Mechanisms of Oleamide as Thinner in Oil Based Drilling Fluids

-

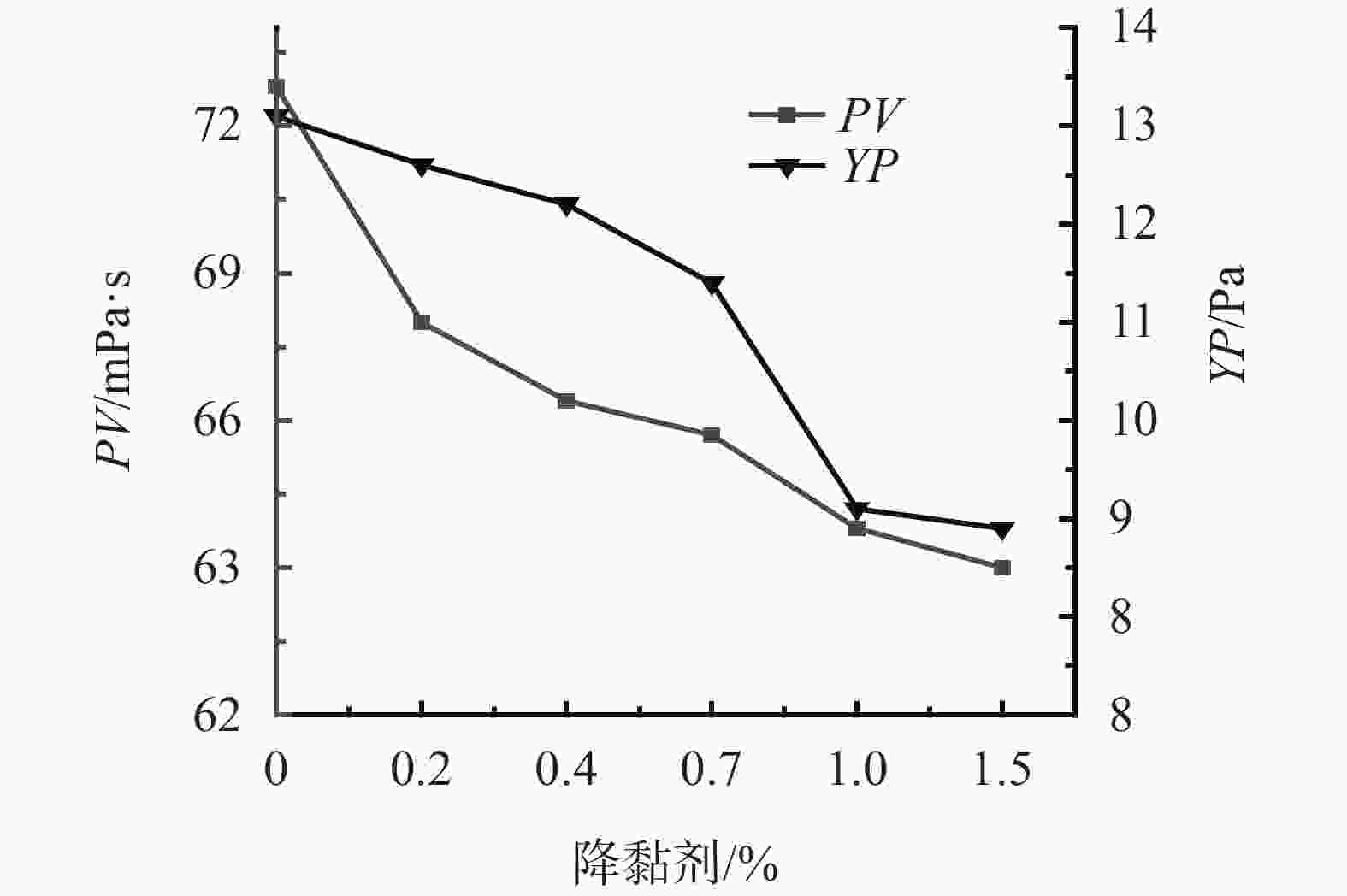

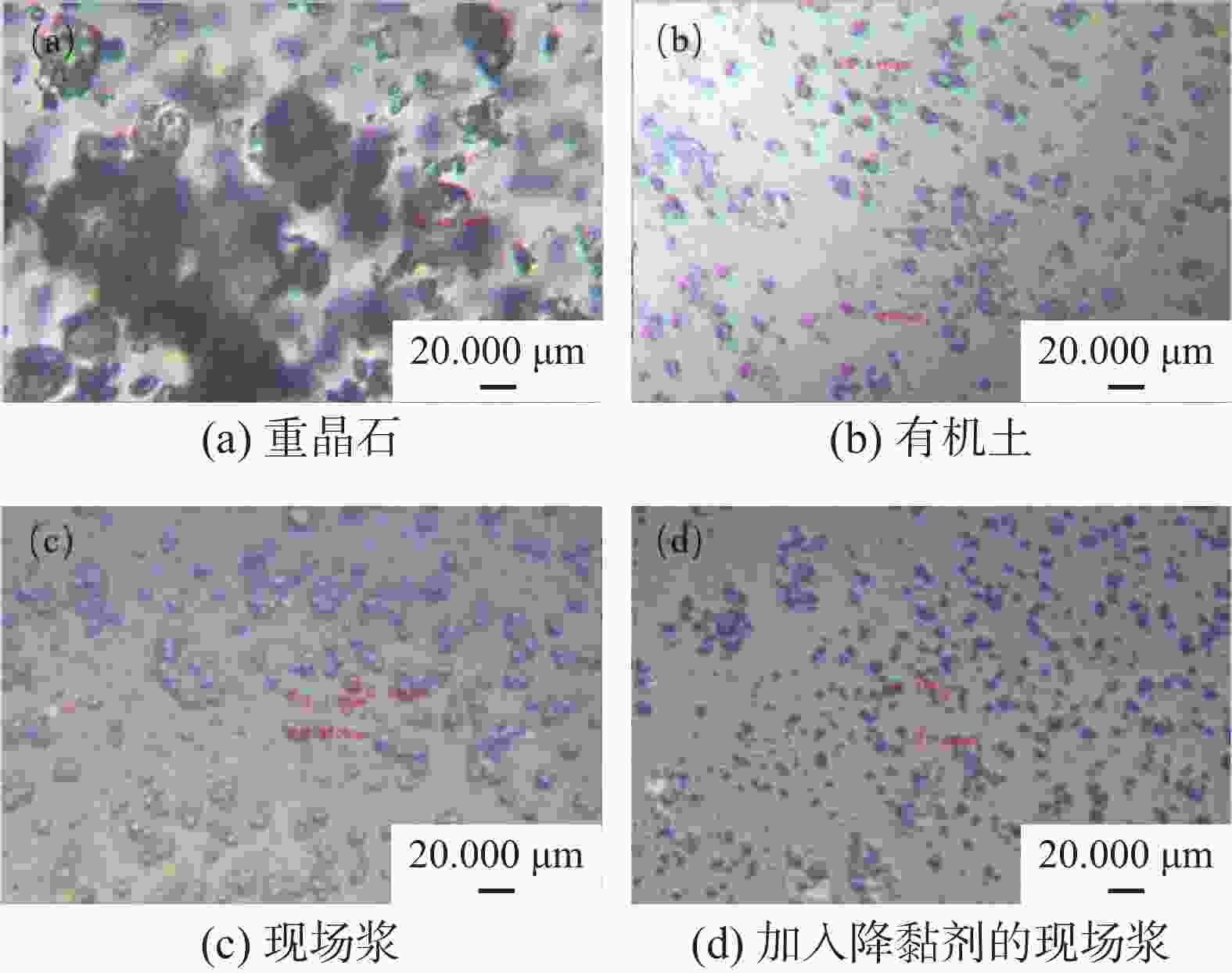

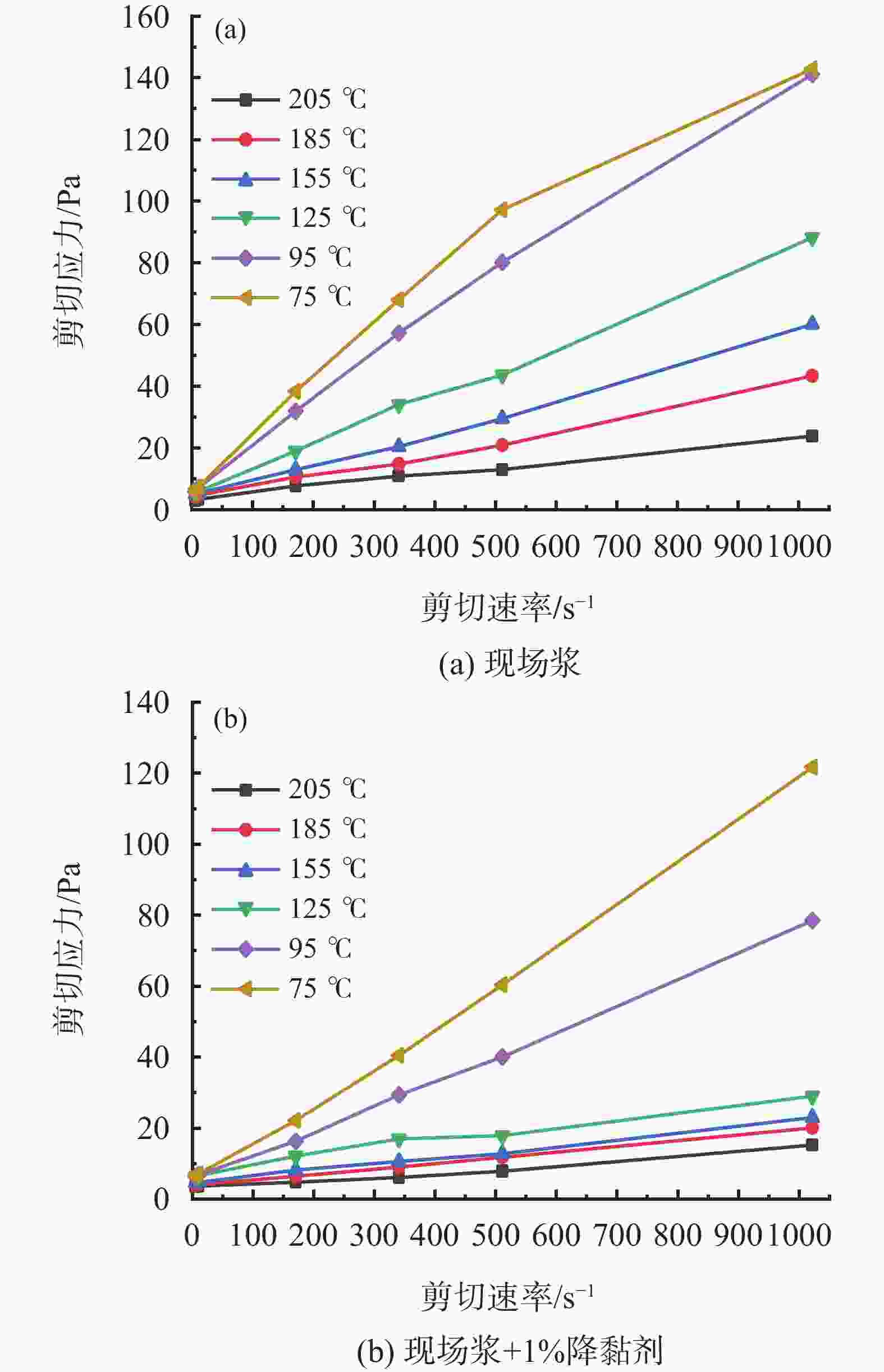

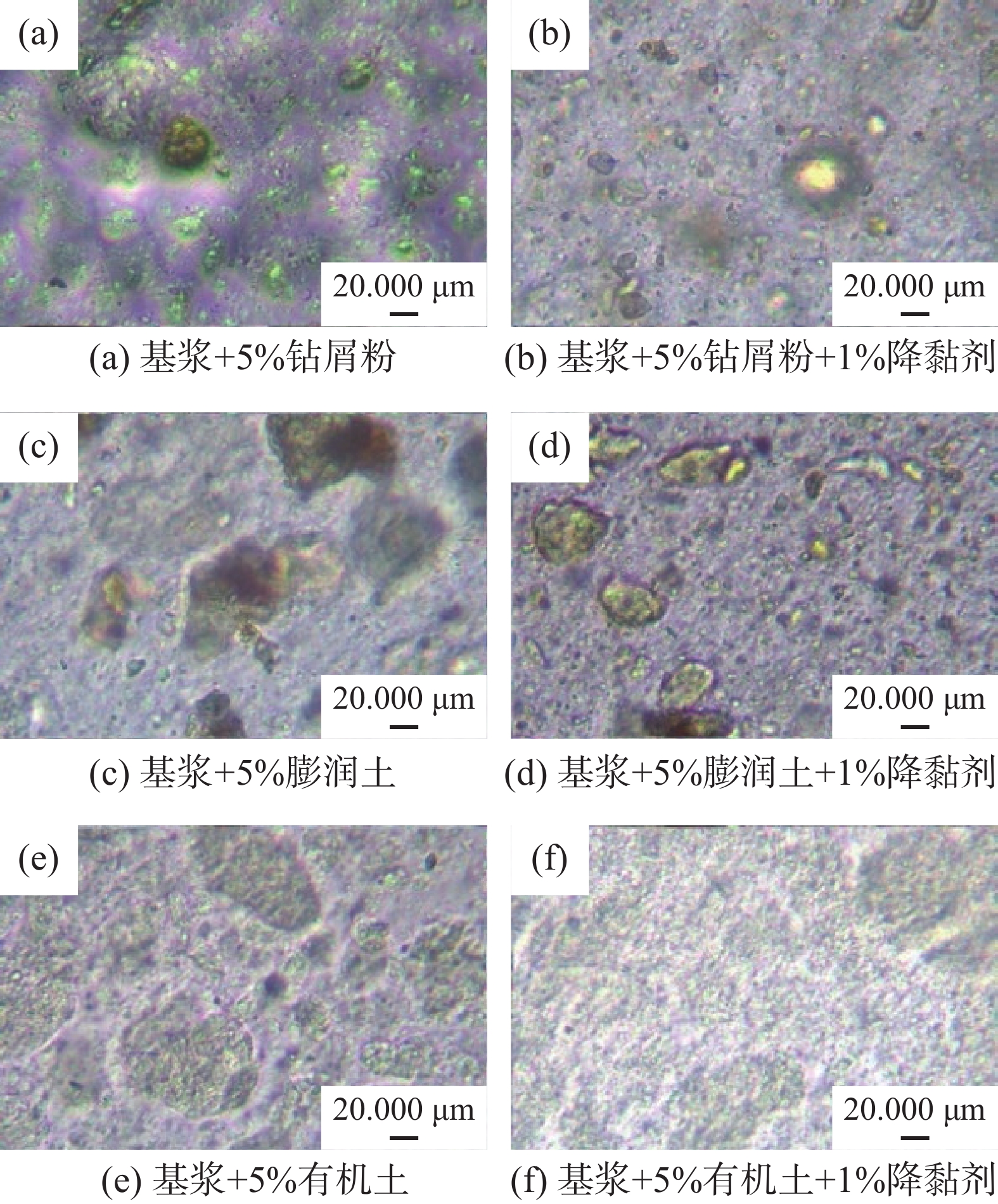

摘要: 在基浆中分别添加不同类型的黏土,模拟地层土对钻井液黏度的影响,添加不同浓度的沥青降滤失剂模拟沥青对钻井液黏度的影响。结果表明,在基浆中分别添加5%有机土、15.5%沥青降滤失剂后基浆塑性黏度增加100%,动切力至少增加370%。在污染后的基浆中添加1%油酸酰胺型降黏剂后,可使混入黏土的基浆塑性黏度降低10%,动切力降低80%以上;添加15.5%沥青的基浆动切力降低73%以上,说明油酸酰胺可拆散劣质固相形成的网架结构。在南缘天安X井现场油基钻井液老浆(密度为2.25 g/cm3)中添加1%油酸酰胺型降黏剂,其塑性黏度降低15%,而动切力可降低30%以上。油酸酰胺降黏剂在油基钻井液老浆中主要作用是拆散劣质固相形成的网架结构,降黏规律与基浆中含有过量黏土和沥青污染物相关。高温高压流变测试结果表明,在205 ℃下油酸酰胺型降黏剂仍能使现场油基钻井液老浆的塑性黏度降低4.76%、屈服值降低8.70%,拆散现场浆中过量的网架结构,有效地改善了现场浆的流变性。Abstract: In laboratory experiment, different types of clay were added to a base mud to investigate the effect of formation clays on the viscosity of the base mud, and an asphalt filter loss reducer was added to a base mud at different concentrations to investigate the effect of asphalt on the viscosity of the mud. After adding 5% organophilic clay and 15.5% asphalt filter loss reducer into the base mud, the plastic viscosity of the base mud was increased by 100%, and the yield point of the base mud was increased by at least 370%. An oleamide type thinner was then added into the base mud contaminated with organophilic clay at 1% and the viscosity of the base mud was reduced by 10%, and the yield point reduced by at least 80%. After adding 1% oleamide type thinner into the base mud treated with 15.5% asphalt, the yield point of the base mud was reduced by at least 73%. These experimental results indicate that oleamide is able to disassemble the network structure formed by the low quality solids in the mud. An oil based mud (density 2.25 g/cm3) sample was taken from a well and was treated with 1% oleamide thinner, the viscosity and yield point of the mud were reduced by 15% and at least 30%, respectively. The major role of the oleamide thinner in the oil based mud sample is to disassemble the network structure formed by the low quality solids in the mud, the mechanism of viscosity reducing is the same as that of the mud contaminated with excessive amount of organophilic clay and asphalt. Rheology test at high temperature high pressure conditions has shown that at 205 °C, oleamide can still reduce the viscosity of an old oil based mud by 4.76% and the yield point of the old oil based mud by 8.70%. The oleamide thinner disassembles the excessive network structure in the mud taken from the rig-site and effectively improves the rheology of the mud.

-

Key words:

- Oil based mud /

- Plastic viscosity /

- Low quality solids /

- Oleamide /

- Thinner

-

表 1 降黏剂对基浆土相增黏的影响

添加材料 PV/

mPa·sYP/

Paφ6/φ3 0 3.0 3.6 2.8/2.8 5%钻屑粉 3.9 4.8 2.7/2.6 5%钻屑粉+1%降黏剂 4.9 1.1 0.1/0.1 5%膨润土 6.2 26.7 16.5/10.5 5%膨润土+1%降黏剂 5.0 2.3 3.1/2.7 5%有机土 5.9 17.2 24.4/18.1 5%有机土+1%降黏剂 5.5 3.3 1.0/1.0 注:黏度数据均为120 ℃、16 h老化后在50 ℃测得 表 2 有机土含量对体系黏度的影响

材料组成及加量 PV/

mPa·sYP/

Paφ6/φ3 基浆 3.0 3.6 2.8/2.8 基浆+2%有机土 4.6 7.0 5.7/5.6 基浆+2%有机土+1%降黏剂 3.8 1.6 0.4/0.4 基浆+5%有机土 5.9 17.2 24.4/18.1 基浆+5%有机土+1%降黏剂 5.5 3.3 1.0/1.0 注:黏度数据均为120 ℃、老化16 h后在50 ℃测得 表 3 降黏剂对基浆中沥青增黏的抑制作用

材料组成及加量 PV/

mPa·sYP/

Paφ6/φ3 白油+5%沥青 2.6 1.3 0.2/0.2 白油+10%沥青 6.1 2.1 0.3/0.3 白油+15.5%沥青 6.5 21.0 11.2/8.0 白油+15.5%沥青+1%降黏剂 7.0 2.6 0.4/0.3 注:黏度数据均为180 ℃、老化16 h后测试,测试温度为50 ℃ 表 4 油酸酰胺降黏剂对现场老浆性能的影响

降黏

剂/%PV/

mPa·sYP/

Paφ6/φ3 Gel/

Pa/PaES/

VFLHTHP

mL0 82.9 14.2 9.4/6.7 7.3/9.6 1368 72.8 13.1 8.3/6.6 7.3/9.5 1522 1.0 1 71.3 12.5 8.0/6.1 7.4/8.8 1349 63.8 9.1 7.4/5.9 7.0/8.2 1466 1.0 注:黏度数据均为120 ℃、16 h老化后测试,测试温度为75 ℃ 表 5 现场浆在不同温度下的流变参数及相关系数

流变模式 75 ℃ 95 ℃ 125 ℃ 155 ℃ 185 ℃ 205 ℃ 宾汉模式 $ {\tau }_{0} $=12.8517 $ {\tau }_{0} $=8.2529 $ {\tau }_{0} $=5.9330 $ {\tau }_{0} $=4.5934 $ {\tau }_{0} $=4.4823 $ {\tau }_{0} $=3.74203 $ {\mu }_{p} $=0.1372 $ {\mu }_{p} $=0.1331 $ {\mu }_{p} $=0.0807 $ {\mu }_{p} $=0.0538 $ {\mu }_{p} $0.0378 $ {\mu }_{p} $=0.02138 $ {R}_{1}^{2} $=0.9579 $ {R}_{1}^{2} $=0.9949 $ {R}_{1}^{2} $=0.9975 $ {R}_{1}^{2} $=0.9944 $ {R}_{1}^{2} $=0.9896 $ {R}_{1}^{2} $=0.9919 卡森模式 $ {\eta }_{\infty }^{\frac{1}{2}} $=0.3331 $ {\eta }_{\infty }^{\frac{1}{2}} $=0.3192 $ {\eta }_{\infty }^{\frac{1}{2}} $=0.2336 $ {\eta }_{\infty }^{\frac{1}{2}} $=0.1795 $ {\eta }_{\infty }^{\frac{1}{2}} $=0.1448 $ {\eta }_{\infty }^{\frac{1}{2}} $=0.1024 $ {\tau }_{0}^{\frac{1}{2}} $=1.8153 $ {\tau }_{0}^{\frac{1}{2}} $=1.6645 $ {\tau }_{0}^{\frac{1}{2}} $=1.6022 $ {\tau }_{0}^{\frac{1}{2}} $=1.5720 $ {\tau }_{0}^{\frac{1}{2}} $=1.5410 $ {\tau }_{0}^{\frac{1}{2}} $=1.4624 $ {R}_{2}^{2} $=0.9899 $ {R}_{2}^{2} $=0.9991 $ {R}_{2}^{2} $=0.9891 $ {R}_{2}^{2} $=0.9677 $ {R}_{2}^{2} $=0.9598 $ {R}_{2}^{2} $=0.9890 幂律模式 K=1.3505 K=0.5152 K=0.1987 K=0.0984 K=0.0891 K=0.3033 n=0.6748 n=0.8095 n=0.8776 n=0.9237 n=0.8899 n=0.6230 $ {R}_{3}^{2} $=0.9936 $ {R}_{3}^{2} $=0.9968 $ {R}_{3}^{2} $=0.9851 $ {R}_{3}^{2} $=0.9717 $ {R}_{3}^{2} $=0.9523 $ {R}_{3}^{2} $=0.9414 表 6 现场浆+1%降黏剂在不同温度下的流变参数及相关系数

流变模式 75 ℃ 95 ℃ 125 ℃ 155 ℃ 185 ℃ 205 ℃ 宾汉模式 $ {\tau }_{0} $=5.4724 $ {\tau }_{0} $=5.2918 $ {\tau }_{0} $=6.4845 $ {\tau }_{0} $=4.2523 $ {\tau }_{0} $=3.8836 $ {\tau }_{0} $=3.4165 $ {\mu }_{p} $=0.1132 $ {\mu }_{p} $=0.0708 $ {\mu }_{p} $=0.0807 $ {\mu }_{p} $=0.0177 $ {\mu }_{p} $0.0158 $ {\mu }_{p} $=0.0112 $ {R}_{1}^{2} $=0.9976 $ {R}_{1}^{2} $=0.9983 $ {R}_{1}^{2} $=0.9684 $ {R}_{1}^{2} $=0.9934 $ {R}_{1}^{2} $=0.9996 $ {R}_{1}^{2} $=0.9677 卡森模式 $ {\eta }_{\infty }^{\frac{1}{2}} $=0.2812 $ {\eta }_{\infty }^{\frac{1}{2}} $=0.2090 $ {\eta }_{\infty }^{\frac{1}{2}} $=0.0950 $ {\eta }_{\infty }^{\frac{1}{2}} $=0.0851 $ {\eta }_{\infty }^{\frac{1}{2}} $=0.0813 $ {\eta }_{\infty }^{\frac{1}{2}} $=0.0619 $ {\tau }_{0}^{\frac{1}{2}} $=1.5549 $ {\tau }_{0}^{\frac{1}{2}} $=1.7771 $ {\tau }_{0}^{\frac{1}{2}} $=2.2681 $ {\tau }_{0}^{\frac{1}{2}} $=1.8362 $ {\tau }_{0}^{\frac{1}{2}} $=1.6727 $ {\tau }_{0}^{\frac{1}{2}} $=1.5849 $ {R}_{2}^{2} $=0.9804 $ {R}_{2}^{2} $=0.9763 $ {R}_{2}^{2} $=0.9889 $ {R}_{2}^{2} $=0.9648 $ {R}_{2}^{2} $=0.9598 $ {R}_{2}^{2} $=0.8654 幂律模式 K=0.1411 K=0.1743 K=2.1034 K=0.7108 K=0.4762 K=0.3104 n=0.9747 n=0.8799 n=0.3650 n=0.4876 n=0.5292 n=0.5461 $ {R}_{3}^{2} $=0.9909 $ {R}_{3}^{2} $=0.9722 $ {R}_{3}^{2} $=0.9114 $ {R}_{3}^{2} $=0.8543 $ {R}_{3}^{2} $=0.8668 $ {R}_{3}^{2} $=0.7207 -

[1] LI J , LI Q , LI N , et al. Ultra-high density oil-based drilling fluids laboratory evaluation and applications in ultra-hpht reservoir[C]// SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition. 2019. [2] 宋晓雪. 密度等因素对油基钻井液性能的影响情况研究[J]. 西部探矿工程,2021,33(4):59-61. doi: 10.3969/j.issn.1004-5716.2021.04.019SONG Xiaoxue. Study on the influence of density and other factors on the performance of oil base drilling fluid[J]. West-china Exploration Engineering, 2021, 33(4):59-61. doi: 10.3969/j.issn.1004-5716.2021.04.019 [3] 吴雄军,林永学,宋碧涛,等. 顺北油气田奥陶系破碎性地层油基钻井液技术[J]. 钻井液与完井液,2020,37(6):701-708. doi: 10.3969/j.issn.1001-5620.2020.06.004WU Xiongjun, LIN Yongxue, SONG Bitao, et al. Oil based drilling fluid technology for Ordovician fractured formation of ultra-deep well in Shunbei oil and gas field[J]. Drilling Fluid & Completion Fluid, 2020, 37(6):701-708. doi: 10.3969/j.issn.1001-5620.2020.06.004 [4] 王星媛,陆灯云,吴正良. 抗220 ℃的高密度油基钻井液的研究与应用[J]. 钻井液与完井液,2020,37(5):550-554.WANG Xingyuan, LU Dengyun, WU Zhengliang. Study and application of a high density oil base drilling fluid with high temperature resistance of 220 ℃[J]. Drilling Fluid & Completion Fluid, 2020, 37(5):550-554. [5] 王建华, 王立辉, 杨海军, 等. 一种油基钻井液的稀释剂及制备方法和应用: CN105950124B[P]. 2018-08-10.WANG Jianhua, WANG Lihui, YANG Haijun, et al. A preparation method and application of diluent for oil-based drilling fluid: CN105950124B[P]. 2018-08-10. [6] 代一钦,梁文利. 油基钻井液降黏剂研制及现场应用[J]. 江汉石油职工大学学报,2019,32(6):39-42.DAI Yiqin, LIANG Wenli. Development and field application of viscosity reducer for oil-based drilling fluid[J]. Journal of Jianghan Petroleum University of Staff and Workers, 2019, 32(6):39-42. [7] 刘政,李俊材,邵平. 准南地区霍尔果斯构造超高密度油基钻井液技术应用[J]. 天然气勘探与开发,2020,43(2):71-78.LIU Zheng, LI Juncai, SHAO Ping. Ultra-high density oil-based drilling fluid and its application to Horgos structure, southern Junggar Basin[J]. Natural Gas Exploration and Development, 2020, 43(2):71-78. [8] 梁文利,代一钦. 针对深层页岩气藏的油基钻井液降黏剂研制及应用[J]. 天然气勘探与开发,2020,43(1):71-76.LIANG Wenli, DAI Yiqin. Viscosity-reducing agent of oil-based drilling fluid used in deeper shale gas reservoirs and its application[J]. Natural Gas Exploration and Development, 2020, 43(1):71-76. [9] SERVICES B F. Innovert® high performance paraffin/mineral oil-based fluids from Baroid: US 6887832[P]. 2008-05-20. [10] WAGLE A, AI-YAMI A. Invert emulsion drilling fluids with fatty acid and fatty diol rheology modifiers: US 201715827575[P]. 2018-05-31. [11] SUN J S, HUANG X B, JIANG G C, et al. Development of key additives for organoclay-free oil-based drilling mud and system performance evaluation[J]. Petroleum Exploration and Development, 2018, 45(4):764-769. doi: 10.1016/S1876-3804(18)30079-X [12] 陈二丁, 张海青, 王俊, 等. 一种油基钻井液用惰性稀释剂的制备方法: CN 109796948A[P]. 2019-05-24.CHEN Erding, ZHANG Haiqing, WANG Jun, et al. A method for preparing inert diluent for oil base drilling fluid: CN 109796948A[P]. 2019-05-24. [13] 耿铁, 赵春花, 孙强, 等. 一种耐高温高压的油基钻井液用降黏剂及其制备方法: CN 111205834 A[P]. 2020-05-29.GENG Tie, ZHAO Chunhua, SUN Qiang, et al. A viscosity-reducing agent for oil-based drilling fluid with high temperature and pressure resistance and the preparation method of it: CN 111205834 A[P]. 2020-05-29. [14] 黄伟, 李英敏, 冯杰, 等. 一种油基钻井液用降黏剂及其制备方法: CN 104152122B [P]. 2017-01-04.HUANG Wei, LI Yingmin, FENG Jie, et al. A viscosity-reducing agent for oil -based drilling fluid and the preparation method of it. CN, 104152122B [P]. 2017-01-04. [15] 蒋官澄, 彭双磊, 贺垠博, 等. 适用于油基钻井液降黏的双嵌段共聚物及其制备方法和应用以及油基钻井液和应用: CN 106220797 B[P]. 2017-06-30.JIANG Guancheng, PENG Shuanglei, HE Yinbo, et al. Diblock copolymer for viscosity reduction of oil-based drilling fluid and its preparation method and application, and oil-based drilling fluid and application: CN 106220797 B[P]. 2017-06-30. [16] 蒋官澄, 彭双磊, 贺垠博, 等. 适用于油基钻井液降黏的添加剂组合物和应用以及油基钻井液和应用: CN 106634881B[P]. 2017-11-14.JIANG Guancheng, PENG Shuanglei, HE Yinbo, et al. Additive compositions and applications for viscosity reduction in oil based drilling fluids and oil based drilling fluids and applications. CN, 106634881B[P]. 2017-11-14. [17] 蒋官澄, 彭双磊, 贺垠博, 等. 适用作低温降黏剂的聚酰胺类共聚物及其制备方法和油基钻井液: CN 109721729 B[P]. 2020-09-01.JIANG Guancheng, PENG Shuanglei, HE Yinbo, et al. The polyamide copolymer suitable for low temperature viscosifier and its preparation method and oil based drilling fluid: CN 109721729 B[P]. 2020-09-01. [18] 陶怀志, 陈俊斌, 舒小波, 等. 油基钻井液用降黏切剂及制备方法和改善流动性方法: CN 111363523A[P]. 2020-07-03.TAO Huaizhi, CHEN Junbing, SHU Xiaobo, et al. Viscosity - reducing cutting agent for oil – based drilling fluid, preparation method and method for improving fluidity: CN 111363523A[P]. 2020.07-03. [19] 杨振周,刘付臣,周春,等. 抗超高温高密度油基钻井液用新型降黏剂的性能[J]. 钻井液与完井液,2018,35(2):35-39. doi: 10.3969/j.issn.1001-5620.2018.02.005YANG Zhenzhou, LIU Fuchen, ZHOU Chun, et al. Study on the performance of new ultra-high temperature high density oil base mud thinners[J]. Drilling Fluid & Completion Fluid, 2018, 35(2):35-39. doi: 10.3969/j.issn.1001-5620.2018.02.005 [20] 秦文政,王震宇,杨燮林,等. 准噶尔盆地南缘探井技术瓶颈及对策[J]. 石化技术,2020,27(9):81-79. doi: 10.3969/j.issn.1006-0235.2020.09.045QIN Wenzheng, WANG Zhenyu, YANG Xielin, et al. Technical bottleneck and Countermeasures of exploration wells in the southern margin of Junggar Basin[J]. Petrochemical Technology, 2020, 27(9):81-79. doi: 10.3969/j.issn.1006-0235.2020.09.045 [21] 卓鲁斌,石建刚,吴继伟,等. 准噶尔盆地南缘钻井技术进展、难点及对策[J]. 西部探矿工程,2020,32(2):75-77. doi: 10.3969/j.issn.1004-5716.2020.02.025ZHUO Lubing, SHI Jianggang, WU Jiwei, et al. Progress, difficulties and countermeasures of drilling technology in the southern margin of Junggar Basin[J]. West-china Exploration Engineering, 2020, 32(2):75-77. doi: 10.3969/j.issn.1004-5716.2020.02.025 [22] 张雪飞,张伟,徐新纽,等. 准噶尔盆地南缘H101井高密度油基钻井液技术[J]. 石油钻探技术,2016,44(1):34-38.ZHANG Xuefei, ZHANG Wei, XU Xinniu, et al. High density oil-based drilling fluid deployed in well H101 the southern margin of the junggar basin[J]. Petroleum Drilling Techniques, 2016, 44(1):34-38. [23] 唐玲娟,刘超,吴伟林,等. 油基钻井液天然岩沥青降滤失剂的环保性能[J]. 钻井液与完井液,2019,36(6):706-710.TANG Lingjuan, LIU Chao, WU Weilin, et al. The environment protection property of a natural rock asphaltene for oil base drilling fluids[J]. Drilling Fluid & Completion Fluid, 2019, 36(6):706-710. [24] 明显森,陶怀志,陈俊斌,等. 高密度油基钻井液降黏剂及其现场应用[J]. 钻井液与完井液,2021,38(4):423-427.MING Xiansen, TAO Huaizhi, CHEN Junbin, et al. A viscosity reducer for oil based drilling fluids and its field application[J]. Drilling Fluid & Completion Fluid, 2021, 38(4):423-427. [25] 张县民,姜雪清,黄宁,等. 油基钻井液堵漏用共混聚合物研究[J]. 钻井液与完井液,2021,38(5):593-597.ZHANG Xianmin,JIANG Xueqing,HUANG Ning, et al. Study on polymer blend used for controlling loss of oil based drilling fluids[J]. Drilling Fluid & Completion Fluid, 2021, 38(5):593-597. [26] 米远祝, 罗跃, 黄志强. 油基钻井液增黏剂的合成及室内评价 [J]. 钻井液与完井液, 2014, 31(1): 4-7.MI Yuanzhu, LUO Yue, HUANG Zhiqiang. Synthesis and laboratory evaluation of viscosifier for oil-based drilling fluids[J]. Drilling Fluid & Completion Fluid, 2014, 31(1): 4-7. -

下载:

下载: