A High Efficiency Oil Wash Spacer for Shale Gas Wells in Changning Oilfield

-

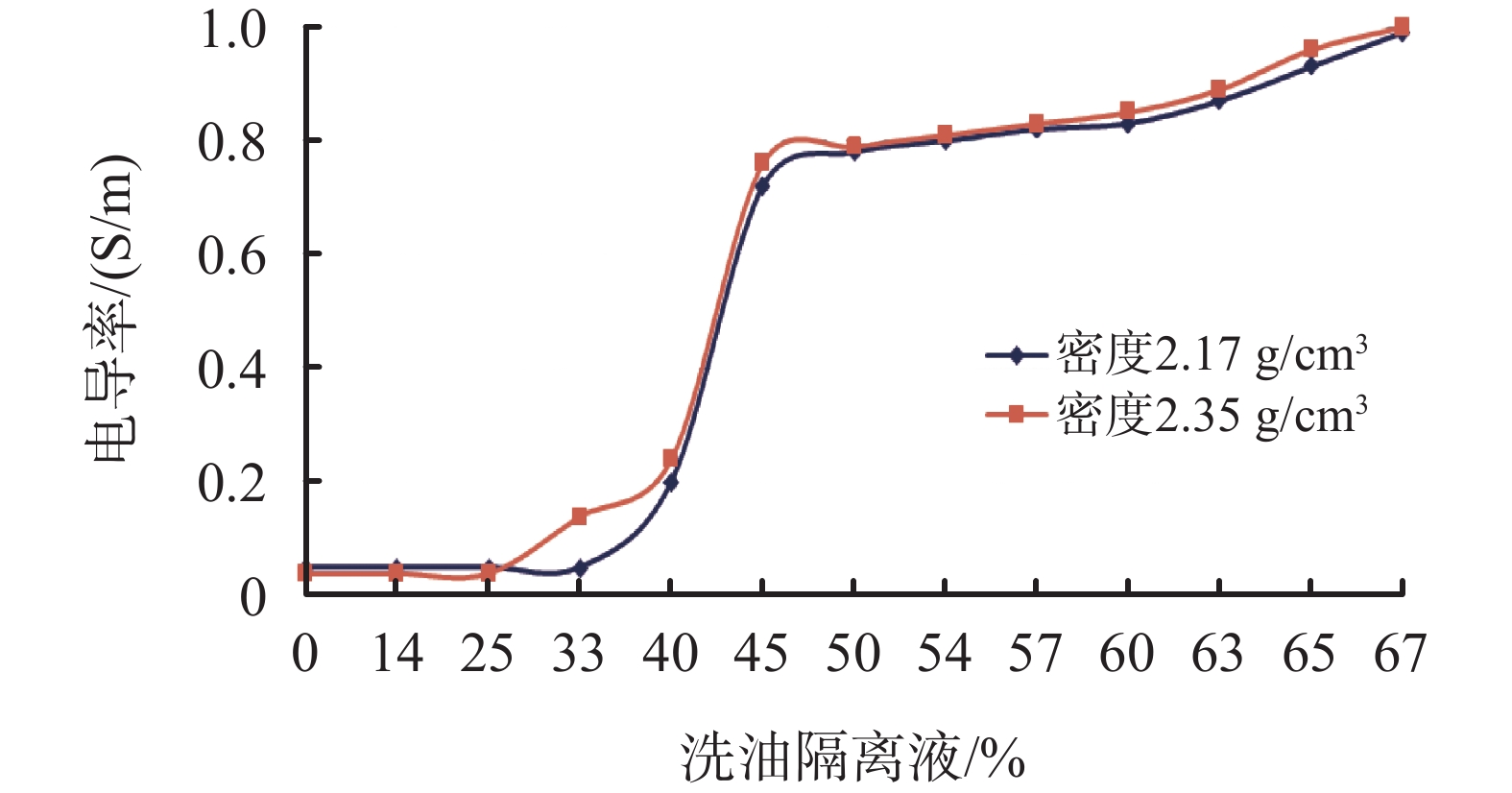

摘要: 针对长宁页岩气水平井所用油基钻井液与水泥浆兼容性差,絮凝混浆滞留环空难以驱替干净的问题,根据表面活性剂的类型、作用原理及HLB值进行设计,开发了洗油冲洗剂BCS-130L,并形成了一种适用于长宁页岩气井的高效洗油隔离液体系。该体系在70~180 ℃,密度为1.5~2.4 g/cm3时可清除环空壁面的油基钻井液,实现界面润湿性能反转,流变性与稳定性良好,与现场钻井液和水泥浆相容性良好,满足长宁页岩气目的层固井要求。Abstract: The oil based drilling fluids used in horizontal drilling of shale gas wells in Changning oilfield are poorly compatible with the cement slurries, resulting in the mixture of the drilling fluid and cement slurry flocculated and difficult to displace from the annular spaces. To solve this problem, an oil wash additive BCS-130L was developed based on the types, functioning principles and HLB levels of surfactants. A high efficiency oil wash spacer was developed using BCS-130L, which is suitable for use in Changning. This spacer, with its density ranging between 1.5 g/cm3 and 2.4 g/cm3, can work normally at temperatures between 70 ℃ and 180 ℃; it cleans the oil based drilling fluids held up on the surface of the annular spaces and reverses the wettability of the surfaces. The spacer has good rheology and stability and is compatible with the drilling fluid and the cement slurry in use, it has satisfied the requirements of shale gas well cementing in Changning oilfield.

-

Key words:

- Shale gas well /

- Spacer /

- Wettability reverse /

- Wash efficiency /

- Compatibility

-

表 1 洗油冲洗剂的性能测试

冲洗剂 界面张力/

mN·m−1电导率/

S·m−1冲洗剂 界面张力/

mN·m−1电导率/

S·m−1a 5.26 0.26 e 6.23 0.25 b 0.13 0.65 f 1.44 0.95 c 0.93 0.72 g 14.73 0.49 d 12.57 0.35 自来水 36.30 0 表 2 温度对洗油隔离液流变参数的影响

T/℃ φ600 φ300 φ200 φ100 φ6 φ3 PV/mPa·s YP/Pa 70 97 63 46 30 9 7 34 14.5 90 95 62 48 31 9 7 33 14.5 120 94 62 47 30 8 7 32 15.0 160 93 61 46 32 8 6 32 14.0 180 90 59 45 31 7 6 31 14.0 表 3 洗油隔离液的沉降稳定性(2.1 g/cm3)

T/

℃ρ上/

g·cm−3ρ下/

g·cm−3△ρ/

g·cm−370 2.095 2.105 0.010 90 2.100 2.110 0.010 120 2.100 2.115 0.015 160 2.090 2.110 0.020 180 2.090 2.110 0.020 表 4 洗油隔离液的润湿效果(90 ℃)

BCS-130L/

%含有不同加量(%)洗油隔离液的混浆电导率/

S·m−10 33 43 50 56 60 64 67 70 30 0.05 0.06 0.80 0.90 1.00 20 0.05 0.05 0.42 0.72 0.89 0.92 1.00 12 0.05 0.05 0.32 0.33 0.35 0.60 0.83 0.89 1.00 表 5 BCS-130L对洗油隔离液冲洗效果影响(90 ℃)

BCS-130L/% 冲洗时间/min 冲洗效果 12 5 外筒冲洗干净 10 5 外筒冲洗干净 8 5 外筒冲洗干净 6 5 外筒冲洗部分干净 注:油基钻井液密度为2.05 g/cm3;冲洗效果评价:①外筒无油基钻井液残留时外筒冲洗干净;②外筒油基钻井液残留小于50%时外筒冲洗部分干净;③外筒油基钻井液残留大于等于50%时外筒冲洗不干净 表 6 洗油隔离液与钻井液、水泥浆混浆流动度实验

水泥浆/

%钻井液/

%隔离液/

%常温流动度/

cm90 ℃流动度/

cm100 23 25.0 100 21 22.0 100 24 26.0 50 50 23 11.0 70 30 22 14.0 30 70 21 17.0 33.30 33.30 33.30 24 19.5 70 20 10 19 19.5 5 95 24 26.0 95 5 22 23.0 表 7 现场油基钻井液混浆相容性 评价(90 ℃×45 MPa×45 min)

水泥浆/% 钻井液/% 隔离液/% t稠化/min 100 222 30 30 30 312 70 10 20 282 注:水泥浆配方为100 g嘉华G级水泥+2.1 gBCF-200S+

0.3 gCF-40S+47 g铁矿粉+0.2 gBXR-200L+52 g水 -

[1] 赵常青,谭宾,曾凡坤,等. 长宁-威远页若气示范区水平井固井技术[J]. 断块油气田,2014,21(2):256-258.ZHAO Changqing, TAN Bin, ZENG Fankun, et al. Cementing technology of horizontal well in Changning-Weiyuan shale gas reservoir[J]. Fault-Block Oil & Gas Field, 2014, 21(2):256-258. [2] 邹才能,赵群,丛连铸. 中国页岩气开发进展、潜力及前景[J]. 天然气工业,2021,41(1):2-3.ZOU Caineng, ZHAO Qun, CONG Lianzhu. Development progress, potential and prospect of shale gas in China[J]. Natural Gas Industry, 2021, 41(1):2-3. [3] 房恩楼, 李浩然, 张浩, 等. 一种低温低密度可固化隔离液的研制与性能评价[J]. 钻井液与完井液, 2020, 37(1): 86-92.FANG Enlou, LI Haoran, ZHANG Hao, et al. Development and performance evaluation of a low temperature low density solidifiable spacer fluid[J]. Drilling Fluid & Completion Fluid, 2020, 37(1): 86-92. [4] 郭永宾, 吴志明, 杨玉豪, 等. 深水油气井环空带压预防弹性隔离液体系[J]. 钻井液与完井液, 2019, 36(5): 654-658.GUO Yongbin, WU Zhiming, YANG Yuhao, et al. An elastic spacer for preventing trapped pressure in annulus of deepwater oil and gas wells[J]. Drilling Fluid & Completion Fluid, 2019, 36(5): 654-658. [5] 谭文礼,王翀,徐玲. BCS隔离液室内研究[J]. 石油天然气学报,2006(1):81-83. doi: 10.3969/j.issn.1000-9752.2006.01.026TAN Wenli, WANG Chong, XU Ling. Laboratory study of BCS spacer fluid[J]. Journal of Oil and Gas Technology, 2006(1):81-83. doi: 10.3969/j.issn.1000-9752.2006.01.026 [6] 谢飞燕, 王翀, 刘爱萍, 等. 用于评价固井冲洗液冲洗效率的设备: CN 204152463 U[P]. 2014-10-28.XIE Feiyan, WANG Chong, LIU Aiping, et al. Equipment for evaluating the flushing efficiency of cementing flushing fluid : CN 204152463 U [P]. 2014-10-28. -

下载:

下载: