Development of Strength of Set Aluminate Cement in Liquid and Gaseous CO2 Environment

-

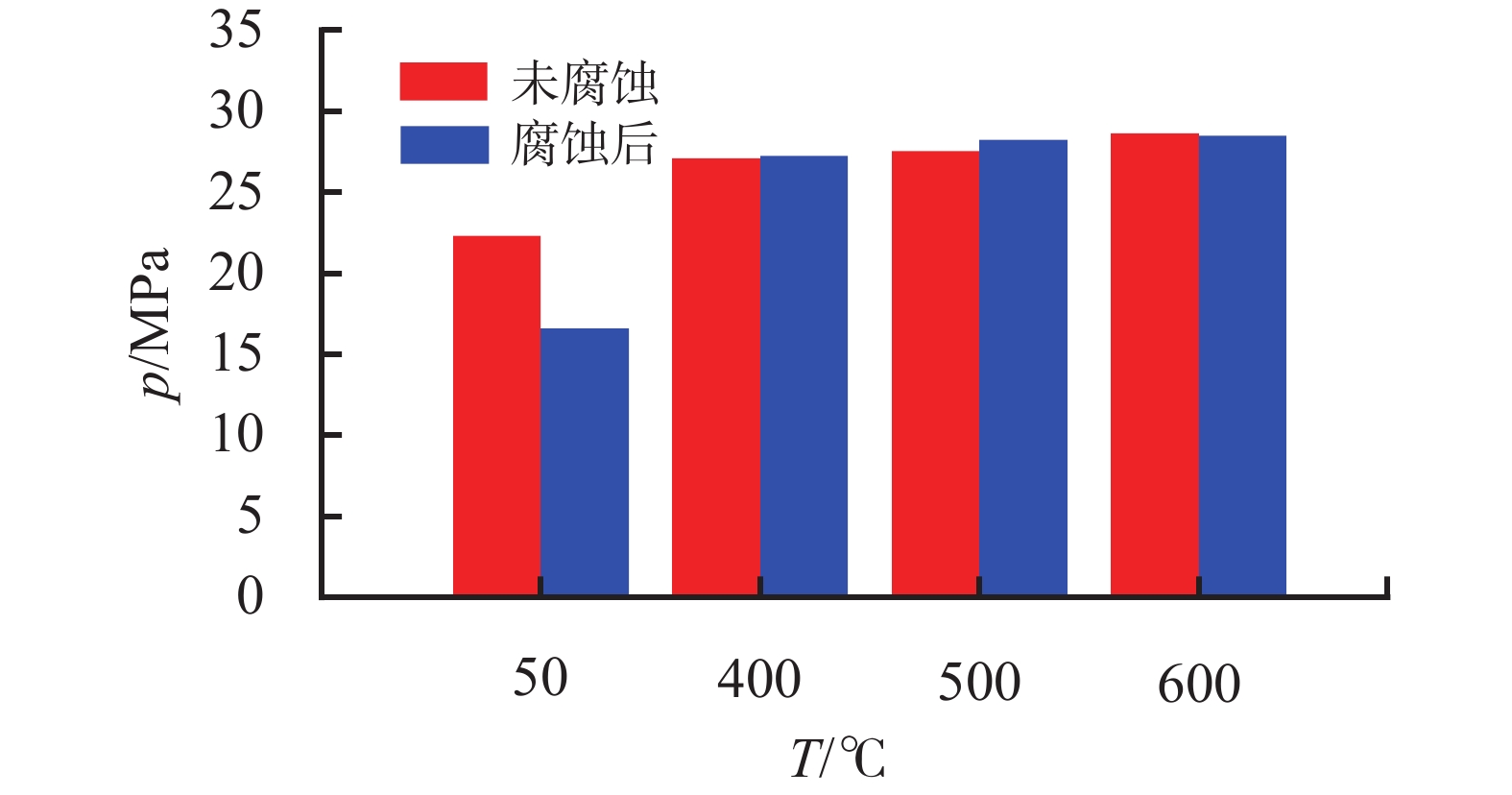

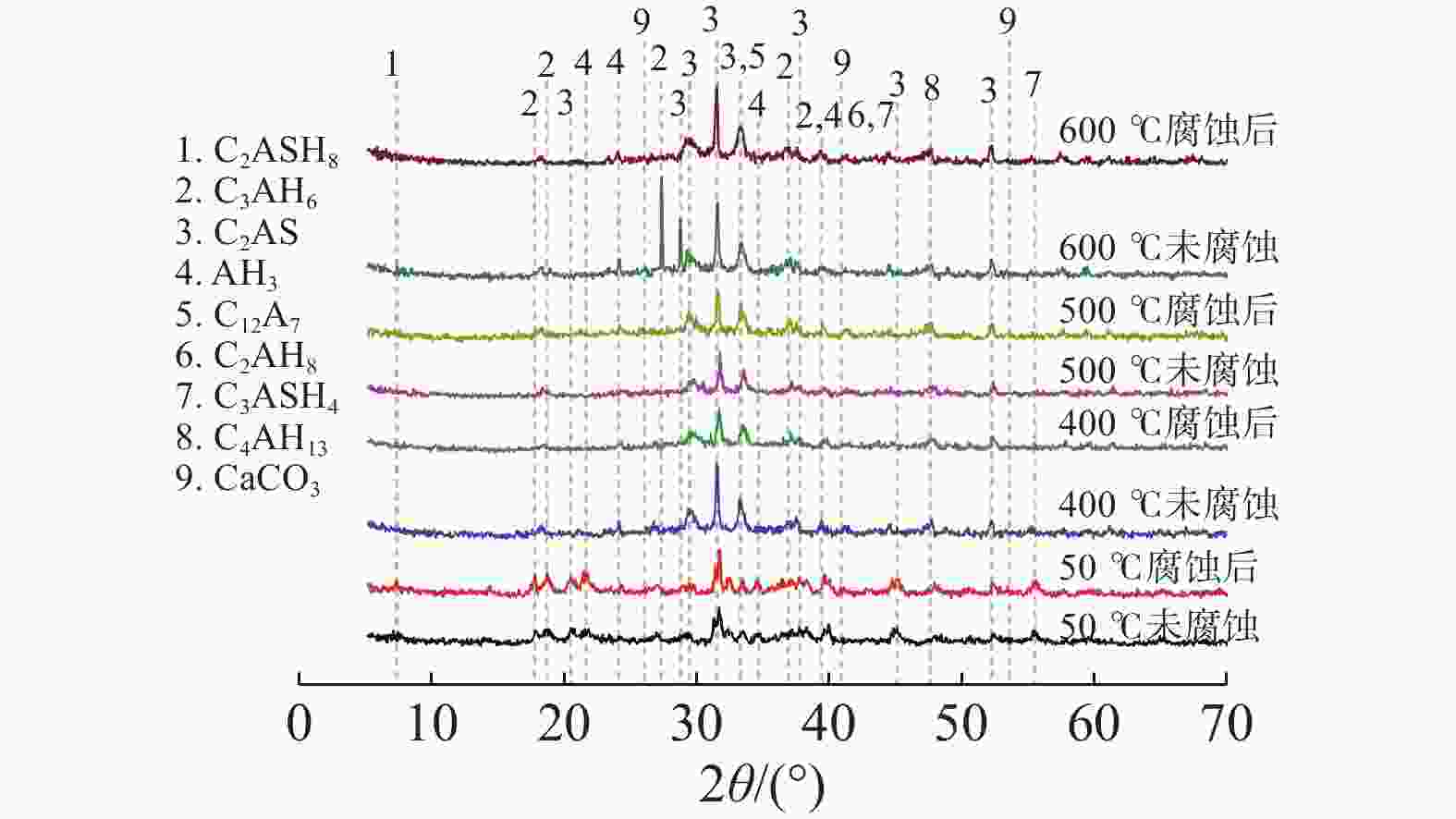

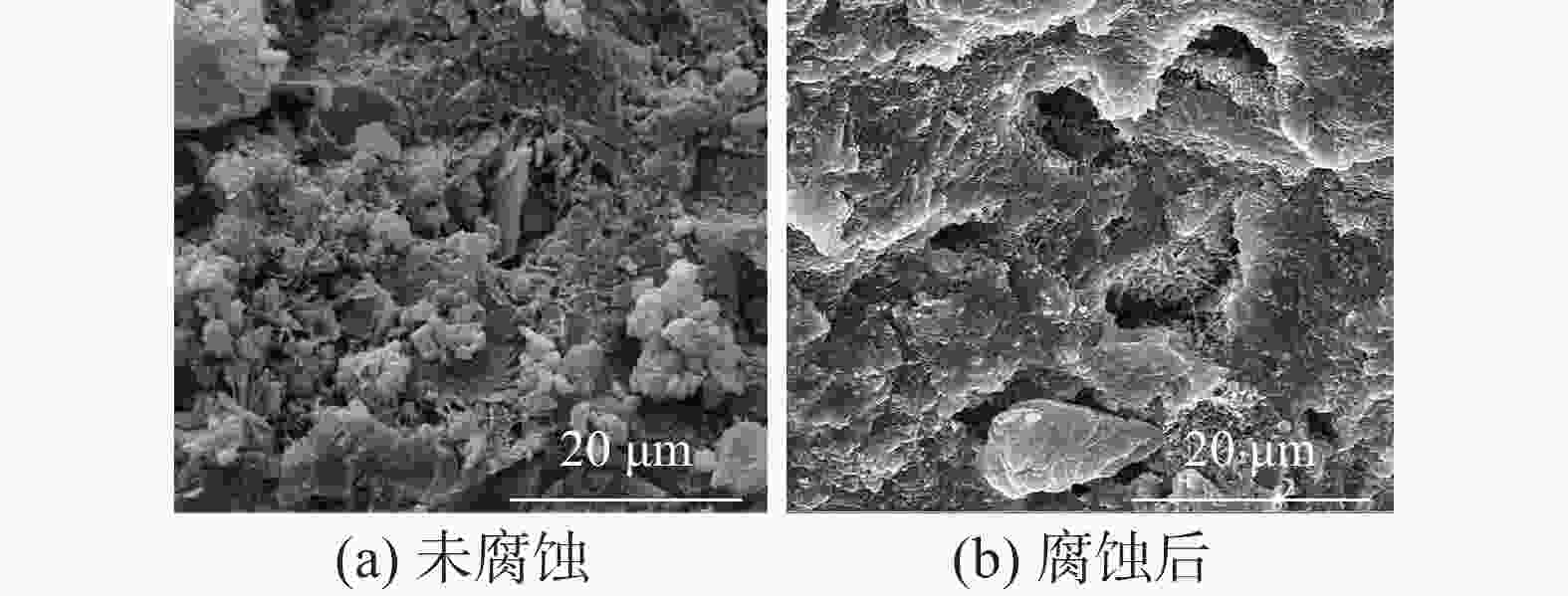

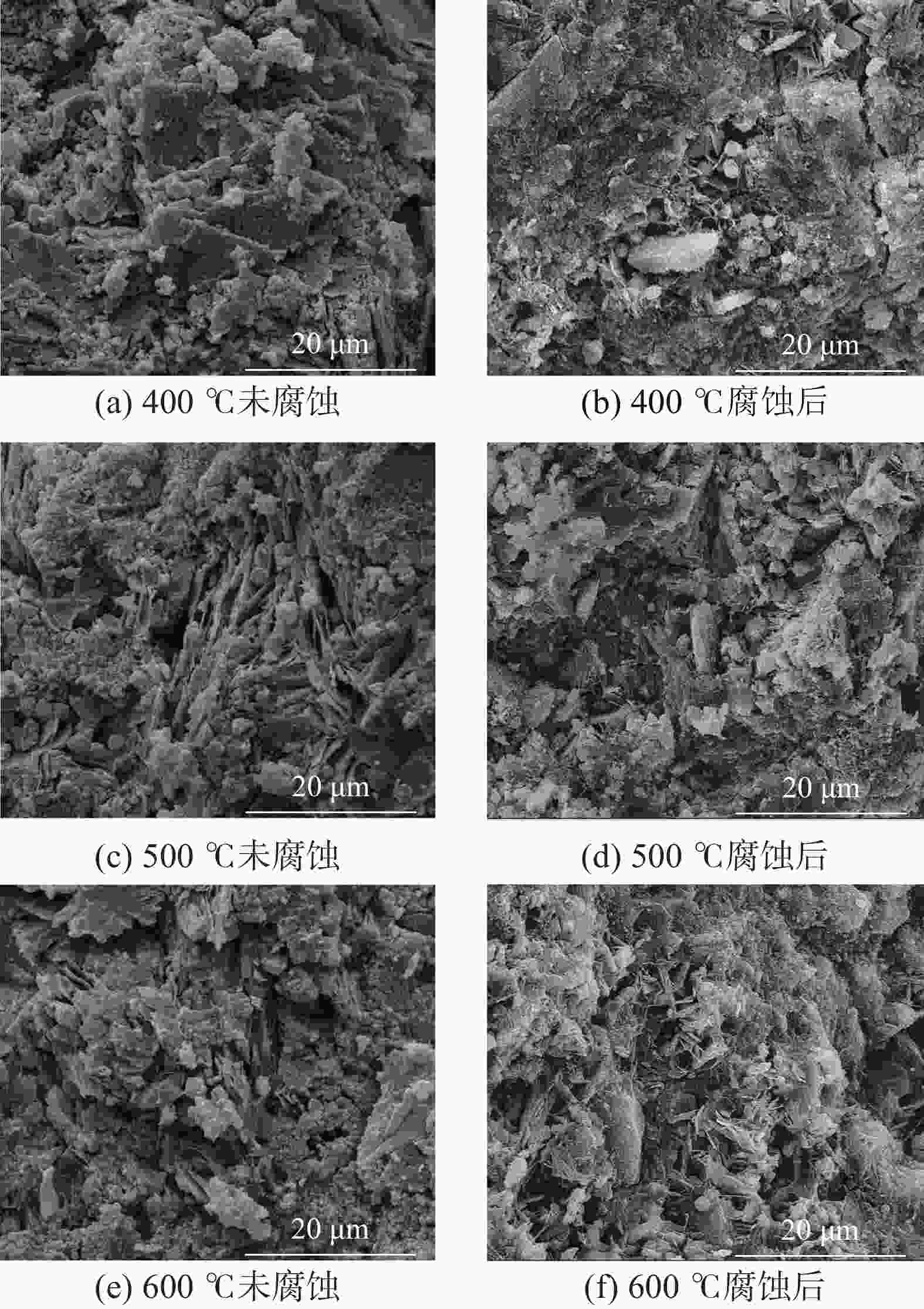

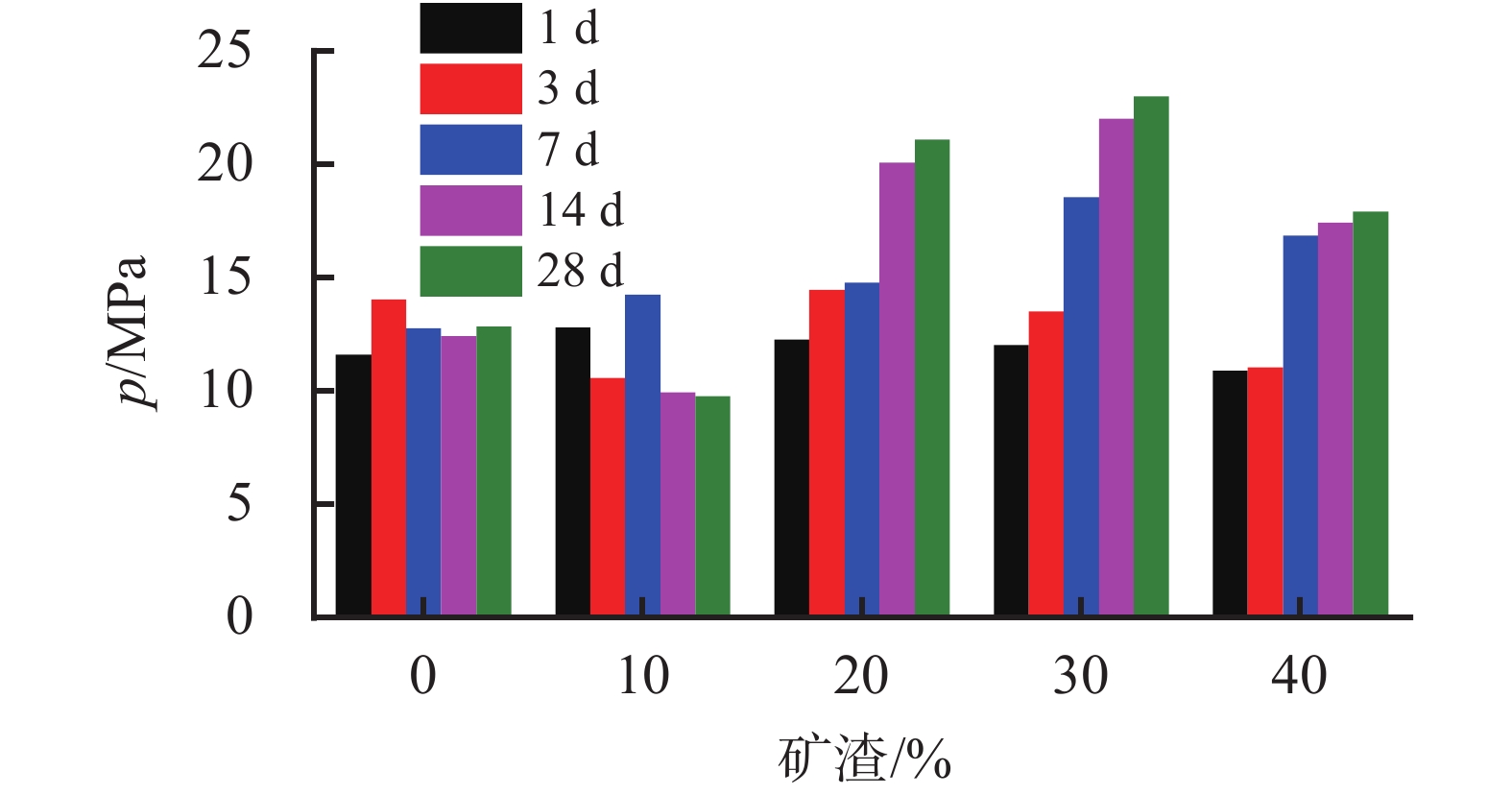

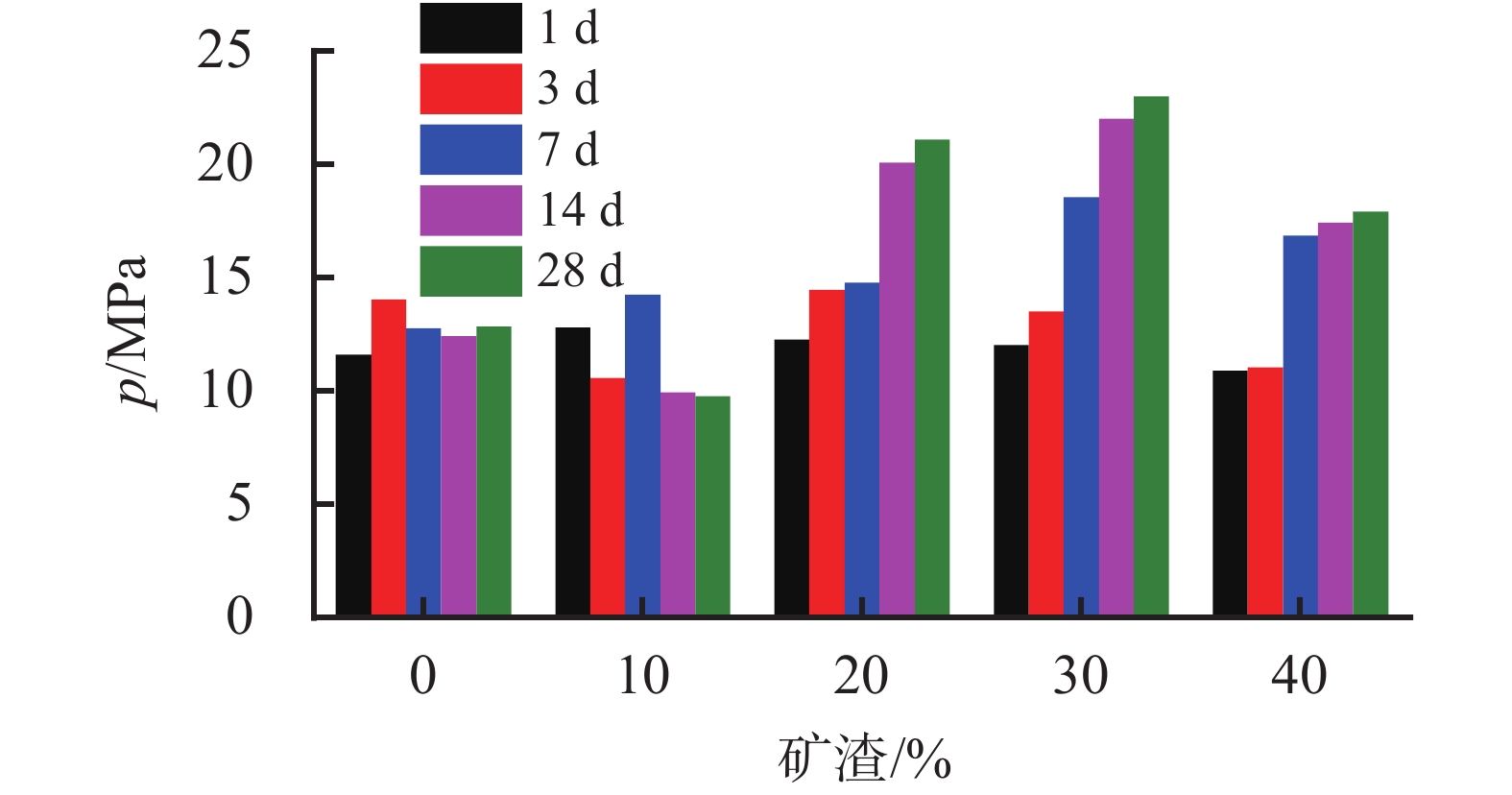

摘要: 火烧油层工况下,固井水泥石服役温度高达500 ℃以上。硅酸盐水泥难以在此温度范围下稳定存在,同时井内伴生大量腐蚀性气体。因此,研究了矿渣改性铝酸盐水泥(CAC)力学性能的可行性,同时模拟火烧油层实际工况,探究了改性铝酸盐水泥石强度发展规律。采用X射线衍射仪、扫描电子显微镜等测试了腐蚀前后改性铝酸盐水泥石的物相组成和微观形貌特征,分析了模拟火烧油层工况下改性铝酸盐水泥石的强度发展规律。结果表明,随着矿渣掺量的增加铝酸盐水泥石抗压强度出现先增加后降低的趋势,且当矿渣掺量为30%左右时其改性效果较好。在50 ℃液相环境下,水泥石被腐蚀产生碳酸钙并产生了孔洞和微裂纹,破坏了水泥石的完整性造成抗压强度降低;而在高温气相环境下,二氧化碳未对水泥石产生腐蚀破坏。在高温下改性CAC水泥石仍可保持较高的抗压强度,并且经过二次高温养护后改性CAC水泥石强度进一步得到发展,具有较好的耐高温性能。该研究为火烧油层工况下CAC水泥石力学性能优化和耐CO2腐蚀提供了一定的理论基础。Abstract: In in-situ combustion operation, the set cement has to experience temperatures up to 500 ℃, under which the silicate cement is unable to retain its stability, and large amount of corrosive gas will be produced in the wellbore. To deal with these problems, the calcium aluminate cement (CAC) modified with slag was chosen to study its mechanical feasibility in cementing high temperature wells. The strength development pattern of the slag CAC was studied in a simulated real in-situ combustion work condition. The material composition and micromorphology of the slag CAC before and after corrosion were tested using X-ray and SEM, and the strength development of the slag CAC under simulated in-situ combustion work condition was investigated. It was found that with the increase in the amount of slag in the CAC, the compressive strength of the set cement first increased and then decreased, a top value was obtained at slag concentration of 30% in the cement. At elevated temperatures, the slag CAC can still retain higher compressive strength, and after secondary curing at high temperature, the strength of the set slag CAC was further developing, indicating that the slag cement has good high temperature resistance. In 50 ℃ liquid environment, corrosion of the set cement produced calcium carbonate and in the set cement there were pores and micro fractures because of the corrosion, all these damaged the integrity of the set cement and caused the strength of the set cement to reduce. In high temperature gaseous environment, CO2 did not cause corrosion damage to the set cement. This study has provided a theoretical base for optimizing the mechanical performance and improving the CO2 corrosion resistance of the set CAC under in-situ combustion work condition.

-

Key words:

- Aluminate cement /

- CO2 /

- Compressive strength /

- Development pattern

-

表 1 铝酸盐水泥CAC的化学组成

% ρ/(g·cm−3) Al2O3 CaO SiO2 Fe2O3 R2O 其他 3.10 50~59 30~45 4~6 1~2 0.2~0.6 1.5 表 2 矿渣的化学组成

% SiO2 CaO MgO Al2O3 TiO2 K2O Na2O Fe2O3 S 36.09 34.27 9.93 9.75 2.92 0.87 0.64 0.42 0.40 表 3 水泥浆体配方

配方 水灰比 水泥/

%分散剂/

%降失水剂/

%缓凝剂/

%消泡剂/

%矿渣/

%1# 0.44 100 0.5 1 0.25 0.02 0 2# 0.44 100 0.5 1 0.25 0.02 10 3# 0.44 100 0.5 1 0.25 0.02 20 4# 0.44 100 0.5 1 0.25 0.02 30 5# 0.44 100 0.5 1 0.25 0.02 40 -

[1] CHENG X, DONG Q, MA Y, et al. Mechanical and thermal properties of aluminate cement paste with blast furnace slag at high temperatures[J]. Construction and Building Materials, 2019, 228:116747. doi: 10.1016/j.conbuildmat.2019.116747 [2] SUYAN K M, DASGUPTA D, GARG S P, et al. Novel cement composition for completion of thermal recovery (ISC) wellbores[C]//SPE/IADC INDIAN Drilling Technology Conference and Exhibition 2006 - Drilling in India: Challenges and Opportunities, 2006. [3] VAFAEI M, ALLAHVERDI A, DONG P, et al. Acid attack on geopolymer cement mortar based on waste-glass powder and calcium aluminate cement at mild concentration[J]. Construction and Building Materials, 2018, 193:363-372. doi: 10.1016/j.conbuildmat.2018.10.203 [4] 王卫仑,李仕群,邢峰,等. 磷铝酸盐水泥浆体抗碳化性能的研究[J]. 建筑材料学报,2012,15(3):334-339. doi: 10.3969/j.issn.1007-9629.2012.03.008WANG Weilun, LI Shiqun, XING Feng, et al. Behaviors of carbonation resistance of phosphoaluminate cement pastes[J]. Journal of Building Materials, 2012, 15(3):334-339. doi: 10.3969/j.issn.1007-9629.2012.03.008 [5] 李仕群, 胡佳山, 刘飚, 等. 掺磷铝酸盐水泥的矿渣硅酸盐水泥水化行为[J]. 建筑材料学报, 2001, 4(1): 22-27.LI Shiqun, HU Jiashan, LIU Biao, et al. Hydration behavior of slag portland cement under the action of novel phosphoaluminate cement[J]. Journal of Building Materials, 2001, 4(1): 22-27. [6] 袁正夏. 矿物掺合料对铝酸盐水泥水化性能的影响研究[D]. 武汉科技大学, 2019.YUAN Zhengxia. Study on the influence of mineral admixtures on the hydration performance of aluminate cement[D]. Wuhan University of Science and Technology, 2019. [7] 马聪,步玉环,赵邵彪,等. 固井用铝酸盐水泥改性试验研究[J]. 建筑材料学报,2015,18(1):100-106. doi: 10.3969/j.issn.1007-9629.2015.01.018MA Cong, BU Yuhuan, ZHAO Shaobiao, et al. Experimental study on modification of aluminate cement for cementing[J]. Journal of Building Materials, 2015, 18(1):100-106. doi: 10.3969/j.issn.1007-9629.2015.01.018 [8] 胡曙光,李悦,丁庆军. 石灰石混合材料改善高铝水泥后期强度的研究[J]. 建筑材料学报,1998(1):51-55.HU Shuguang, LI Yue, DING Qingjun. Research on limestone admixture to improve the late strength of high alumina cement[J]. Journal of Building Materials, 1998(1):51-55. [9] 李早元,伍鹏,程小伟,等. 矿渣对铝酸盐水泥石性能影响的研究[J]. 硅酸盐通报,2014,33(12):3338-3342.LI Zaoyuan, WU Peng, CHENG Xiaowei, et al. Influence study on the performance of aluminate cement with slag[J]. Bulletin of the Chinese Ceramic Society, 2014, 33(12):3338-3342. [10] LI G, ZHANG A, SONG Z, et al. Study on the resistance to seawater corrosion of the cementitious systems containing ordinary Portland cement or/and calcium aluminate cement[J]. Construction and Building Materials, 2017, 157:852-859. doi: 10.1016/j.conbuildmat.2017.09.175 [11] PARK S M, JANG J G, SON H M, et al. Stable conversion of metastable hydrates in calcium aluminate cement by early carbonation curing[J]. Journal of CO2 Utilization, 2017, 21:224-226. doi: 10.1016/j.jcou.2017.07.002 [12] 袁正夏,廖宜顺,沈晴,等. 大掺量矿物掺合料对铝酸盐水泥浆体性能的影响[J]. 混凝土与水泥制品,2019(5):26-30.YUAN Zhengxia, LIAO Yishun, SHEN Qing, et al. The effect of high-volume mineral admixtures on the properties of aluminate cement paste[J]. China Concrete and Cement Products, 2019(5):26-30. [13] MOSTAFA N Y, ZAKI Z I, ABD ELKADER O H. Chemical activation of calcium aluminate cement composites cured at elevated temperature[J]. Cement and Concrete Composites, 2012, 34(10):1187-1193. doi: 10.1016/j.cemconcomp.2012.08.002 [14] MIDGLEY H G. Quantitative determination of phases in high alumina cement clinkers by X-ray diffraction[J]. Cement and Concrete Research, 1976, 1(6):217-224. -

下载:

下载: