Study on Mechanisms of Carbon Nanotube as a Nanosized Plugging Agent in Water Based Drilling Fluids

-

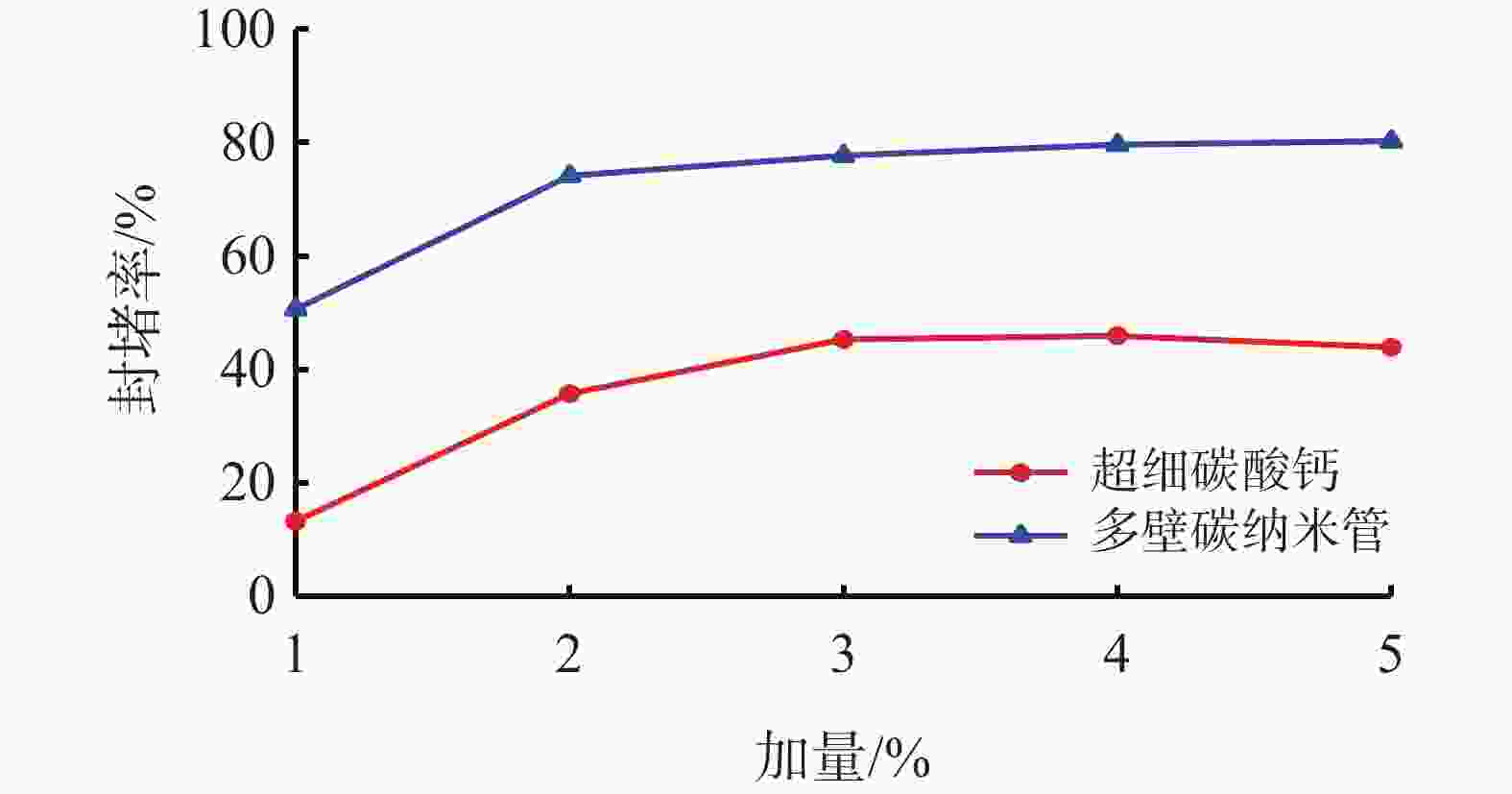

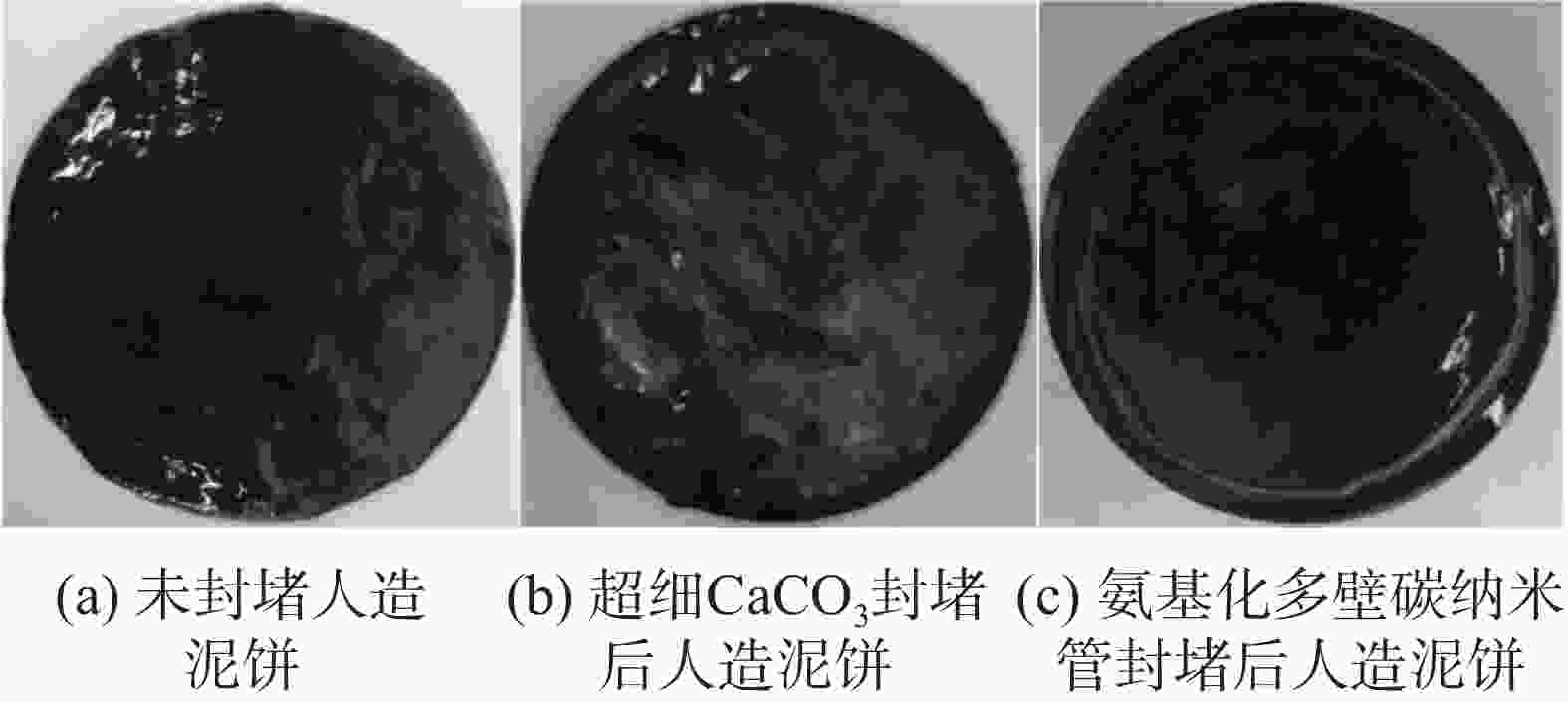

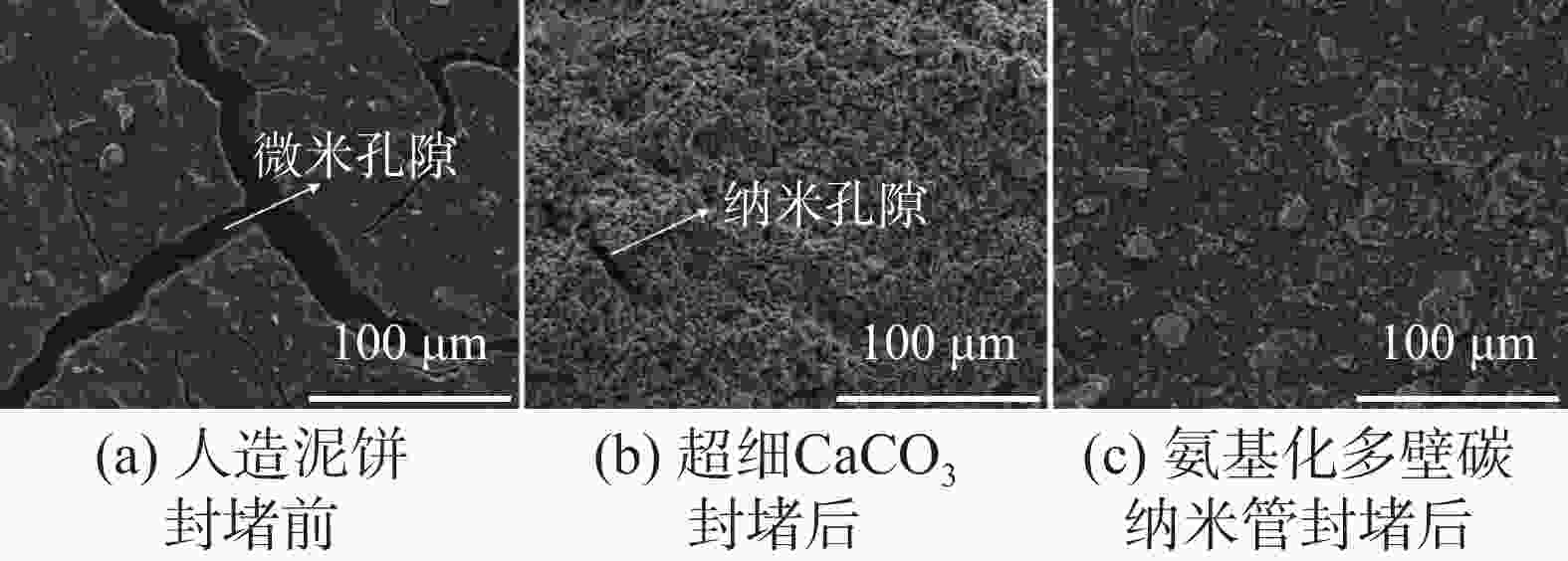

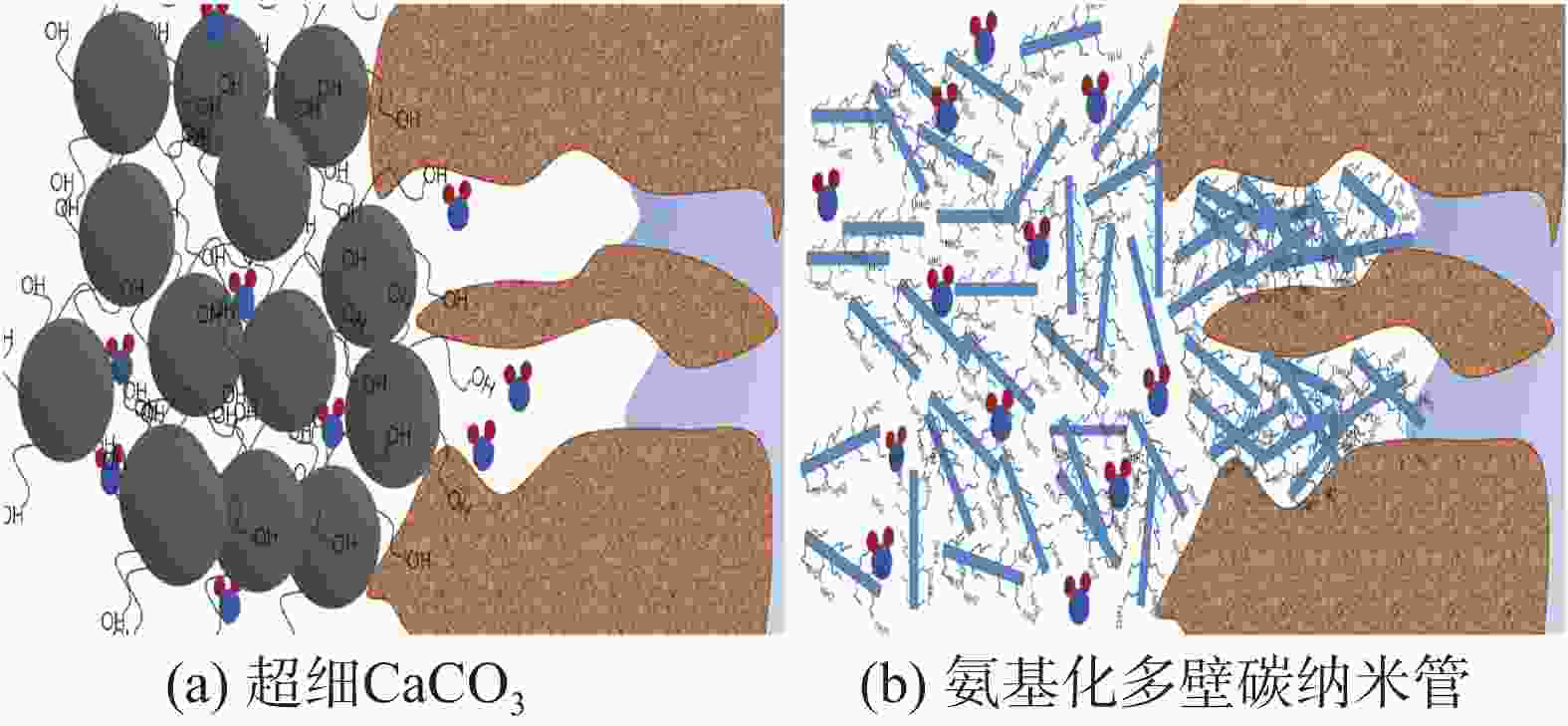

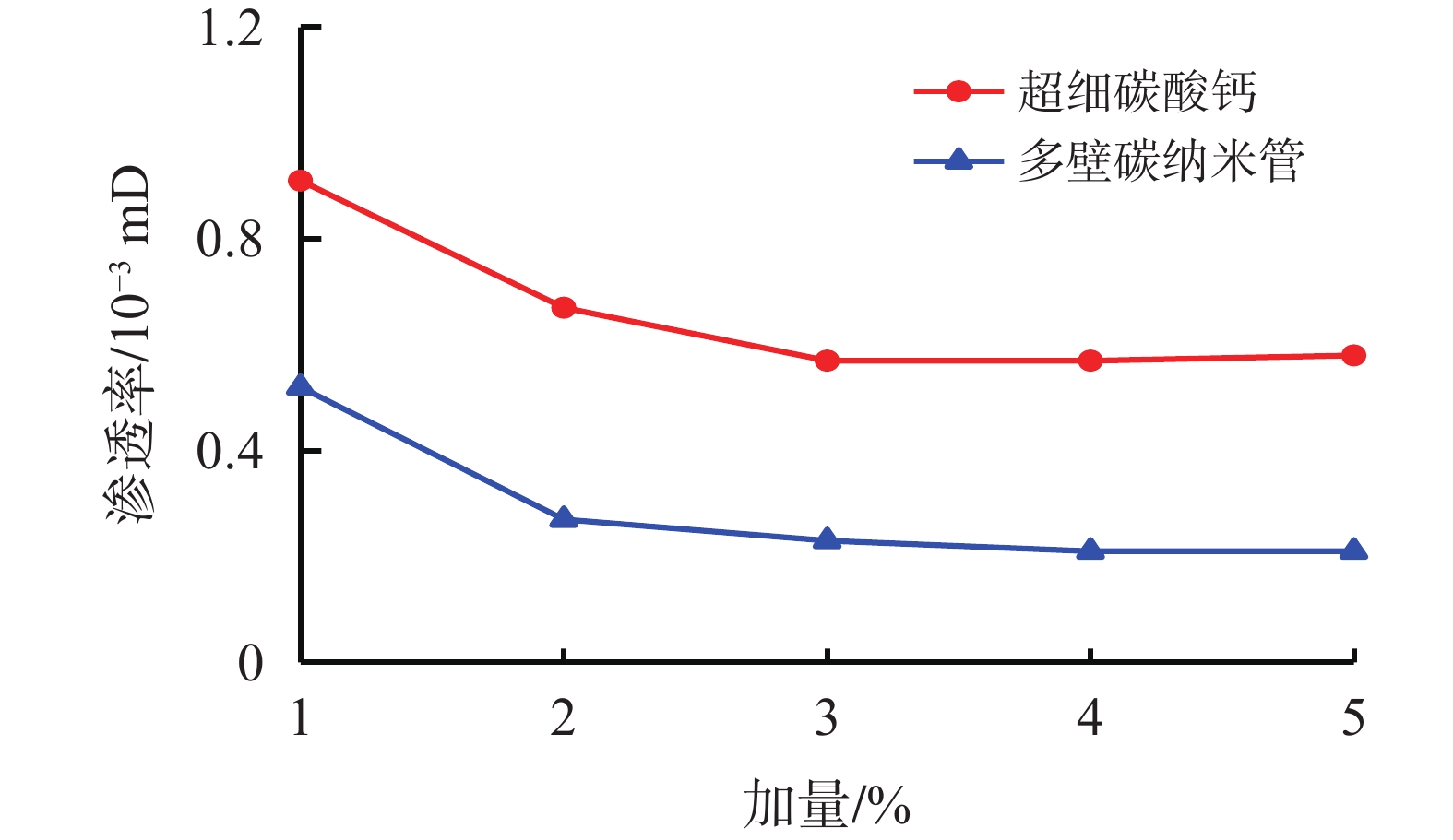

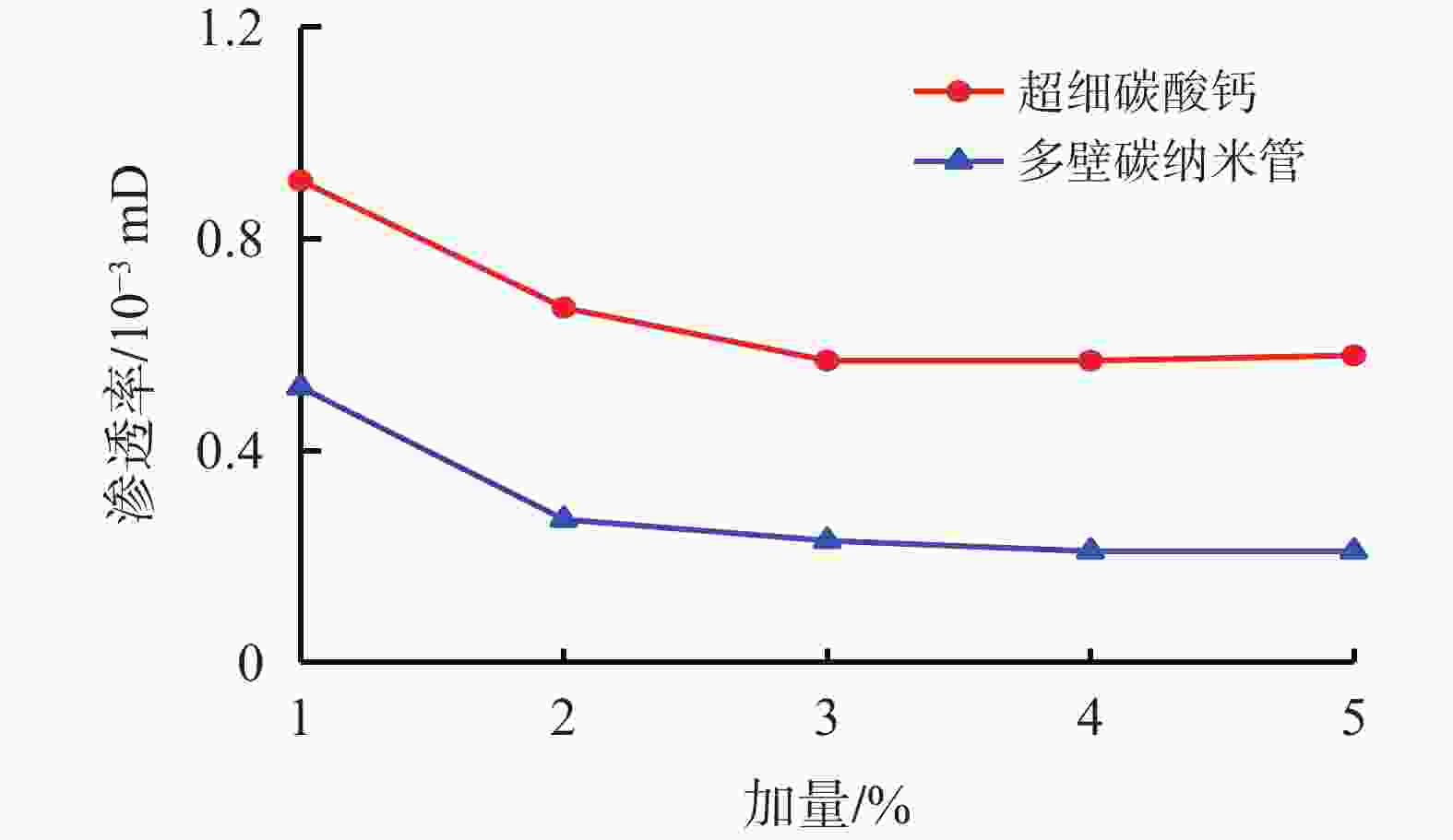

摘要: 针对微米级封堵材料无法对纳米孔缝进行有效封堵的问题,以微米级超细CaCO3作为对比,研究了氨基化多壁碳纳米管作为纳米封堵材料对钻井液流变参数的影响,通过人造泥饼滤失实验和人造岩心渗透实验研究了其封堵机理。研究结果表明,超细CaCO3使得钻井液的流变性能变差,而氨基化多壁碳纳米管对钻井液流变性能几乎没有影响;氨基化多壁碳纳米管对人造泥饼或人造岩心的封堵率随着其加量的增加而升高,当其加量为3%时封堵率可达77.70%和79.41%,而相同加量的超细CaCO3对人造泥饼的封堵率仅为45.28%和为61.76%。这充分说明纳米尺寸的封堵剂对纳米孔缝的封堵效果远优于微米封堵材料,碳酸钙只能在孔缝端面进行堆积,而氨基化多壁碳纳米管能够进入纳米孔缝形成架桥封堵,表面的氨基紧紧地吸附于孔缝的壁面上,阻止滤液的渗入。Abstract: Micron-scale plugging agents are unable to effectively plug the nanosized fractures. To overcome this problem, aminated multi-walled carbon nanotubes were selected as the nanosized plugging agent. The effects of the aminated multi-walled carbon nanotubes on the rheology of drilling fluids were studied using the micron-scale ultrafine CaCO3 as a comparison. The plugging mechanism of the aminated multi-walled carbon nanotubes was studied through filtration test on artificial mud cakes and osmosis experiment on artificial cores. The study results showed that the carbon nanotube has almost no effect on the rheological parameters of the drilling fluid, and addition of ultra-fine CaCO3 into the drilling fluid made its rheology deteriorated. Plugging of the artificial mud cakes with the aminated multi-walled carbon nanotube becomes improved with the increase in the amount of the nanotubes added. When the concentration of the aminated multi-walled carbon nanotube was 3%, 77.70% of the mud cakes can be plugged, while the addition of the same concentration of ultra-fine CaCO3 only plugged 45.28% of the artificial mud cakes. Experiment on artificial cores showed that at a concentration of 3% aminated multi-walled carbon nanotube, the core was plugged by 79.41%, while at a concentration of 3% ultra-fine CaCO3, the core was plugged only by 61.76%. These experimental results fully demonstrate that the nanosized plugging agents are much better than micron-scale plugging agents in terms of plugging; the calcium carbonate can only accumulate on the face of a fractured surface, while the aminated multi-walled carbon nanotube can penetrate into the nanosized fractures and form bridges therein. By tightly adsorbing on the surfaces inside the fractures with the amino groups, the aminated multi-walled carbon nanotube prevents the filtrate from going into the fractures.

-

表 1 超细CaCO3、氨基化多壁碳纳米管对老化前钻井液性能的影响

封堵剂 AV/

mPa·sPV/

mPa·sYP/

PaYP/PV/

Pa/mPa·sFL/

mLFLHTHP/

mL1%多壁碳纳米管 31 20 11 0.53 2.8 5.0 1%超细碳酸钙 34 22 12 0.52 4.2 7.5 2%多壁碳纳米管 35 21 14 0.67 2.3 3.2 2%超细碳酸钙 32 21 11 0.50 3.8 7.2 3%多壁碳纳米管 34 18 16 0.89 1.6 2.5 3%超细碳酸钙 37 23 14 0.61 3.4 7.0 4%多壁碳纳米管 37 21 16 0.74 1.2 2.3 4%超细碳酸钙 32 18 13 0.75 3.2 6.8 5%多壁碳纳米管 37 20 17 0.85 0.7 1.9 5%超细碳酸钙 38 24 14 0.56 3.0 6.5 表 2 加有超细CaCO3或氨基化多壁碳纳米管的钻井液在150 ℃老化16 h后的性能

封堵剂 AV/

mPa·sPV/

mPa·sYP/

PaYP/PV/

Pa/mPa·sFL/

mLFLHTHP/

mL1%多壁碳纳米管 30 20 10 0.50 2.9 5.2 1%超细碳酸钙 31 19 12 0.63 5.2 8.2 2%多壁碳纳米管 36 21 15 0.69 2.5 3.4 2%超细碳酸钙 22 17 5 0.26 4.6 8.0 3%多壁碳纳米管 37 22 15 0.66 1.8 2.7 3%超细碳酸钙 18 11 7 0.64 4.3 7.8 4%多壁碳纳米管 38 22 16 0.70 1.4 2.5 4%超细碳酸钙 19 16 3 0.19 4.2 7.6 5%多壁碳纳米管 39 26 13 0.50 0.8 2.2 5%超细碳酸钙 19 16 3 0.16 3.8 7.0 表 3 超细CaCO3、氨基化多壁碳纳米管 在150 ℃下人造岩心封堵效果评价

名称 封堵后渗透率/

10−3 mD封堵率/ 钻井液滤液 0.68 3%超细CaCO3+

钻井液滤液0.26 61.76 3%氨基化多壁碳纳米管+

钻井液滤液0.14 79.41 -

[1] 龙大清,樊相生,王昆,等. 应用于中国页岩气水平井的高性能水基钻井液[J]. 钻井液与完井液,2016,33(01):17-21.LONG Daqing, FAN Xiangsheng, WANG Kun, et al. High-performance water-based drilling fluids used in horizontal shale gas wells in China[J]. Drilling Fluid & Completion Fluid, 2016, 33(01):17-21. [2] 王治法,蒋官澄,林永学,等. 美国页岩气水平井水基钻井液研究与应用进展[J]. 科技导报,2016,34(23):43-50.WANG Zhifa, JIANG Guancheng, LIN Yongxue, et al. Research and application progress of water-based drilling fluids for horizontal shale gas wells in the United States[J]. Science and Technology Review, 2016, 34(23):43-50. [3] 孙金声,刘敬平,闫丽丽,等. 国内外页岩气井水基钻井液技术现状及中国发展方向[J]. 钻井液与完井液,2016,33(05):1-8.SUN Jinsheng, LIU Jingping, YAN Lili, et al. Current status of water-based drilling fluid technology for shale gas wells at home and abroad and development direction in China[J]. Drilling Fluid & Completion Fluid, 2016, 33(05):1-8. [4] 王森,陈乔,刘洪,等. 页岩地层水基钻井液研究进展[J]. 科学技术与工程,2013,13(16):4597-4602. doi: 10.3969/j.issn.1671-1815.2013.16.023WANG Sen, CHEN Qiao, LIU Hong, et al. Research progress of water-based drilling fluids in shale formations[J]. Science Technology and Engineering, 2013, 13(16):4597-4602. doi: 10.3969/j.issn.1671-1815.2013.16.023 [5] 张易航,潘宏霖,张易成. 纳米材料在油田生产开发中的研究进展[J]. 化学工程师,2017,31(10):48-50.ZHANG Yihang, PAN Honglin, ZHANG Yicheng. Research progress of nanomaterials in oilfield production and development[J]. Chemical Engineers, 2017, 31(10):48-50. [6] YOUNGSOO JUNG, ON, JUNGKUN Lee, et al. Rheological behavior of clay nanoparticle hybrid-added bentonite suspensions: specific role of hybrid additives on the gelation of clay-based fluids[J]. ACS Applied Materials and Interfaces, 2011, 3(9):3515-3522. doi: 10.1021/am200742b [7] HUANG Bin, ZHANG Weise, ZHOU Quan, et al. Preparation and experimental study of a low-initial-viscosity gel plugging agent[J]. ACS Omega, 2020, 5(25):15715-15727. doi: 10.1021/acsomega.0c02242 [8] 朱华银,唐立根,庞宇来,等. 裂缝—孔隙型储层在交变压力条件下的渗透率变化—以四川盆地东部沙坪场石炭系气藏为例[J]. 天然气地球科学,2021,32(6):914-922.ZHU Huayin, TANG Ligen, PANG Yulai, et al. Permeability changes of fractured-porous reservoirs under alternating pressure conditions: Taking the Carboniferous gas reservoir in Shapingchang, eastern Sichuan Basin as an example[J]. Natural Gas Geoscience, 2021, 32(6):914-922. [9] 陈金霞. 纳微米防塌钻井液技术的研究与应用[J]. 油田化学,2017,34(3):402-407.CHEN Jinxia. Research and application of nano-micron anti-collapse drilling fluid technology[J]. Oil Field Chemistry, 2017, 34(3):402-407. [10] SOEDER, DANIEL J. Porosity and permeability of eastern devonian gasshale[J]. SPE Formation Evaluation, 1988, 3(1):116-124. doi: 10.2118/15213-PA [11] 刘凡,蒋官澄,王凯,等. 新型纳米材料在页岩气水基钻井液中的应用研究[J]. 钻井液与完井液,2018,35(1):27-33. doi: 10.3969/j.issn.1001-5620.2018.01.005LIU Fan, JIANG Guancheng, WANG Kai, et al. Application of new nanomaterials in shale gas water-based drilling fluids[J]. Drilling Fluid & Completion Fluid, 2018, 35(1):27-33. doi: 10.3969/j.issn.1001-5620.2018.01.005 [12] 徐琳,邓明毅,郭拥军,等. 纳米SiO2接枝超支化聚酰胺的合成及性能评价[J]. 石油化工,2016,45(11):1352-1356. doi: 10.3969/j.issn.1000-8144.2016.11.011XU Lin, DENG Mingyi, GUO Yongjun, et al. Synthesis and performance evaluation of nano-SiO2 grafted hyperbranched polyamide[J]. Petrochemical Industry, 2016, 45(11):1352-1356. doi: 10.3969/j.issn.1000-8144.2016.11.011 [13] 卢震,黄贤斌,孙金声,等. 水基钻井液用耐高温纳米聚合物封堵剂的研制[J]. 石油钻采工艺,2020,42(5):587-591.LU Zhen, HUANG Xianbin, SUN Jinsheng, et al. Development of high temperature resistant nano polymer plugging agent for water-based drilling fluids[J]. Oil Drilling & Production Technology, 2020, 42(5):587-591. [14] 徐同台,卢淑芹,何瑞兵,等. 钻井液用封堵剂的评价方法及影响因素[J]. 钻井液与完井液,2009,26(2):60-62. doi: 10.3969/j.issn.1001-5620.2009.02.019XU Tongtai, LU Shuqin, HE Ruibing, et al. Evaluation methods and influencing factors of plugging agents for drilling fluids[J]. Drilling Fluid & Completion Fluid, 2009, 26(2):60-62. doi: 10.3969/j.issn.1001-5620.2009.02.019 [15] 方静,牛晓,何仲,等. 两性离子钻井液成膜封堵剂的研制及性能研究[J]. 应用化工,2017,46(2):234-239.FANG Jing, NIU Xiao, HE Zhong, et al. Development and performance study of amphoteric ion drilling fluid film-forming plugging agent[J]. Applied Chemical Industry, 2017, 46(2):234-239. [16] GOSHTASP CHERAGHIAN. Nanoparticles in drilling fluid: A review of the state of the art[J]. Journal of Materials Research and Technology, 2021, 9(13):737-753. [17] 武元鹏,田应佩,罗平亚,等. 纳米CaCO3的制备及在水基钻井液的应用研究[J]. 钻井液与完井液,2019,36(4):407-413. doi: 10.3969/j.issn.1001-5620.2019.04.002WU Yuanpeng, TIAN Yingpei, LUO Pingya, et al. Preparation of nano-CaCO3 and its application in water-based drilling fluids[J]. Drilling Fluid & Completion Fluid, 2019, 36(4):407-413. doi: 10.3969/j.issn.1001-5620.2019.04.002 [18] 王平全,敬玉娟,彭真,等. 针对页岩气井钻井液的新型滤失造壁性能评价方法[J]. 钻井液与完井液,2017,34(2):51-56. doi: 10.3969/j.issn.1001-5620.2017.02.009WANG Pingquan, JING Yujuan, PENG Zhen, et al. A new filter loss-making wall performance evaluation method for shale gas well drilling fluid[J]. Drilling Fluid & Completion Fluid, 2017, 34(2):51-56. doi: 10.3969/j.issn.1001-5620.2017.02.009 [19] FANG Junwei, LUO Yujing, LI Shuanggui, et al. Effectiveness of copolymer of polymethylmethacrylate and styrene as a plugging agent in water-based drilling fluids[J]. Chemistry and Technology of Fuels and Oils, 2021, 57(1):83-94. doi: 10.1007/s10553-021-01229-8 [20] 周春玲,朱趁安,王妍琼,等. 人造岩心的研制及渗透率影响因素研究[J]. 石油化工应用,2017,36(9):85-89. doi: 10.3969/j.issn.1673-5285.2017.09.021ZHOU Chunling, ZHU Chen'an, WANG Yanqiong, et al. Development of artificial cores and research on influencing factors of permeability[J]. Petrochemical Industry Application, 2017, 36(9):85-89. doi: 10.3969/j.issn.1673-5285.2017.09.021 [21] 曹成,蒲晓林,王贵,等. 水基钻井液用防塌封堵剂封堵效果实验研究[J]. 应用化工,2015,44(2):247-249.CAO Cheng, PU Xiaolin, WANG Gui, et al. Experimental study on plugging effect of anti-collapse plugging agent for water-based drilling fluid[J]. Applied Chemical Industry, 2015, 44(2):247-249. [22] BAHATTAB Mohammed A, DONATE-ROBLES JESSICA, GARCIA-PACIOS VANESA. Characterization of polyurethane adhesives containing nanosilicas of different particle size[J]. International Journal of Adhesion & Adhesives, 2011, 31(2):97-103. [23] CHOI H, CHEN I. Surface-modified silica colloid for diagnostic imaging[J]. Journal of Colloid& Interface Science, 2003, 258(2):435-437. [24] 曲建峰,邱正松,郭保雨,等. 氧化石墨烯新型抗高温降滤失剂的合成与评价[J]. 钻井液与完井液,2017,34(04):9-14. doi: 10.3969/j.issn.1001-5620.2017.04.002QU Jianfeng, QIU Zhengsong, GUO Baoyu, et al. Synthesis and evaluation of a new type of graphene oxide anti-high temperature fluid loss agent[J]. Drilling Fluid & Completion Fluid, 2017, 34(04):9-14. doi: 10.3969/j.issn.1001-5620.2017.04.002 [25] MAHTO V, SRIKANTH P, VAMSI K B. Development of non-damaging and inhibitive water based oil well drilling fluids[J]. Petroleum Science and Technology, 2013, 31(7):721-726. doi: 10.1080/10916466.2010.531353 [26] 田月昕,黄进军,郭星波,等. 纳米封堵剂Fe3O4性能评价与机理探究[J]. 化学世界,2018,59(7):440-447.TIAN Yuexin, HUANG Jinjun, GUO Xingbo, et al. Performance evaluation and mechanism exploration of nanometer plugging agent Fe3O4[J]. Chemical World, 2018, 59(7):440-447. [27] 向朝纲,蒲晓林,陈勇. 新型封堵剂FDJ-EF封堵特性及其作用机理[J]. 断块油气田,2012,19(2):249-252.XIANG Chaogang, PU Xiaolin, CHEN Yong. The plugging characteristics and mechanism of the new plugging agent FDJ-EF[J]. Fault Block Oil and Gas Field, 2012, 19(2):249-252. -

下载:

下载: