Study and Application of Fluid Loss Additive Used in Cement Slurries for Cementing Salt-Gypsum Stratum

-

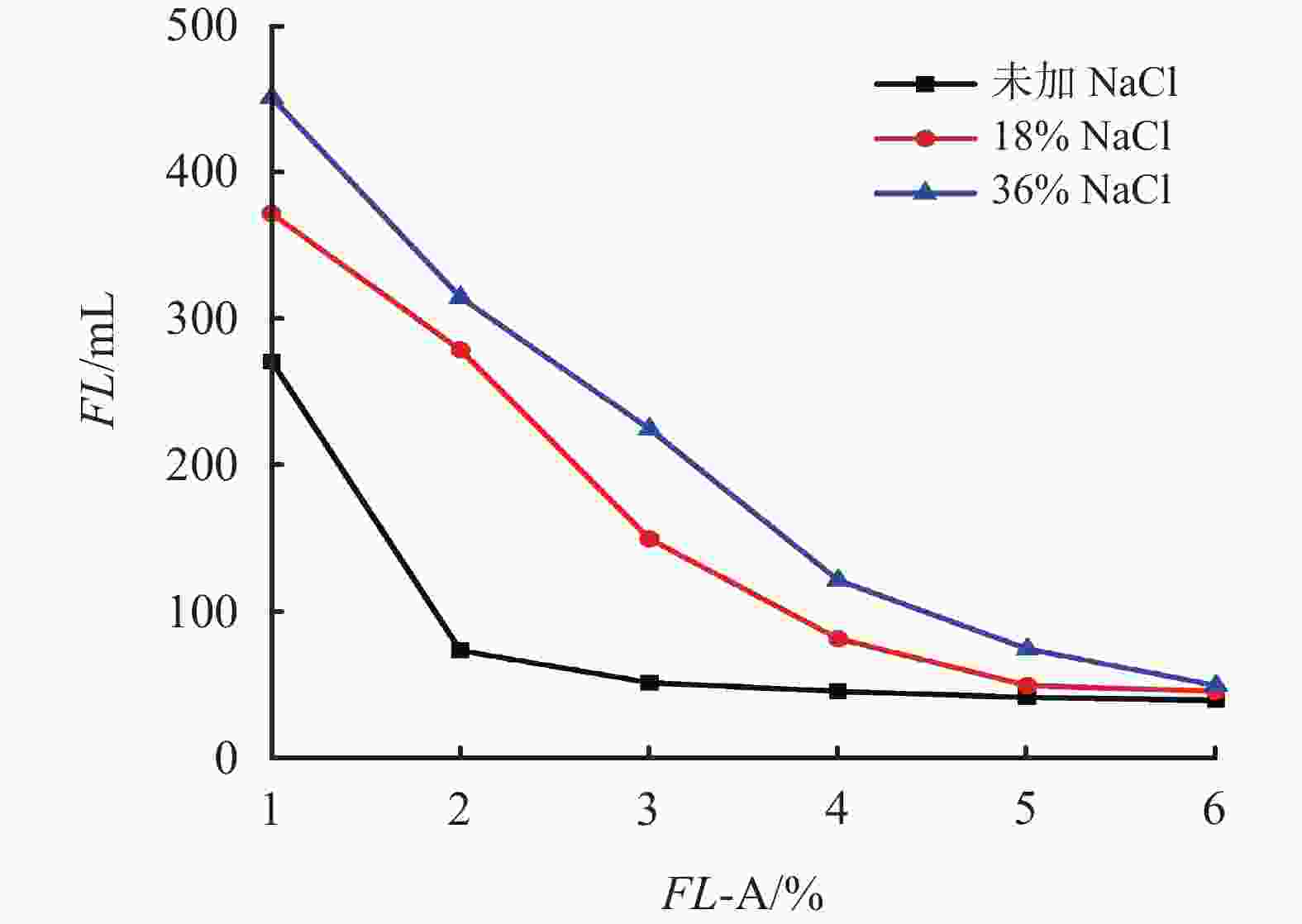

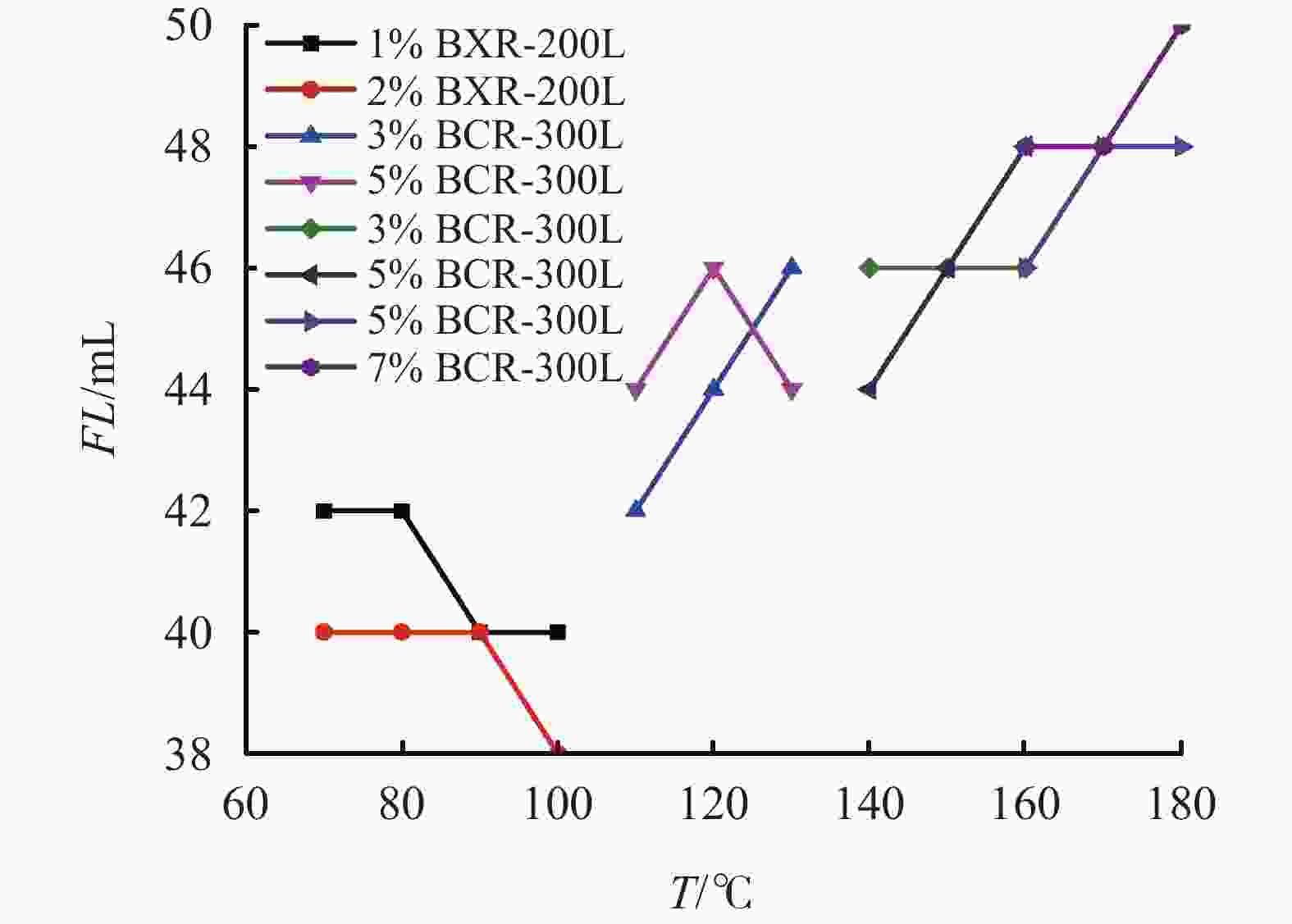

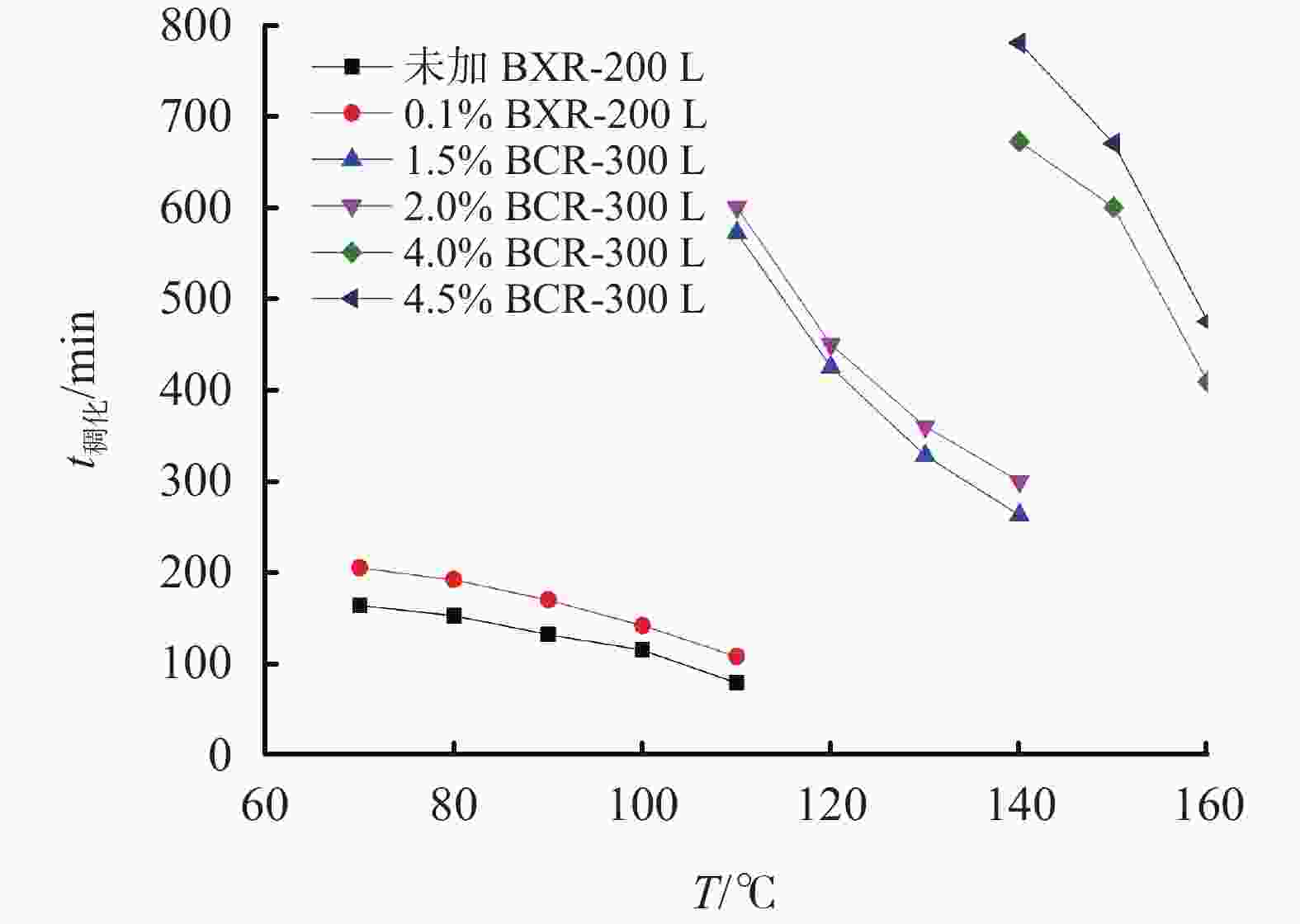

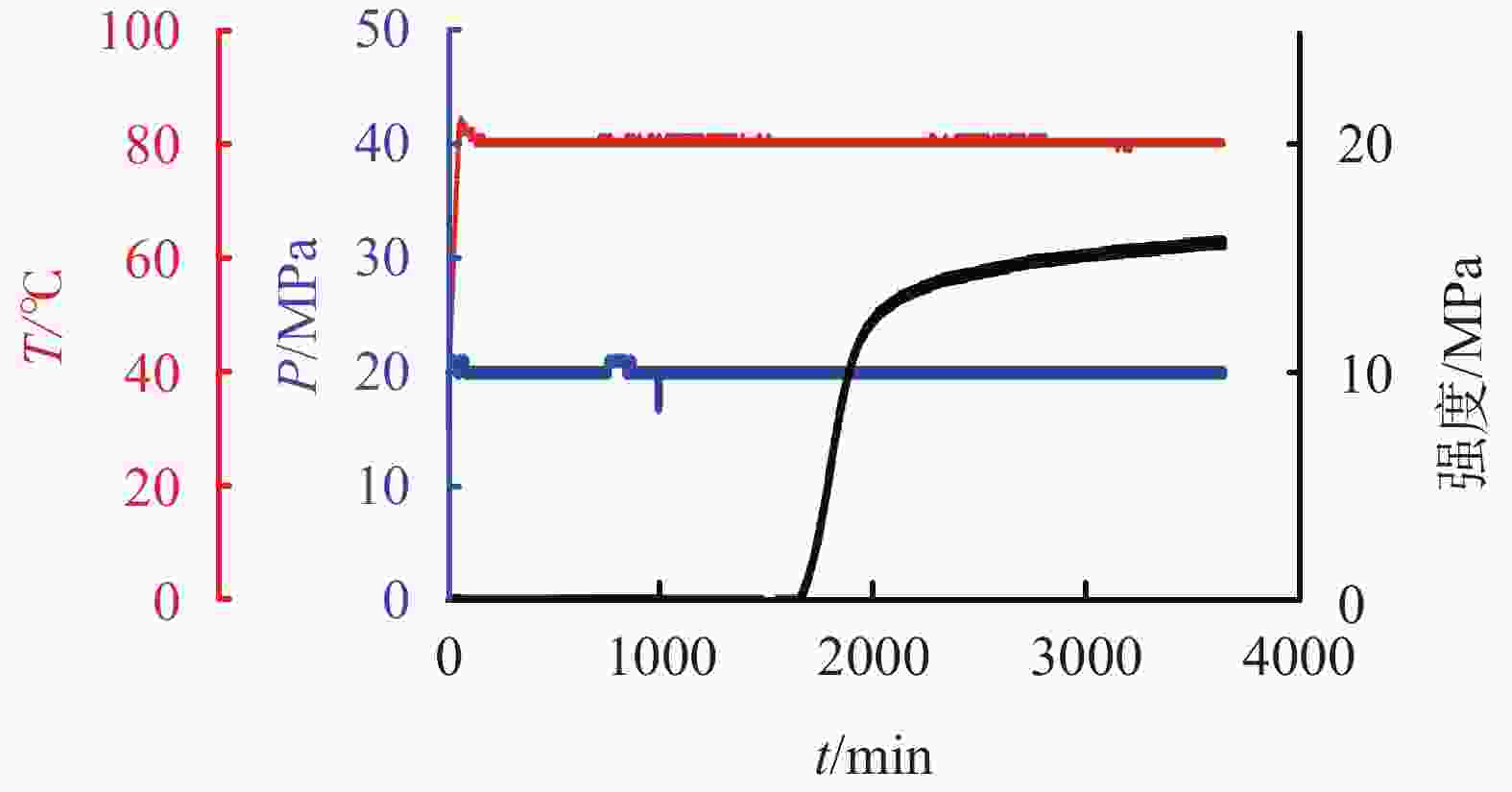

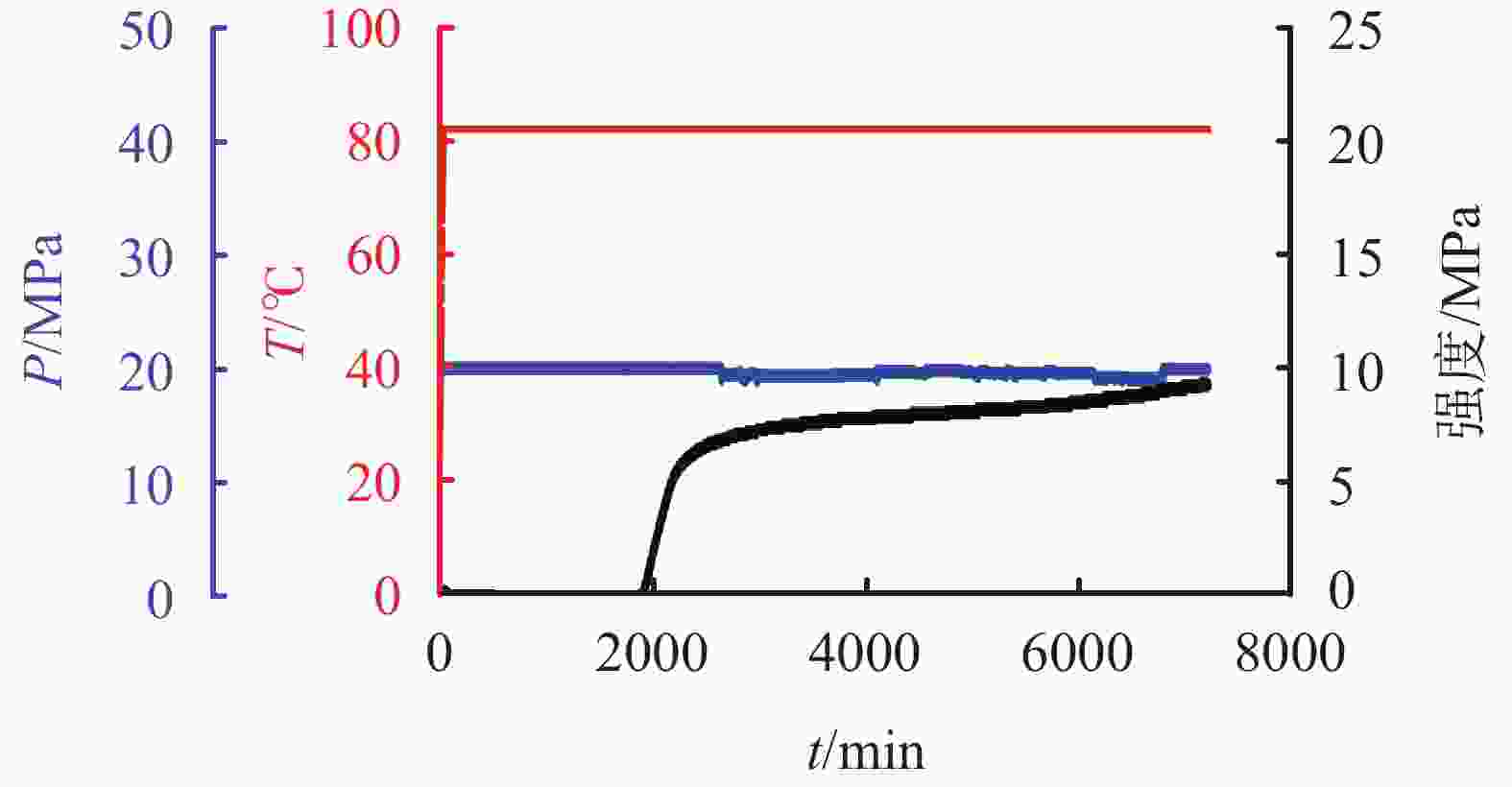

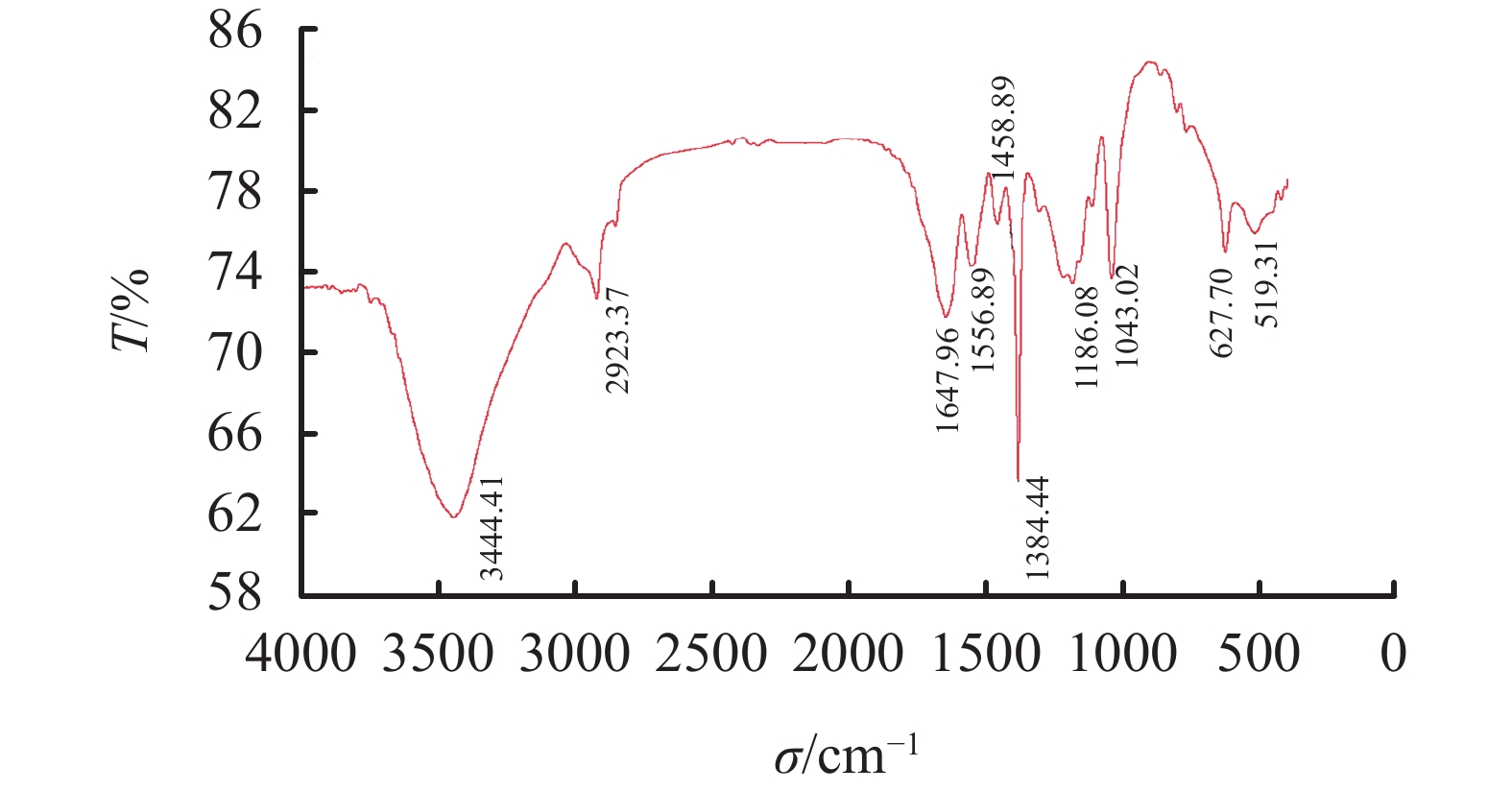

摘要: 针对塔里木油田库车山前高压天然气井盐膏层溢漏同存、安全密度窗口窄等固井难题,通过优选功能性单体,合成了具有耐温抗盐且分散性好等特性的降失水剂FL-A。红外光谱分析结果表明,单体均参与了聚合反应;热重分析结果表明,FL-A具有良好的耐热性能,耐温达300 ℃;水泥浆性能评价表明,该降失水剂控失水性能好,抗盐达饱和,与其他外加剂配伍性好,稠化线型正常。采用该降失水剂配制的密度为2.3~2.6 g/cm3含盐高密度水泥浆体系在105~180 ℃高温下具有液固比低、失水量小、沉降稳定性好、流变性能优、强度发展快等特性。在盐膏层固井应用10余井次,封固质量良好,高压盐水均得到有效封隔。Abstract: High pressure natural gas well cementing in the piedmont structure in Kuche, Tarim Basin has encountered problems such as coexistence of well kick and mud losses in the salt-gypsum stratum, and narrow safe drilling windows etc. To deal with these problems, some functional monomers were selected and used to produce a fluid loss additive FL-A with high temperature tolerance, salt resistance and good dispersibility. IR analysis showed that the monomers all took part in the polymerization reaction. Thermogravimetric analysis showed that FL-A has good thermal stability; it functions normally at 300 ℃. In laboratory evaluation, cement slurries treated with FL-A has good filtration control capacity, and can be used in salt-saturated cement slurries. FL-A has good compatibility with other additives and normal thickening curve. Several cement slurries, with their densities between 2.3 g/cm3 and 2.6 g/cm3, were formulated with saturated saltwater and treated with FL-A. These cement slurries have low liquid/solid ratios, low filtration rate, good settling stability, excellent rheology and fast-developing strengths. They have been used more than 10 times in cementing wells penetrating salt-gypsum stratum, the job quality was satisfactory and the high pressure formation saltwater was effectively isolated.

-

表 1 掺有FL-A的水泥浆流变性能

FL-A/% NaCl/% FL/mL n K/Pa·sn 3 0 52 0.69 0.69 4 46 0.67 0.82 4 18 82 0.72 0.55 5 50 0.75 0.48 6 46 0.81 0.42 5 36 75 0.85 0.12 6 48 0.87 0.13 7 42 0.87 0.14 表 2 含盐高密度水泥浆的性能

配方 ρ/

g·cm−3液固

比T/

℃P/

MPa流动

度/cmFL/

mL游离

液/%t稠化/

min△ρ/

g·cm−3p24 h/

MPa1# 2.30 0.316 120 140 24.0 30 0 512 0.05 27.1 1# 2.30 0.316 130 140 24.0 30 0 421 0.05 2# 2.40 0.296 140 160 24.5 32 0 471 0.04 2# 2.40 0.296 150 160 24.5 32 0 382 0.04 29.2 3# 2.45 0.306 105 120 24.0 38 0 495 0.02 26.8 4# 2.50 0.284 160 180 24.5 36 0 483 0.05 36.2 4# 2.50 0.284 170 180 24.5 36 0 398 0.05 5# 2.60 0.280 180 180 25.0 36 0 450 0.03 34.6 表 3 含盐高密度水泥浆的流变性能

配方 φ3 φ6 φ100 φ200 φ300 φ600 K/(Pa·sn) 1# 2 4 50 86 117 202 0.44 2# 2 4 53 95 129 223 0.47 3# 3 6 58 103 145 256 0.42 4# 3 6 56 104 146 240 0.40 5# 3 5 51 93 138 253 0.35 -

[1] 周健,贾红军,刘永旺,等. 库车山前超深超高压盐水层安全钻井技术探索[J]. 钻井液与完井液,2017,34(1):54-59. doi: 10.3969/j.issn.1001-5620.2017.01.010ZHOU Jian, JIA Hongjun, LIU Yongwang, et al. Research on safe drilling technology for ultra deep ultrahigh pressure saltwater zones in piedmont area, Kuche[J]. Drilling Fluid & Completion Fluid, 2017, 34(1):54-59. doi: 10.3969/j.issn.1001-5620.2017.01.010 [2] 刘伟,周英操,石希天,等. 塔里木油田库车山前超高压盐水层精细控压钻井技术[J]. 石油钻探技术,2020,48(2):23-28. doi: 10.11911/syztjs.2020034LIU Wei, ZHOU Yingcao, SHI Xitian, et a1. Precise managed pressure drilling technology for ultra-high pressure brine layer in the Kuqa piedmont of the Tarim oilfield[J]. Petroleum Drilling Techniques, 2020, 48(2):23-28. doi: 10.11911/syztjs.2020034 [3] 李晓春,李坤,刘锐,等. 塔里木盆地超深天然气井全过程塞流防漏注水泥技术[J]. 天然气工业,2016,39(10):102-109. doi: 10.3787/j.issn.1000-0976.2016.10.013LI Xiaochun, LI Kun, LIU Rui, et al. Plug flow based full-process leakage-proof cementing technology for ultra-deep gas wells in the Tarim basin[J]. Natural Gas Industry, 2016, 39(10):102-109. doi: 10.3787/j.issn.1000-0976.2016.10.013 [4] 刘洪涛,黎丽丽,吴军,等. 库车山前高温高压气井测试管柱优化配置与应用[J]. 钻采工艺,2016,39(5):42-45. doi: 10.3969/J.ISSN.1006-768X.2016.05.14LIU Hongtao, LI Lili, WU Jun, et a1. Optimum configuration and application of well testing string for ultra-deep HTHP gas wells in Kuqa, Tarim[J]. Drilling & Production Technology, 2016, 39(5):42-45. doi: 10.3969/J.ISSN.1006-768X.2016.05.14 [5] NELSON E B, GUILLOT. Well cementing[M], 3nd Edition. Sugar Land, TX: Schlumberger Dowell, 2006. [6] 刘崇建, 黄柏宗, 徐同台. 等. 油气井注水泥理论与应用[M]. 北京: 石油工业出版社, 2001.LIU Chongjian, HUANG Baizong, XU Tongtai, et a1. The theory and application of the primary cementing [M]. Beijing: Petroleum Industry Press, 2001. [7] 袁燊. 高密度水泥浆体系研究[D]. 中国石油大学(华东), 2013.YUAN Shen. Research on high density cement slurry system[D]. China University of Petroleum(East China), 2013. [8] 郭锦棠,卢海川,刘硕琼,等. 新型固井降失水剂HTF-200C[J]. 石油勘探与开发,2012,39(3):359-364.GUO Jintang, LU Haichuan, LIU Shuoqiong, et al. The novel fluid loss additive HTF-200C for oil field cementing[J]. Petroleum Exploration and Development, 2012, 39(3):359-364. [9] 郭锦棠,夏修建,刘硕琼,等. 适用于长封固段固井的新型高温缓凝剂HTR-300L[J]. 石油勘探与开发,2013,40(5):611-615. doi: 10.11698/PED.2013.05.16GUO Jintang, XIA Xiujian, LIU Shuoqiong, et al. Synthesis and performance research of a new high temperature retarder used in long cementing segment[J]. Petroleum Exploration and Development, 2013, 40(5):611-615. doi: 10.11698/PED.2013.05.16 [10] 郭锦棠,邹双,喻文娟,等. 新型固井降失水剂HTF-210C的研发及性能评价[J]. 天津大学学报(自然科学与工程技术版),2016,49(3):261-266.GUO Jintang, ZOU Shuang, YU Wenjuan, et al. Preparation and performance of new fluid loss additive HTF-210C for oil well cementing[J]. Journal of Tianjin University(Science and Technology) , 2016, 49(3):261-266. [11] 邹建龙,屈建省,吕光明,等. 新型固井降失水剂BXF-200L的研制与应用[J]. 钻井液与完井液,2005,22(2):20-23. doi: 10.3969/j.issn.1001-5620.2005.02.006ZOU Jianlong, QU Jianxing, LYU Guangming, et al. Preparation and application of novel fluid loss additive BXF-200L for oil field cementing[J]. Drilling Fluid & Completion Fluid, 2005, 22(2):20-23. doi: 10.3969/j.issn.1001-5620.2005.02.006 [12] 于永金,刘硕琼,刘丽雯,等. 高温水泥浆降失水剂DRF-120L的制备及评价[J]. 石油钻采工艺,2011,33(3):24-27. doi: 10.3969/j.issn.1000-7393.2011.03.007YU Yongjin, LIU Shuoqiong, LIU Liwen, et al. Preparation and evaluation of high temperature cement slurry loss reduction additive DRF-120L[J]. Oil Drilling & Production Technology, 2011, 33(3):24-27. doi: 10.3969/j.issn.1000-7393.2011.03.007 [13] TIEMEYER C, PLANK J. Working mechanism of a high temperature (200 ℃) synthetic cement retarder and its interaction with an AMPS®-based fluid loss polymer in oil well cement[J]. Journal of Applied Polymer Science, 2012, 124(6):4772-4781. [14] LUMMER N R, PLANK J. Combination of lignosulfonate and AMPS®-co-NNDMA water retention agent—An example for dual synergistic interaction between admixtures in cement[J]. Cement and Concrete Research, 2012, 42(5):728-735. doi: 10.1016/j.cemconres.2012.02.009 [15] PLANK J, BRANDL A, LUMMER N R. Effect of different anchor groups on adsorption behavior and effectiveness of poly (N, N-dimethylacrylamide-co-Ca2-acrylamido-2-methylpropanesulfonate) as cement fluid loss additive in presence of acetone-formaldehyde-sulfite dispersant[J]. Journal of Applied Polymer Science, 2007, 106(6):3889-3894. doi: 10.1002/app.26897 [16] 李晓岚, 郑志军, 郭鹏. 高温油井水泥降失水剂ZFA-1的合成及性能[J]. 钻井液与完井液, 2020, 37(2): 209-213,220.LI Xiaolan, ZHENG Zhijun, GUO Peng. Synthesis and performance of high temperature filter loss reducer ZFA-1 for oil well cement slurries[J]. Drilling Fluid & Completion Fluid, 2020, 37(2): 209-213,220. [17] 夏修建, 于永金, 靳建洲, 等. 耐高温抗盐固井降失水剂的制备及性能研究[J]. 钻井液与完井液, 2019, 36(5): 610-616.XIA Xiujian, YU Yongjin, JIN Jianzhou, et al. Development and study on a high temperature salt resistant filter loss reducer for well cementing[J]. Drilling Fluid & Completion Fluid, 2019, 36(5): 610-616. [18] 刘文明, 付家文, 胡星彤, 等. 抗高温抗盐多元共聚物类降失水剂的研究与应用[J]. 钻井液与完井液, 2014, 31(6): 52-54.LIU Wenming,FU Jiawen, HU Xingtong,et al.Synthesis and evaluation of a copolymer filter loss reducer BZF-L1[J].Drilling Fluid & Completion Fluid,2014, 31(6): 52-54. -

下载:

下载: