Viscoelasticity of Polymers and Carrying Capacity of Drilling Fluids When Sidetracking through Surface Casing

-

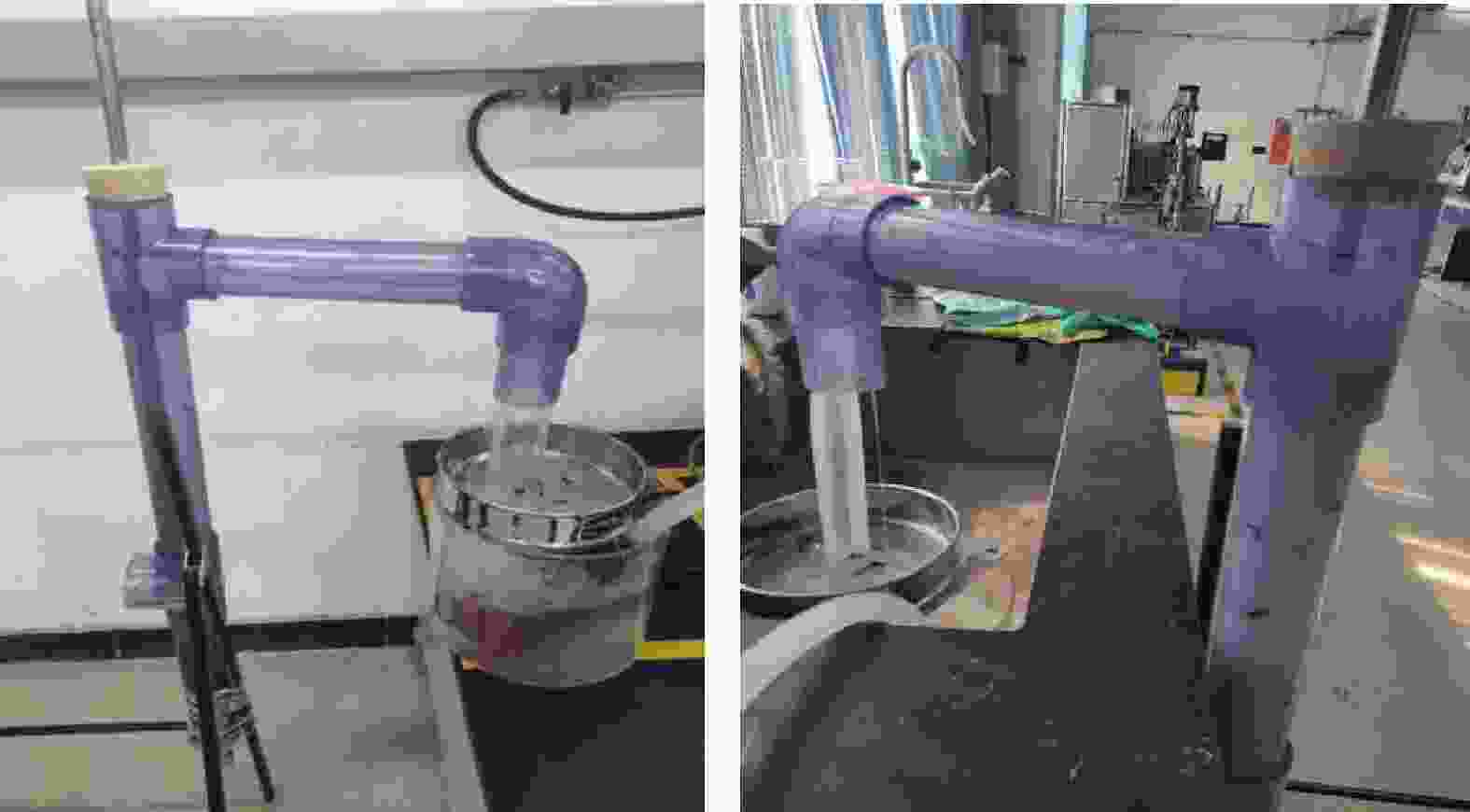

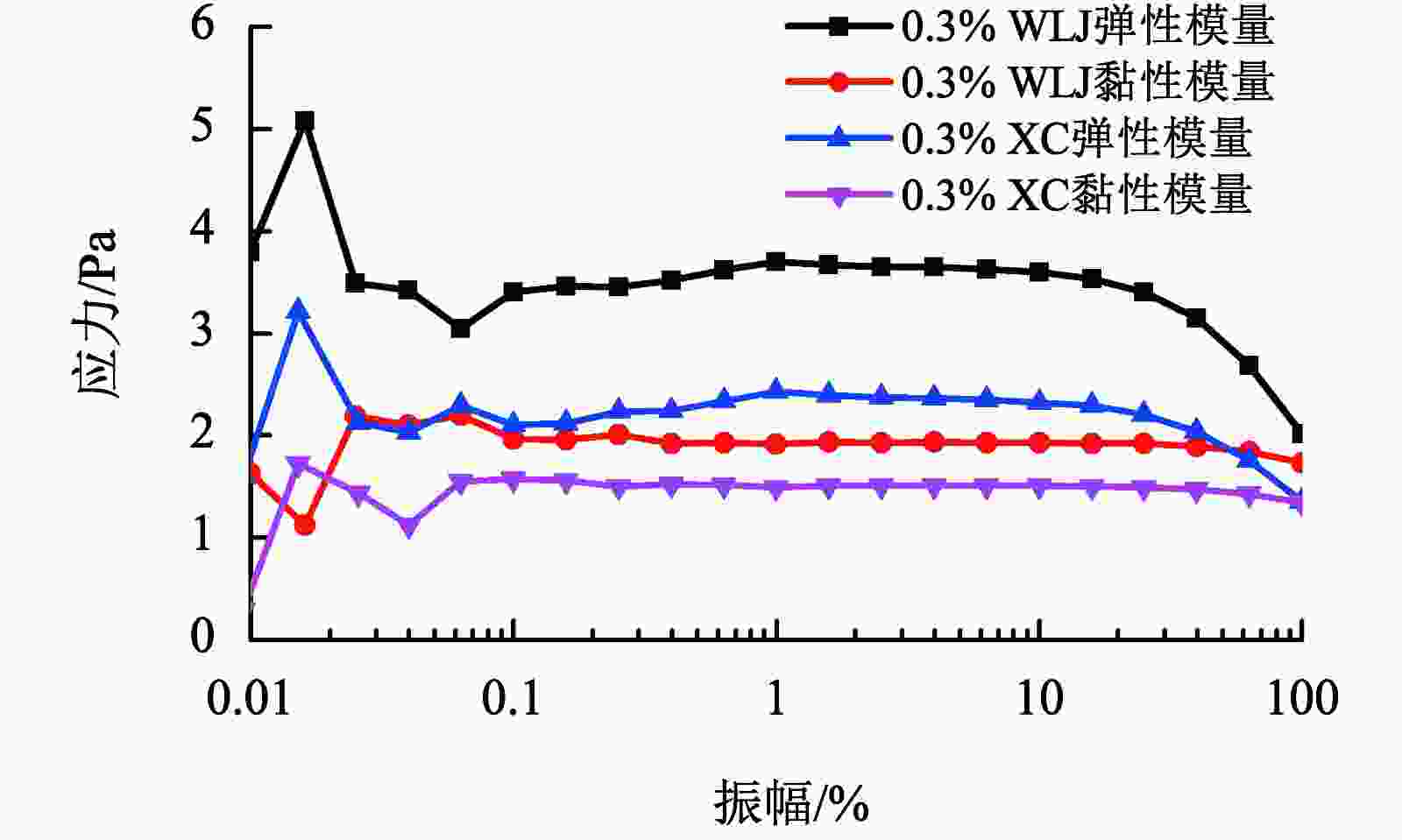

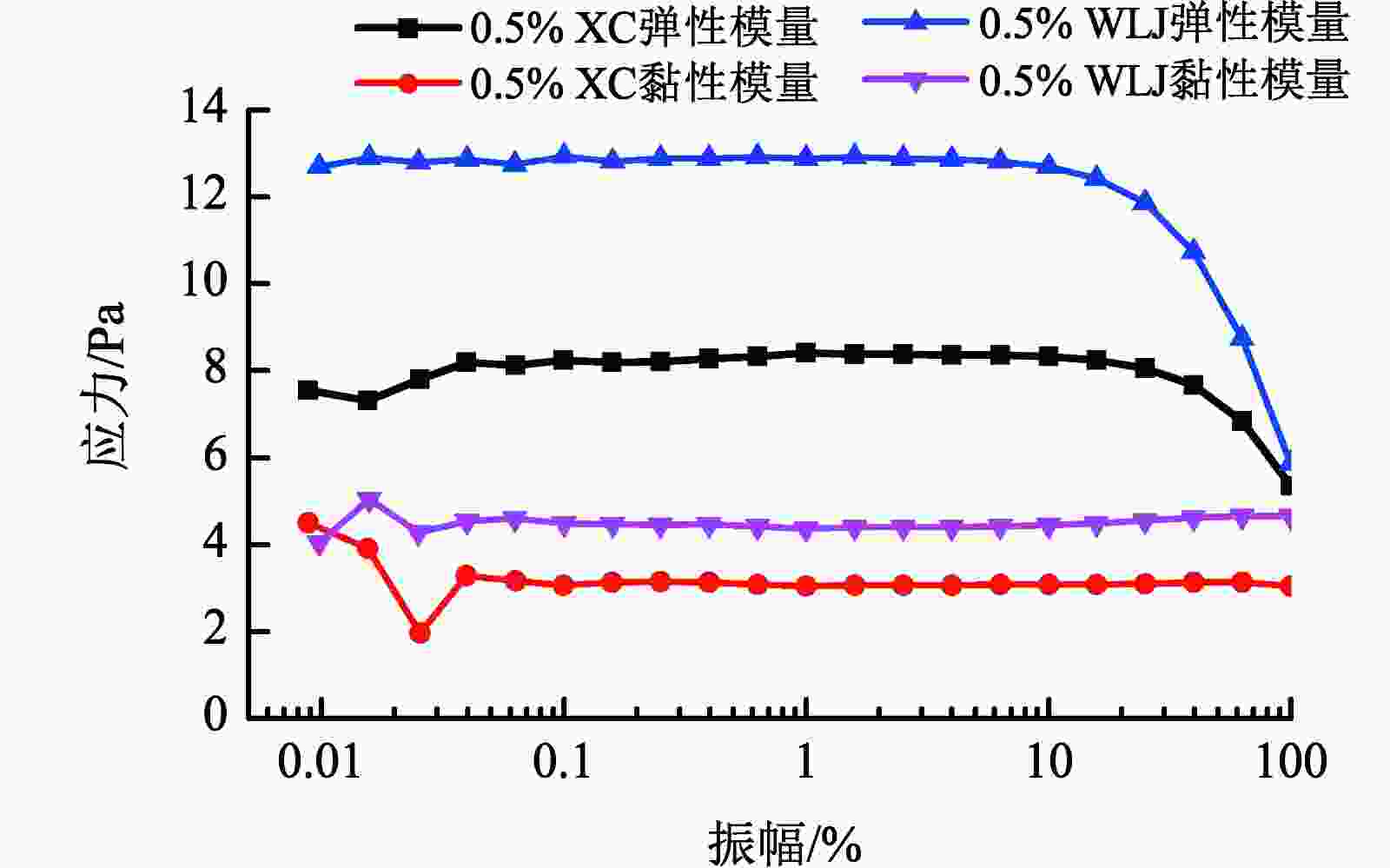

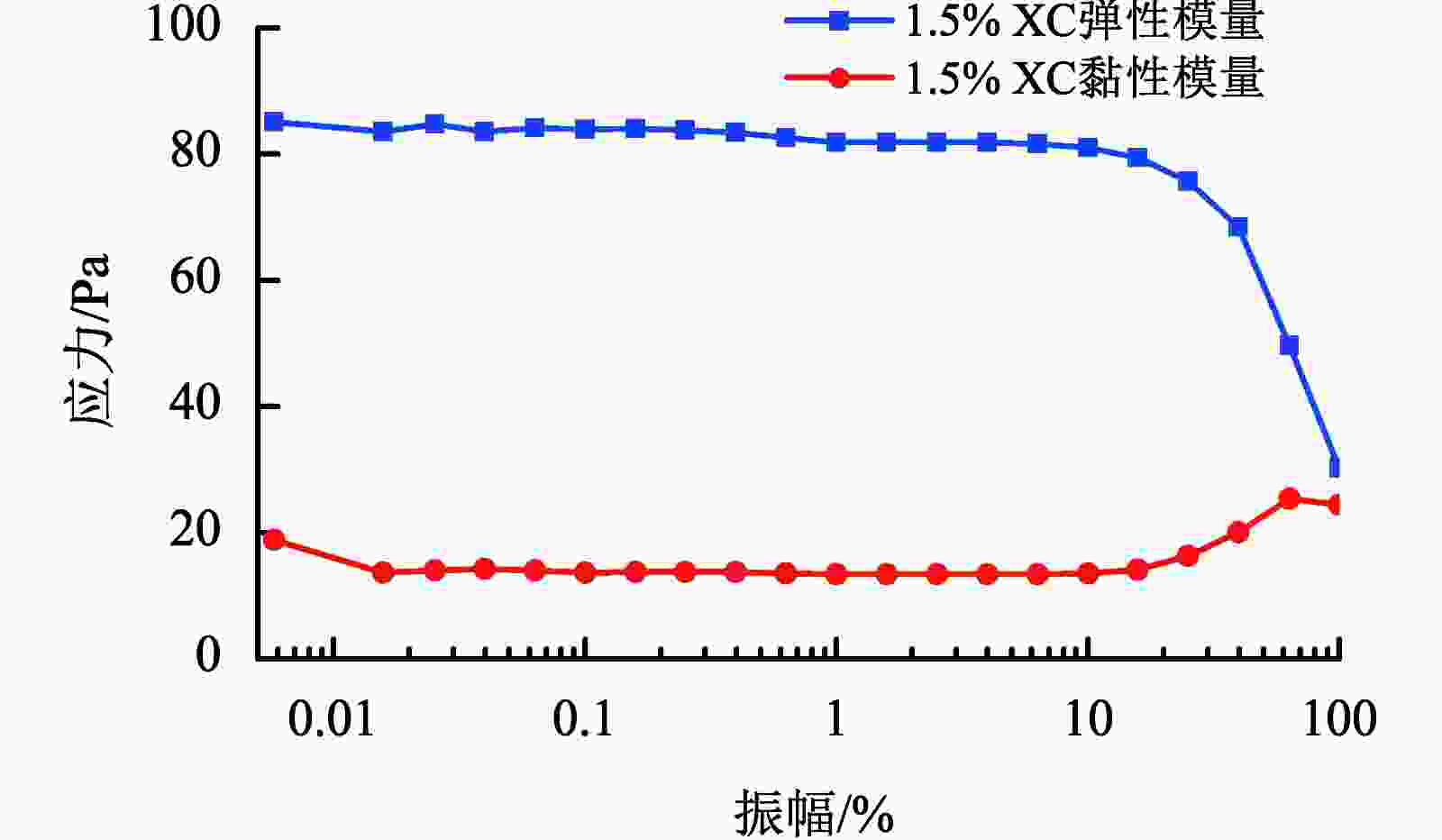

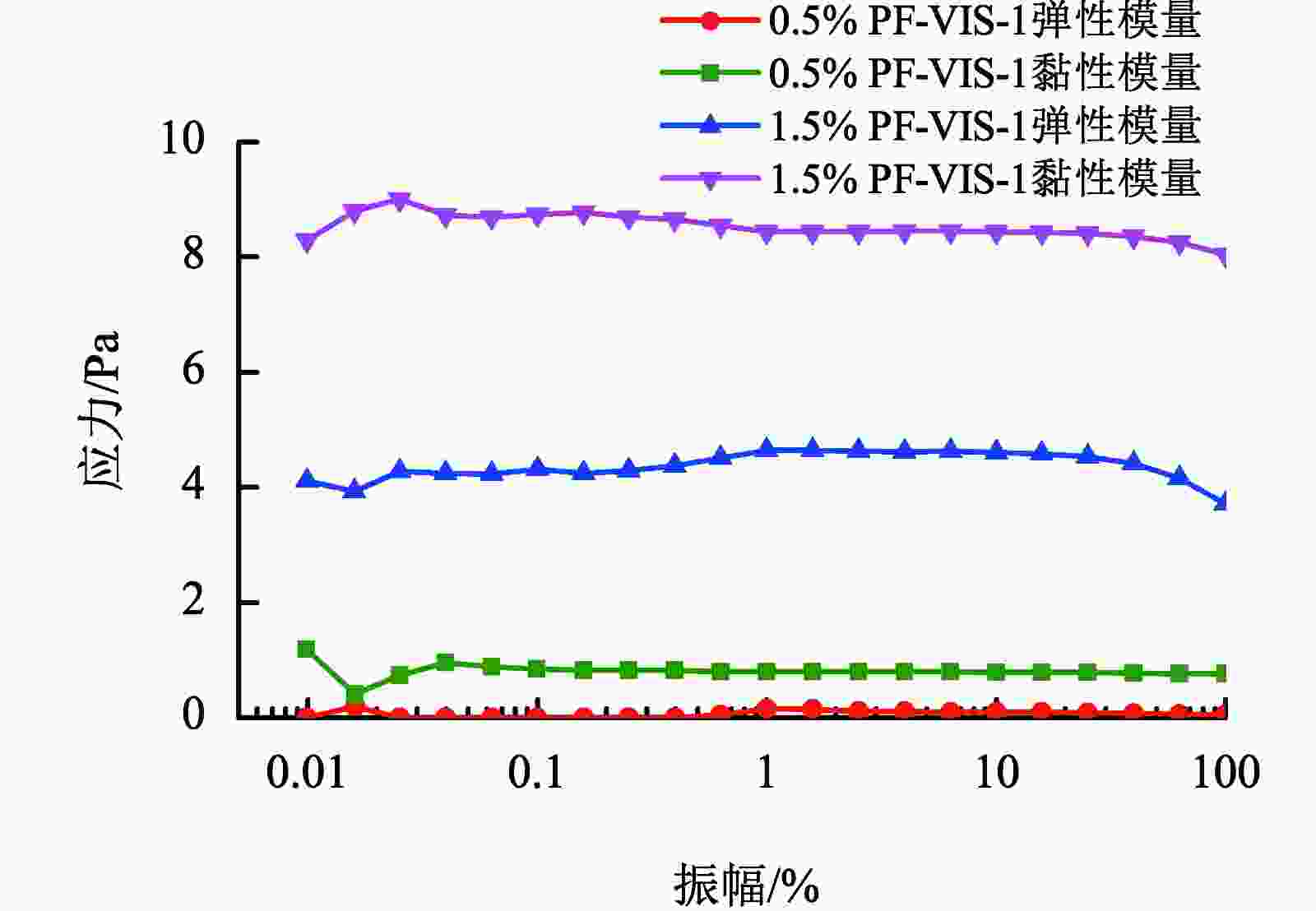

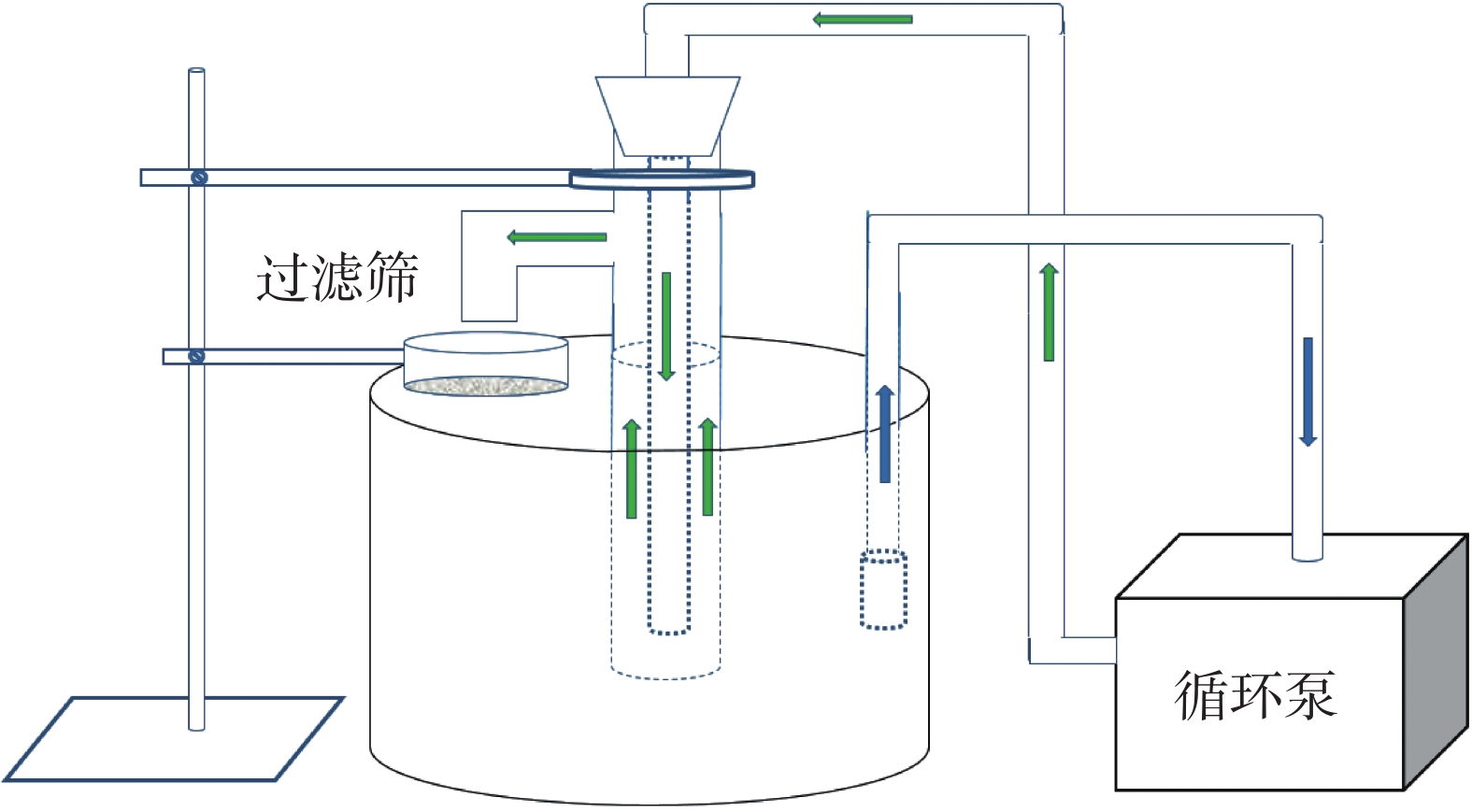

摘要: 在开窗作业过程中产生的铁屑,因为其密度高,在环空中下沉速率较快,同时这些铁屑形状各异,在被钻井液携带上返时容易互相缠绕形成笼状,进一步增加井眼的清洁难度。通过室内动态携带效率模拟评价设备,比较了不同聚合物溶液在不同浓度下对铁屑的携带能力。结果表明,随着聚合物流体弹性应力的增大,使得环空中流体在层流时的法应力也随之增大,钻屑或铁屑在被携带上返时出现黏壁的现象愈发明显,也会在一定程度上降低钻井液的携带效率。因此,聚合物流体的黏弹性在一定范围内对流体的携带能力有正面影响,但超过这个范围就要考虑其产生的副作用对携带能力的削弱。Abstract: Through-casing sidetracking is one of the important technical methods for production and efficiency enhancement. When opening windows on the walls a several layers of casing strings, large quantities of iron fillings are produced, imposing a challenge to the hole cleaning capacity of the drilling fluid used. The iron fillings produced in the windowing operation have high density and are therefore settling fast in the drilling fluid. Meanwhile, the iron fillings have different shapes, when carried up the annular space they tend to intertwine with each other to form cage-shaped structures, further increasing the difficulty of borehole cleaning. Several polymer solutions, each with different concentrations of the same polymer, have been evaluated on a laboratory dynamic carrying efficiency tester for their ability to carry the iron fillings. Through these tests, the rheological property of the polymer solutions affecting the carrying of the iron fillings during window-opening operation was studied from the viscoelasticity aspect of these polymers.

-

Key words:

- Through-casing sidetracking /

- Polymer /

- Carrying efficiency /

- Borehole cleaning /

- Viscoelasticity

-

表 1 不同配方溶液的流变性能

配方 PV/mPa·s YP/Pa φ600/φ300/φ200/φ100/φ6/φ3 3%膨润土浆 4 3.5 15/11/10/8/4/3.5 5%膨润土浆 3 6.0 18/15/13/12/8/7 海水+0.5%XC 8 11.0 38/30/26/21/12/11 3%膨润土浆+0.4%XC 10 12.5 45/35/31/24/14/12 3%膨润土浆+0.4%WLJ 11 14.5 51/40/35/29/17/16 表 2 不同配方溶液铁屑携带效率

配方 上返速度/

m·s−1返出铁屑

质量/g平均质

量/g携带效

率/%3%膨润土浆 0.27 0.64/0.55/0.42/

0.70/0.58/0.570.58 2.89 5%膨润土浆 0.25 1.76/1.77/1.52/

1.71/1.65/1.731.69 8.18 海水+0.5%XC 0.24 6.70/6.33/6.05/

5.17/5.09/5.805.86 28.40 3%膨润土浆+0.4%XC 0.24 5.64/4.89/4.02/

4.18/4.07/4.564.56 22.08 3%膨润土浆+0.4%WLJ 0.25 5.16/5.61/5.99/

7.23/7.67/6.246.32 30.60 表 3 不同浓度增稠剂PF-VIS-1海水溶液性能

PF-VIS-1/% PV/mPa·s YP/Pa φ600/φ300/φ200/φ100/φ6/φ3 0.2 8 3.0 22/14/10/6/1/1 0.5 12 7.5 39/27/21/14/2/1 0.8 19 17.5 73/54/46/32/5/4 表 4 不同浓度增稠剂PF-VIS-1海水溶液携带效率

PF-VIS-1/

%上返速度/

m·s−1返出铁屑

质量/g平均

质量/g携带

效率/%0.2 0.24 6.39/6.18/5.56/

6.37/6.21/6.05/

6.41/5.99/5.74/5.586.05 24.20 0.5 0.22 13.52/11.41/11.20/

12.74/13.42/11.22/

11.48/12.14/12.77/11.9812.20 48.80 0.8 0.22 19.21/19.18/18.23/

19.56/18.38/18.65/

19.78/17.86/20.0118.98 75.93 -

[1] 黄立新, 王昌军, 向兴金, 等. 钻井液流变性能与携砂能力关系的研究[J]. 流变学进展, 1999, 11(5): 511-513.HUANG Lixin, WANG Changjun, XIANG Xingjin, et al. A study of relationship between rheological properties of drilling fluid and detritus carrying[J]. Advances in Rheology, 1999, 11(5): 511-513. [2] 袁敏, 贾忠伟, 袁纯玉, 等. 聚合物溶液黏弹性影响因素研究[J]. 大庆石油地质与开发, 2005, 24(5): 74-76.YUAN Min, JIA Zhongwei, YUAN Chunyu, et al. Research on influential factors to viscoelasticity of polymer solution[J]. Petroleum Geology & Oilfield Development in Daqing, 2005, 24(5): 74-76. [3] 黄善波,李兆敏. 黏弹性流体环空内脉动层流流动的理论解析[J]. 中国石油大学学报:自然科学版,2011,35(5):94-98.HUANG Shanbo, LI Zhaomin. Theoretical analysis of pulsating laminar flow of viscoelastic fluid in annuli[J]. Journal of China University of Petroleum, 2011, 35(5):94-98. [4] 韩洪生,王德民,国丽萍,等. 黏弹性流体法向应力对抽油杆偏磨的影响机理[J]. 石油学报,2004,25(4):92-95. doi: 10.3321/j.issn:0253-2697.2004.04.021HAN Hongsheng, WANG Demin, GUO Liping, et al. Partial abrasion mechanism of sucker rod caused by normal stress of visco-elastic fluid[J]. Journal of Petroleum, 2004, 25(4):92-95. doi: 10.3321/j.issn:0253-2697.2004.04.021 [5] 聂立宏,孙文丽,管玉荣,等. 黏弹性表面活性剂压裂液的化学和流变学原理[J]. 油田化学,2005,22(3):279-282. doi: 10.3969/j.issn.1000-4092.2005.03.025NIE Lihong, SUN Wenli, GUAN Yurong, et al. Chemical and rheological principles of viscoelastic surfactant fracturing fluid[J]. Oilfield Chemistry, 2005, 22(3):279-282. doi: 10.3969/j.issn.1000-4092.2005.03.025 [6] 段玉秀,雷晓岚,吴金桥,等. 黏弹性表面活性剂清洁压裂液破胶剂筛选实验[J]. 石油地质与工程,2013,27(5):136-138. doi: 10.3969/j.issn.1673-8217.2013.05.039DUAN Yuxiu, LEI Xiaolan, WU Jinqiao, et al. Selection of gel breaker for viscoelastic surfactant clean fracturing fluid[J]. Petroleum Geology and Engineering, 2013, 27(5):136-138. doi: 10.3969/j.issn.1673-8217.2013.05.039 [7] 杨浩珑,向祖平,李龙,等. CO2泡沫双子表面活性剂清洁压裂液研究与试验[J]. 石油钻探技术,2018,46(2):92-97.YANG Haolong, XIANG Zuping, LI Long, et al. Research and experiments of a clean fracturing fluid system with CO2 foam gemini surfactant[J]. Petroleum Drilling Techniques, 2018, 46(2):92-97. [8] 潘一, 王瞳煜, 杨双春, 等. 黏弹性表面活性剂压裂液的研究与应用进展[J]. 化工进展, 2018, 37(4): 1566-1574.PAN Yi,WANG Tongyu,YANG Shuangchun, et al.Progress in research and application of viscoelastic surfactant fracturing fluid[J].Chemical Industry and Engineering Progress,2018,37(4):1566-1574. [9] 李钦, 陈馥. 黏弹性表面活性剂及其在油田中的应用[J]. 日用化学工业, 2004, 34(3): 173-175.LI Qin, CHEN Fu. Visco-elastic surfactant and its applications in oil field operation[J].China Surfactant Detergent & Cosmetics, 2004, 34(3): 173-175. [10] 何竹梅,杨小敏,王建,等. 江苏油田开窗侧钻井KCl聚合物钻井液应用研究[J]. 复杂油气藏,2021,14(4):97-101.HE Zhumei,YANG Xiaomin,WANG Jian,et al. Application of KCl polymer drilling fluid in sidetrack drilling in Jiangsu oilfield[J]. Complex Hydrocarbon Reservoirs, 2021, 14(4):97-101. [11] 李东进, 孙永刚, 高玉强, 等. 吉林油田星A6-6开窗侧钻井钻井完井液技术[J]. 钻井液与完井液, 2002, 19(6): 133-134.LI Dongjin, SUN Yonggang, GAO Yuqiang, et al.Drilling in fluid technology for the sidetracking well Xing A6-6 in Jilin oilfield[J].Drilling Fluid & Completion Fluid, 2002, 19(6): 133-134. -

下载:

下载: