZHANG Jun, et al. Progress of drag reducers used in slickwater hydrofracturing of unconventional hydrocarbons[J]. Oilfield Chemistry, 2021, 38(2): 347-359. [2] 张文龙, 伊卓, 杜凯, 等. 水溶性减阻剂在页岩气滑溜水压裂中的应用进展[J]. 石油化工, 2015, 44(1): 121-126.ZHANG Wenlong, YI Zhuo, DU Kai, et al. Recent advances in water-soluble friction reducers for slickwater hydraulic fracturing used in completion of shale gas[J]. Petrochemical Technology, 2015, 44(1): 121-126. [3] ASIDIN M A, SUALI E, JUSNUKIN T, et al. Review on the applications and developments of drag reducing polymer in turbulent pipe flow[J]. Chinese Journal of Chemical Engineering, 2019, 27(8): 1921-1932. [4] TOMS B A. Some observations on the flow of linear polymer solutions through straight tubes at large reynolds numbers [C]//Proceeding of First International Rheological, 1948: 135-141. [5] EDOMWONYI-OTU L C, ANGELI P. Separated oil-water flows with drag reducing polymers[J]. Experimental Thermal and Fluid Science, 2019, 102: 467-478. [6] GILLISSEN J J J. Polymer flexibility and turbulent drag reduction[J]. Physical Review E, 2008, 78(4): 1-6. [7] VIRK P S. Drag reduction fundamentals[J]. Aiche Journal, 1975, 21(4): 625-656. [8] GASLJEVIC K, AGUILAR G, MATTHYS E F. An improved diameter scaling correlation for turbulent flow of drag-reducing polymer solutions[J]. Journal of Non-newtonian Fluid Mechanics, 1999, 84(2): 131-148. [9] KARAMI H R, MOWLA D. A general model for predicting drag reduction in crude oil pipelines[J]. Journal of Petroleum Science and Engineering, 2013, 111: 78-86. [10] ZABIHI R, MOWLA D, KARAMI H R. Artificial intelligence approach to predict drag reduction in crude oil pipelines[J]. Journal of Petroleum Science and Engineering, 2019, 178: 586-593. [11] VARNASERI M, PEYGHAMBARZADEH S M. The effect of polyacrylamide drag reducing agent on friction factor and heat transfer coefficient in laminar, transition and turbulent flow regimes in circular pipes with different diameters[J]. International Journal of Heat and Mass Transfer, 2020, 154: 1-15. [12] HAN W, DONG Y, CHOI H. Applications of water-soluble polymers in turbulent drag reduction[J]. Processes, 2017, 5(2): 24-25. [13] 刘倩, 管保山, 刘玉婷, 等. 滑溜水压裂液用降阻剂的研究与应用进展[J]. 油田化学. 2020, 37(3): 545-551.LIU Qian, GUAN Baoshan, LIU Yuting, et al. Progress of development and application of drag reduction agents for slick-water fracturing[J]. Oilfield Chemistry, 2020, 37(3): 545-551. [14] 张世岭, 郭继香, 杨矞琦, 等. 滑溜水压裂液技术的发展现状[J]. 四川化工. 2015, 18(4): 21-24.ZHANG Shiling, GUO Jixiang, YANG Yuqi, et al. The development status of slickwater fracturing technology[J]. Sichuan Chemical Industry, 2015, 18(4): 21-24. [15] LIU D, WANG Q, WEI J. Experimental study on drag reduction performance of mixed polymer and surfactant solutions[J]. Chemical Engineering Research and Design, 2018, 132: 460-469. [16] 王春晓, 陆江银, 薄文敏. 高分子减阻剂减阻性能的影响因素研究[J]. 中国塑料. 2011, 25(6): 70-76.WANG Chunxiao, LU Jiangyin, BO Wenmin. Research on factors influencing drag reduction properties of polymer drag reducers[J]. China Plastics, 2011, 25(6): 70-76. [17] KARAMI H R, RAHIMI M, OVAYSI S. Degradation of drag reducing polymers in aqueous solutions[J]. Korean Journal of Chemical Engineering, 2018, 35(1): 34-43. [18] 方波. 化工流变学概论[M]. 北京: 中国纺织出版社, 2010: 136-142.FANG Bo. Introduction to chemical engineering rheology[M]. Beijing: China Textile and Apparel Press, 2010: 136-142. [19] METZNER A B, REED J C. Flow of non-newtonian fluids-correlation of the laminar, transition, and turbulent-flow regions[J]. Aiche Journal, 1955, 1(4): 434-440. [20] 方波, 邹春昱, 何良好, 等. 阳离子Gemini表面活性剂18-3-18/水杨酸钠胶束体系流变和减阻性能研究[J]. 高校化学工程学报. 2013, 27(1): 18-23.FANG Bo, ZOU Chunyu, HE Lianghao, et al. Rheologic and drag-reduction properties of cationic Gemini surfactant/sodium salicylate micelle systems[J]. Journal of Chemical Engineering of Chinese Universities, 2013, 27(1): 18-23. -

下载:

下载: