Preparation and Performance Study of an Adsorptive Retardant for Acid Job

-

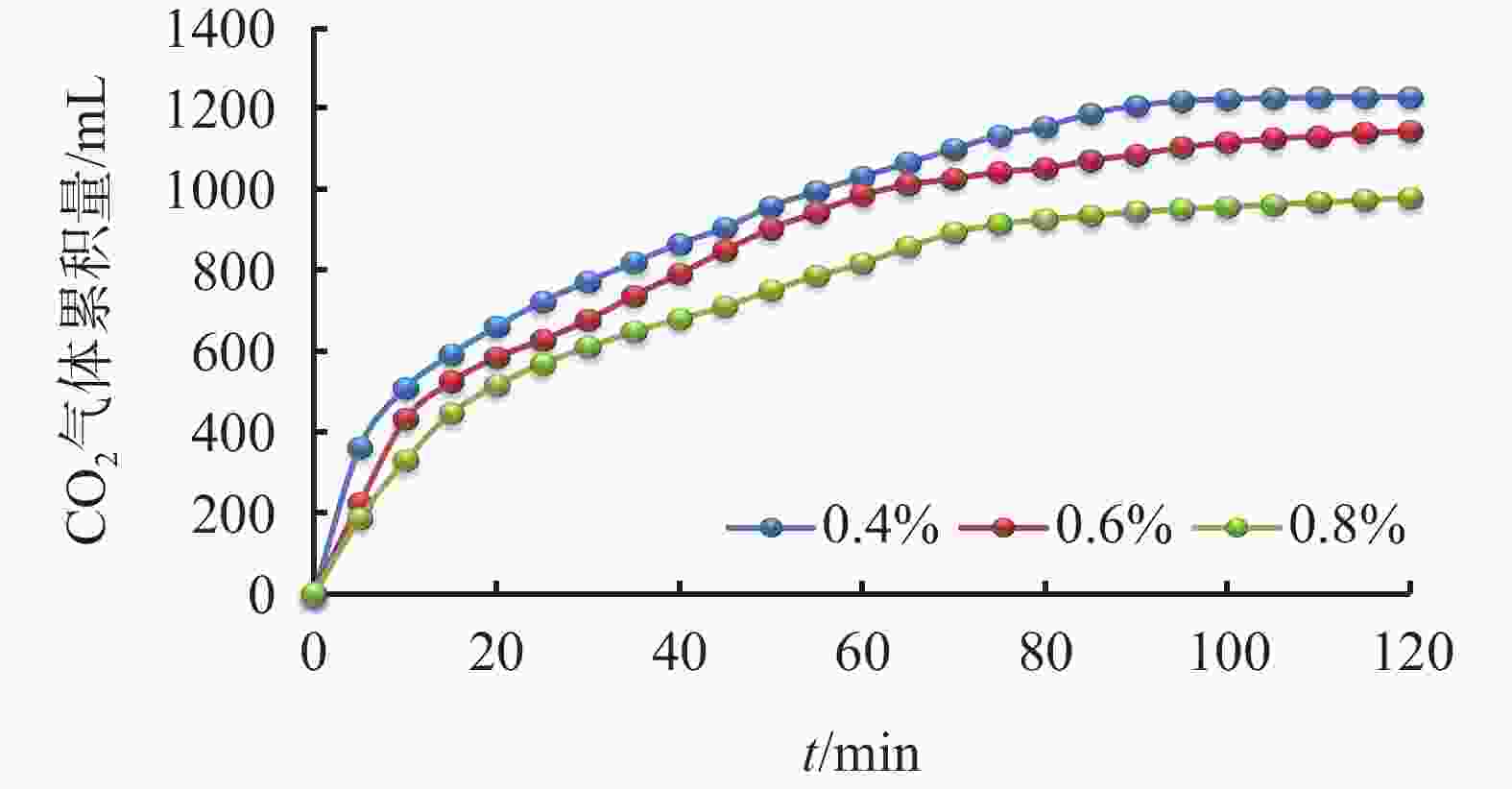

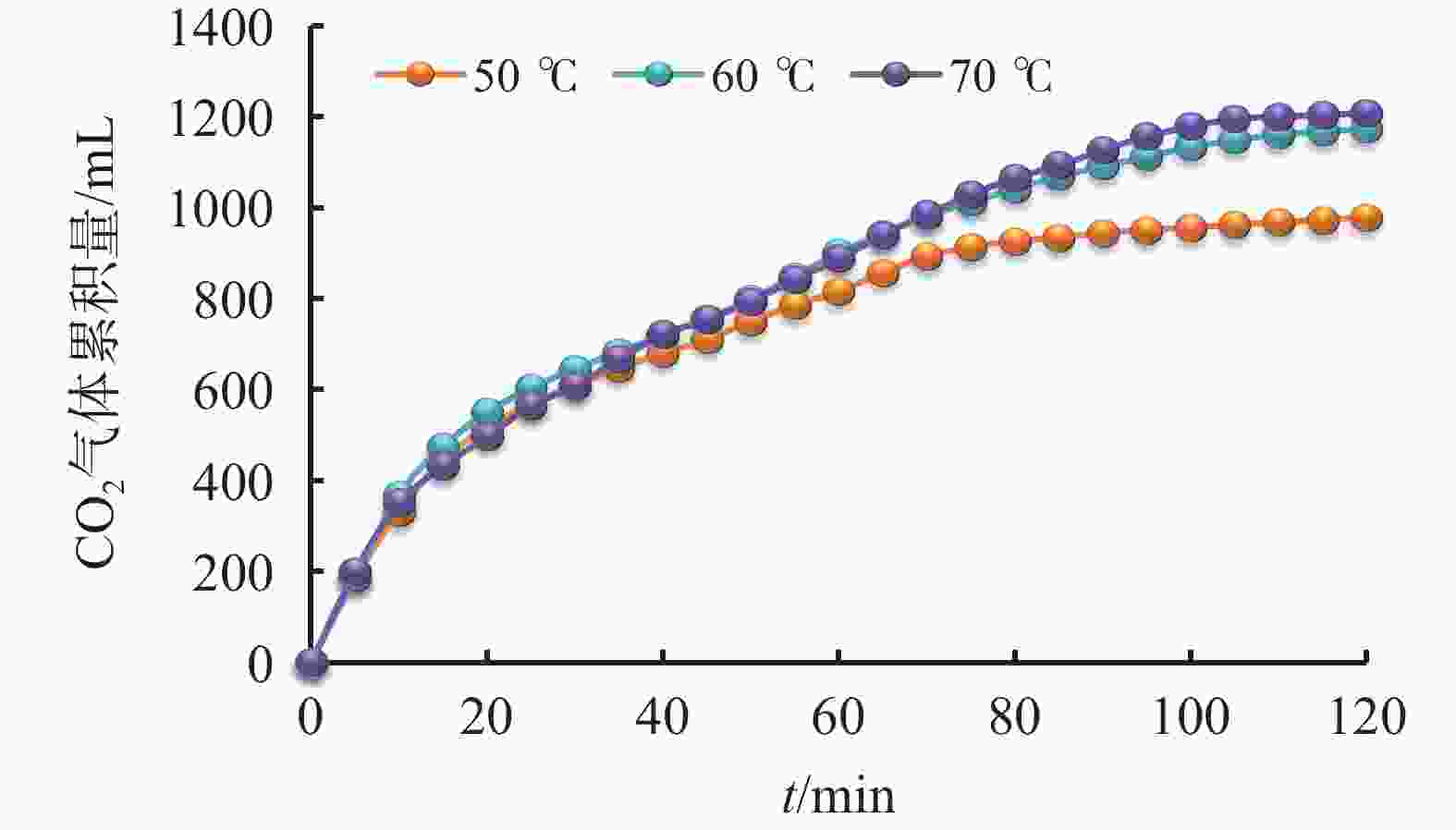

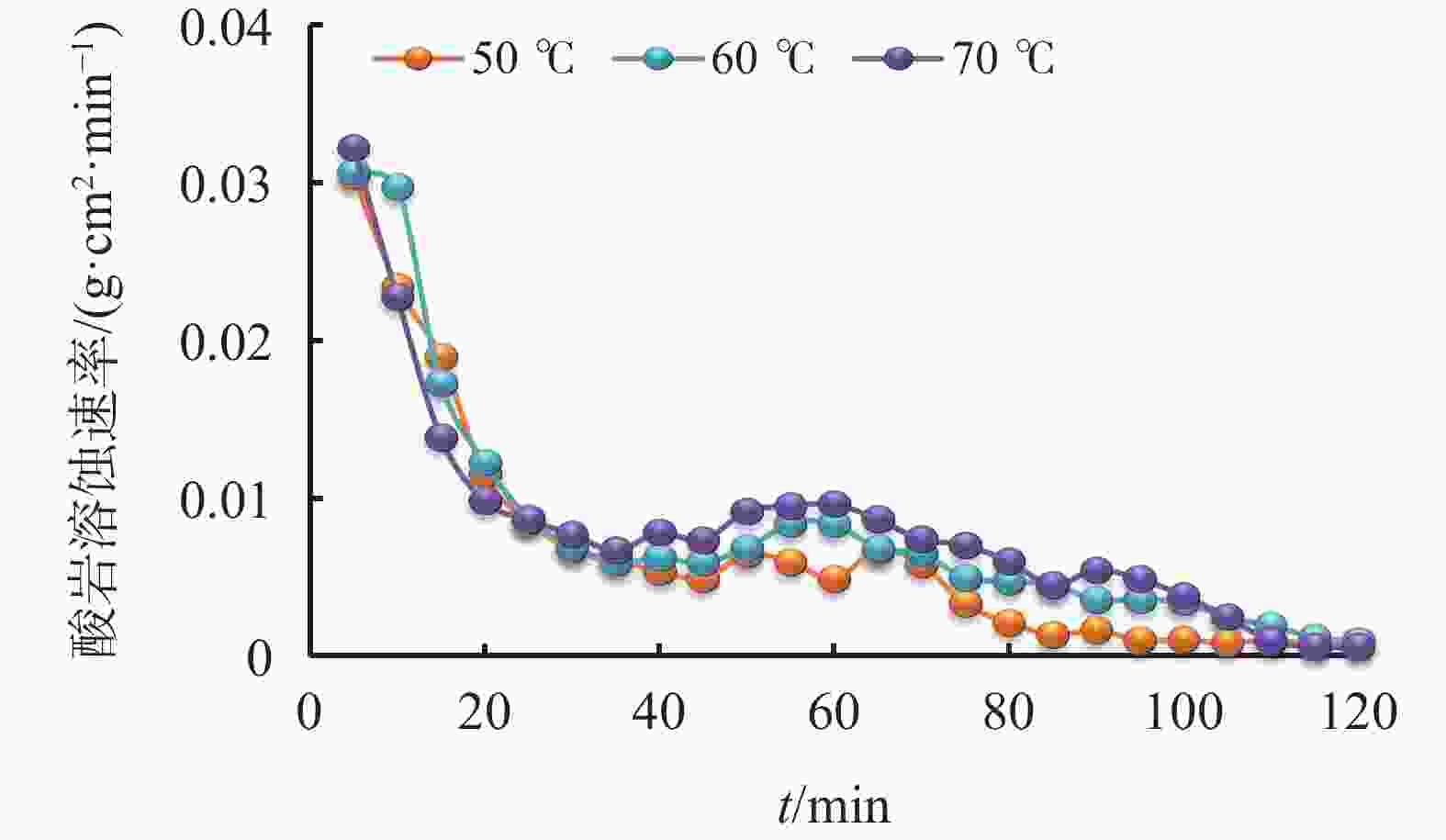

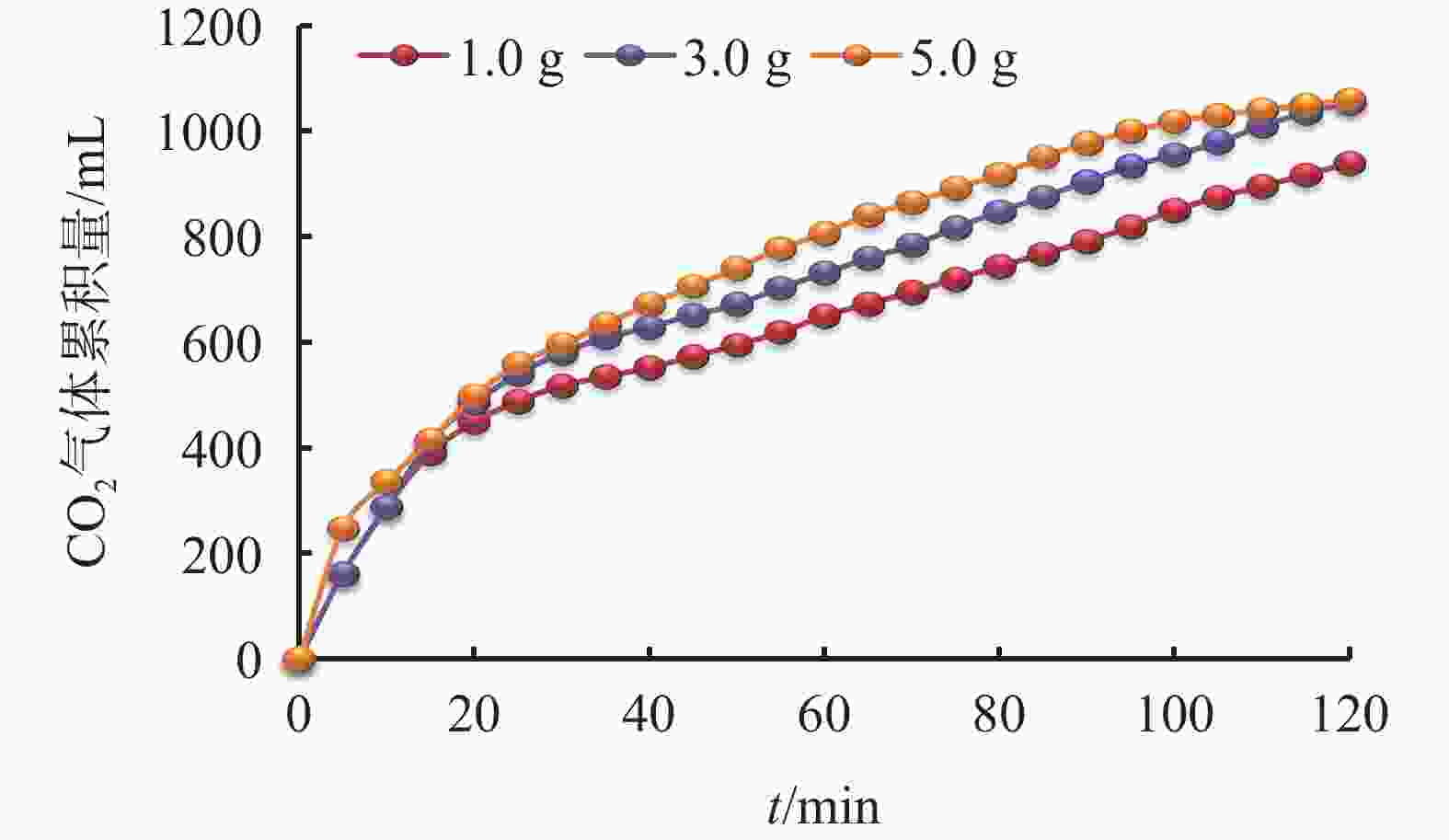

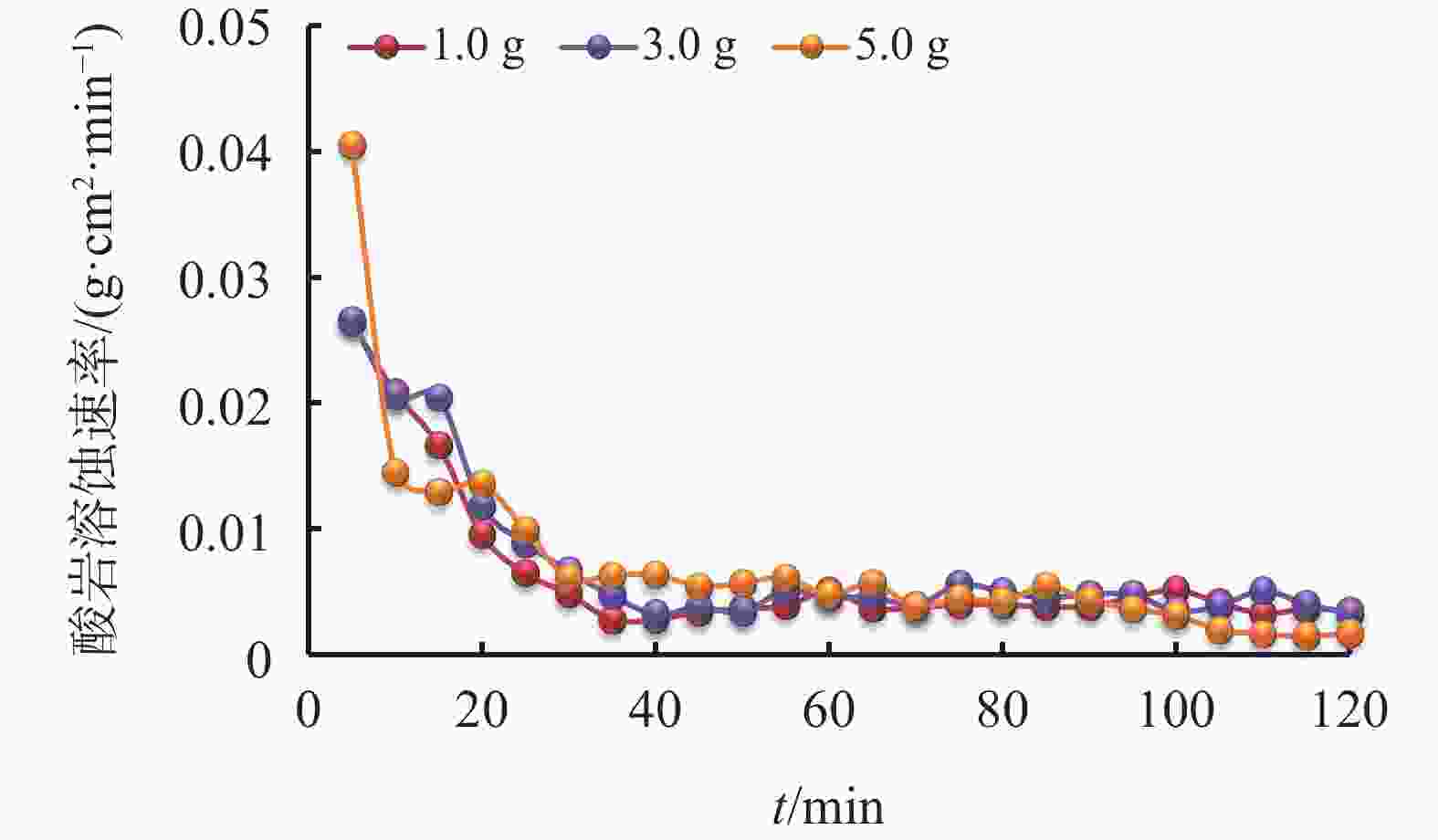

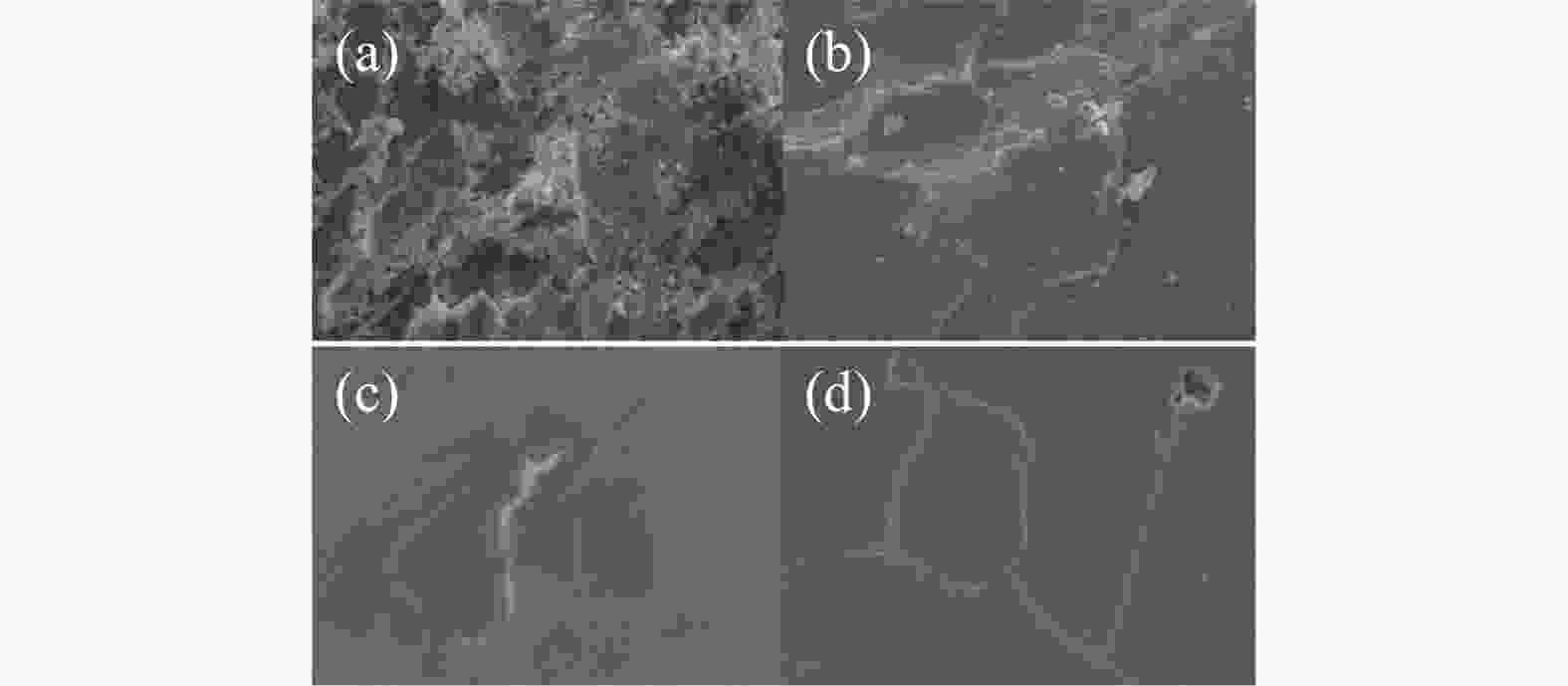

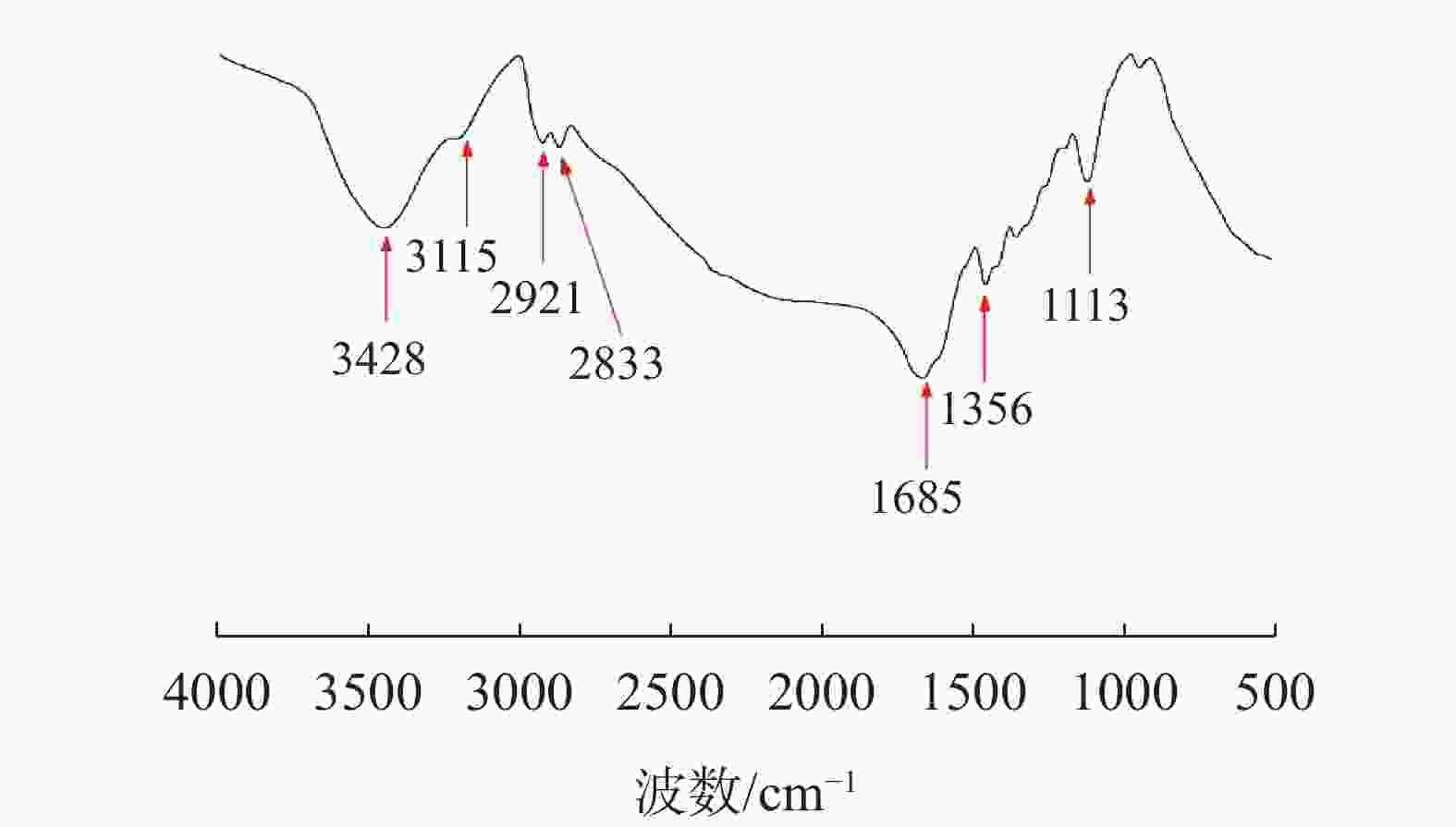

摘要: 针对酸化作业中存在的酸岩反应速度快、残酸返排困难、二次伤害大等问题,以丙烯基聚氧乙烯醚(APEE)、酯类单体(EX)、丙烯酰胺(AM)为原料,通过乳液聚合成功制备出一种吸附型酸化缓速剂。通过单因素优化法,确定了最佳合成条件为:m(AM)∶m(APEE)∶m(EX)=10.66∶1.05∶0.17,单体质量分数加量15%,引发剂质量分数加量0.25%,反应温度50 ℃ ,反应时间6.0 h采用红外光谱对缓速剂分子进行了结构表征,并研究了缓速剂加量、温度和钙盐含量对缓速剂延缓酸岩反应性能的影响。 结果表明,缓速剂质量分数加量为0.8%时,酸岩反应时间可延长至120 min;在70 ℃下,缓速剂依然具有良好的缓速性能;缓速剂配制而成的缓速酸具有优良的抗钙盐性能。 通过SEM成功观察到缓速剂吸附在岩石表面,有效延缓了氢离子与碳酸钙表面的接触,从而降低了酸岩反应速率。Abstract: Acid job has long been faced with a series of problems such as fast acid – rock reaction, difficulties in flowing back the residue acids as well as high secondary formation damage etc. To deal with these problems, an adsorptive retardant for acid job was developed through emulsion polymerization with raw materials such as allyl polyoxyethylene ether (APEE), an ester monomer EX and acrylamide (AM). The optimum reaction condition for the synthesis reaction obtained through single-factor optimization is as follows: m(AM)∶m(APEE)∶m(EX) = 10.66∶1.05∶0.17, the total mass fraction concentration of the monomers is 15%, the mass fraction concentration of the initiator 0.25%, the reaction temperature 50 ℃, and the reaction time 6.0 h. The molecular structure of the retardant was characterized with IR spectroscopy and studies were done on the effects of several factors, such as the concentration of the retardant in acid, temperature and concentration of calcium salts, on the retardant’s ability to retard the acid – rock reaction. It was found in the studies that when the mass fraction concentration of the retardant is 0.8%, the acid – rock reaction time can be extended to 120 min. The retardant was able to show good retarding performance at 70 ℃. The retarded acid prepared with the retardant has excellent resistance to calcium salts. SEM observation has shown that the retardant is adsorbed on the surfaces of the rocks, effectively retarding the contact of the hydrogen ions with the surfaces of calcium carbonate rocks and hence reducing the reaction rate between the acid and the rocks.

-

Key words:

- Acidize /

- Adsorb /

- Retardant /

- Acid-rock reaction

-

表 1 单体配比对缓速剂溶蚀率的影响

m(AM)∶m(APEE)∶m(EX) 溶蚀率/% 3.56∶0.35∶0.17 86.0 5.33∶0.35∶0.17 82.8 7.11∶0.35∶0.17 87.2 8.89∶0.35∶0.17 83.2 10.66∶0.35∶0.17 78.2 10.66∶0.70∶0.17 80.9 10.66∶1.05∶0.17 71.8 10.66∶1.40∶0.17 81.3 10.66∶1.75∶0.17 73.8 10.66∶2.10∶0.17 81.8 10.66∶2.45∶0.17 90.3 10.66∶2.80∶0.17 95.2 10.66∶3.15∶0.17 96.5 10.66∶3.50∶0.17 96.1 表 2 单体浓度对缓速剂溶蚀率的影响

单体质量分数/% 溶蚀率/% 10 61.7 15 59.6 20 67.8 25 63.4 30 71.8 35 83.0 表 3 引发剂浓度对目标产物溶蚀率的影响

引发剂质量分数/% 溶蚀率/% 0.20 53.5 0.25 50.9 0.30 59.6 0.35 56.4 0.40 61.1 表 4 反应温度对目标产物溶蚀率的影响

T/℃ 溶蚀率/% 35 未聚合 40 52.5 45 53.6 50 50.9 55 58.7 60 71.0 表 5 反应时间对目标产物溶蚀率的影响

t/h 溶蚀率/% 4.0 61.4 4.5 52.6 5.0 50.9 5.5 64.4 6.0 43.8 6.5 55.3 -

[1] 郭建春,陈朝刚. 酸化工作液发展现状[J]. 河南石油,2004,18(6):40-42.GUO Jianchun, CHEN Chaogang. Development situation of acidizing fluid[J]. Henan Oil, 2004, 18(6):40-42. [2] WELTON T D, VAN DOMELEN M S. High viscosity yield acid systems for high-temperature stimulation[C]. SPE International Symposium and Exhibition on Formation Damage Control. Society of Petroleum Engineers, 2006. [3] 王奕. 新型稠化酸液的制备及其性能研究[D]. 四川大学, 2007.WANG Yi. Preparation and performance research of new thickened acid[D]. Sichuan University, 2007. [4] 崔文娟. 耐酸抗高温酸液稠化剂的合成与评价[D]. 河南工业大学, 2010.CUI Wenjuan. Synthesis and evaluation of acid - resistant high temperature acid thickener[D]. Henan Technology University, 2010. [5] GOMAA A M, NASR-EL-DIN H A. New insights into the viscosity of polymer-based in-situ-gelled acids[J]. SPE Production & Operations, 2010, 25(3):367-375. [6] RUNTUWENE M, FASA M H, RACHMAWATI F D, et al. Crosslinked acid as an effective diversion agent in matrix acidizing[C]. IADC/SPE Asia Pacific Drilling Technology Conference and Exhibition. Society of Petroleum Engineers, 2010. [7] RABIE A I, GOMAA A M, NASR-EL-DIN H A. HCl/Formic in-situ-gelled acids as diverting agents for carbonate acidizing[J]. SPE Production & Operations, 2012, 27(2):170-184. [8] 中华人民共和国石油天然气行业标准. SY/T 5694—95 酸化用酸液稠化剂 CT1-6[S].北京: 中国石油天然气总公司, 1995-10-21.Petroleum and natural gas industry standards of the people's republic of China.SY/T 5694-95 Acid thickener for acidification CT1-6[S]. Beijing: China National Petroleum Corporation, 1995-10-21. [9] 汪志臣. 疏水缔合水溶性聚合物酸液稠化剂的合成与评价[D]. 西南石油大学, 2010.WANG Zhichen. Synthesis and evaluation of thickeners for hydrophobic associating water soluble polymer acid fluid[D]. Southwest Petroleum University, 2010. [10] 熊春明,周福建,马金绪,等. 新型乳化酸选择性酸化技术[J]. 石油勘探与开发,2007,34(6):740-744. doi: 10.3321/j.issn:1000-0747.2007.06.018XIONG Chunming, ZHOU Fujian, MA Jingxu,et al. New selective acidification technology for emulsified acid[J]. Petroleum Exploration and Development, 2007, 34(6):740-744. doi: 10.3321/j.issn:1000-0747.2007.06.018 [11] 何春明,陈红军,翟锐. 乳化酸酸岩反应动力学实验研究[J]. 油田化学,2009,26(3):245-249.HE Chunming, CHEN Hongjun, ZHAI Rui. The emulsified acid experiment study on reaction kinetics of acid rock[J]. Oilfield Chemistry, 2009, 26(3):245-249. [12] SAYED M, NASR-EL-DIN H A, NASRABADI H. Reaction of emulsified acids with dolomite[J]. Journal of Canadian Petroleum Technology, 2013, 52(3):164-175. doi: 10.2118/151815-PA [13] 陈彦东,方波,房鼎业,等. 耐高温阳离子 Gemini 柴油微乳盐酸体系研究[J]. 油田化学,2014,31(2):182-186.CHEN Yandong, FANG Bo, FANG Dingye, et al. The research of high temperature resistant cationic Gemini diesel microemulsion hydrochloric acid system[J]. Oilfield Chemistry, 2014, 31(2):182-186. [14] 原励,熊颖,蒋永,等. 一种高温乳化酸的研制与评价[J]. 石油与天然气化工,2014,43(5):521-524. doi: 10.3969/j.issn.1007-3426.2014.05.012YUAN Li, XIONG Ying, JIANG Yong, et al. Preparation and evaluation of a high temperature emulsifying acid[J]. Petroleum and Natural Gas Chemicals, 2014, 43(5):521-524. doi: 10.3969/j.issn.1007-3426.2014.05.012 [15] SAYED M A, ASSEM A I, NASR-EL-DIN H A. Effect of oil saturation on the flow of emulsified acids in carbonate rocks[J]. SPE Production & Operations, 2014, 29(1):29-41. [16] 周生田,李兆敏,王飞. 水平井泡沫酸化分流数值模拟[J]. 石油学报,2012,33(3):448-452. doi: 10.7623/syxb201203015ZHOU Shengtian, LI Zhaomin, WANG Fei. Numerical simulation of foam acidizing shunt in horizontal wells[J]. Journal of Petroleum, 2012, 33(3):448-452. doi: 10.7623/syxb201203015 [17] 徐永辉. 泡沫酸特性研究及其应用[D]. 北京: 中国石油大学, 2007.XU Yonghui. Application and study of foamed acid fluid[D]. Beijing: China University of Petroleum, 2007. [18] 敬显武. 清洁转向酸酸岩反应特性研究[D]. 西南石油大学, 2014.JING Xianwu. The clean steering acid characteristics study on the reaction between acid and rock[D]. Southwest Petroleum University, 2014. [19] AL-SADAT W, NASSER M S, CHANG F, et al. Laboratory evaluation of the effects of additives and pH on the thermorheological behavior of a viscoelastic zwitterionic surfactant used in acid stimulation[J]. Journal of Petroleum Science and Engineering, 2014, 122:458-467. doi: 10.1016/j.petrol.2014.08.006 [20] 李小玲,丁里,石华强,等. 新型清洁转向酸的研制及性能评价[J]. 陕西科技大学学报:自然科学版,2014,32(6):105-109.LI Xiaoling, DING Li, SHI Huaqiang, et al. Development and performance evaluation of new cleaning steering acid fluid[J]. Journal of Shanxi University of Science and Technology:Natural Science Edition, 2014, 32(6):105-109. [21] FANG Yuyan, ZHANG Ye, YANG Fangzhen, et al. Performance evaluation of a kind of high temperature in-situ acid fluid[J]. Oilfield Chemistry, 2014(2):191-194. [22] QUAN H, LI H, HUANG Z, et al. Copolymer MCJS as a retarder of the acid–rock reaction speed for the stimulation of deep carbonate reservoirs[J]. Journal of Applied Polymer Science, 2015, 132(7):2259-2262. [23] QUAN H, CHEN Z, WU Y, et al. Adsorption behavior of the copolymer AM/DMC/APEG/DMAAC-16 on a carbonate rock and its application for acidizing[J]. RSC Advances, 2017, 7(50):31771-31778. doi: 10.1039/C7RA04069E [24] QUAN H, LU Q, CHEN Z, et al. Adsorption–desorption behavior of the hydrophobically associating copolymer AM/APEG/C-18/SSS[J]. RSC Advances, 2019, 9(22):12300-12309. doi: 10.1039/C9RA01932D [25] 吴洋. AM/APEG/DMC/DMAAC-16酸液缓速剂及吸附行为研究[D]. 西南石油大学, 2016.WU Yang. Study on AM/APEG/DMC/DMAAC-16 acid retarder and adsorption behavior[D]. Southwest Petroleum University, 2016. -

下载:

下载: