Application of Autonomous Healing Cement Slurry System in Sichuan

-

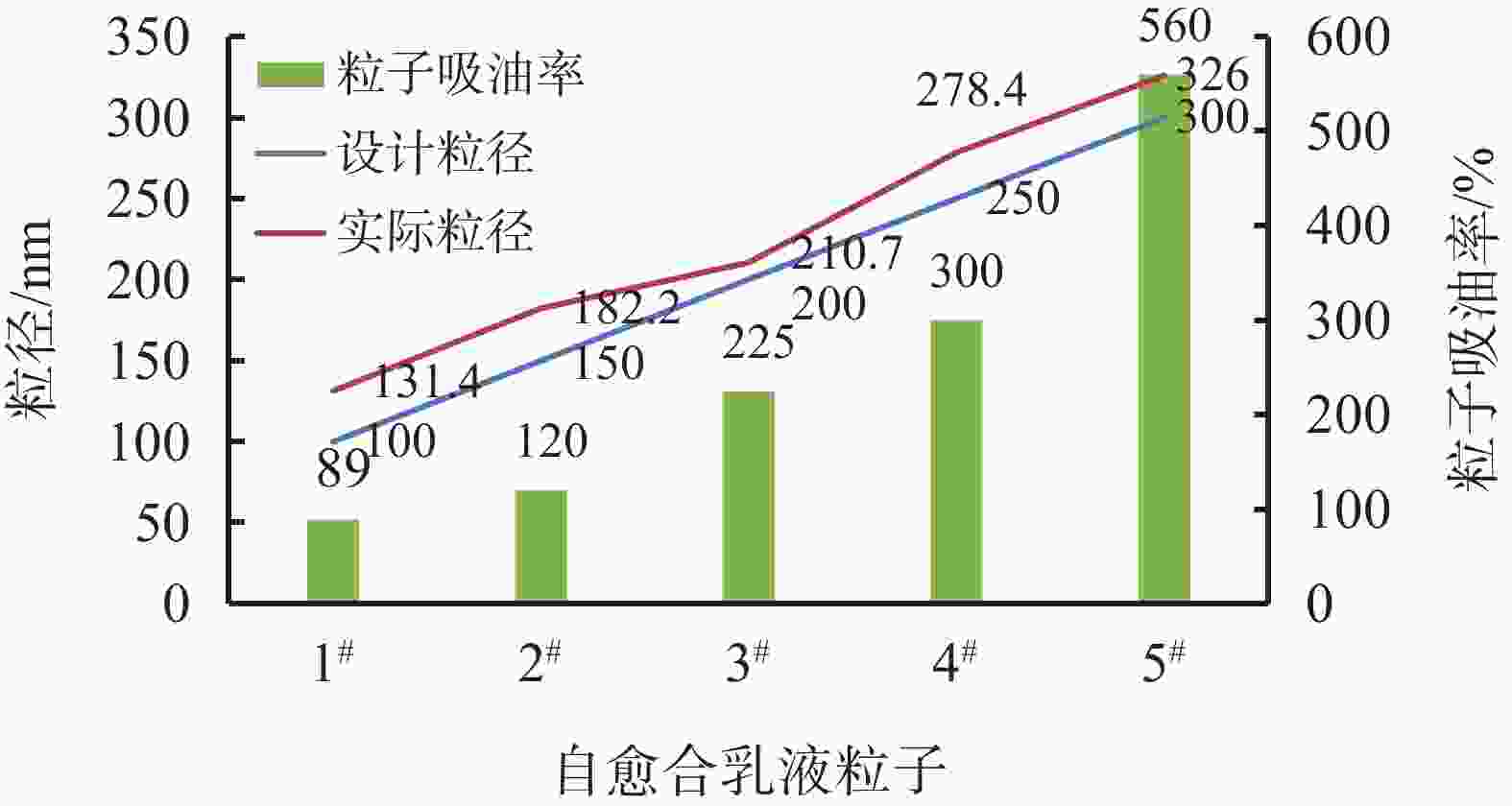

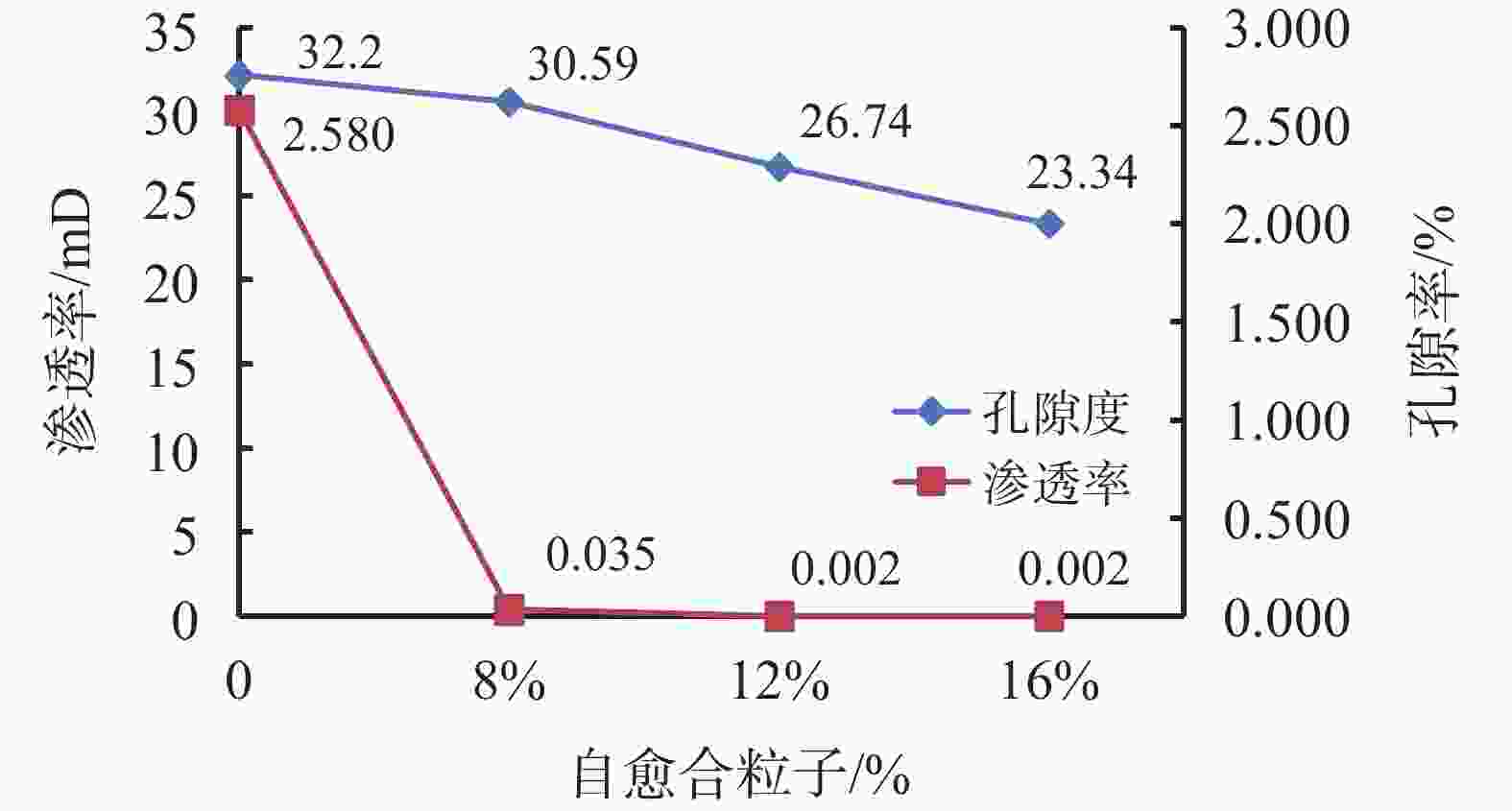

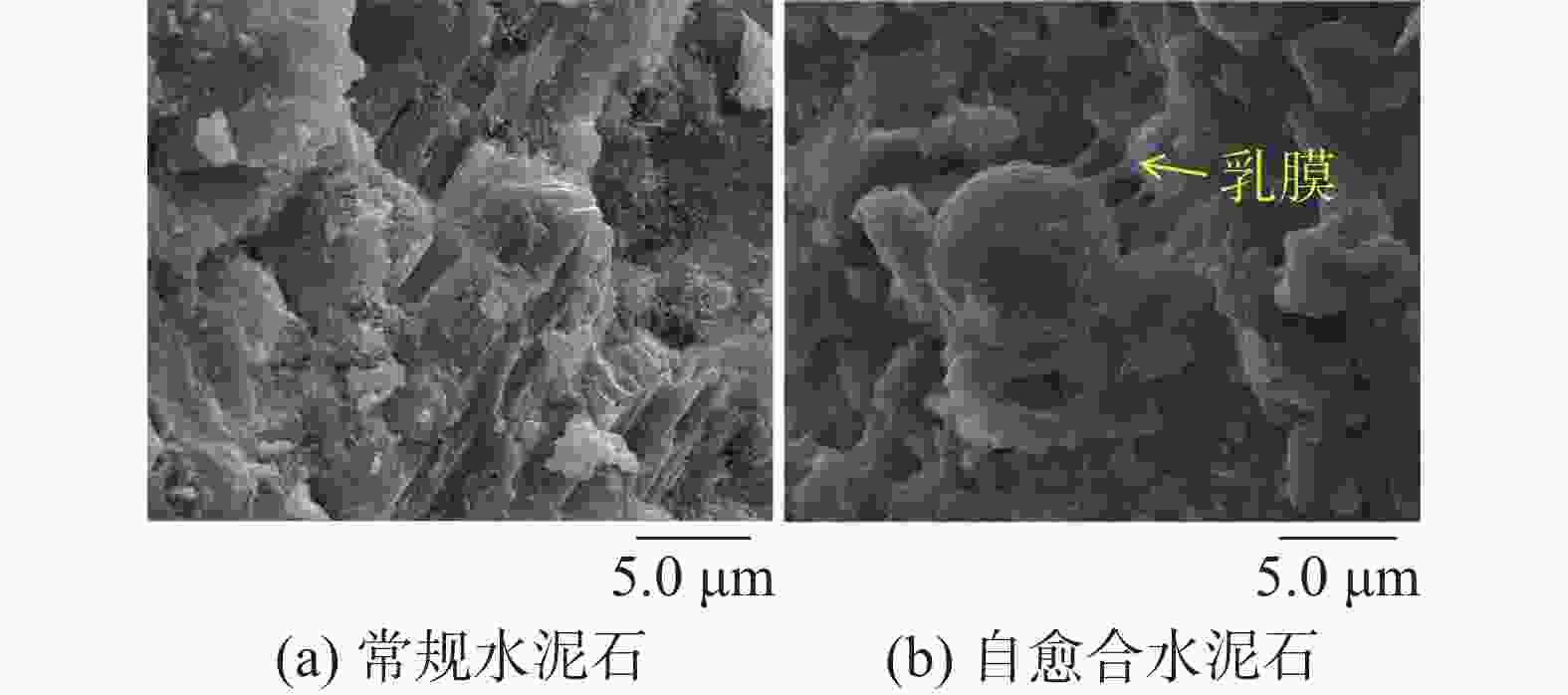

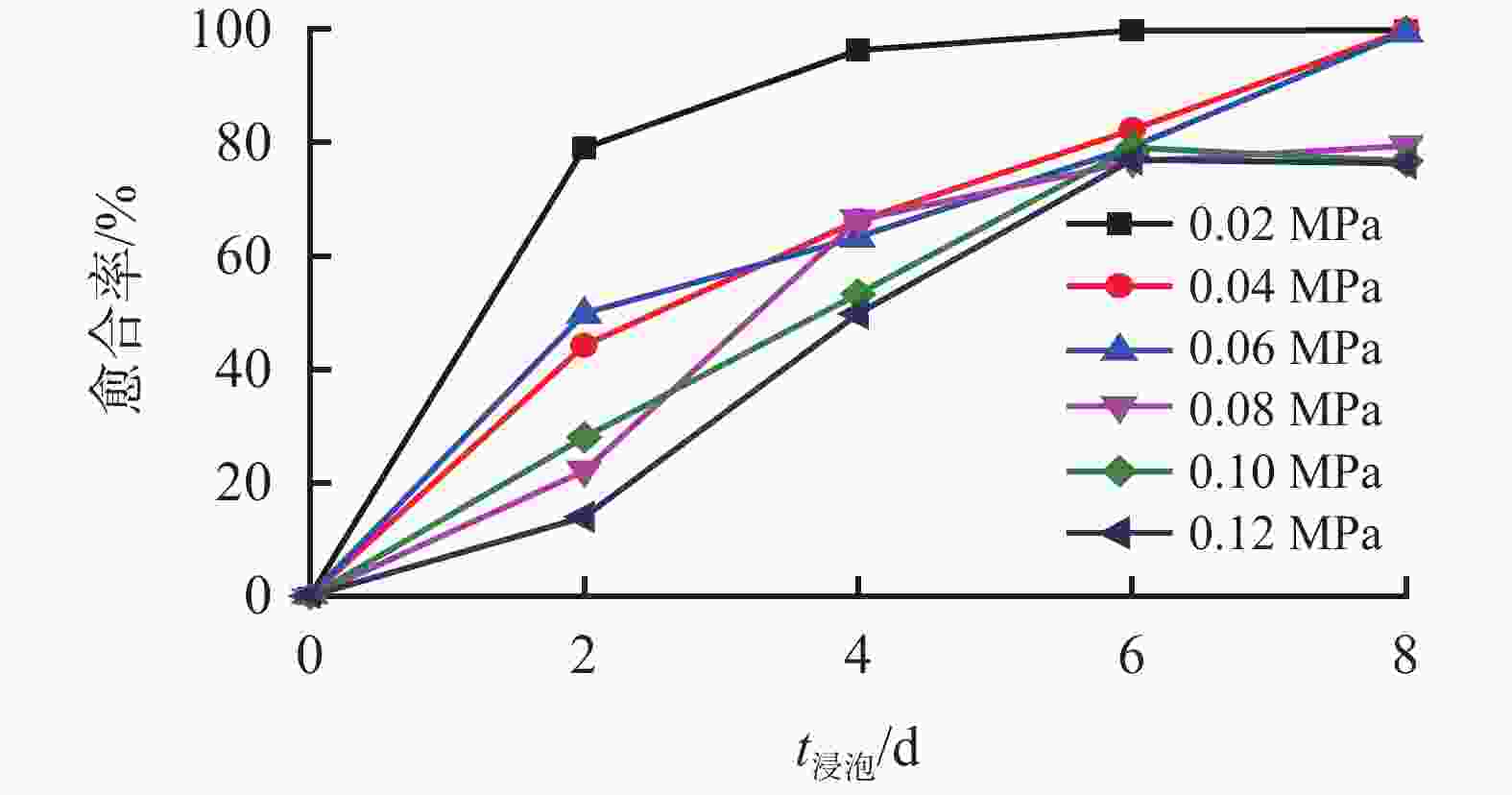

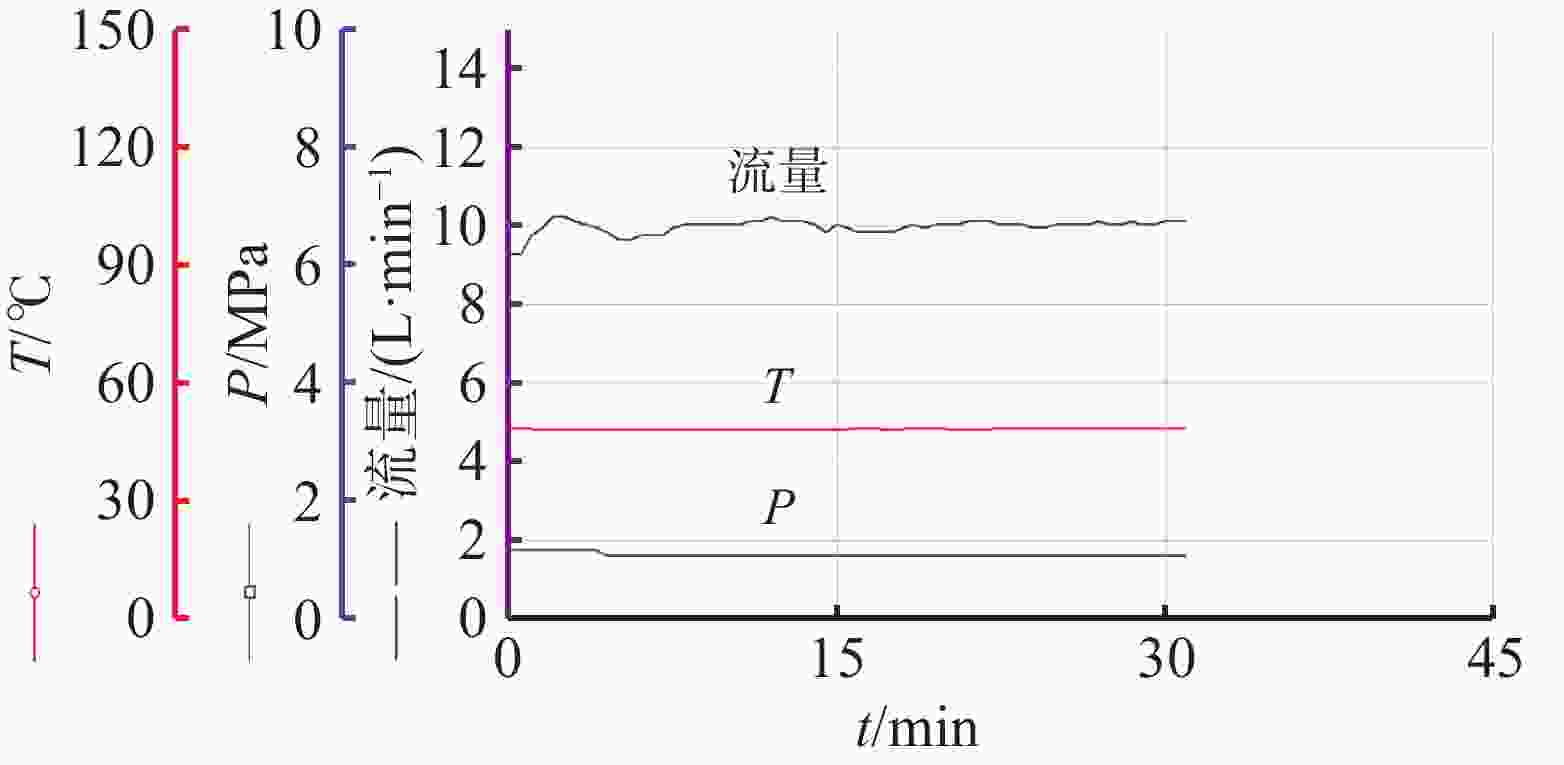

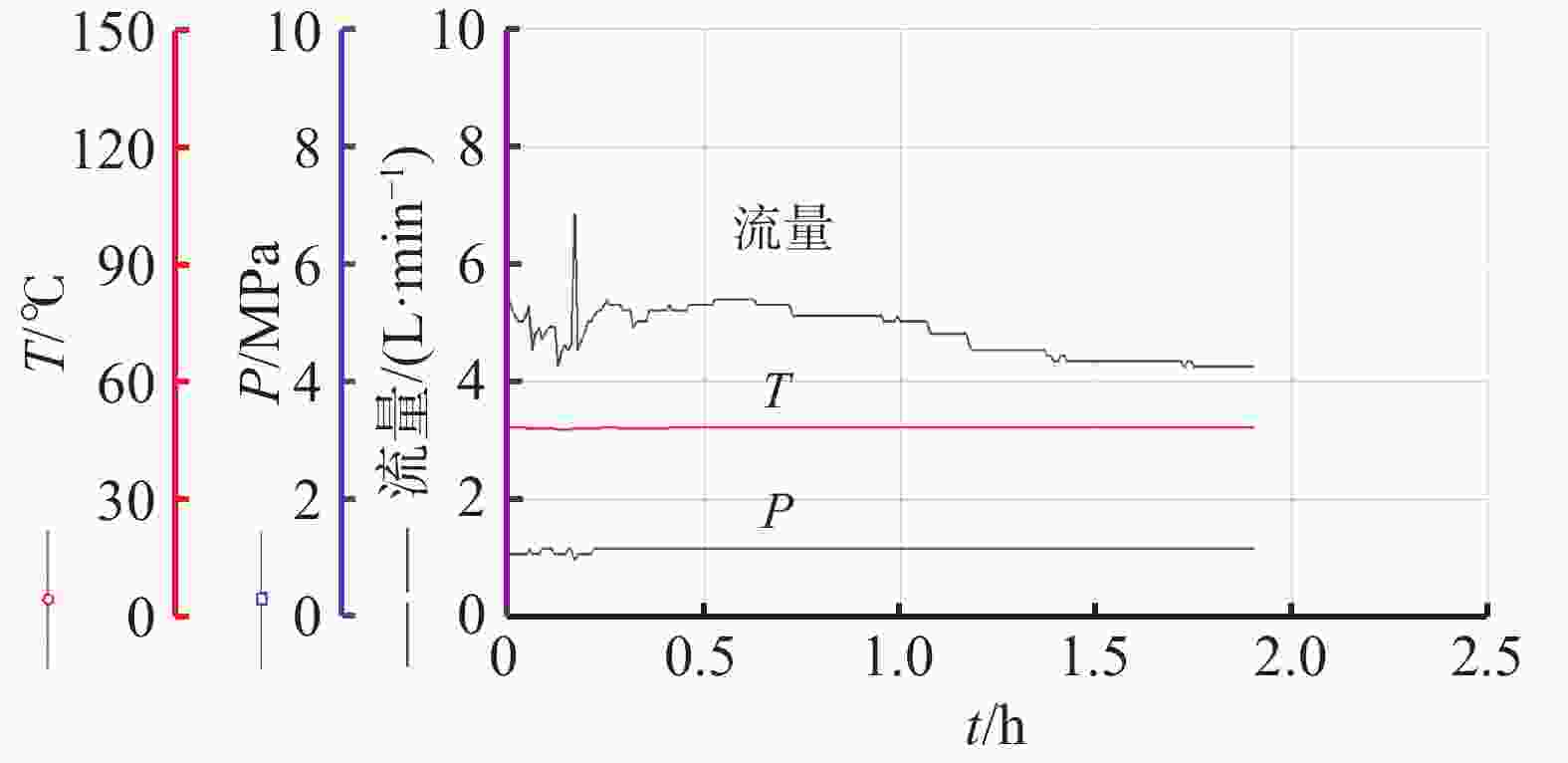

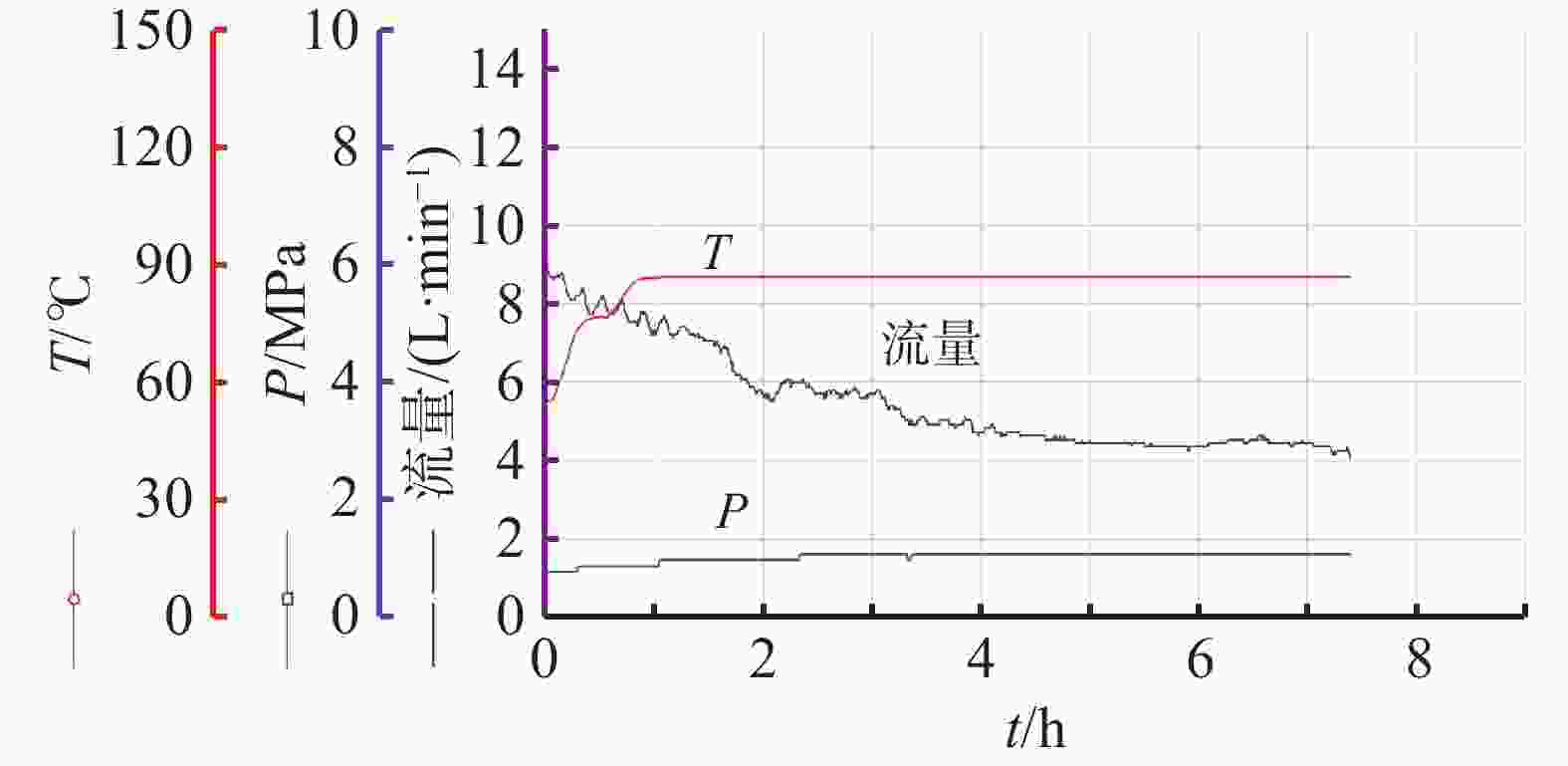

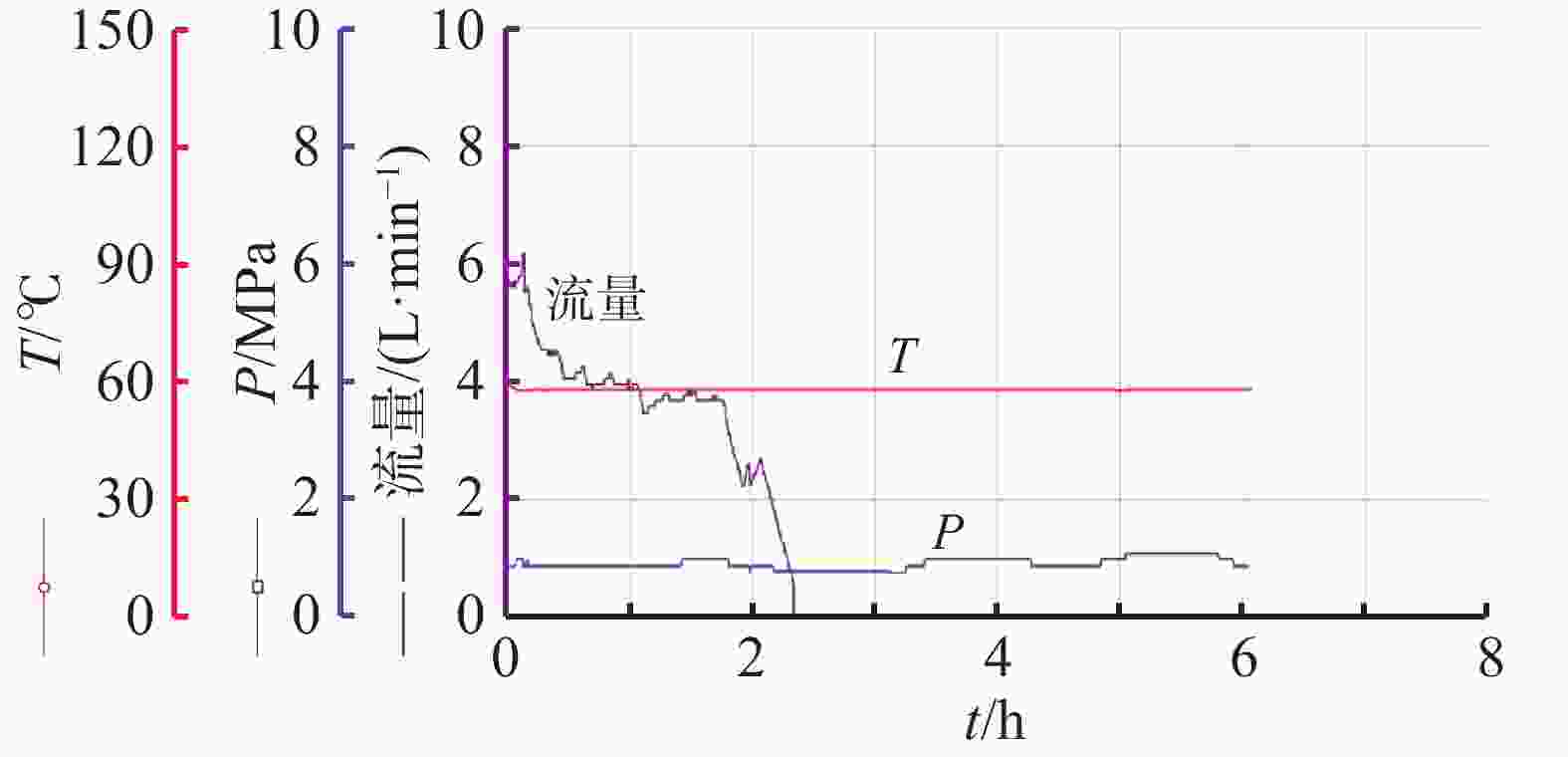

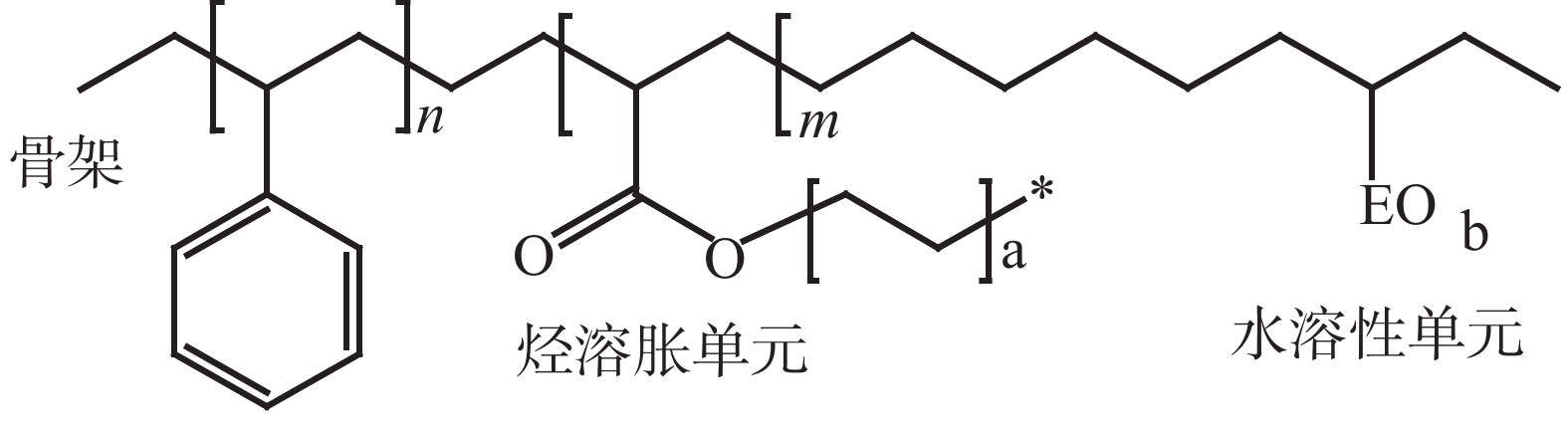

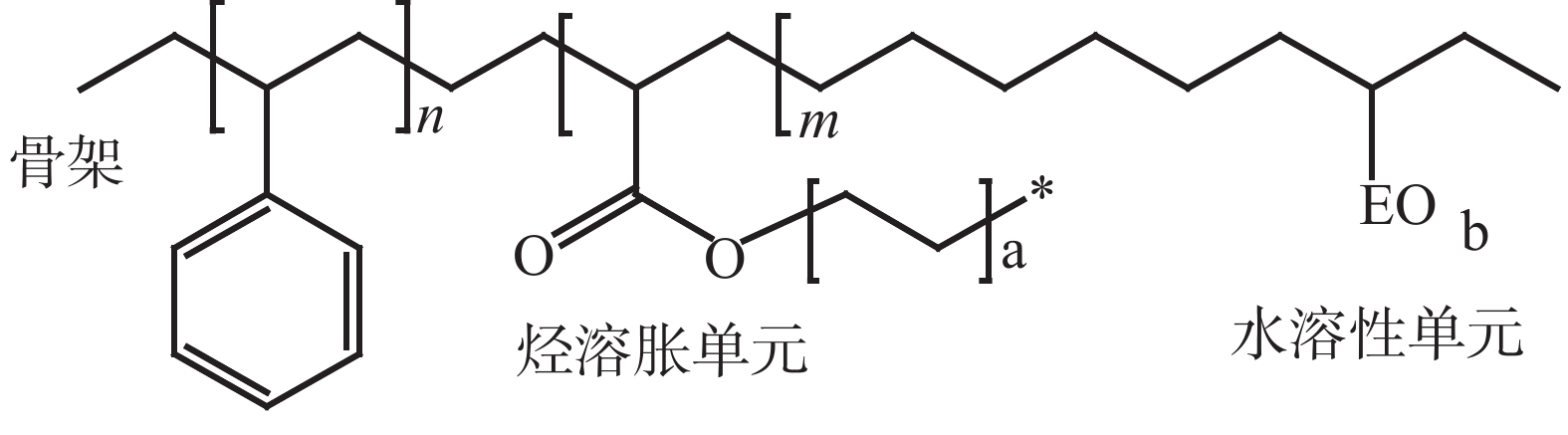

摘要: 针对油气井开发过程中水泥环受损产生裂缝而破坏固井封隔效果,以烃触发溶胀型聚合物为自愈合乳液粒子,形成自愈合水泥浆体系。结果表明,自愈合乳液粒子的粒径在200~250 nm,其加量为10%时水泥石吸油愈合效果及机械性能较佳;8 d内水泥石裂缝愈合率达70%~100%,2 d抗压强度为16.2 MPa,弹性模量为6 GPa;渗流实验结果表明,水泥石出现大于0.1 mm裂缝时,柴油气流速由9 g/min降至6 g/min,小于0.1 mm的裂缝时柴油流速由6 g/min可降低为0。说明自愈合水泥石一旦产生损伤,裂缝中渗入的油气分子使自愈合乳液粒子自发膨胀黏连并逐步修复闭合裂隙,裂缝越小自愈合效果越好,实现了水泥石自愈合修复功能。现场应用表明,该水泥浆体系固井质量优质率达到 88.9%,固井及压裂后技术套管均不带压,显示出良好的应用效果。Abstract: Aiming at the problem of damage effect of cementing isolation caused by formation of crack in cement sheath during the development of oil and gas wells, the hydrocarbon-triggered swelling polymer was used as self-healing particles to form an autonomous healing cement slurry system. The experimental results show that when the self-healing particle size is 200-250 nm and the amount is about 10%, the cement stone has better oil absorption healing effect and mechanical properties: the cement stone crack healing rate is 70%-100% within 8 days, and the 2 d compressive strength is 16.2 MPa, elastic modulus 6 GPa. Seepage experiments show that the flow rate of oil and gas in cracks of cement stone larger than 0.1 mm is reduced from 9 g/min to 6 g/min, and the flow rate of cracks smaller than 0.1 mm can be reduced from 6 g/min to 0. This shows that once the autonomous healing cement is damaged, the oil and gas molecules infiltrated into the crack and the self-healing particles spontaneously expand and adhere, then the cracks are gradually repaired. It can realize that the cement has self-healing function. The smaller the crack, the better the self-healing effect. The field application in Sichuan shows that the cementing quality of the autonomous healing cement system reached 88.9%, and the technical casing pressures after cementing and fracturing were not appeared, showing good application effects.

-

表 1 自愈合乳液粒子对水泥石抗压强度的影响

自愈合

乳液粒

子/%抗压

强度/

MPa抗压强

度下降

率/%自愈合

乳液粒

子/%抗压

强度/

MPa抗压强

度下降

率/%0 25.9 10 16.2 37.4 5 21.7 16.2 20 14.3 44.8 表 2 不同密度自愈合水泥浆体系的基本性能

ρ/

g·cm−3FLAPI/

mLT/

℃φ600 φ300 φ200 φ100 φ6 φ3 p48 h/

MPat稠化/

min1.87 32 26 252 133 109 54 12 8 16.2 274 90 >300 247 165 34 10 8 1.90 22 26 268 143 121 59 10 8 18.5 242 90 >300 257 178 22 8 6 2.00 20 26 >300 265 193 108 11 7 20.8 262 90 >300 269 190 109 11 8 2.10 18 26 >300 296 218 128 18 13 20.3 230 90 >300 >300 267 194 29 21 2.30 18 26 >300 286 214 127 19 16 21.6 206 90 >300 277 208 132 22 17 注:45 ℃游离液为0;稠化时间测定温度为90 ℃ 表 3 自愈合水泥在四川地区的应用情况

井号 套管层次 T地层/℃ ρ钻井液/(g·cm−3) ρ水泥浆/(g·cm−3) 固井质量 威页29-4HF Φ139.7 mm+Φ145.6 mm油层尾管 136 2.25 2.30(中浆应用自愈合水泥) 优质 江沙220HF Φ139.7 mm油层尾管 79 1.95 2.10 合格 中江122 Φ244.5 mm油层套管 62.5 1.75 1.95 优质 元坝272-2 Φ206.4 mm+Φ193.7 mm油层尾管 150 2.13 2.25 优质 元坝702 Φ273.1+282.6 mm技术尾管( 48套气层) 120 2.26 2.4 优质 元坝702 Φ139.7 mm油层尾管 162 2.25 2.35 优质 合深5井 Φ127 mm油层尾管 149 1.30 1.88 优质 马6井 Φ193.7 mm技术尾管 119 1.91 2.05 优质 河嘉204H Φ193.7 mm+Φ200.03 mm +Φ206.4 mm油层套管 95 1.60 1.85 优质 -

[1] 孙坤忠,陶谦,周仕明,等. 丁山区块深层页岩气水平井固井技术[J]. 石油钻探技术,2015,43(3):55-60.SUN Kunzhong, TAO Qian, ZHOU Shiming, et al. Cementing tech-nology for deep shale gas horizontal well in the Dingshan Block[J]. Petroleum Drilling Techniques, 2015, 43(3):55-60. [2] 程常修, 曾时田. 天然气钻井应重点考虑的几个技术问题 [J]. 天然气工业, 2002, 22(2): 50-53.CHENG Changxiu, ZENG Shitian.Several technical problems considered Emphatically for drilling natural Gas wells[J]. Natural Gas Industry, 2002, 22(2): 50-53. [3] 胥永杰. 高陡复杂构造地应力提取方法与井漏机理研究[D]. 成都 : 西南石油学院油气井工程专业, 2005.XU Yongjie. Stress extraction method and mechanism of high and steep complex structures[D]. Chengdu: Southwest Petroleum University, 2005 [4] 朱弘. 元坝地区固井技术难点与对策探讨[J]. 石油地质与工程,2015,29(3):119-121. doi: 10.3969/j.issn.1673-8217.2015.03.035ZHU Hong. Difficulties and countermeasures for cementing in Yuanba area, petroleum geology and engineering[J]. Petroleum Geology and Engineering, 2015, 29(3):119-121. doi: 10.3969/j.issn.1673-8217.2015.03.035 [5] 舒刚,刘健,冯逢,等. 储气库注采井水泥环破坏机理实验研究[J]. 钻井液与完井液,2020,37(4):507-511,520. doi: 10.3969/j.issn.1001-5620.2020.04.017SHU Gang, LIU Jian, FENG Feng, et al. Experimental study on failure mechanism of cement sheath in injection production well of gas storage[J]. Drilling Fluid & Completion Fluid, 2020, 37(4):507-511,520. doi: 10.3969/j.issn.1001-5620.2020.04.017 [6] 高元,杨广国,陆沛青,等. 一种大温差弹韧性水泥浆[J]. 钻井液与完井液,2019,36(1):97-101,108. doi: 10.3969/j.issn.1001-5620.2019.01.019GAO Yuan, YANG Guangguo, LU Peiqing, et al. Study and application of a large temperature difference cement slurry with good elasticity and toughness[J]. Drilling Fluid & Completion Fluid, 2019, 36(1):97-101,108. doi: 10.3969/j.issn.1001-5620.2019.01.019 [7] 吕忠, 陈惠苏. 水泥基材料裂缝自主愈合研究进展[J]. 硅酸盐学报, 2014, 42(2): 156–168.LV Zhong, CHEN Huisu. Autonomous healing of cracks in cementituous materials-a shore, recoveryJ chin ceram soc, 2014, 42(2): 156–168. [8] 姚嘉诚 , 延永东, 徐鹏飞等: 水泥基渗透结晶型防水材料和纳米二氧化硅改性混凝土自修复性能的研究[J]硅酸盐通报, 2020, 39(6): 1773-1777YAO Jiacheng, YAN Yongdong, XU Pengfei, et al. Self -healing properties of concrete modified by cementitious capillary crystalline waterproofing and nanosilica[J]. Bulletin of the Chinesece Amic Society, 2020, 39(6): 1773-1777 [9] 伍贤柱, 万夫磊, 陈作, 等. 四川盆地深层碳酸盐岩钻完井技术实践与展望[ J] . 天然气工业, 2020 40(2): 97-105.WU Xianzhu, WAN Fulei, CHEN Zuo, et al. Drillingand completion technologies for deep carbonate rocks inthe Sichuan Basin: Practices and prospects[J]. Natural Gas Industry, 2020, 40(2): 97-105. [10] 周仕明,李根生,方春飞. 元坝地区 Φ146.1mm 尾管固井技术难点与对策[J]. 石油钻探技术,2010,38(4):41-44.ZHOU Shiming, LI Gensheng, FANG Chunfei. Diffi-culties and countermeasures for Φ146.1 mm liner cement-ing in Yuanba area[J]. Petroleum Drilling Techniques, 2010, 38(4):41-44. -

下载:

下载: