High Temperature Resistance of Conventional Set Sand Cement under Cumulative Working Conditions

-

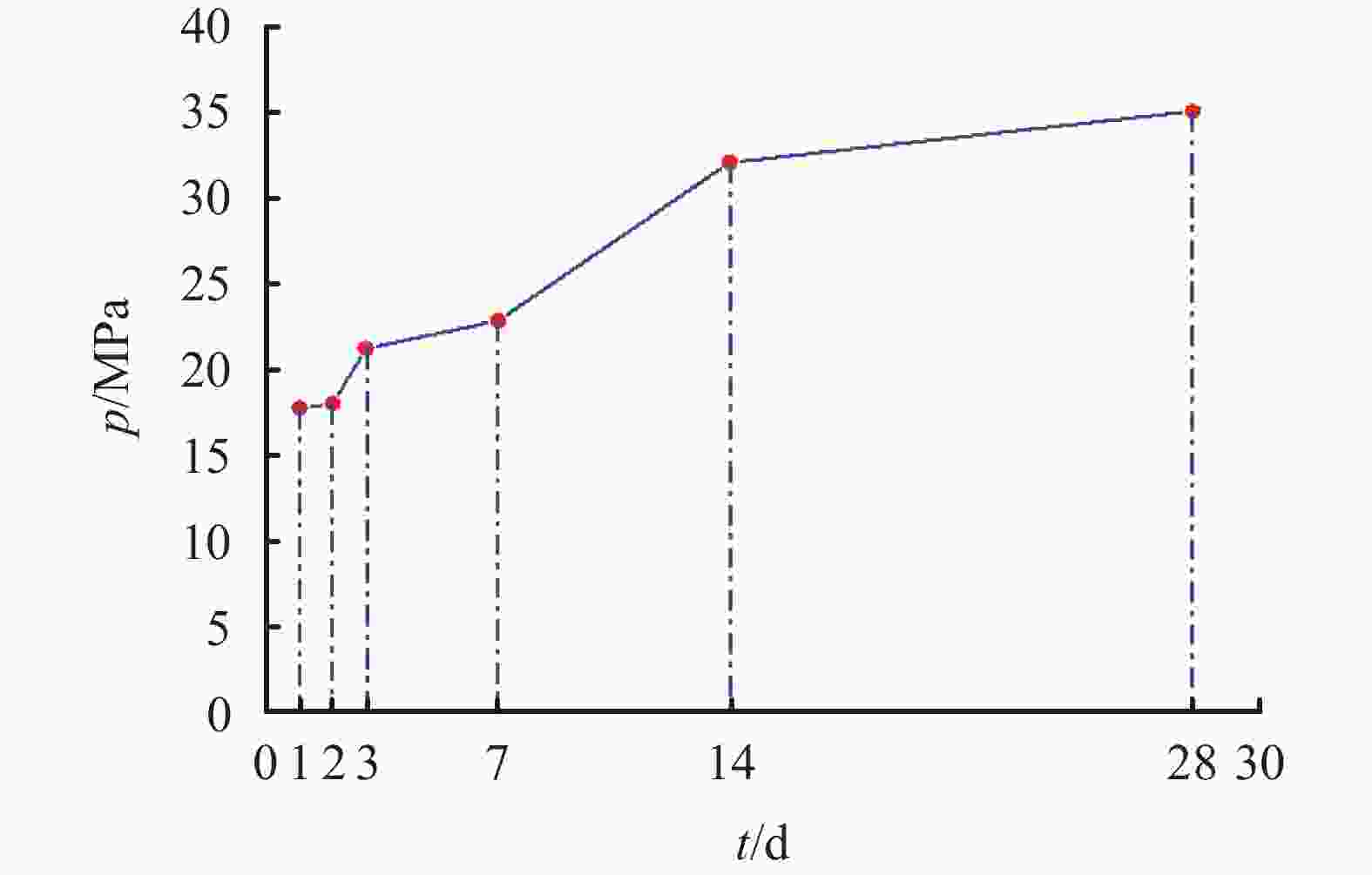

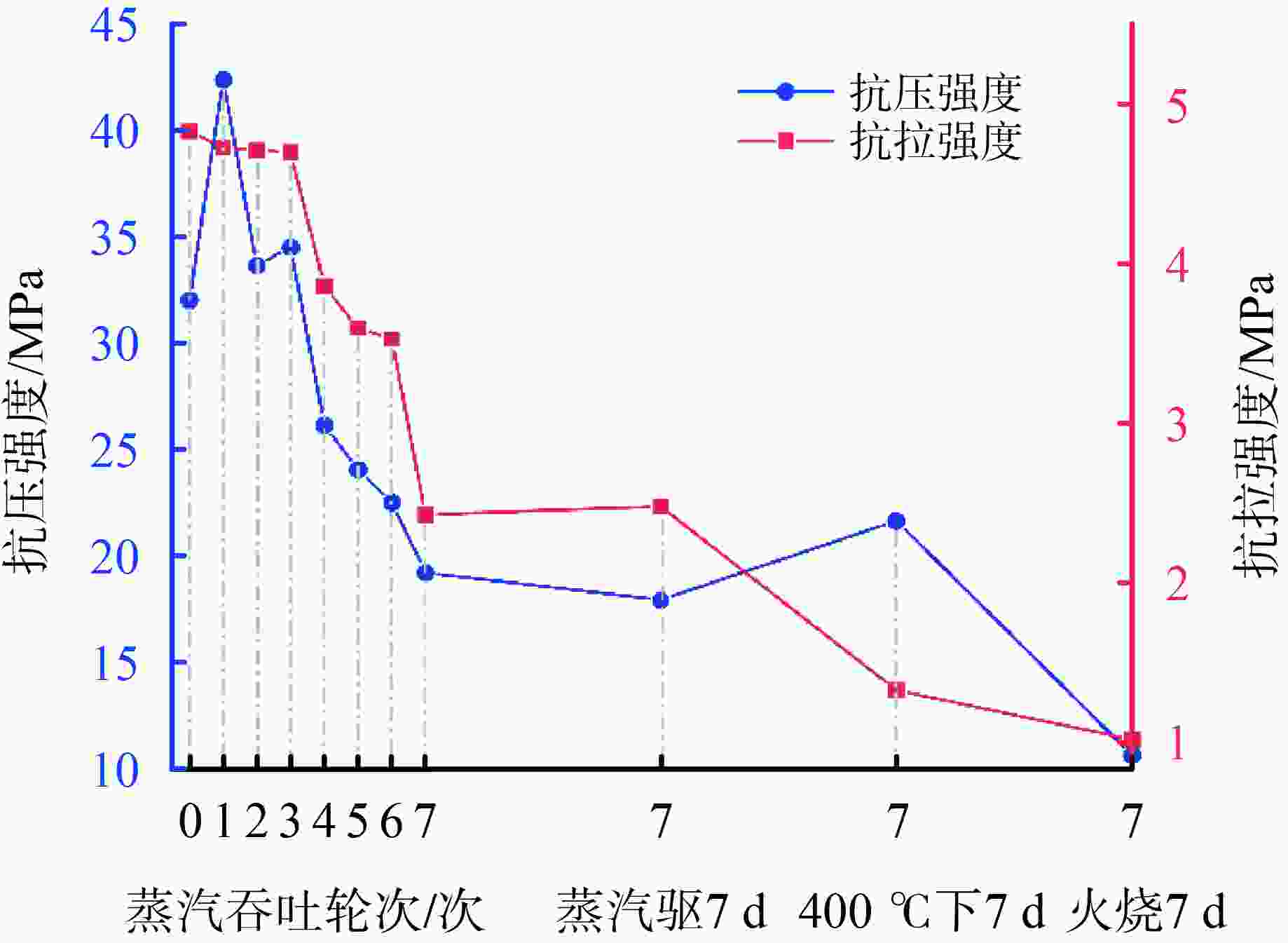

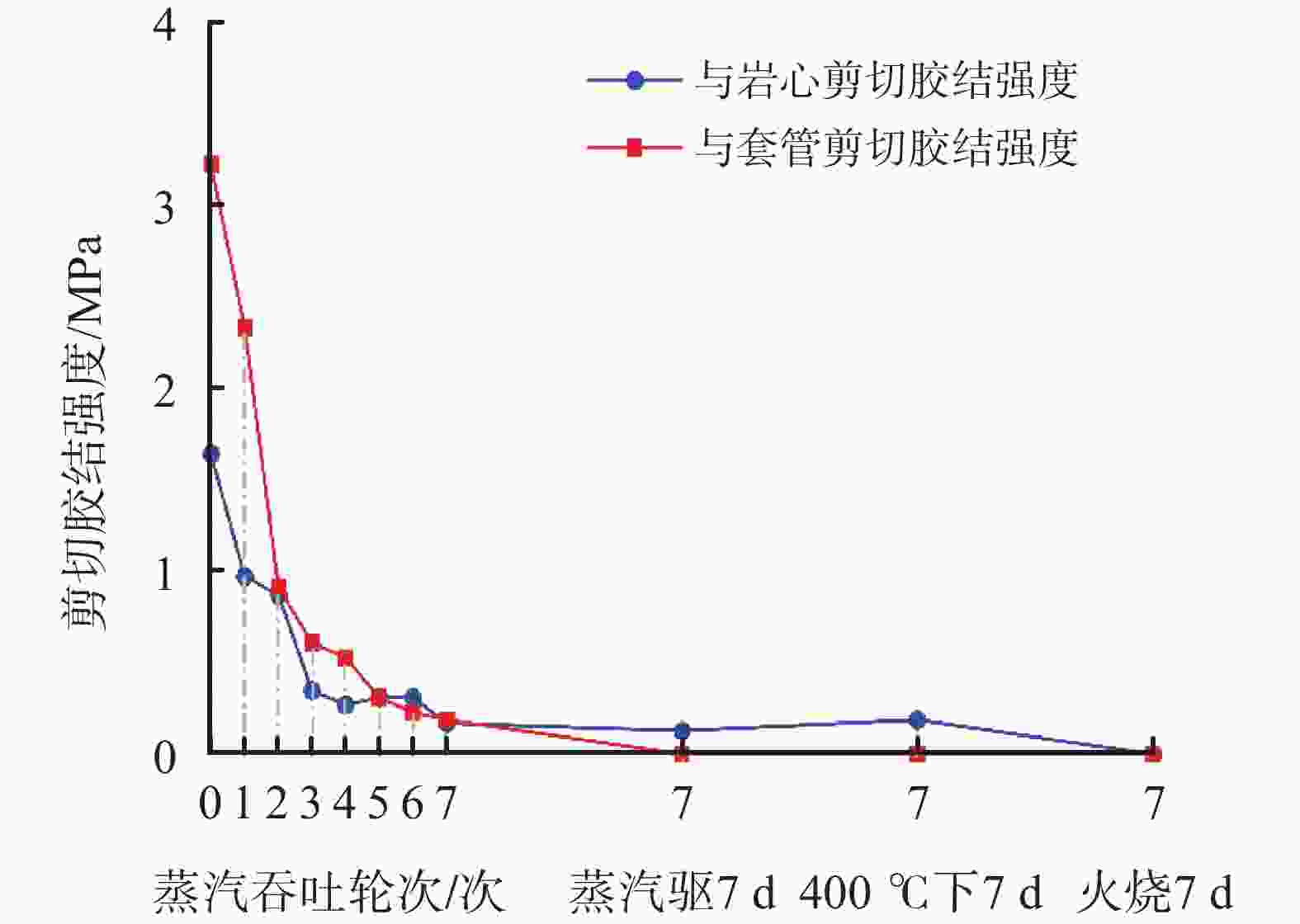

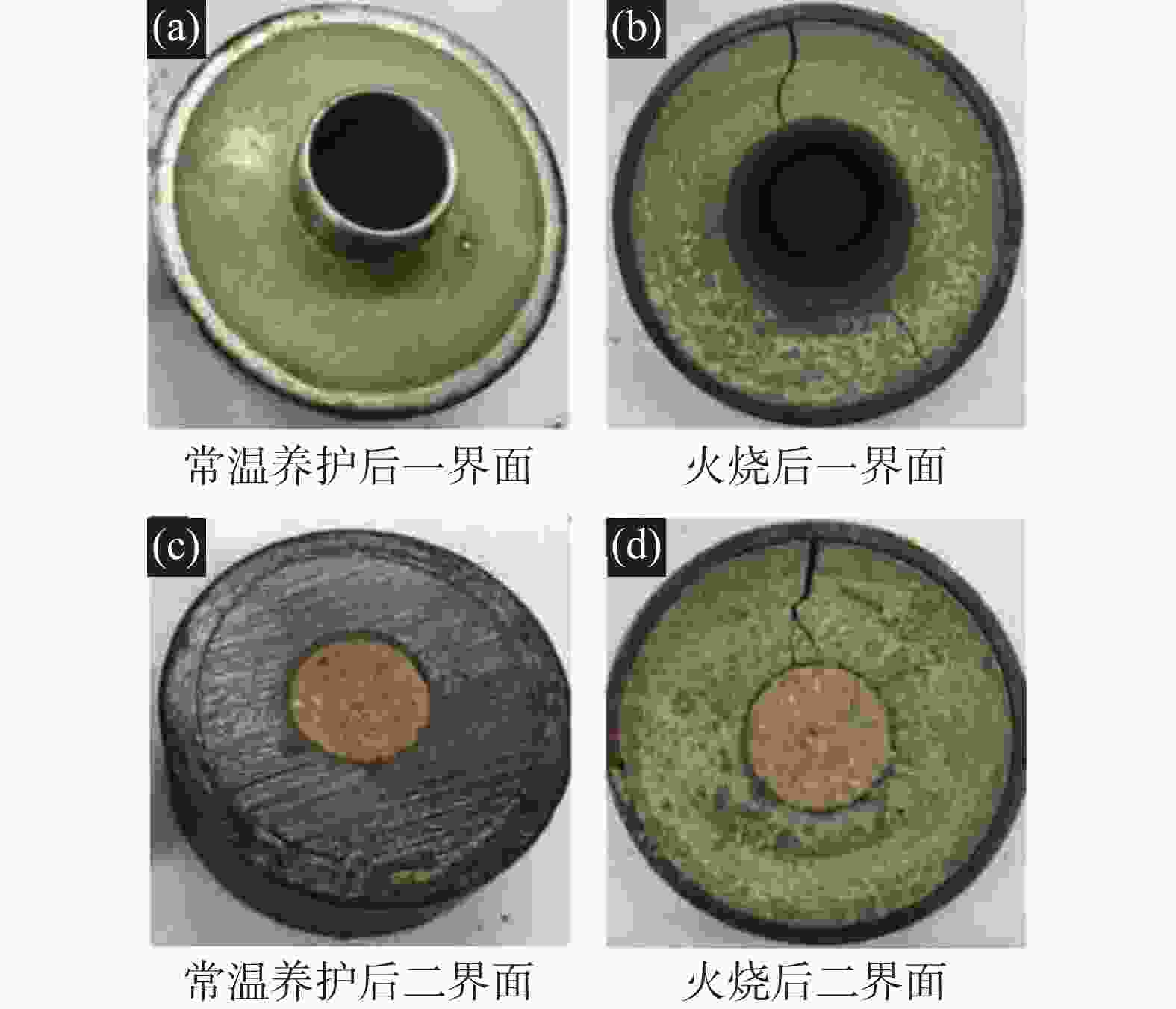

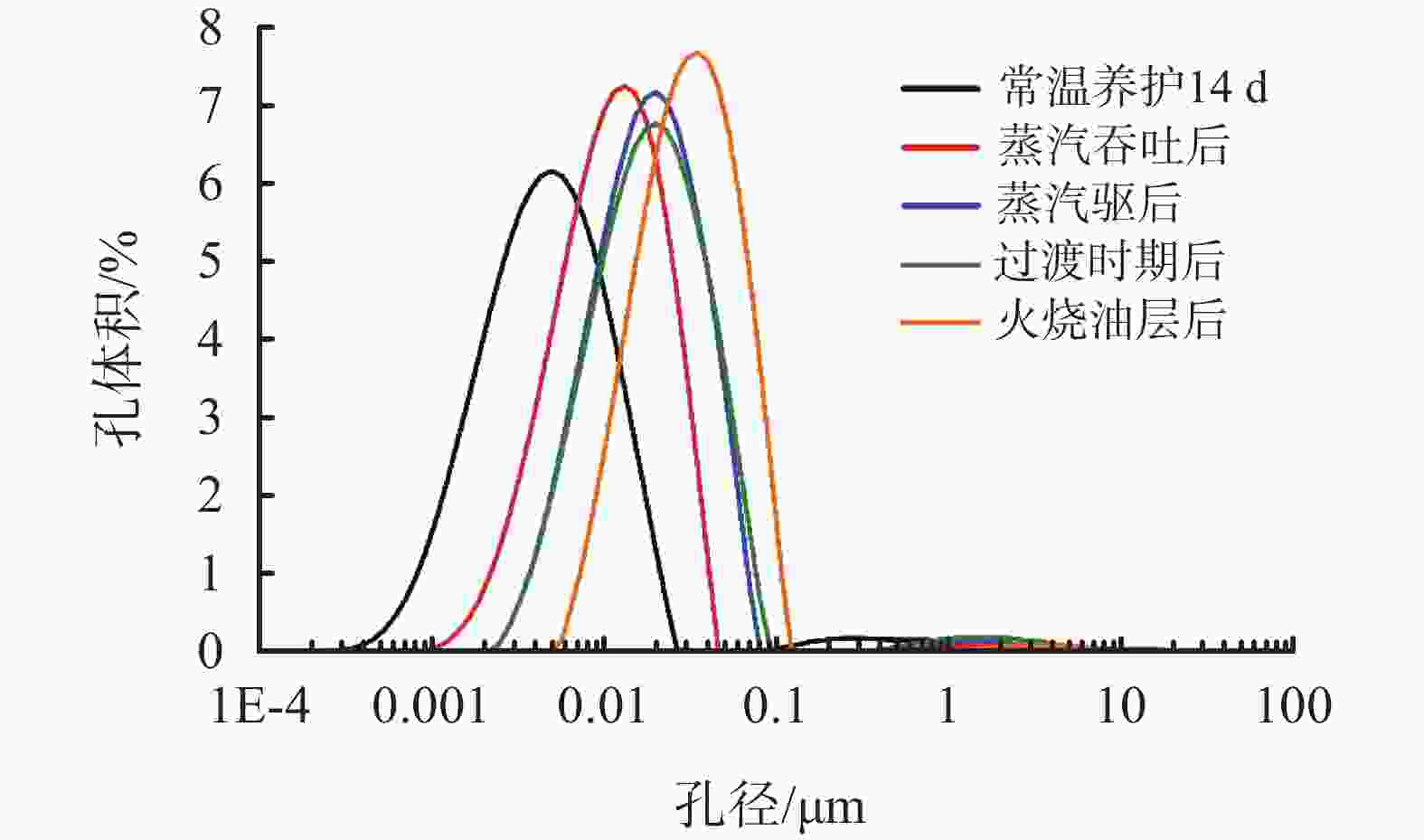

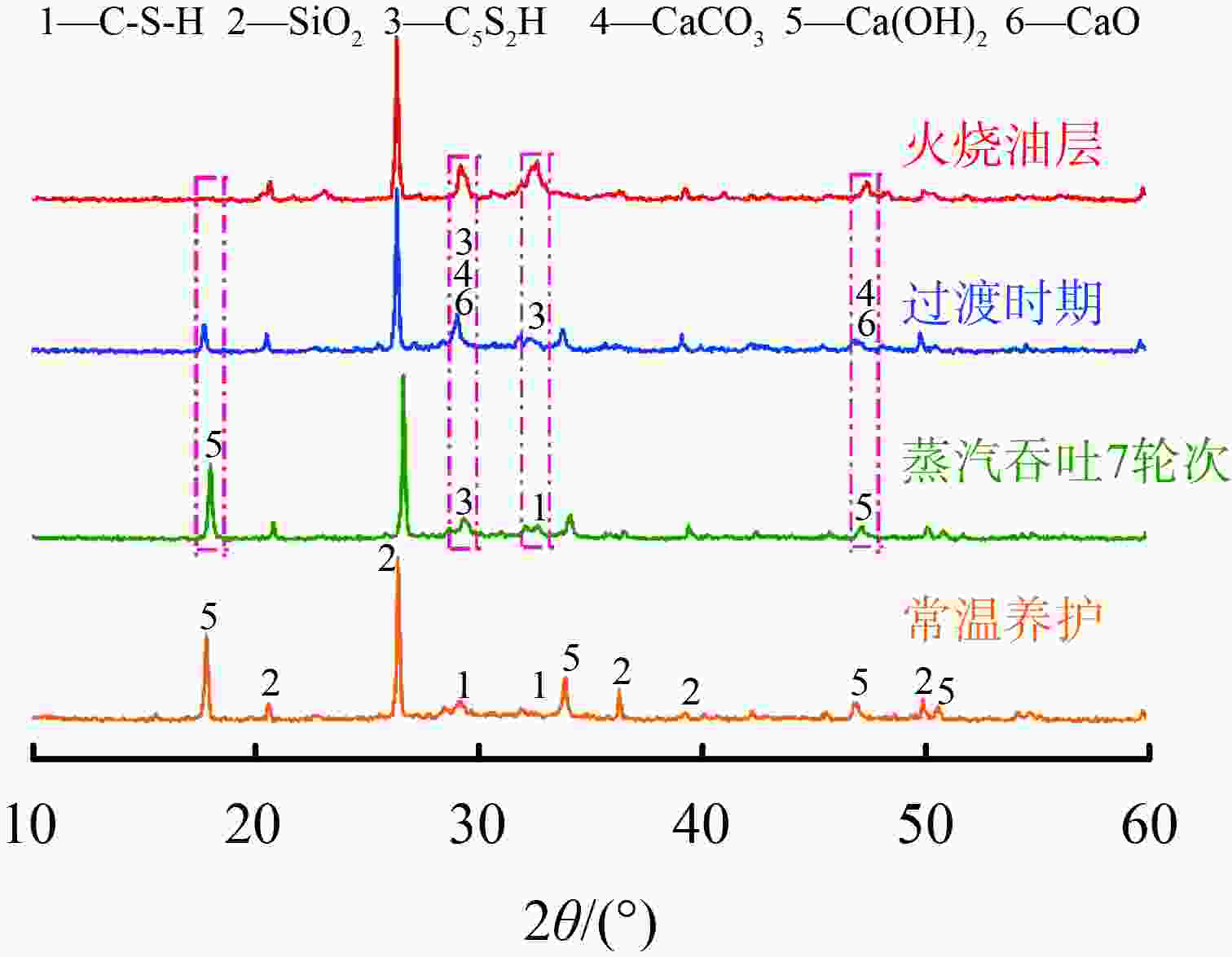

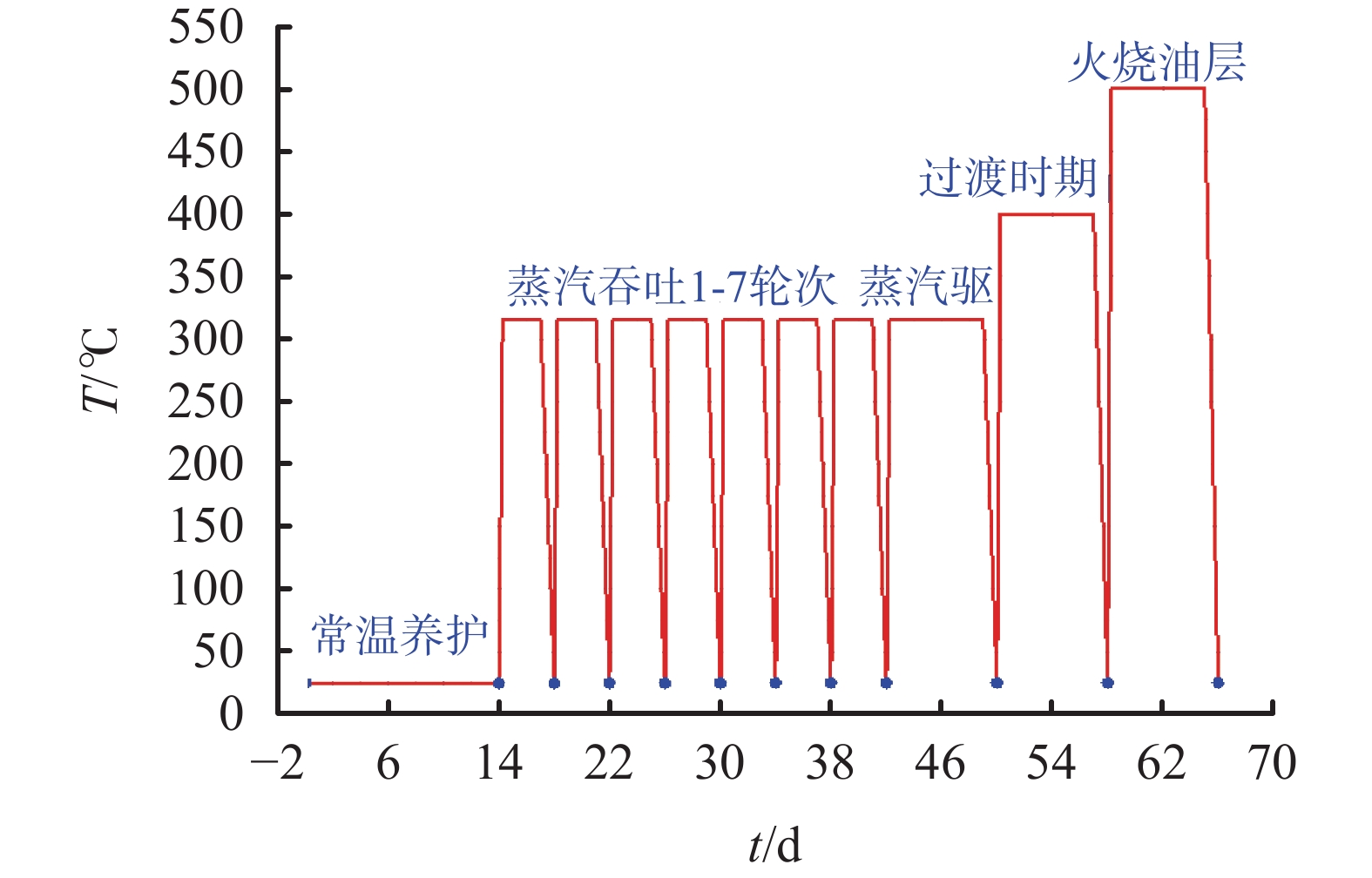

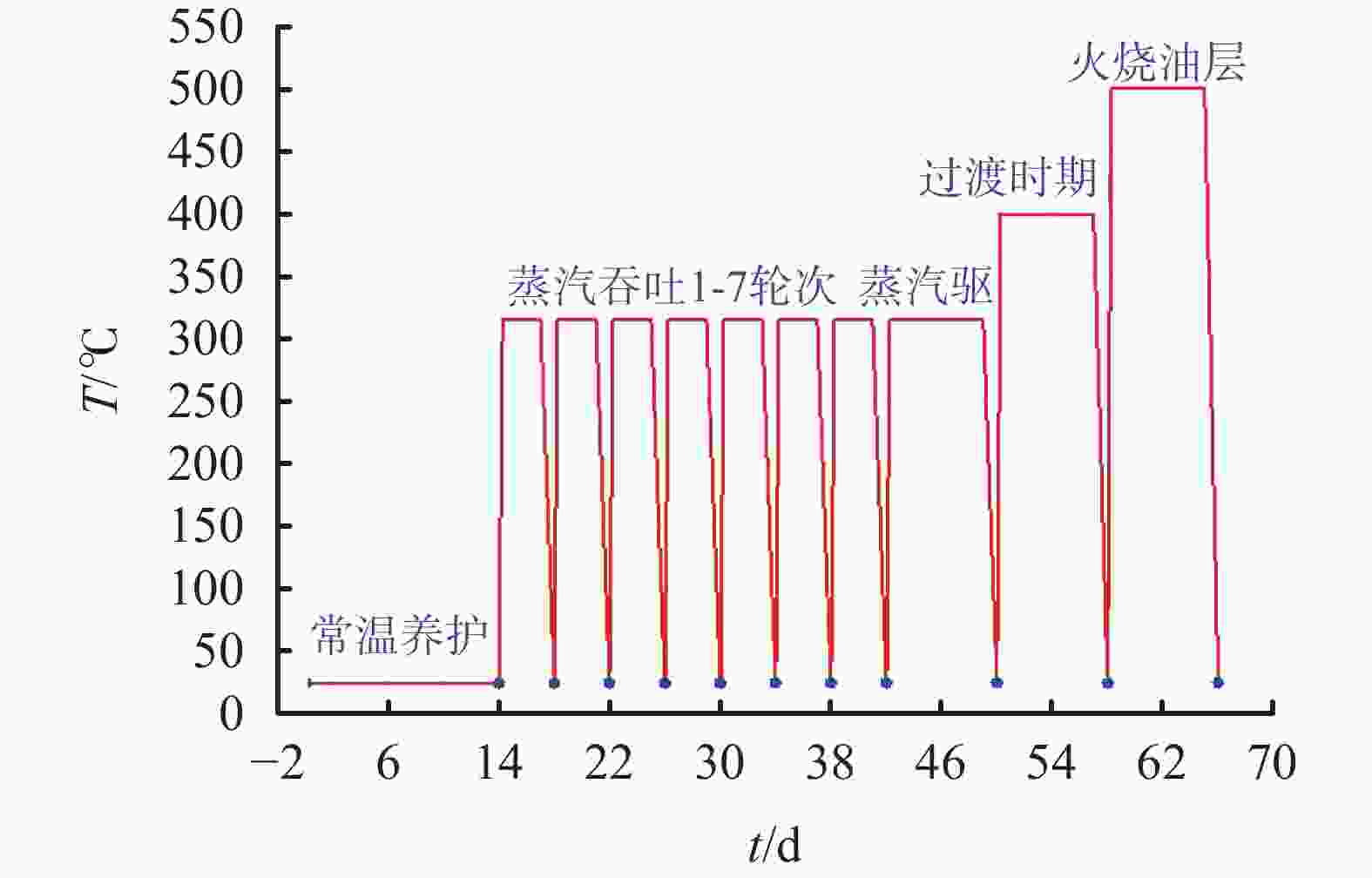

摘要: 为了准确探究常规加砂水泥石的耐温能力,根据其在井下先经历蒸汽吞吐、蒸汽驱,再经历过渡期及稠油火烧的实际工况,利用核磁共振、XRD和SEM等技术,探明了累积工况下常规加砂水泥石孔隙度、渗透率、水化产物化学结构及微观结构的变化情况。实验结果表明,水泥石经常温养护14 d后,抗压强度达31.8 MPa,是养护28 d的90.86%,且孔渗性相对较低;经稠油火烧后,水泥石抗压强度衰退率达67.92%,孔隙度及渗透率也分别增长53.85%和77.31%,已不能满足稠油井的生产要求。这是由于高温环境下水泥石中部分“网状”或“链状”结构的水化硅酸钙转化为“颗粒状”的粒硅钙石,从而导致孔径及孔隙率变大、抗压强度降低;同时,Ca(OH)2脱羟基生成CaO并产生大量粗大孔隙及裂纹,有利于维持水泥石力学性能的物相已基本失效。Abstract: In field operations, the set cement with sand in downhole conditions will experience huff-n-puff and steam flooding, followed by transitional stage and fire flooding. To accurately understand the high temperature resistance of the set cement with sand, NMR, XRD and SEM were used to investigate the porosity, permeability, chemical structure and microstructure of the hydration products of the set cement with sand under cumulative working conditions. Laboratory experimental results demonstrated that after curing at room temperature for 14 d, the compressive strength of set cement was 31.8 MPa, which is 90.86% of the compressive strength of the set cement after curing in the same conditions for 28 d. Meanwhile, this set cement had low porosity and low permeability. After fire flooding, the compressive strength of the set cement was reduced by 67.92%, and the porosity and permeability of the set cement were both increased by 53.85% and 77.31% respectively, apparently unable to satisfy the needs of heavy oil production. The reason for the decrease in compressive strength and increase in porosity and permeability of the set cement is that at high temperatures, part of the hydrated calcium silicate with “network” structure or “chain” structure in the set cement is converted into “granular” wollastonite, thereby resulting in increased porosity and permeability and decreased compressive strength of the set cement. Meanwhile, de-hydroxylation of Ca(OH)2 produces CaO and plenty of big pores and cracks, failing the materials which are beneficial for the set cement to maintain its mechanical performance.

-

表 1 累积工况下加砂水泥石的渗透率和孔隙度

累积工况 Ka/mD φ/% 常温(25 ℃) 0.113 21.13 吞吐7轮次(315 ℃) 0.328 31.52 蒸汽驱(315 ℃) 0.387 39.56 过渡时期(400 ℃) 0.412 41.88 火烧油层(500 ℃) 0.498 45.79 -

[1] 王苏雯. 稠油火驱开采技术研究[J]. 石化技术,2018,25(3):87-94. doi: 10.3969/j.issn.1006-0235.2018.03.066WANG Suxia. Research on fire flooding technology of heavy oil[J]. Petrochemical Technology, 2018, 25(3):87-94. doi: 10.3969/j.issn.1006-0235.2018.03.066 [2] CHENG X, DONG Q, MA Y, et al. Mechanical and thermal properties of aluminate cement paste with blast furnace slag at high temperatures[J]. Construction and Building Materials, 2019, 228:84-95. [3] 江航,许强辉,马德胜,等. 注空气开采过程中稠油结焦量影响因素[J]. 石油学报,2016,37(8):1030-1036.JIANG Hang, XU qianghui, MA Desheng, et al. Influencing factors of heavy oil coking amount in air injection production[J]. Journal of Petroleum, 2016, 37(8):1030-1036. [4] GUO S, BU Y, LIU H, et al. The abnormal phenomenon of class G oil well cement endangering the cementing security in the presence of retarder[J]. Construction and Building Materials, 2014, 54:118-122. doi: 10.1016/j.conbuildmat.2013.12.057 [5] KRAKOWIAK K J, THOMAS J J, MUSSO S, et al. Nano-chemo-mechanical signature of conventional oil-well cement systems: Effects of elevated temperature and curing time[J]. Cement and Concrete Research, 2015, 67:103-121. doi: 10.1016/j.cemconres.2014.08.008 [6] 张景富. G级油井水泥的水化硬化及性能[D]. 浙江大学, 2001.ZHANG Jingfu. Hydration hardening and properties of grade G oil well cement[D]. Zhejiang University, 2001. [7] ALONSO C, FERNANDEZ L. Dehydration and rehydration processes of cement paste exposed to high temperature environments[J]. Journal of Materials Science, 2004, 39(9):3015-3024. doi: 10.1023/B:JMSC.0000025827.65956.18 [8] LIU K, CHENG X, ZHANG C, et al. Evolution of pore structure of oil well cement slurry in suspension-solid transition stage[J]. Construction and Building Materials, 2019, 214:382-398. [9] LIU K, CHENG X, LI J, et al. Effects of microstructure and pore water on electrical conductivity of cement slurry during early hydration[J]. Composites:Part B, Engineering, 2019, 177:1-15. [10] 杨智光,崔海清,肖志兴,等. 深井高温条件下油井水泥强度变化规律研究[J]. 石油学报,2008,29(3):435-437. doi: 10.3321/j.issn:0253-2697.2008.03.024YANG Zhiguang, CUI Haiqing, XIAO Zhixing, et al. Study on strength variation of oil well cement under high temperature in deep well[J]. Journal of Petroleum, 2008, 29(3):435-437. doi: 10.3321/j.issn:0253-2697.2008.03.024 [11] GARNIER A, SAINT-MARC J. An innovative methodology for designing cement-sheath integrity exposed to steam stimulation[C]. SPE 117709, 2010. [12] PERNITES R B, SANTRA A K. Portland cement solutions for ultra-high temperature wellbore applications[J]. Cement and Concrete Composites, 2016, 72:89-103. doi: 10.1016/j.cemconcomp.2016.05.018 [13] LEONARDO B, COSTA D S, Cezar J, et al. Silica content in fluence on cement compressive strength in wells subjected to steam injection[J]. Journal of Petroleum Science and Engineering, 2017, 158:626-633. doi: 10.1016/j.petrol.2017.09.006 [14] 程小伟,张明亮,李早元,等. 火烧油层工况下加砂油井水泥石失效演化研究[J]. 硅酸盐通报,2016,35(8):2335-2340.CHENG Xiaowei, ZHANG Mingliang, LI Zaoyuan, et al. Study on failure evolution of cement paste in sand adding oil well under in situ combustion condition[J]. Silicate Bulletin, 2016, 35(8):2335-2340. [15] 中国国家标准化管理委员会, GB/T 19139-2012油井水泥试验方法[S]. 北京: 中国标准出版社, 2012.National Standardization Administration of China, test methods for oil well cement[S]. Beijing: China Standard Press , 2012. [16] IRICO S, GASTALDI D, CANONICO F, et al. Investigation of the microstructural evolution of calcium sulfoaluminate cements by thermoporometry[J]. Cement and Concrete Research, 2013, 53:239-247. doi: 10.1016/j.cemconres.2013.06.012 -

下载:

下载: