Research on Preparation Technology of Temperature-Controlled Expansion Plugging Agent Based on Shape Memory Polymer

-

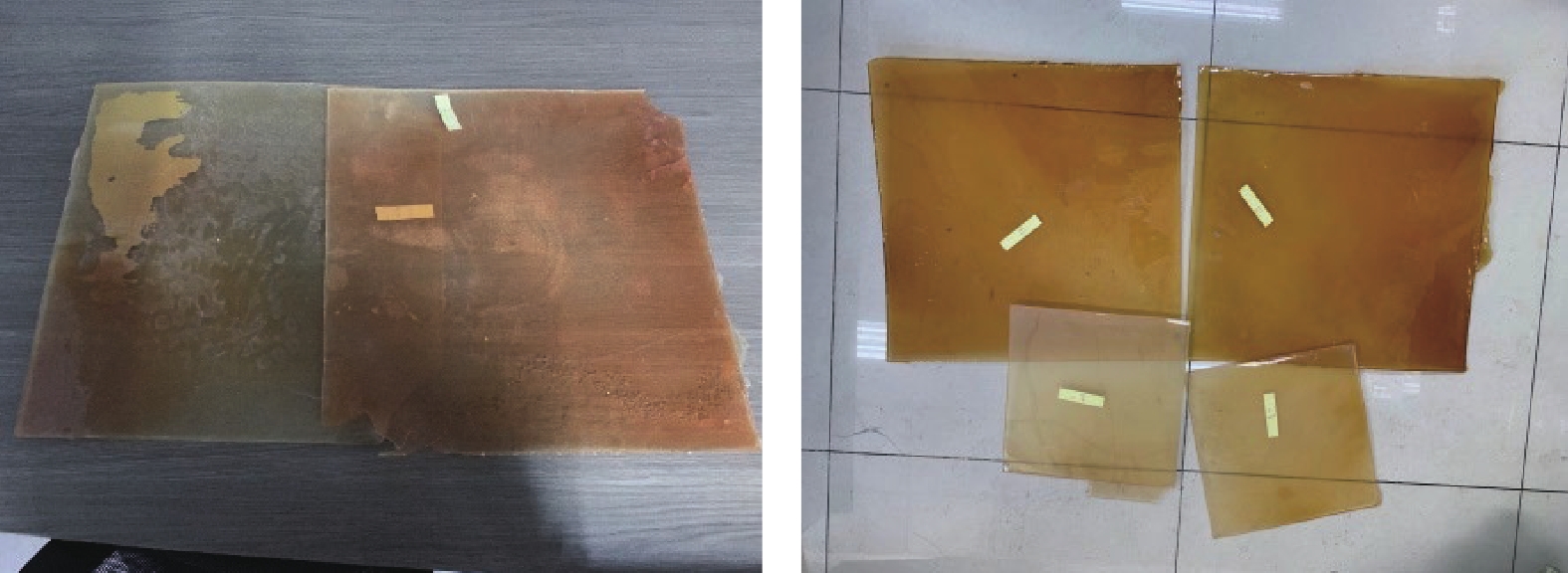

摘要: 利用温度触发型的形状记忆材料制备温控膨胀堵漏剂,以实现堵漏液在裂缝中感应温度下的膨胀架桥。探讨了基于形状记忆聚合物型的温控膨胀堵漏剂制备工艺技术,利用低聚物树脂单体与不同高温交联剂在催化剂作用下,经不同温度和时间加热交联固化,脱模后热压成型以储备形变记忆功能,冷却后造粒制得。温控膨胀堵漏剂SDP,该堵漏玻璃化激活温度可调,粒径可调,抗拉强度大,高温高压膨胀量较大,在150 ℃、20 MPa老化后D90粒度增长率为44.71%~54.17%,能自适应裂缝架桥堵塞,经挤压变形,能够提高堵漏液的滞留能力和承压能力。Abstract: A kind of temperature-controlled expansion plugging agent based on temperature-triggered shape-memory material is prepared to achieve expansion bridging in fractured stratum after the temperature reaches the excitation temperature point. This paper discusses the preparation technology of the temperature-controlled expansion plugging agent. Firstly, an oligomer resin monomer and different high-temperature cross-linking agents are mixed to reaction by a catalyst under different heating temperature and time, then the mixture will be solidified through crosslinking. Secondly the reaction product after taking off the mold is pressed in the specific temperature in order to reserve deformation memory function. Finally the new polymer is crushed and granulated into various particle sizes according to demand at room temperature. The new plugging agent prepared has adjustable glass transition temperature, adjustable particle size, large compressive strength, large expansion at high temperature and high pressure, and the particle size growth rate of D90 after aging at 150 ℃ and 20 MPa is 44.71% ~ 54.17%. It can adapt to crack size to bridging, moreover, block leaking channels deformed by squeezing to improve the retention capacity and pressure endurance capacity of the plugging fluid.

-

表 1 不同固化度下多元胺的用量

固化度/

%PJ1用量/

g多元胺/

g固化度/

%PJ1用量/

g多元胺/

g60 100 13.50 80 100 18.00 70 100 15.75 90 100 20.25 注:固化反应条件:90 ℃下加热4 h 表 2 单一反应温度对产品力学性能的影响

T/

℃抗拉强度/

MPa抗冲击强度/

MPaT/

℃抗拉强度/

MPa抗冲击强度/

MPa60 未固化 未固化 120 21.78 5.7 90 16.39 3.4 150 30.46 4.2 表 3 复合反应温度对产品力学性能的影响

T/℃ 抗拉强度/MPa 抗冲击强度/MPa 110 32.87 15.3 130 40.19 20.5 150 46.27 17.2 注:固化反应条件为:90 ℃加热2 h后,然后在不同温度下加热2 h 表 4 固化时间对产品转化温度和力学性能的影响

t/h 抗拉强度/MPa 抗冲击强度/MPa Tg/℃ 1 35.32 13.4 73.24 2 40.19 15.6 81.29 3 42.63 21.2 83.14 4 44.18 19.3 85.27 注:固化反应条件为:90 ℃加热2 h后,然后在130 ℃加热不同时间 表 5 增韧剂加量对产品转化温度和力学性能影响

增韧剂/

%抗拉强度/

MPa抗冲击强度/

MPaTg/

℃0 40.19 21.2 83.14 5 36.78 24.3 70.43 10 30.43 26.2 63.29 15 21.65 22.7 51.37 表 6 不同尺寸温控膨胀堵漏剂膨胀性能实验

粒径/

目T激活/

℃激活前/mm 激活后/mm △D50增

长率/%△D90增

长率/%D50 D90 D50 D90 10~20 72.86 2.48 3.12 3.41 4.81 37.50 54.17 20~40 88.90 1.42 1.98 1.91 2.98 34.50 50.50 40~80 102.35 0.60 0.85 0.80 1.23 33.33 44.71 -

[1] 王中华. 复杂漏失地层堵漏技术现状及发展方向[J]. 中外能源,2014,19(1):39-48. doi: 10.3969/j.issn.1673-579X.2014.01.007WANG Zhonghua. The status and development direction of plugging technology for complex formation lost circulation[J]. Sino-Global Energy, 2014, 19(1):39-48. doi: 10.3969/j.issn.1673-579X.2014.01.007 [2] EI-HASSAN H, ABDELRAHMAN M, JOHNSON C, et al. Using a combination of cement systems to defeat severe lost-circulation zones in u. A. E. -A case history[C]// Middle East Oil and Gas Show and Conference, 12-15March 2005, Kingdom of Bahrain. [3] 石晓兵,熊继有,吴建,等. 山前构造裂缝地层钻井液漏失规律研究[J]. 天然气技术与经济,2011,5(2):41-43.SHI Xiaobing, XIONG Jiyou, WU Jin, et al. Study on the law of drilling fluid loss in fractured strata of piedmont structure[J]. Natural Gas Technology and Economy, 2011, 5(2):41-43. [4] 王明波,郭亚亮,方明君,等. 裂缝性地层钻井液漏失动力学模拟及规律[J]. 石油学报,2017,38(5):597-606. doi: 10.7623/syxb201705013WANG Mingbo, GUO Yaliang, FANG Mingjun, et al. Dynamics simulation and drilling fluid loss in fractuered formation[J]. Acta Petrolei Silica, 2017, 38(5):597-606. doi: 10.7623/syxb201705013 [5] 王中华. 聚合物凝胶堵漏剂的研究与应用[J]. 精细化工与专用化学品,2011,19(4):16-20.WANG Zhonghua. Research and application progress of the polymer gel plugging agent[J]. Fine and Specialty Chemicals, 2011, 19(4):16-20. [6] KULKARNI S D, IAMISON D E, TEKE K D. Managing suspension characteristics of lost-circulation materials in a drilling fluid[C]//SPE Deepwater Drilling and Completions Conference. Galveston: SPE, 2014. [7] KULKARNI S D. IAMISON D E, SAVARI S, et al. Modelling suspension of lost circulation materials in a drilling fluid[C]//AADE-14-FTFC-24. Houston, Texas: American Association of Drilling Engineers, 2014. [8] 李敏,黎厚斌. 形状记忆材料研究综述[J]. 包装学报,2014,6(4):17-23. doi: 10.3969/j.issn.1674-7100.2014.04.004LI Min, LI Houbin. Review of shape memory materials[J]. Packing-aging Journal, 2014, 6(4):17-23. doi: 10.3969/j.issn.1674-7100.2014.04.004 [9] 刘婷婷,朱光明,魏堃,等. 形状聚合物复合材料的研究进展[J]. 高分子材料科学与工程,2013,29(11):183-190.LIU Tingting, ZHU Guangming, WEI Kun, et al. Advances in shape memory polymer composites[J]. Polymer Materials Science & Engineer, 2013, 29(11):183-190. [10] 王刚,史新妍. 聚合物形状记忆材料的研究进展[J]. 高分子通报,2016(6):23-30.WANG Gang, SHI Xinyan. The research progress of shape memory polymer[J]. Polymer Bulletin, 2016(6):23-30. [11] 王敏生,光新军,孔令军. 形状记忆聚合物在石油工程中的应用前景[J]. 石油钻探技术,2018,46(5):14-20.WANG Minsheng, GUANG Xinjun, KONG Lingjun. The prospects of applying shape memory polymer in petroleum engineering[J]. Petroleum Drilling Technique, 2018, 46(5):14-20. [12] 刘振东, 李公让, 高杨, 等. 一种智能堵漏剂(P). 中国: CN 108239530 A. 2018.07. 03.LIU Zhendong, LI Gongrang, GAO Yang, et al. An intelligent plugging agent[P]. China: CN 108239530 A. 2018.07. 03. [13] 王强. 智能堵漏剂室内研究[D]. 沈阳: 东北石油大学, 2012.WANG Qiang. Indoor research on the intelligent plugging agents[D]. Shenyang: Northeast Petroleum University, 2012. [14] 林雅,刘铁民. 形状记忆高分子材料的研究进展[J]. 硅酸盐通报,2015,34(Sl):78-81.LIN Ya, LIU Tiemin. Research progress of shape memory polymer[J]. Bulletin of The Chinese Ceramic Society, 2015, 34(Sl):78-81. [15] 暴丹,邱正松,赵欣,等. 基于温敏形状记忆特性的智能化堵漏材料研究展望[J]. 钻井液与完井液,2019,36(3):265-272. doi: 10.3969/j.issn.1001-5620.2019.03.001BAO Dan, QIU Zhengsong, ZHAO Xin, et al. Outlook on the research on intelligent LCM with temperature sensitive shape memory property[J]. Drilling Fluid & Completion Fluid, 2019, 36(3):265-272. doi: 10.3969/j.issn.1001-5620.2019.03.001 [16] 暴丹,邱正松,叶链,等. 热致形状记忆“智能”型堵漏剂的制备与特性实验[J]. 石油学报,2020,41(1):106-115. doi: 10.7623/syxb202001010BAO Dan, QIU Zhengsong, YE Lian, et al. Preparation and chatacteristic experiments of intelligent lost circulation materials based on thermaly shape memory polymer[J]. Acta Petrolei Silica, 2020, 41(1):106-115. doi: 10.7623/syxb202001010 -

下载:

下载: