Mechanical Performance of High Density Set Cement for HTHP Applications

-

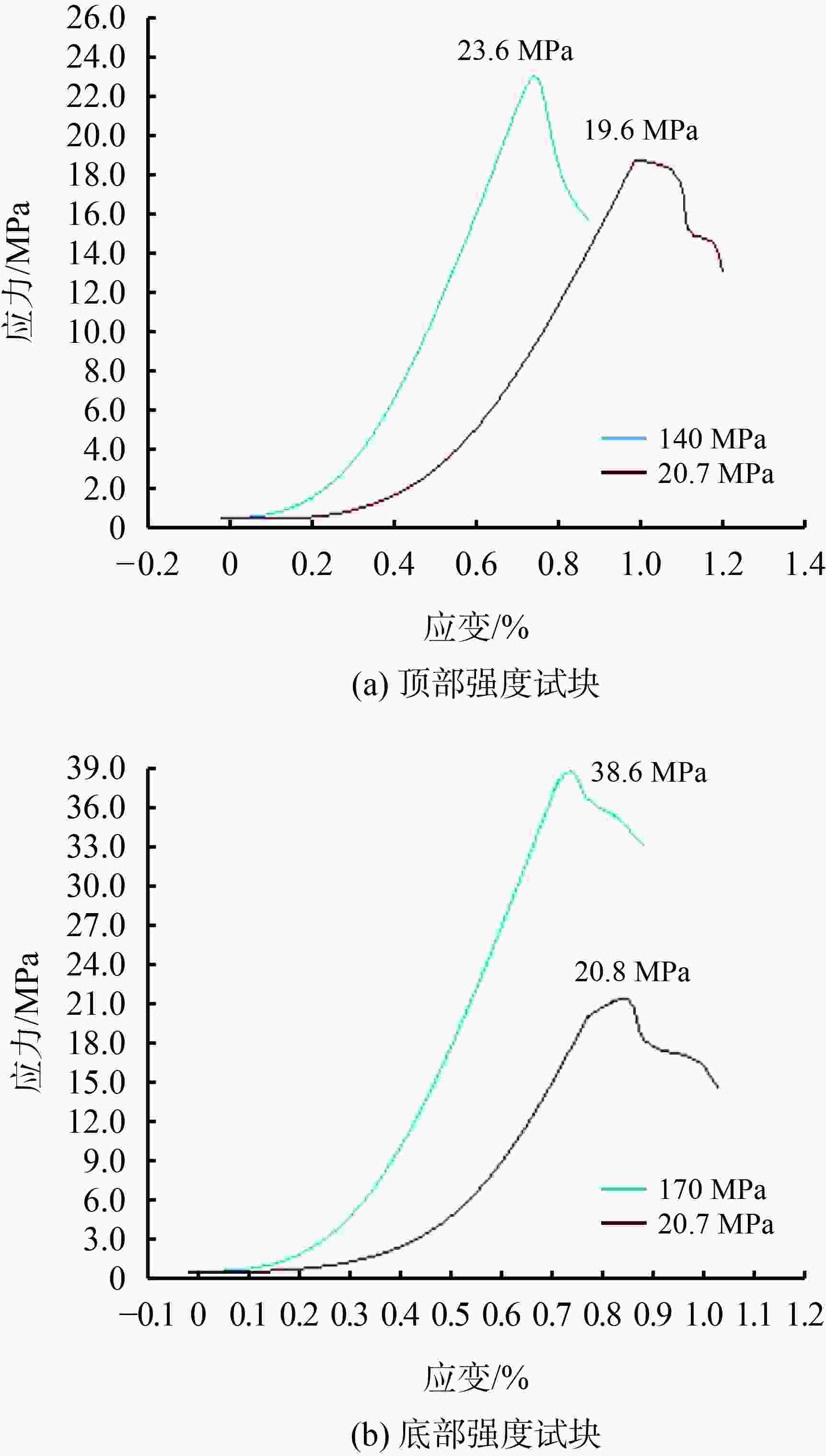

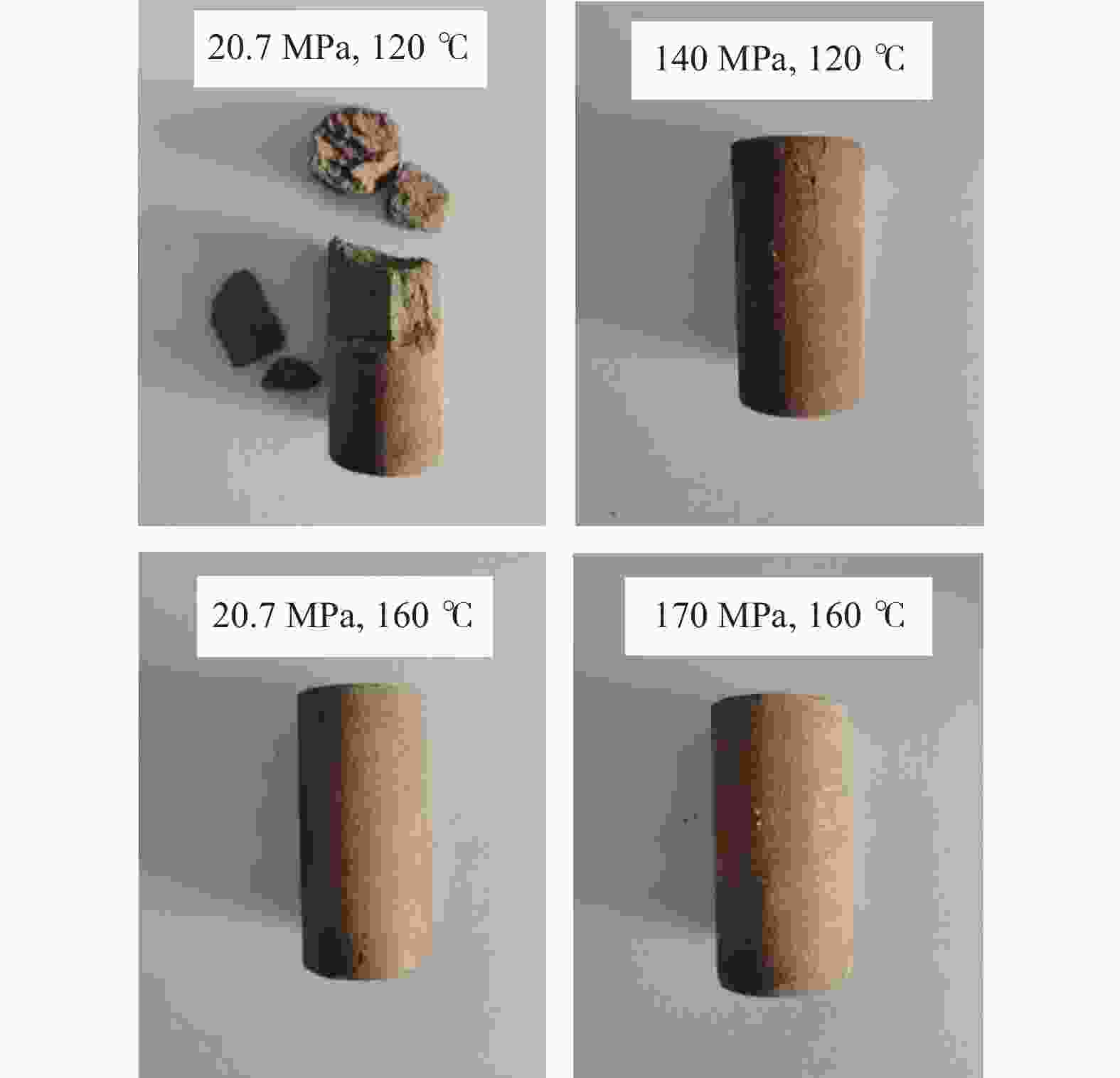

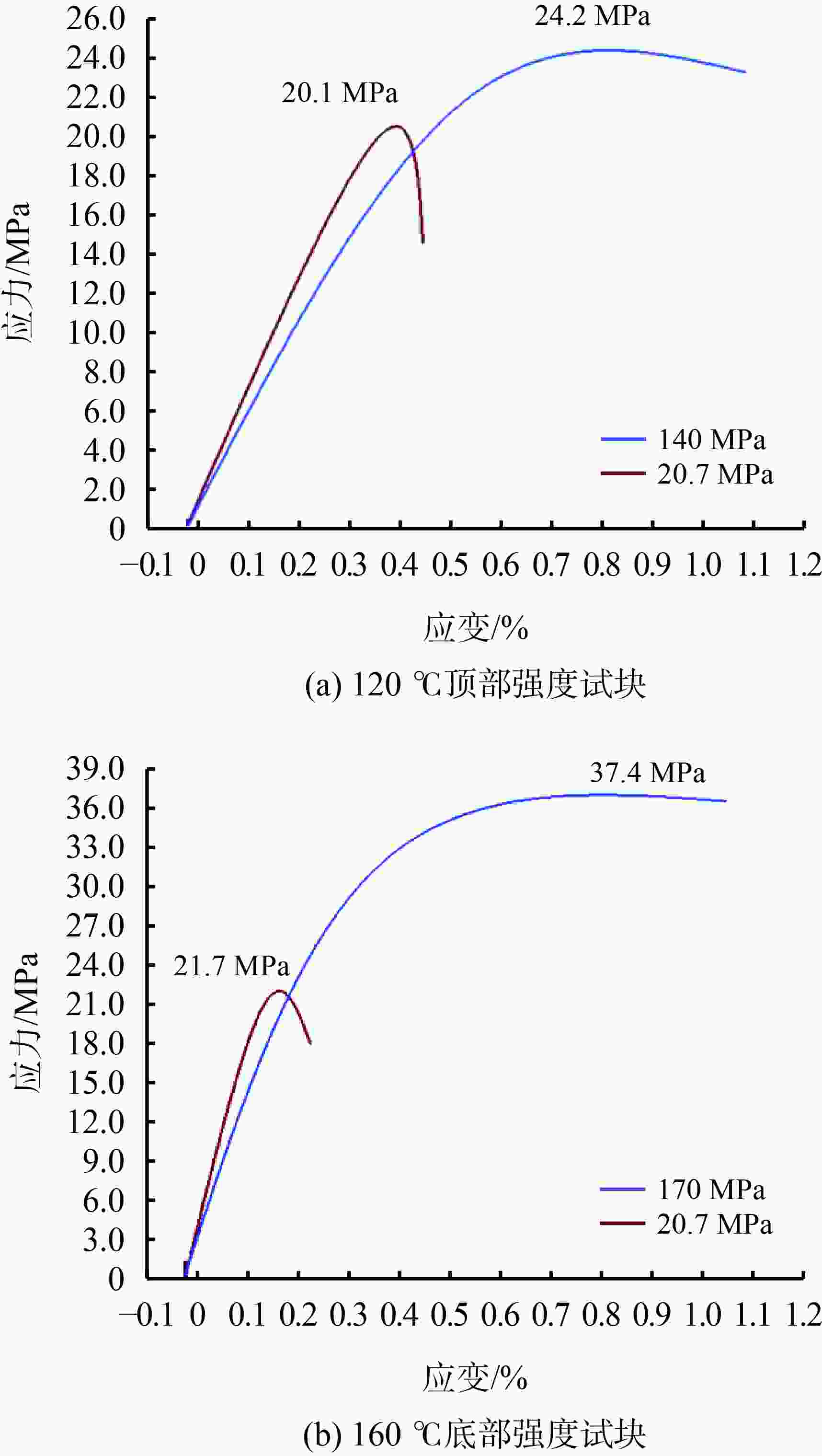

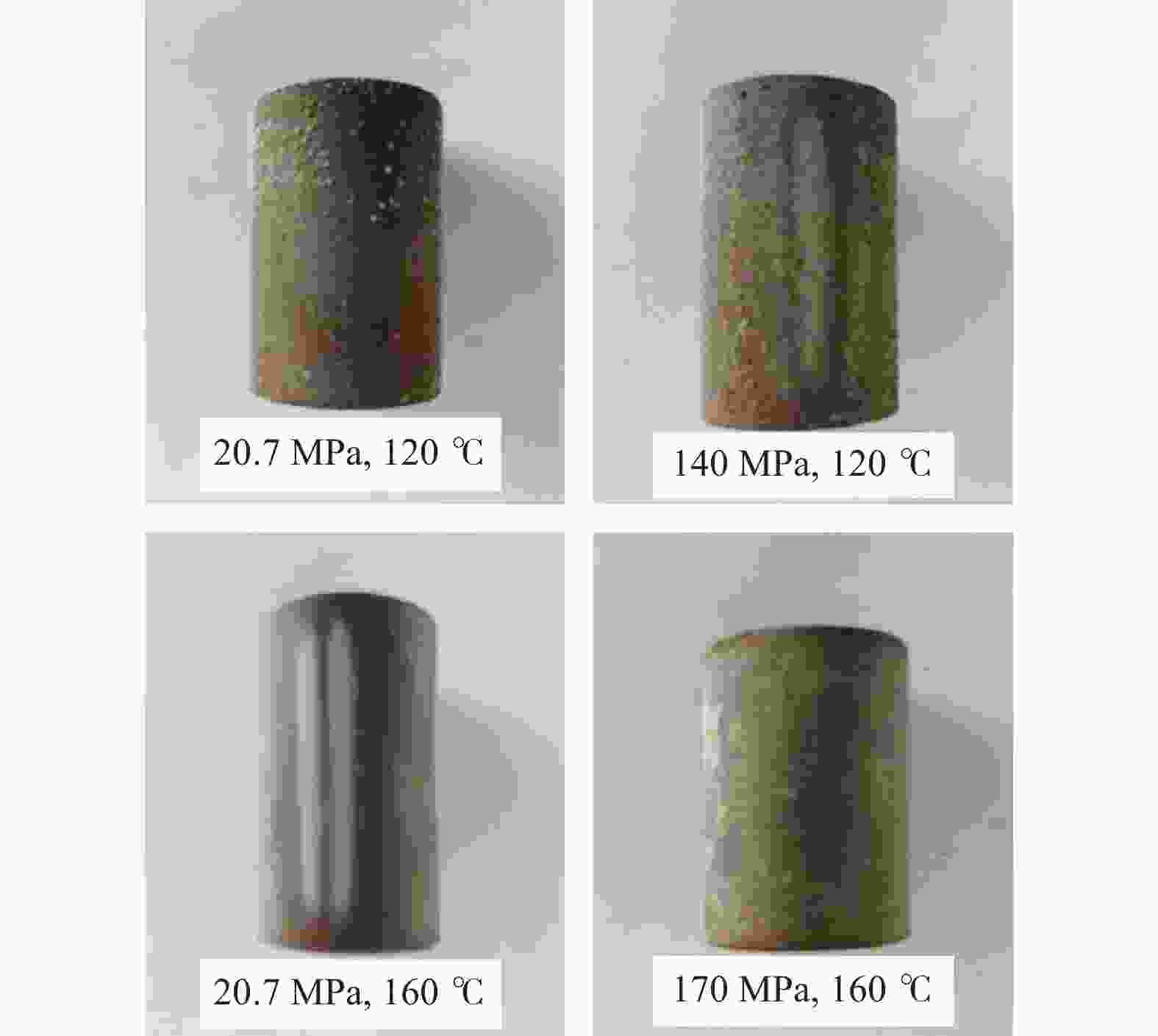

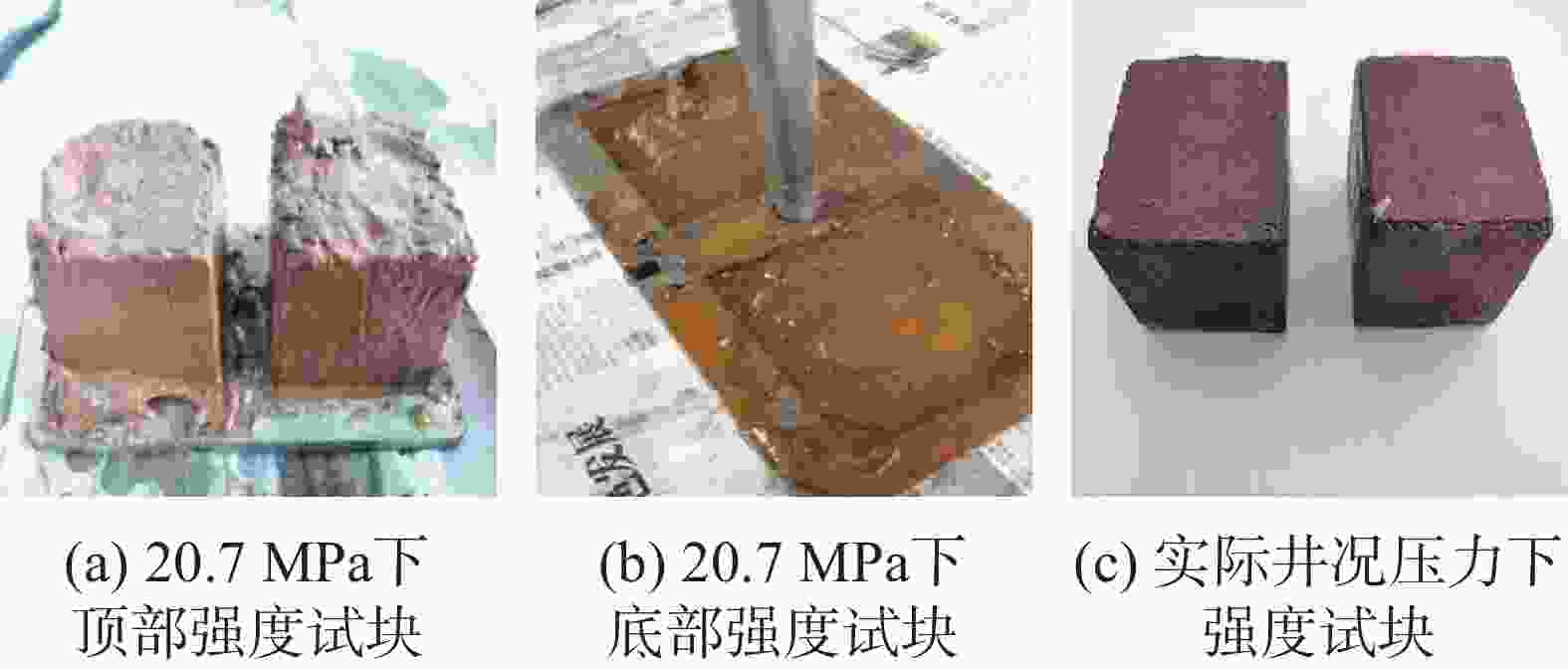

摘要: 准噶尔南缘区块是新疆油田增储上产的重点区块,井深6000~8000 m,预测井底温度为160 ℃,井底压力为170 MPa,属于典型的“三超”井。在该井区耐高温高压超高密度水泥浆基本性能的基础上,针对高温高压下超高密度水泥石的力学性能进行了研究。重点结合井下实际强度发育情况和实验室内强度发育结果吻合度相差较大的情况,按照该井区耐高温高压超高密度水泥浆体系配方,在120和160 ℃下,分别模拟井下实际压力和GB/T 19139—2012中要求的20.7 MPa压力下进行水泥试块的制备,开展常温抗压强度、抗折强度、单轴压缩实验以及井下温度下的三轴压缩实验,探究压力对超高密度水泥石抗压强度、抗折强度的影响以及试块的变形、破坏模式等力学特征。实验结果表明,压力是超高密度水泥石早期强度发展的关键因素之一;随着养护压力的增加,超高密度水泥试块的顶部抗压强度增加61.53%、底部抗压强度增加了120%;顶部抗折强度增加了65.2%,底部抗折强度增加了62.8%;常温下单轴压缩实验水泥石表现出明显的弹脆特性,在20.7 MPa下养护后试块端部出现明显破损,随着养护压力的增加,试块的峰值应力和弹性模量增加,抵抗变形破坏的能力增强;高温下的三轴压缩实验表明,超高密度水泥石的各项力学参数比单轴情况下均有较大提高,试块的变形均以轴向压缩变形为主,未形成明显的宏观裂纹,体现出良好的抵抗破坏变形的能力,更加接近线弹性-理想塑性材料。建议室内实验检测和模拟方法应充分考虑实际井况条件对水泥石力学性能的影响。Abstract: The south rim of the Junggar Basin is a key block for reserve increase of the Xinjiang oilfield. Wells drilled in this area are 6,000-8,000 m in depth, the bottom hole temperature and pressure of which are 160 ℃ and 170 MPa respectively, typical “three high” wells. Studies were conducted on the basic properties of the high temperature high pressure and ultra-high density cement slurries used in this area as well as the mechanical performance of the ultra-high density set cement under high temperature high pressure. In general laboratory studies, the strength development of a cement slurry is always quite different than the strength development of the same cement slurry in field operation. To understand the causes for this phenomenon, set cement test samples made from the typical cement slurry compositions used in this area were tested at 120 ℃ and 160 ℃, respectively under simulated actual downhole pressures and the pressure specified in the standard GB/T 19139—2012, which is 20.7 MPa. The tests include compressive strength test, flexural strength test and uniaxial compression test at room temperatures and triaxial compression test at actual downhole temperatures. Through these tests, the effects of pressure on the compressive strength and flexural strength of ultra-high density set cement, as well as the mechanical characteristics (deformation, failure mode etc.) of the set cement samples were investigated. The test results showed that pressure is one of the key factors affecting the development of the early strength of ultra-high density set cement. As the curing pressure increases, the compressive strengths of the top and bottom of the set cement were increased by 61.53% and 120%, respectively, the flexural strength of the top and bottom of the set cement were increased by 65.2% and 62.8%, respectively. Set cement tested in uniaxial compressive test at room temperatures showed obvious brittleness. After curing under 20.7 MPa, the ends of the set cement samples were obviously damaged. As the curing pressure was increased, the peak stress and elastic modulus were both increased, and the ability of the set cement samples to resist deformation failure was improved. High temperature triaxial compression test results showed that all mechanical parameters of ultra-high density set cement were greatly increased compared with the mechanical parameters obtained in uniaxial compression test, and the deformation of the set cement was mainly in a form of axial compression deformation, no obvious macro cracks were ever developed in the set cement, indicating that the set cement performed very well in resisting deformation failure, and was more like a linear-elastic – ideal plastic material. It is suggested that in laboratory examination and simulation experiment, the effects of actual downhole conditions on the mechanical performance of set cement be taken into account.

-

表 1 实际井况下超高密度水泥石8 h抗压强度

p8 h,底部/MPa

(160 ℃、170 MPa)p8 h,顶部/MPa

(120 ℃、140 MPa)9.42 8.33 5.33 2.60 6.55 8.62 6.20 3.88 7.32 9.11 4.93 4.07 5.78 8.41 3.88 4.22 6.62 5.43 4.62 3.86 8.25 6.74 4.44 2.12 表 2 20.7 MPa下超高密度水泥石抗压强度

p24 h,底部/MPa

(160 ℃、20.7 MPa)p48 h,顶部/MPa

(120 ℃、20.7 MPa)18.55 18.94 14.30 12.88 17.68 20.38 15.51 16.22 18.69 21.22 17.35 19.00 16.33 20.48 14.88 14.28 19.03 17.58 18.69 13.96 21.32 20.08 13.09 13.02 表 3 实际井况压力下超高密度水泥石抗压强度

p24 h,底部/MPa

(160 ℃、170 MPa)p48 h,顶部/MPa

(120 ℃、140 MPa)45.32 46.25 22.90 27.42 44.36 40.23 25.81 24.41 48.32 41.58 27.31 24.39 44.02 40.66 20.65 23.99 39.57 37.65 24.33 27.03 45.32 46.25 22.90 27.42 表 4 超高密度水泥石抗压强度离散性分析

养护条件 μ/MPa σ CV/% 120 ℃、 20.7 MPa 15.26 2.14 13.90 120 ℃、 140 MPa 24.65 2.38 9.66 160 ℃、 20.7 MPa 19.19 1.55 8.06 160 ℃、 170 MPa 42.22 3.34 7.91 注:变异系数计算公式:CV = σ/μ,其中,CV为变异系数,σ为标准偏差,μ为平均抗压强度 表 5 超高密度水泥石的抗折强度

48 h抗折强度/

MPa(120 ℃)24 h抗折强度/

MPa(160 ℃)20.7 MPa 140 MPa 20.7 MPa 170 MPa 5.42 8.76 7.33 13.48 4.70 9.01 8.24 12.66 4.21 6.58 8.36 12.47 3.98 7.33 8.02 13.00 5.21 7.01 7.55 11.98 4.07 6.97 7.45 12.60 表 6 超高密度水泥石力学参数统计结果

项目 养护条件 围压/

MPaT/

℃峰值应力/

MPa弹性模量/

GPa泊松比 单轴 120 ℃、 20.7 MPa 0 25 19.6 2.9 0.15 120 ℃、 140 MPa 0 25 23.6 5.8 0.18 160 ℃、 20.7 MPa 0 25 20.8 6.3 0.22 160 ℃、 170 MPa 0 25 38.6 7.5 0.24 三轴 120 ℃、 20.7 MPa 21 120 20.1 7.0 0.09 120 ℃、 140 MPa 21 120 24.2 6.0 0.08 160 ℃、 20.7 MPa 21 160 21.7 9.0 0.07 160 ℃、 170 MPa 21 160 37.4 8.0 0.05 -

[1] 刘崇健, 黄柏宗, 徐同台, 等. 油气井注水泥理论与应用[M]. 石油工业出版社, 2001.LIU Chongjian, HUANG Baizong, XU Tongtai, et al. Theory and application of cementing in oil and gas well[M]. Petroleum Industry Press, 2001. [2] 汪汉花,高莉莉. 固井水泥石力学性能研究现状浅析[J]. 西部探矿工程,2010,22(4):70-74. doi: 10.3969/j.issn.1004-5716.2010.04.026WANG Hanhua, GAO Lili. Study on mechanical properties of oil well cement[J]. West-China Exploration Engineering, 2010, 22(4):70-74. doi: 10.3969/j.issn.1004-5716.2010.04.026 [3] 王磊,曾义金,张青庆,等. 高温环境下油井水泥石力学性能实验[J]. 中国石油大学学报(自然科学版),2018,42(6):89-94.WANG Lei, ZENG Yijin, ZHANG Qingqing, et al. Experimental study on mechanical properties of oil well cement under high temperature[J]. Journal of China University of Petroleum(Edition of Natural Science) , 2018, 42(6):89-94. [4] 中国石油集团工程技术研究院. GB/T 19139—2012油井水泥实验方法[S]. 北京: 中国标准出版社, 2012.CNPC Engineering Technology Research Institute. GB/T 19139—2012 Testing of well cements [S]. Beijing: China Standard Press, 2012. [5] BERGS, NOORS, BARNETTN, et al. Cementing high pressure formations in the Kingdom of Saudi Arabia[R]. SPE120802, 2008. [6] 杨广国,陶谦,高元,等. 高温高压气井复合型水泥浆体系研究与应用[J]. 科学技术与工程,2016,16(20):151-155. doi: 10.3969/j.issn.1671-1815.2016.20.026YANG Guangguo, TAO Qian, GAO Yuan, et al. Reaserch and application of high temperature high pressure gas well complex cement slurry[J]. Science Technology and Engineering, 2016, 16(20):151-155. doi: 10.3969/j.issn.1671-1815.2016.20.026 [7] 张景富. G 级油井水泥的水化硬化及性能[D]. 浙江: 浙江大学, 2001.ZHANG Jingfu. Hydration, hardening and properties of class G oil well cement[D]. Zhejiang: Zhejiang University, 2001. [8] LYOMOV S K. Disscussion of modelling early-time gas migration through cement slurries[J]. SPE Drilling & Completion, 1996(6):125. [9] WITTMANN F H. Interaction of hardened cement paste and water[J]. J. Amer. Ceram. Soc., 1973, 56(8):409-415. doi: 10.1111/j.1151-2916.1973.tb12711.x [10] PROHASKA M, FRUHWIRTH R, ECONOMIDES M J. Authors’ reply to discussion of modelling early-time gas migration through cement slurries[J]. SPE Drilling & Completion, 1996, 11(4):126. [11] 叶中郎,朱泽华,吴品华,等. 温度, 压力及 pH 值对水泥固化的影响[J]. 中国水泥,2016,16(20):151-155.YE Zhonglang, ZHU Zehua, WU Pinhua, et al. The influence of temperature, pressure and pH on cement solidification[J]. China Cement, 2016, 16(20):151-155. -

下载:

下载: