Research on Evaluation Device and Method of Emulsification Stability of High Temperature and High Pressure Oil-based Drilling Fluid

-

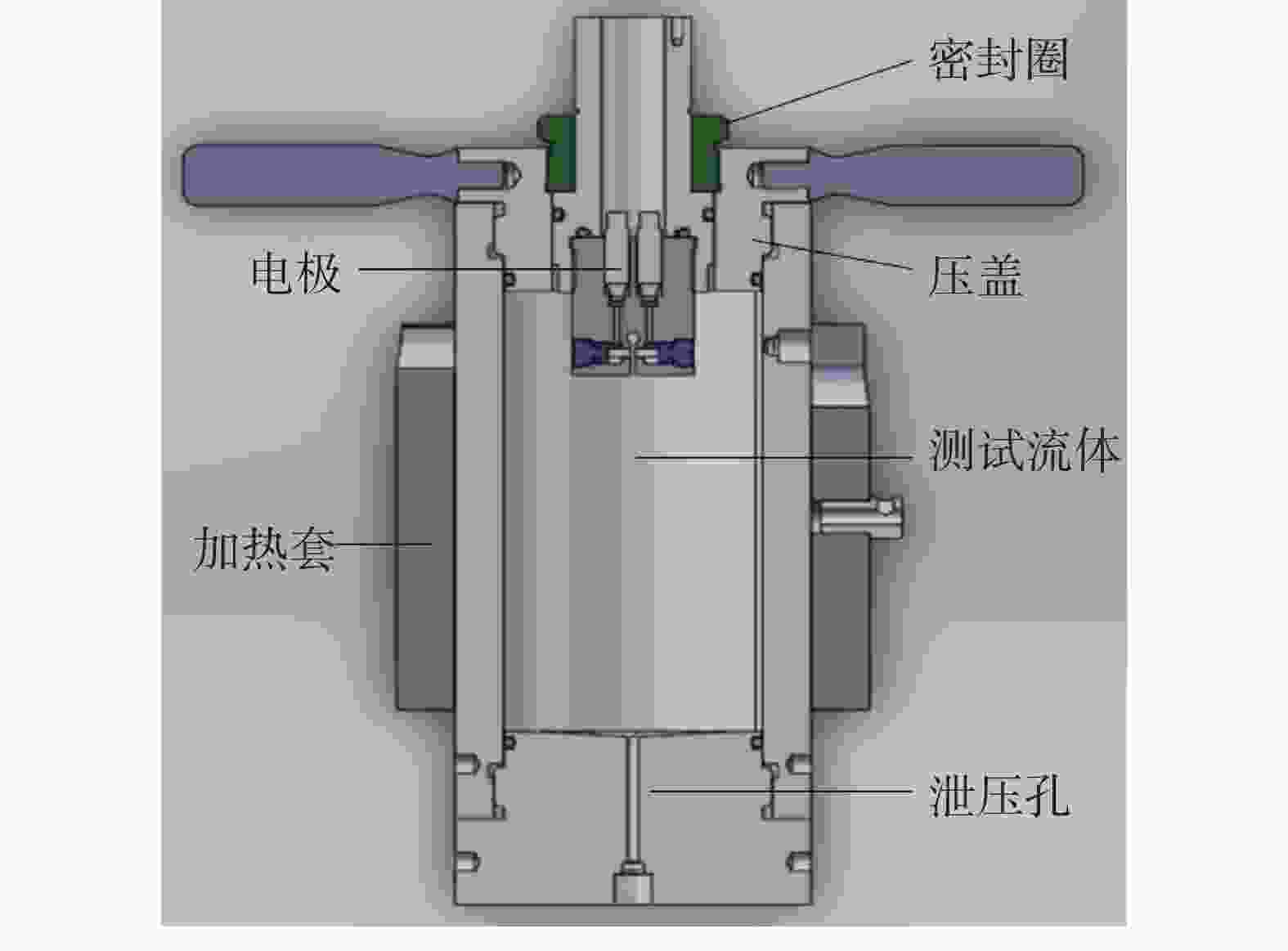

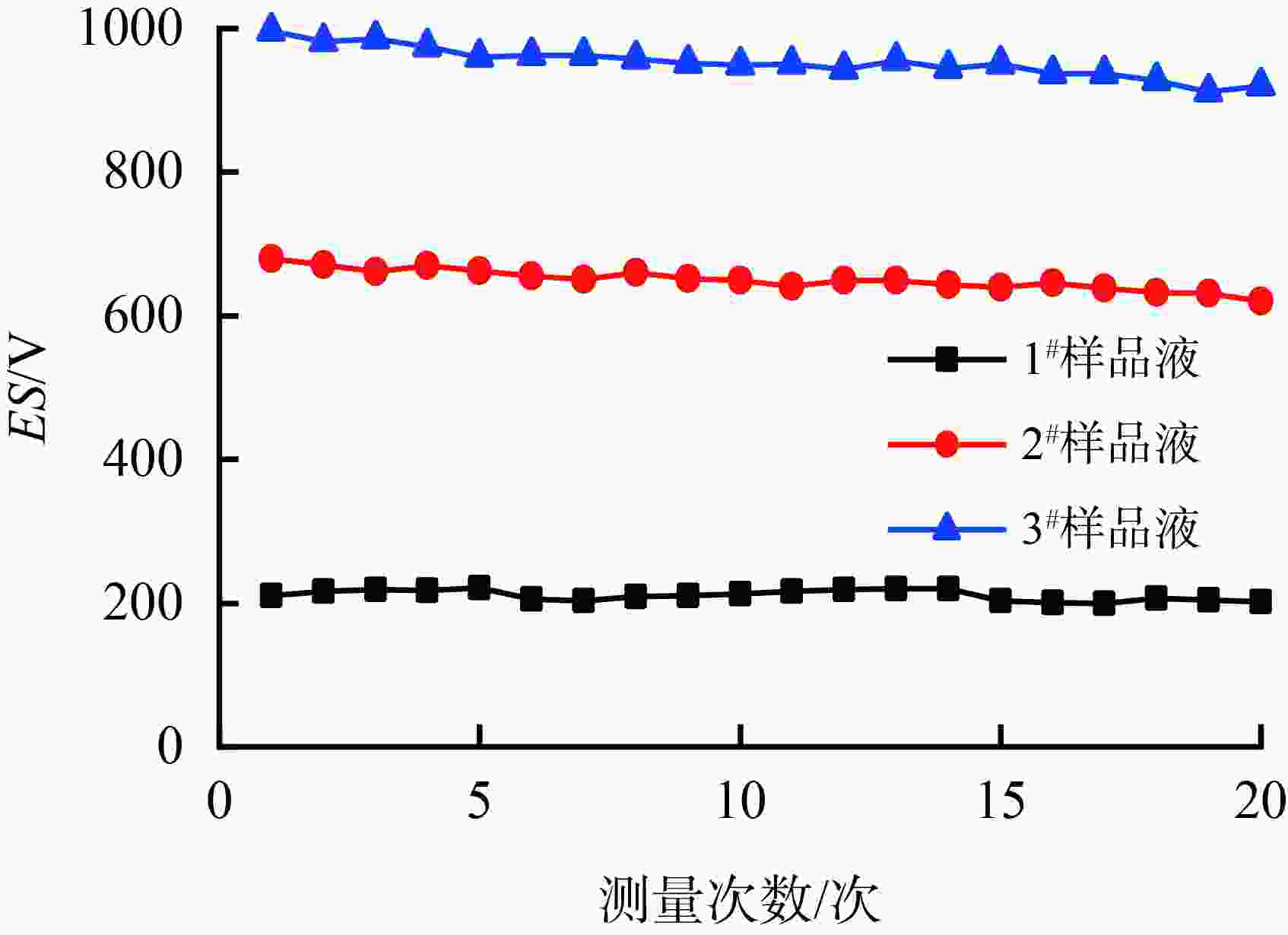

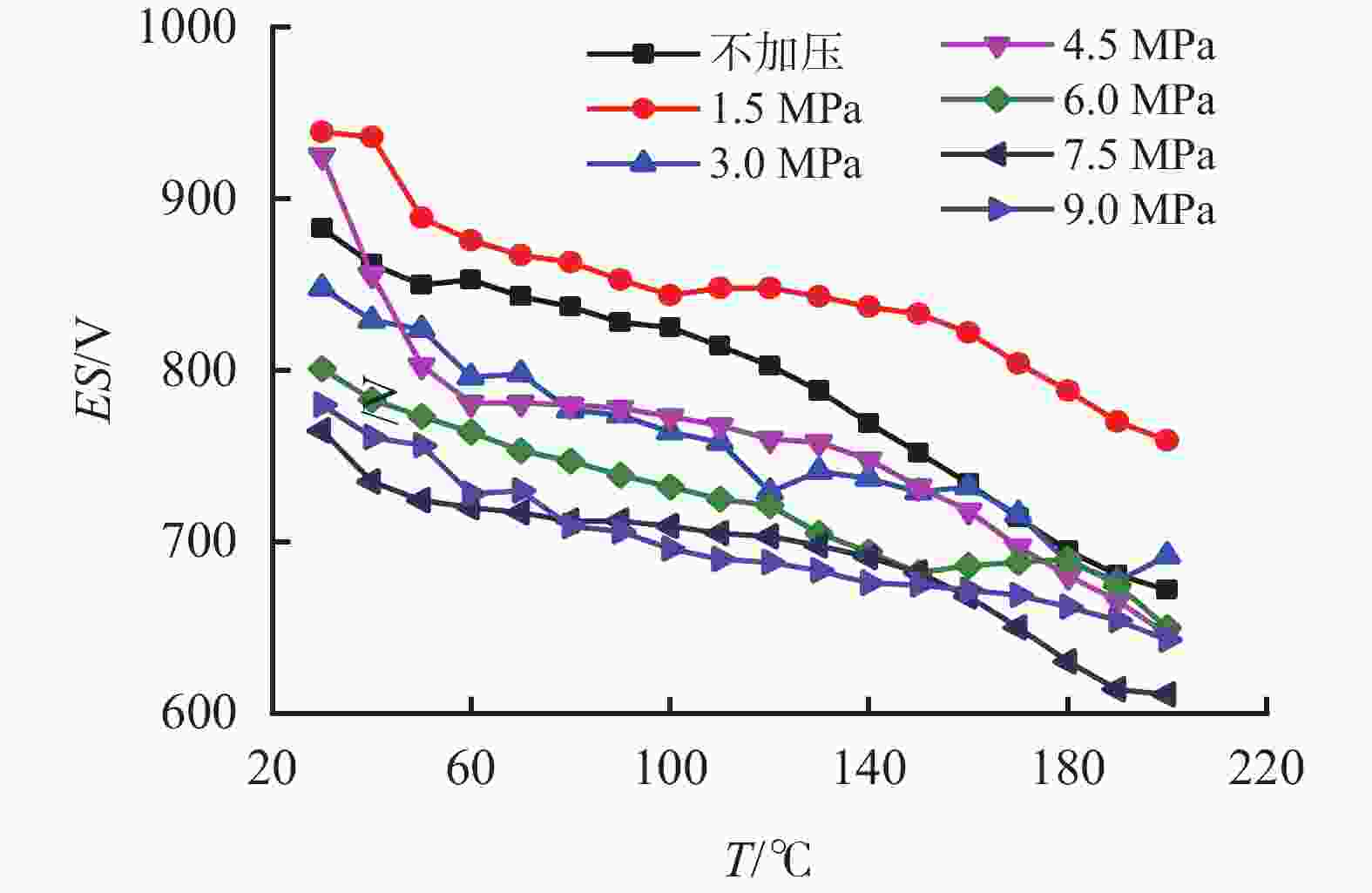

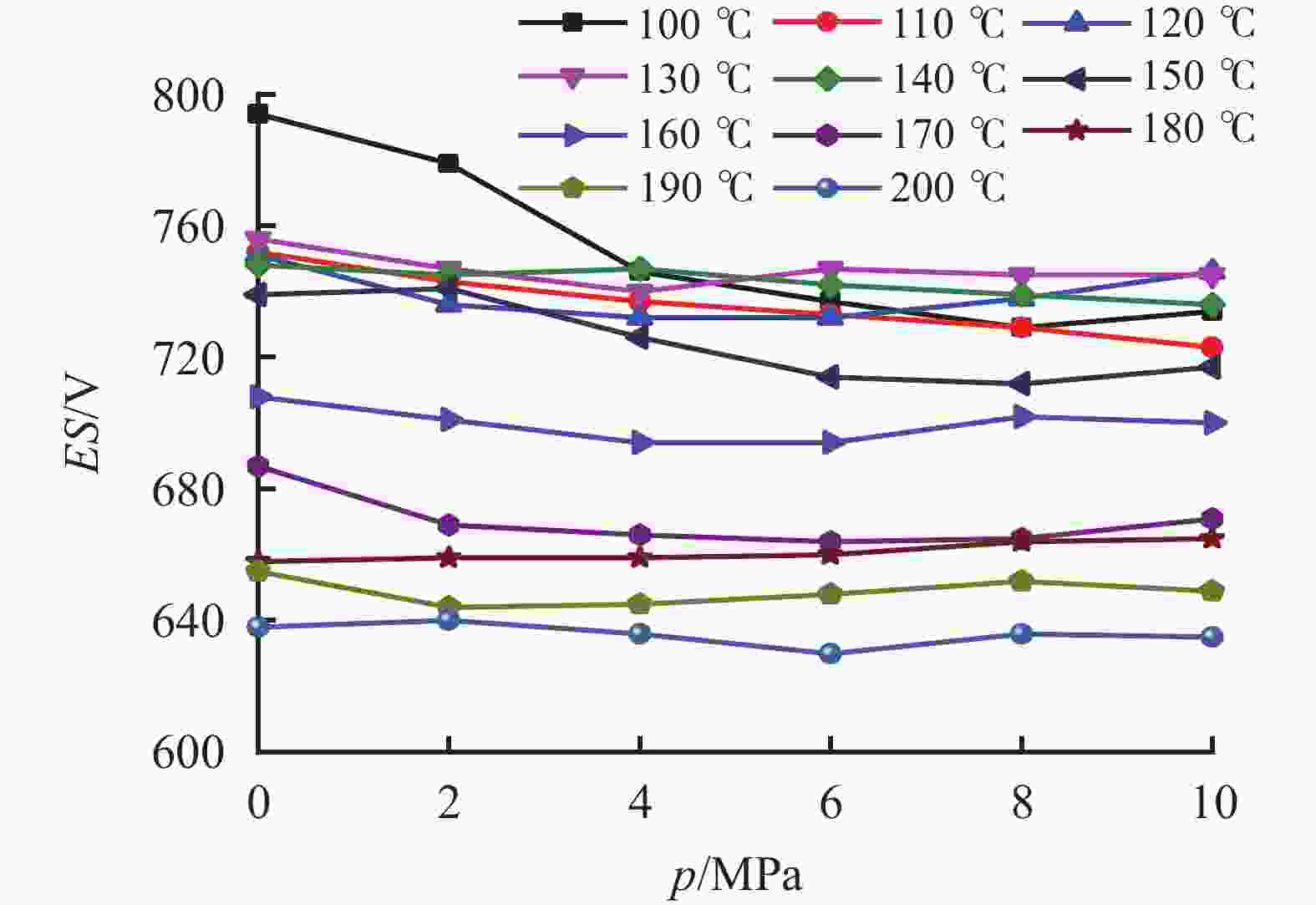

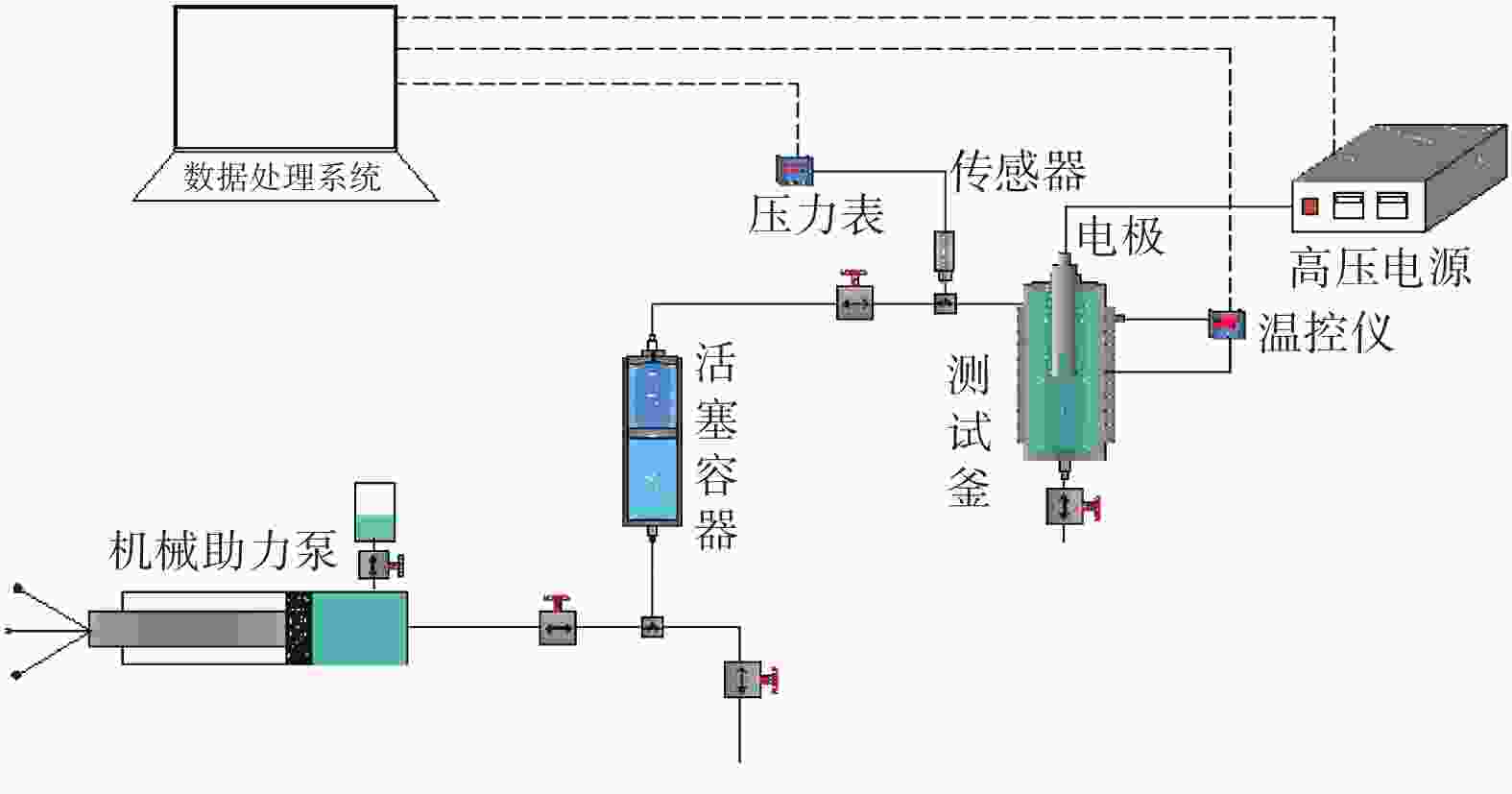

摘要: 高温高压油基钻井液乳化稳定性评价仪主要由高温高压不锈钢腔体、测试电极、温度控制系统、压力控制系统以及测试系统组成,高温电极选用PEEK材料,测试的电极距离设计为1.5 mm,电极的放电电压最高设计为2000 V,温度控制系统以T89C51 单片机为核心,采用铸铝电加热器包裹在高温高压不锈钢腔体外部进行加热,压力控制系统采用液压方式加压。对仪器的稳定性进行了测试并与常温常压下电稳定性测试仪进行了对比,结果表明,该仪器可以实现高温高压油基钻井液乳化稳定性评价,并且测试数据稳定、可靠,测量误差不大于5%。研究了油基钻井液在高温高压下乳化稳定性的规律,当维持压力不变时,随着温度的升高,破乳电压值呈下降趋势;当温度低于120 ℃时,随着压力的升高,破乳电压值有所减小,当温度达到120 ℃以上时,破乳电压值基本不随压力的变化而发生改变。Abstract: The high temperature and high pressure oil-based drilling fluid emulsion stability evaluation instrument is mainly composed of high temperature and high pressure stainless steel chamber, test electrode, temperature control system, pressure control system and test system. The high temperature electrode is made of PEEK material. The test electrode distance is designed to be 1.55 mm. The maximum discharge voltage is designed to be 2000 V, and the voltage change rate is 150±10V persecond. The temperature control system is based on the T89C51 single-chip microcomputer. The cast aluminum electric heater is used to wrap the outside of the test vessel for heating. The pressure control system uses hydraulic pressure. The stability test of the instrument and the comparison test with the electrical stability tester under normal temperature and pressure are carried out. The results show that the instrument can realize the evaluation of the emulsion stability of oil-based drilling fluid at high temperature and high pressure, and the test data is stable and reliable, with measurement errors ≤5%. The emulsification stability of oil-based drilling fluid under high temperature and high pressure conditions is studied. When the pressure is kept constant, the demulsification voltage decreases with the increase of temperature. When the temperature is below 120 ℃, the demulsification voltage decreases with the increase of pressure. When the temperature reaches above 120 ℃, the demulsification voltage does not change with the pressure.

-

表 1 新研制仪器与DWY-2型电稳定性测试仪对比

乳状

液DWY-2电稳定性

测试仪破乳电压/V高温高压乳化稳定性

测试仪破乳电压/V第1次 第2次 第3次 平均值 第1次 第2次 第3次 平均值 1# 259 258 265 261 270 266 255 263 2# 511 510 517 513 515 512 507 511 3# 911 898 870 893 899 874 918 898 -

[1] 高海洋, 黄进军, 崔茂荣 , 等. 高温下乳状液稳定性的评价方法[J]. 西南石油学院学报, 2001, 23(4): 57-59.GAO Haiyang, HUANG Jinjun, CUI Maorong, et al. Evaluation method of emulsion stability at high temperature[J]. Journal of Southwest Petroleum Institute, 2001, 23(4): 57-59. [2] EOW J S , GHADIRI M , SHARIF A . Deformation and break-up of aqueous drops in dielectric liquids in high electric fields[J]. Journal of Electrostatics, 2001, 51: 463-469. [3] WU C J, FU T H. Effective voltage flicker calculation algorithm using indirect demodulation method[J]. Iee Proceedings Generation Transmission & Distribution, 2003, 150(4):493-500. [4] HUTTON ALISTAIR, VICKERS STEPHEN, DAVIDSON MARCUS, et al. Design and application of invert emulsion drilling and aqueous completion fluids for long horizontal multilateral wells[R]. SPE 121905, 2009. [5] 刘刚, 罗健生, 田荣剑, 等. 油包水乳状液稳定性的室内评价方法研究[J]. 应用化工, 2012, 41(1): 152-154.LIU Gang, LUO Jiansheng, TIAN Rongjian, et al. Research on indoor evaluation methods of water-in-oil emulsion stability[J]. Applied Chemical Industry, 2012, 41(1): 152-154. [6] 王建华, 闫丽丽, 谢盛, 等. 塔里木油田库车山前高压盐水层油基钻井液技术[J]. 石油钻探技术, 2020, 48(2): 29-33.WANG Jianhua, YAN Lili, XIE Sheng, et al. Oil-based drilling fluid technology for high pressure brine layer in Kuqa Piedmont of the Tarim Oilfield[J].Petroleum Drilling Techniques, 2020, 48(2): 29-33. [7] 张雄, 余进, 毛俊, 等. 准噶尔盆地玛东油田水平井高性能油基钻井液技术[J]. 石油钻探技术, 2020, 48(6): 21-27.ZHANG Xiong, YU Jin, MAO Jun, et al. High-performance oil-based drilling fluid technology for horizontal wells in the Madong oilfield, Junggar basin[J].Petroleum Drilling Techniques, 2020, 48(6): 21-27. [8] 黄红玺, 张峰, 许明标, 等. 油包水乳状液稳定性影响因素分析[J]. 断块油气田, 2009, 16(6): 98-101.HUANG Hongxi, ZHANG Feng, XU Mingbiao, et al. Analysis of factors affecting the stability of water-in-oil emulsion[J]. Fault-Block Oil and Gas Field, 2009, 16(6): 98-101. [9] 李官敏. 智能电击穿性能测试仪的研制[D].北京: 中国地质大学(北京), 2014.LI Guanmin. Development of an intelligent electrical breakdown performance tester[D]. Beijing: China University of Geosciences (Beijing). 2014. [10] 闫晶. 油包水钻井液稳定性影响因素研究[J] . 中国科技信息, 2010(23): 51-52.YAN Jing. Research on the factors affecting the stability of water-in-oil drilling fluids[J]. China Science and Technology Information, 2010(23): 51-52. [11] 鄢捷年. 钻井液工艺学[M]. 中国石油大学出版社, 2006: 236-263.YAN Jienian. Drilling fluid technology [M]. China University of Petroleum Press, 2006: 236-263. [12] 王霞,潘成松,陈军,等. O/W 型稠油乳状液的静态稳定性评价[J]. 钻采工艺,2009,32(6):46-48. doi: 10.3969/j.issn.1006-768X.2009.06.014WANG Xia, PAN Chengsong, CHEN Jun, et al. Evaluation of static stability of O/W heavy oil emulsion[J]. Drilling & Production Technology, 2009, 32(6):46-48. doi: 10.3969/j.issn.1006-768X.2009.06.014 [13] 张福贵,赵剑曦,蒋家兴,等. 离心-电导联用法快速评价O/W乳状液稳定性[J]. 应用化学,2007,24(8):957-960. doi: 10.3969/j.issn.1000-0518.2007.08.023ZHANG Fugui, ZHAO Jianxi, JIANG Jiaxing, et al. Rapid evaluation of O/W emulsion stability by centrifugal-electrical lead method[J]. Chinese Journal of Applied Chemistry, 2007, 24(8):957-960. doi: 10.3969/j.issn.1000-0518.2007.08.023 -

下载:

下载: