Application of Supramolecular Polymer Plugging Technology in Changqing Oilfield

-

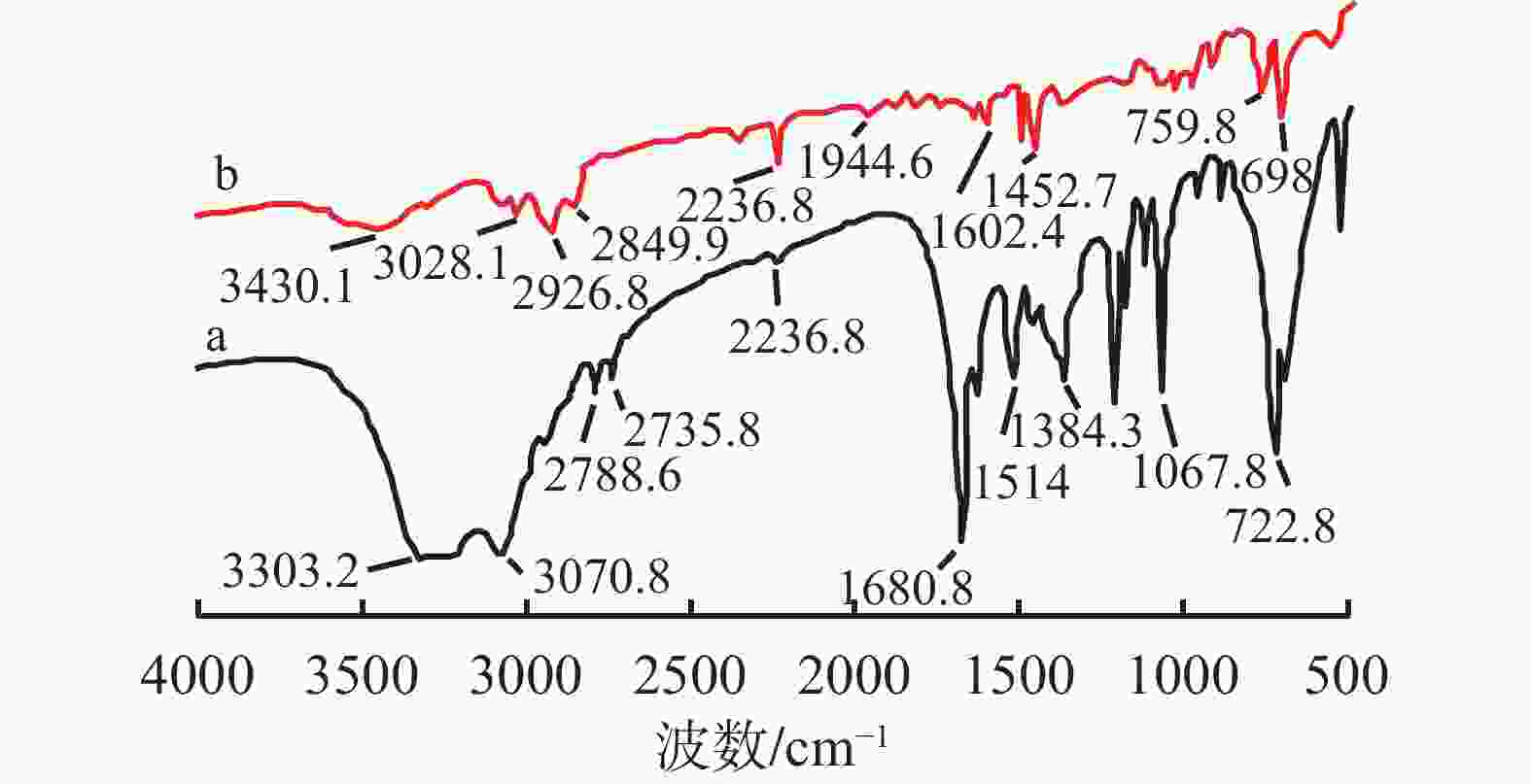

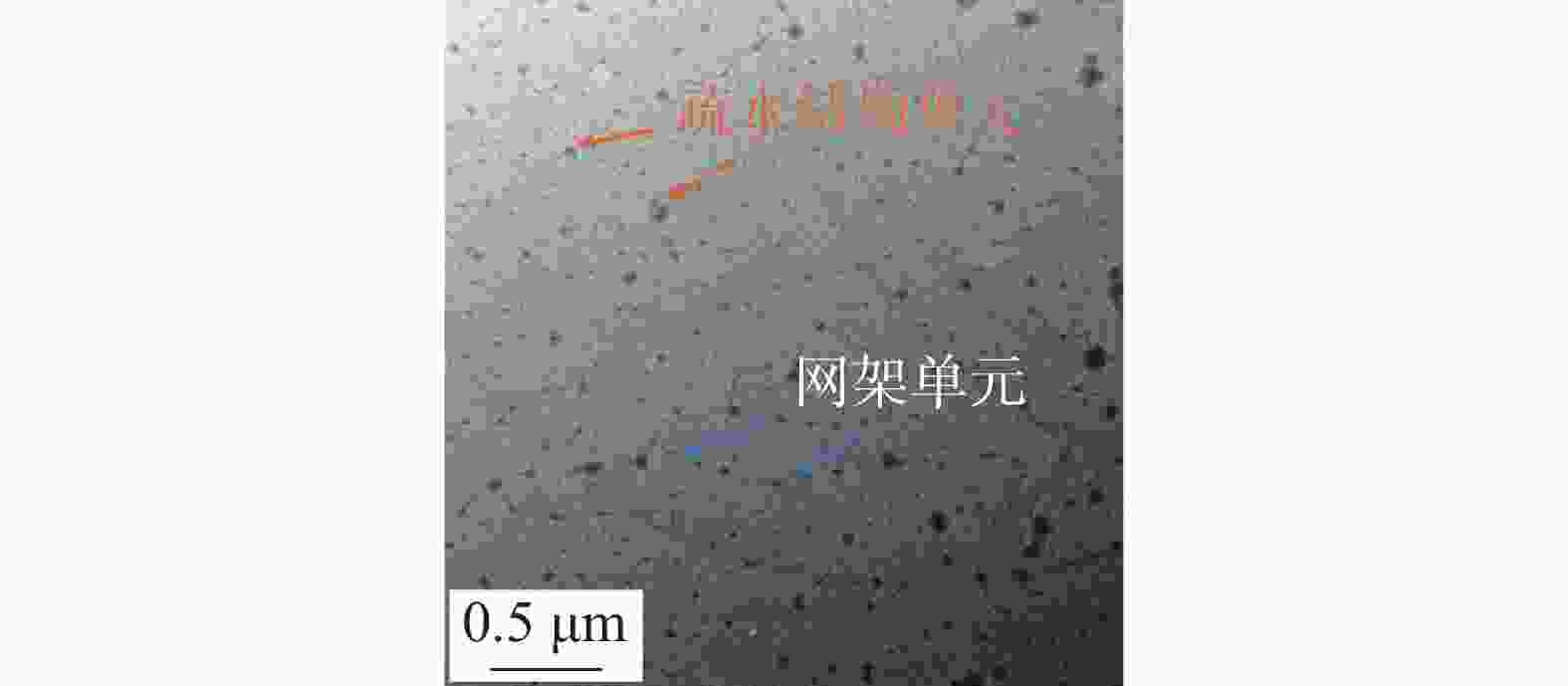

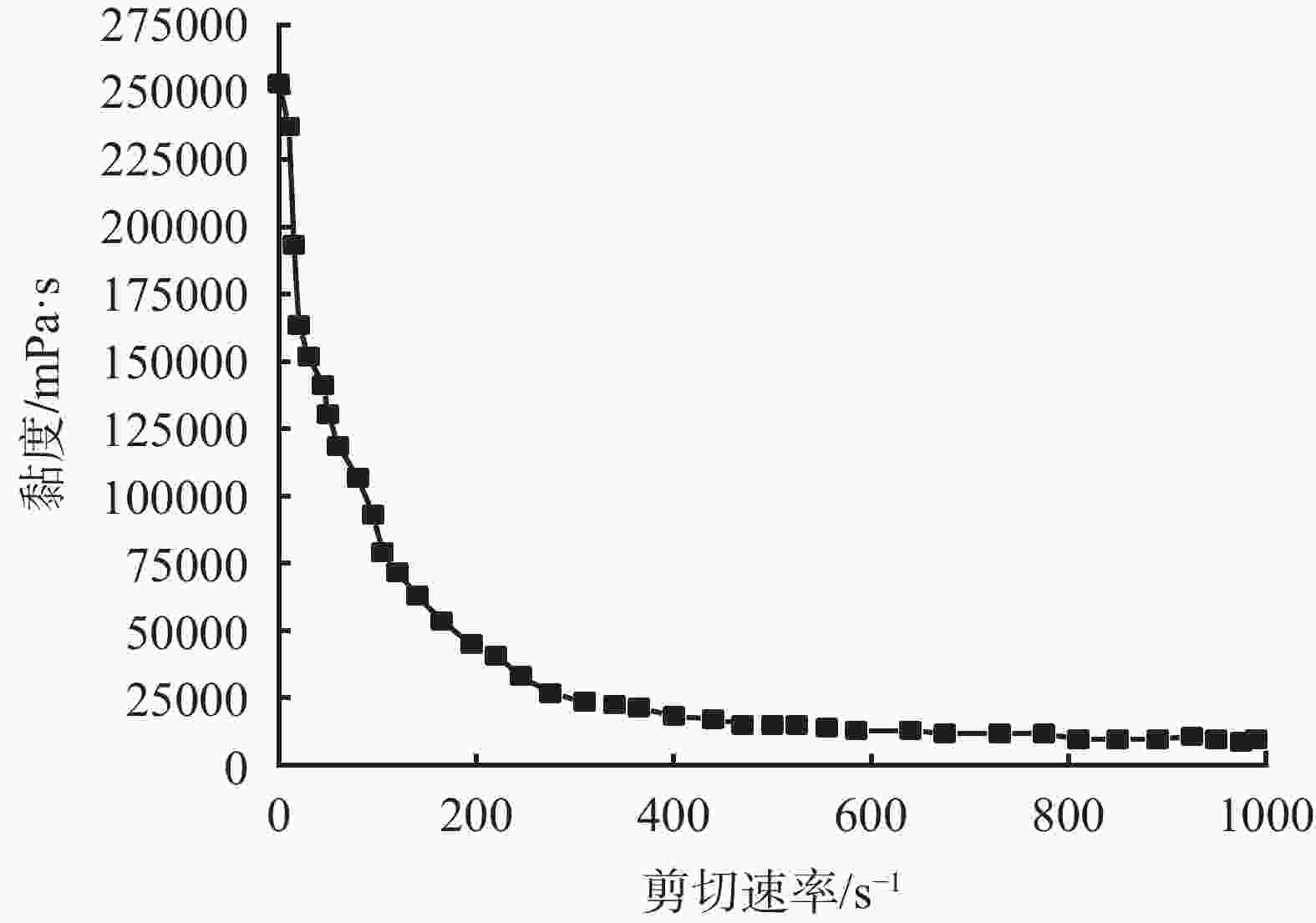

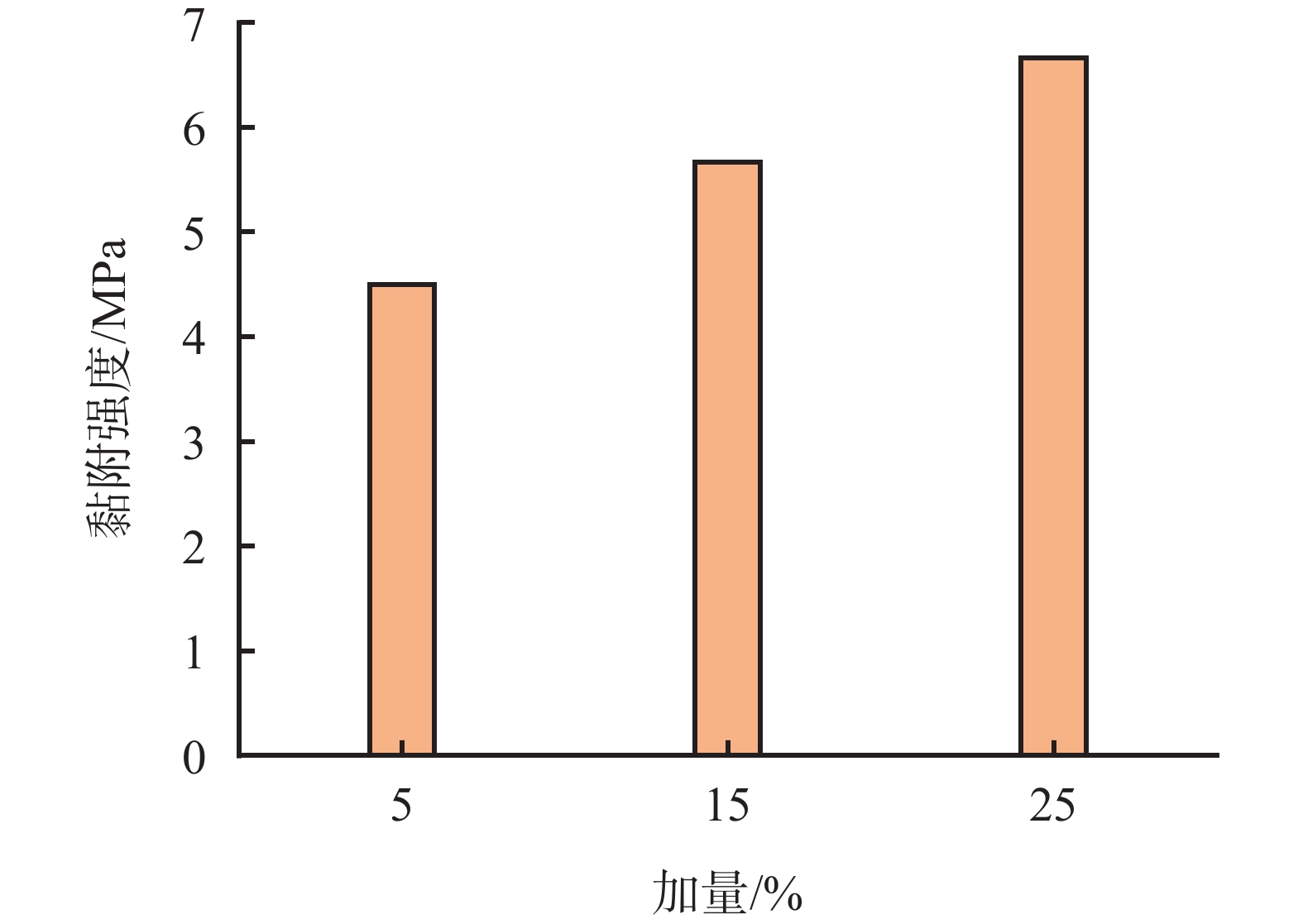

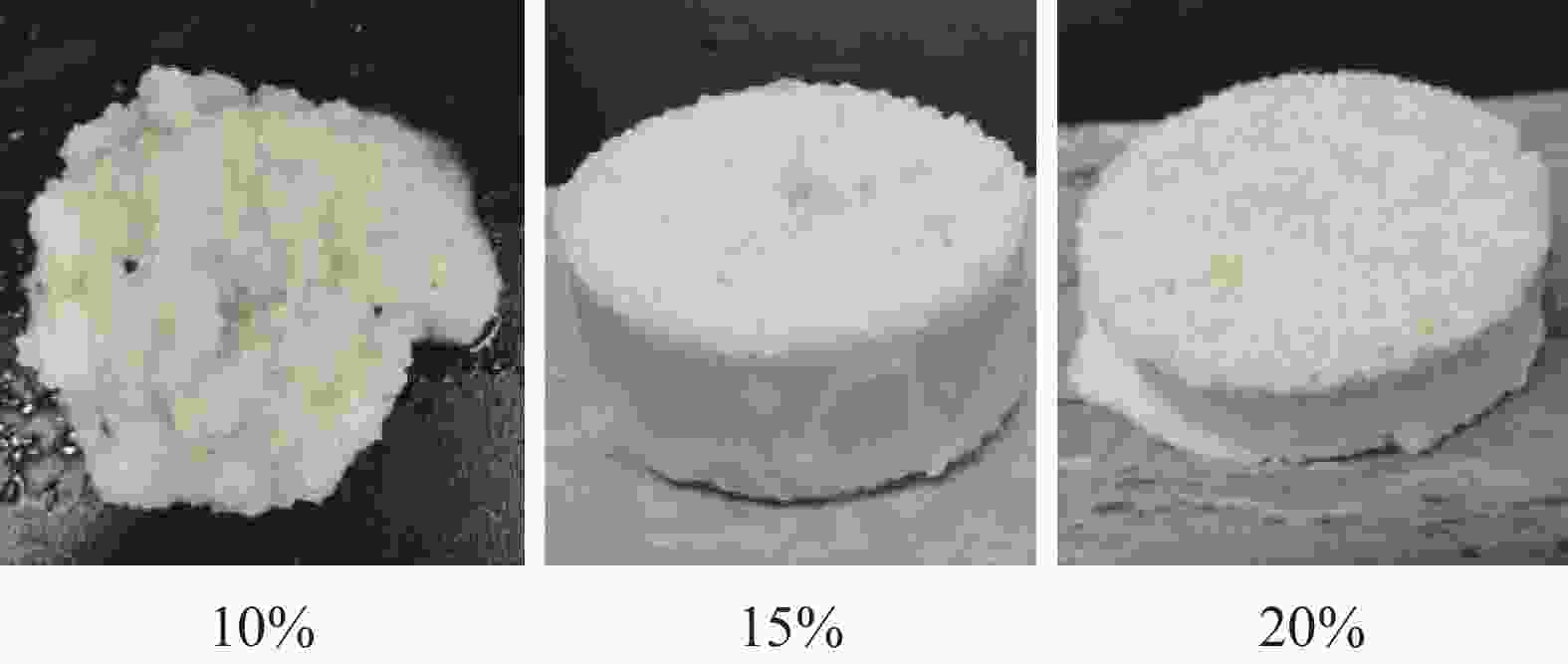

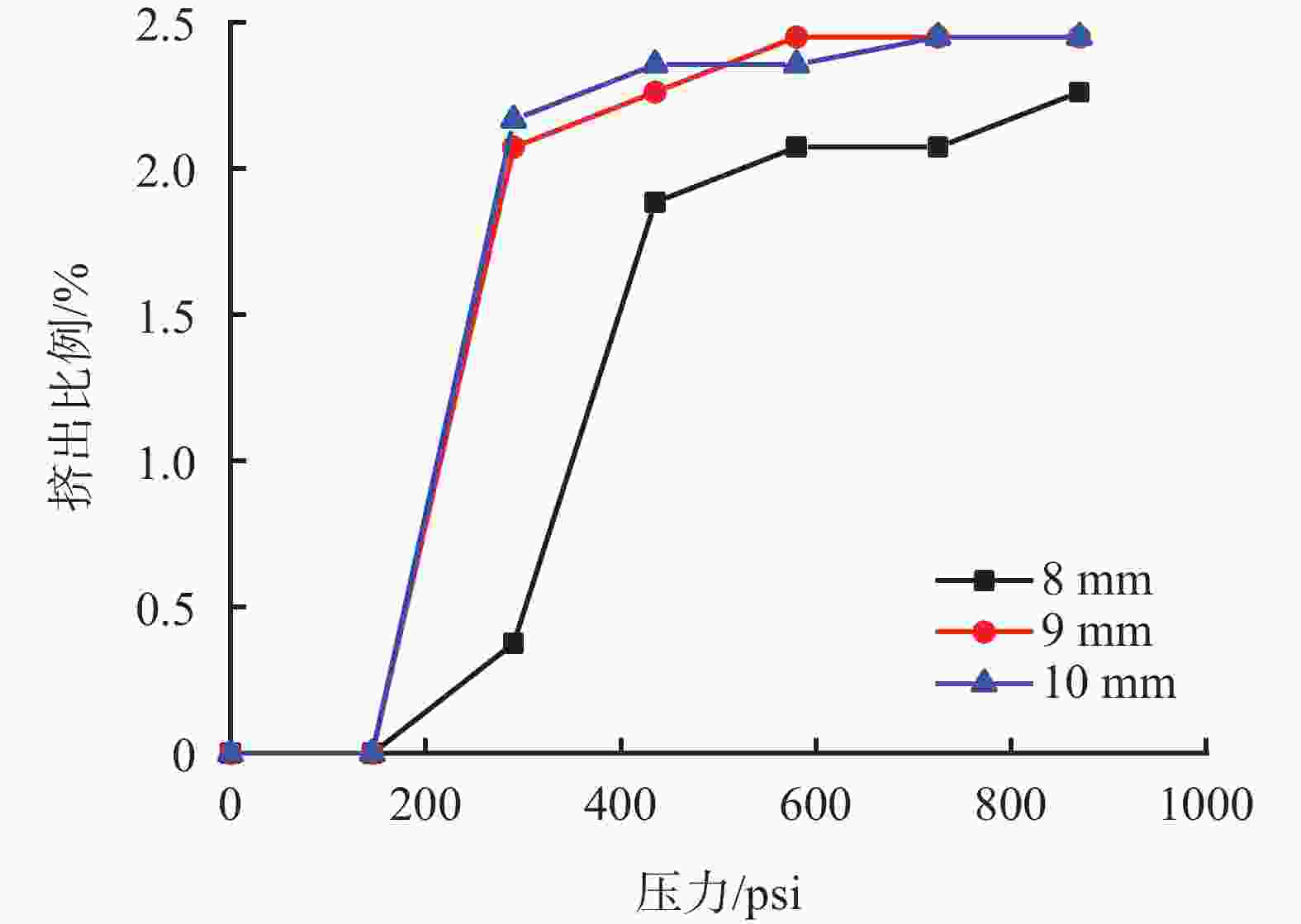

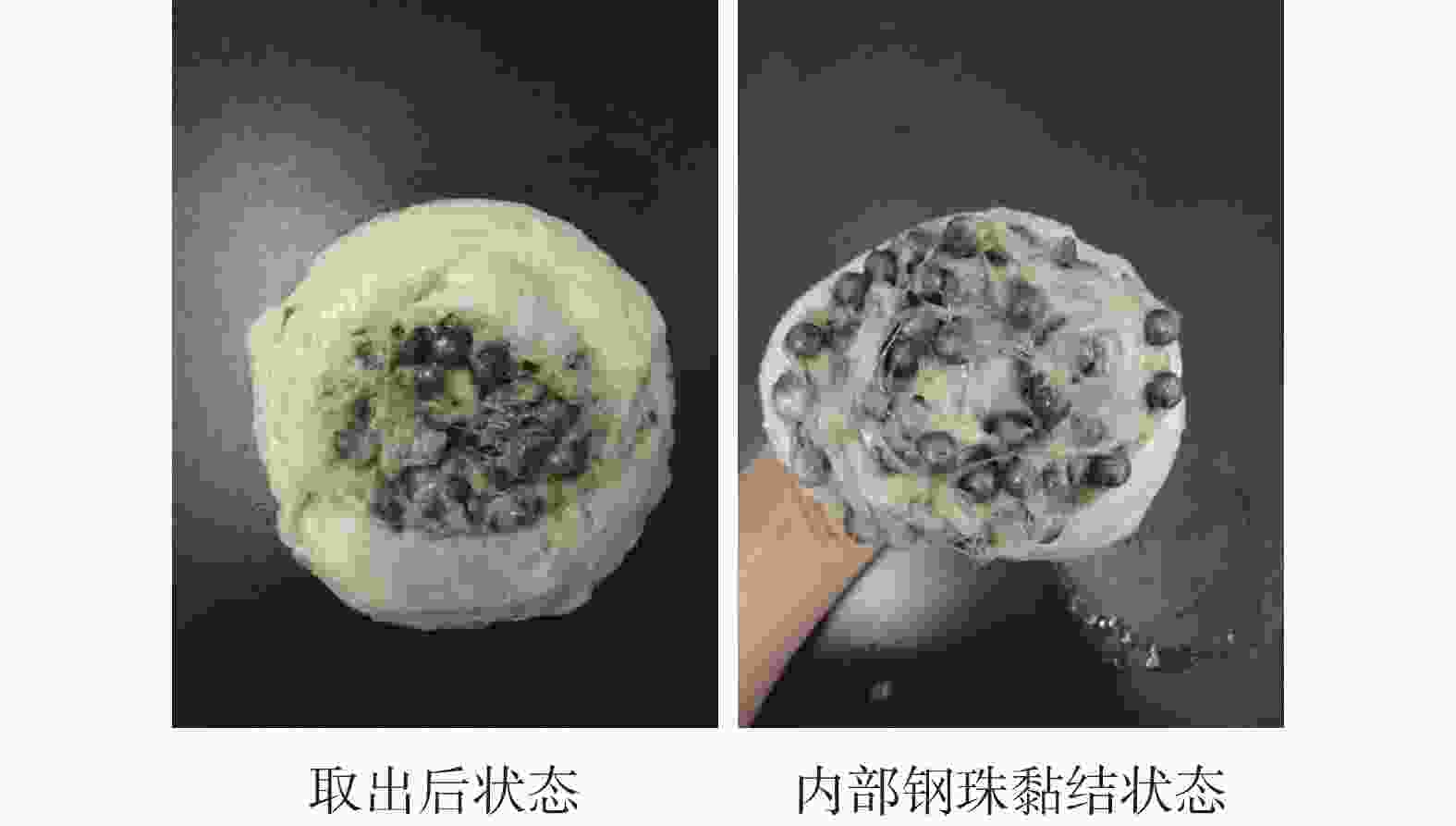

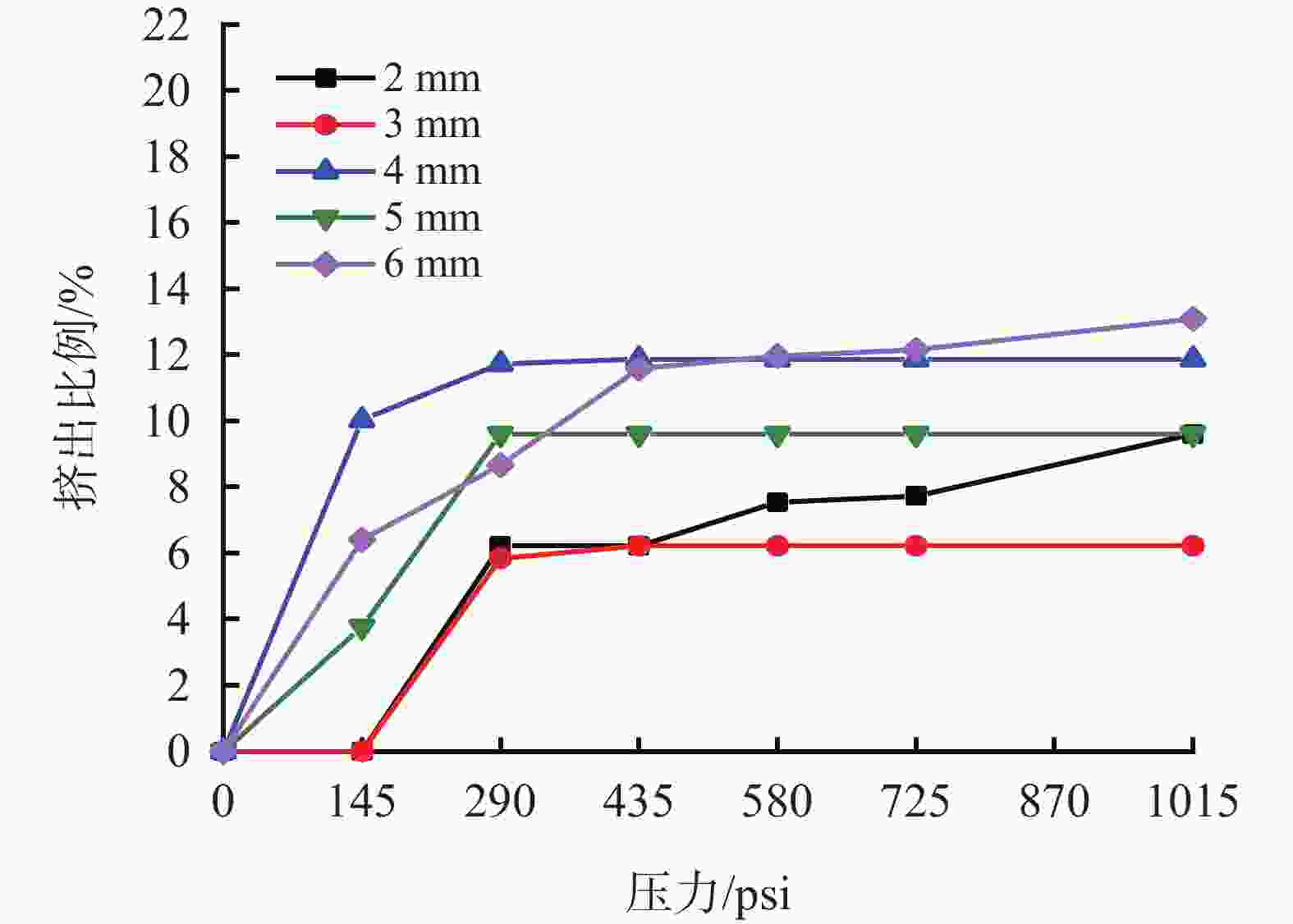

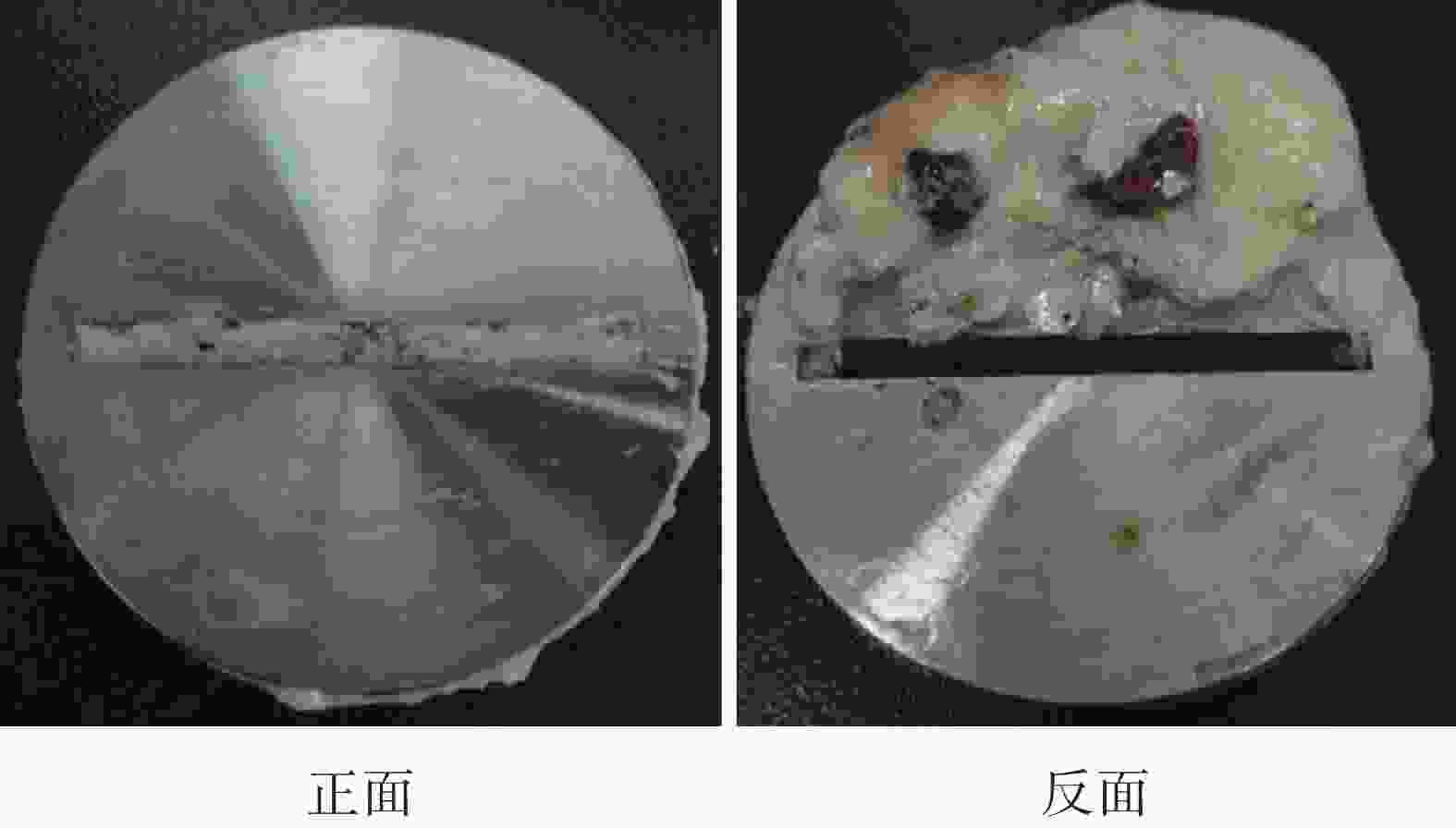

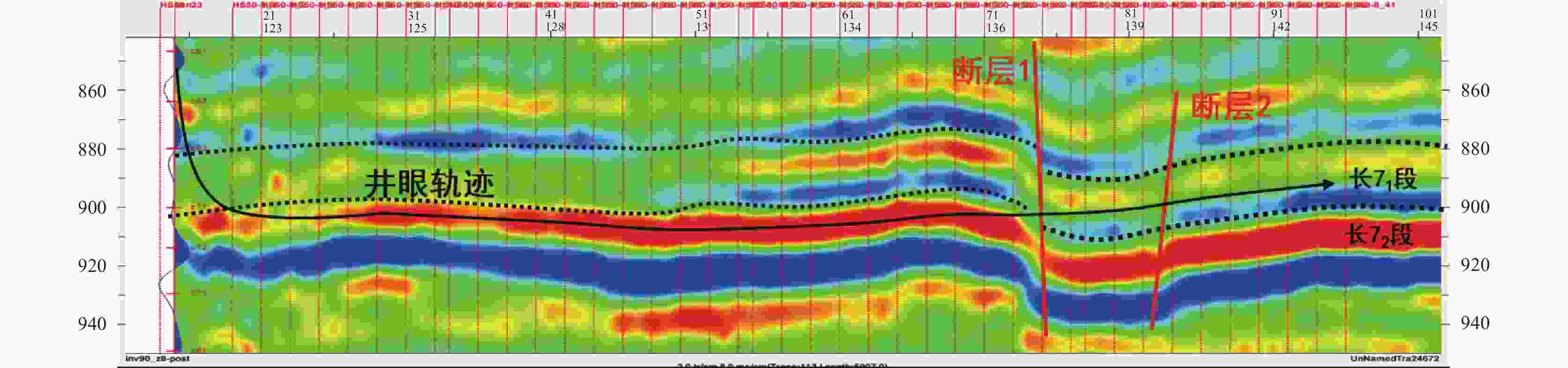

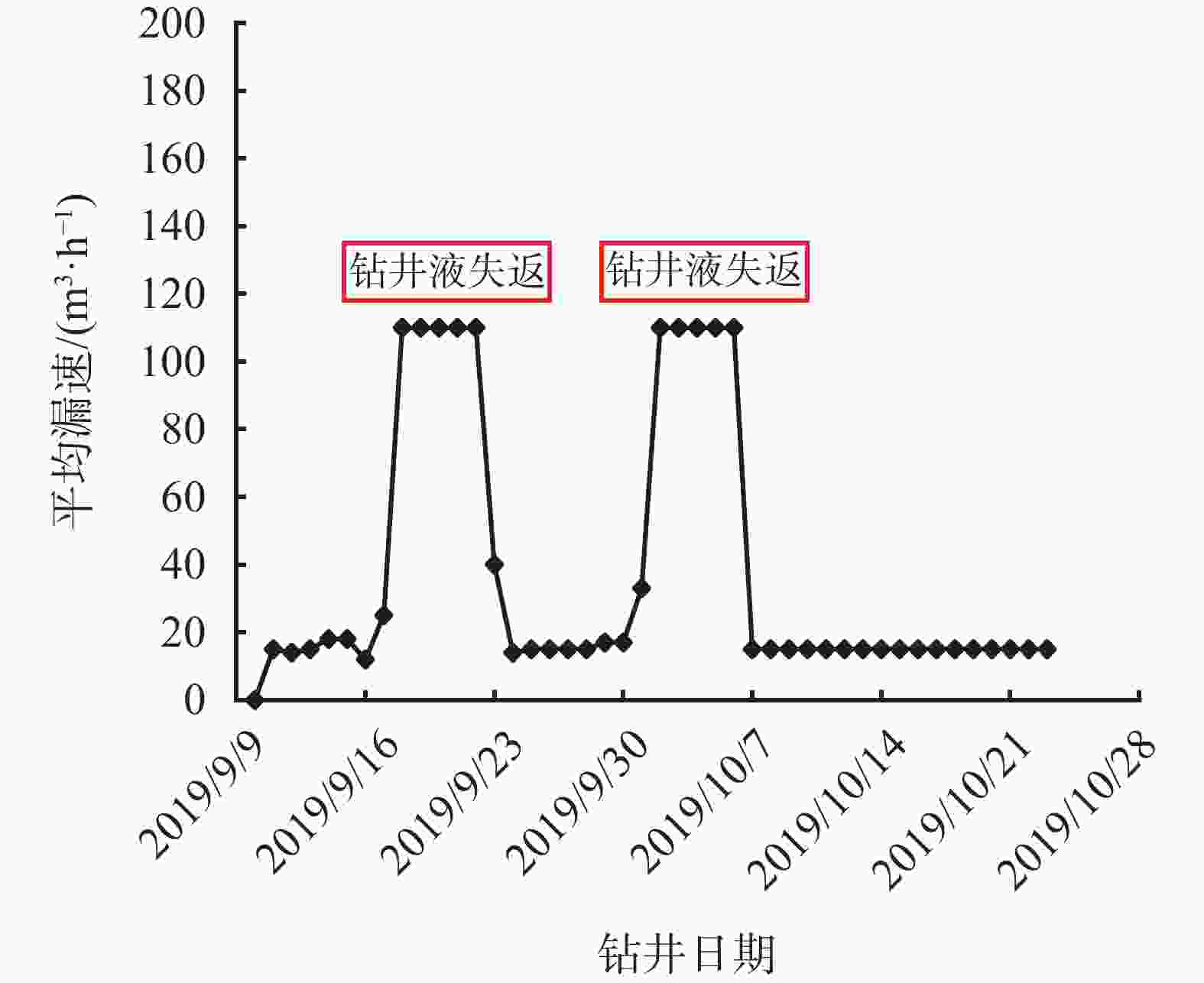

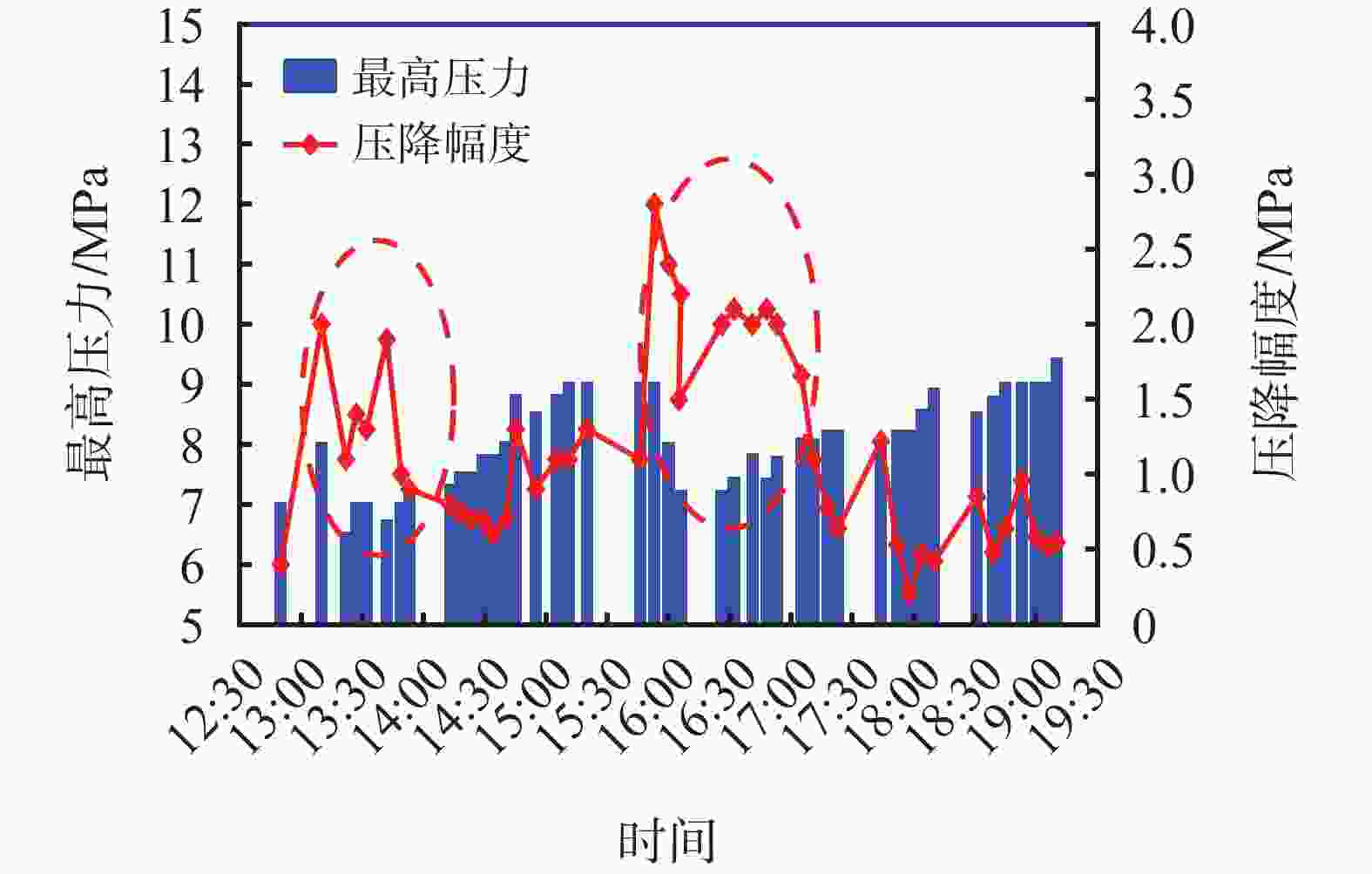

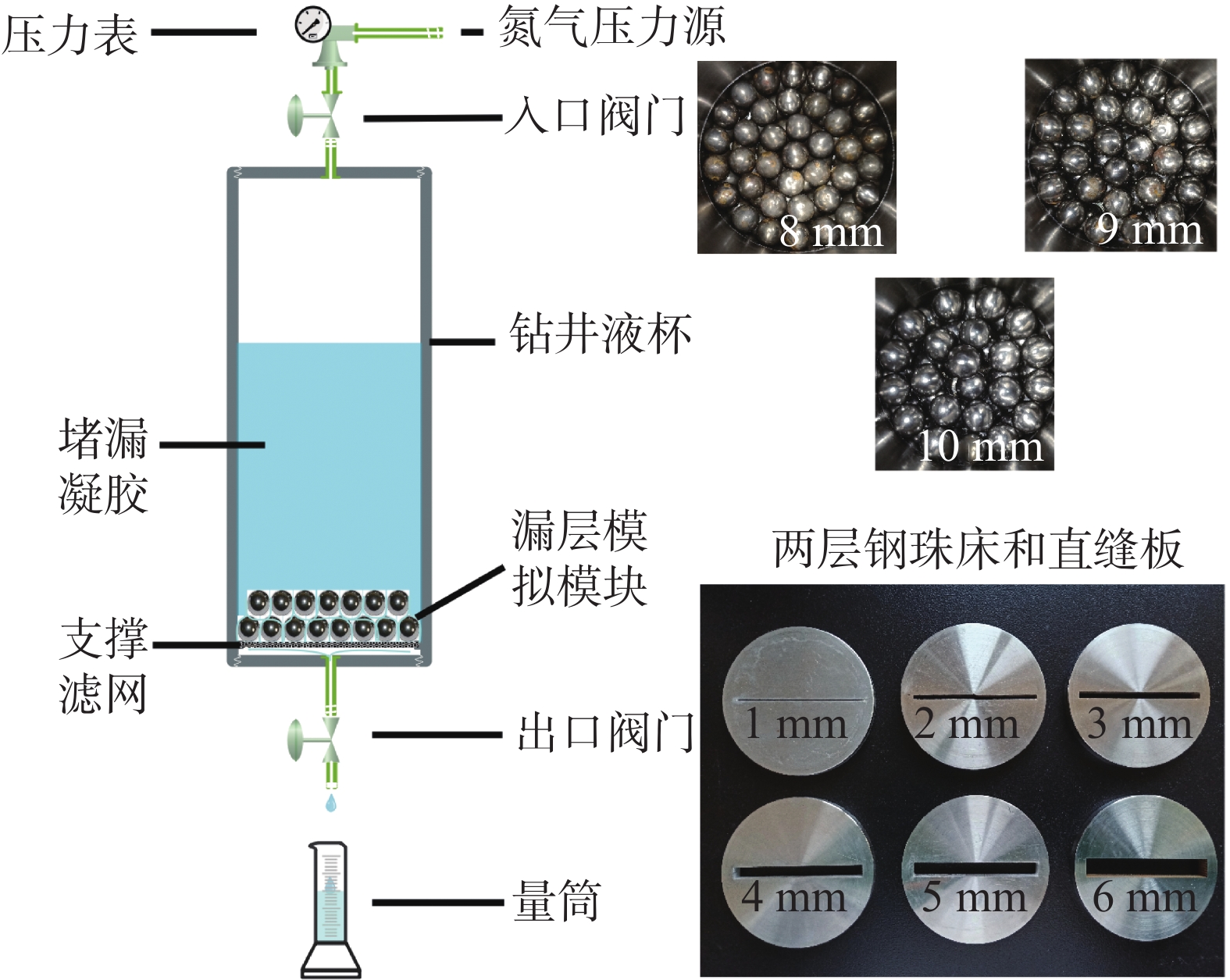

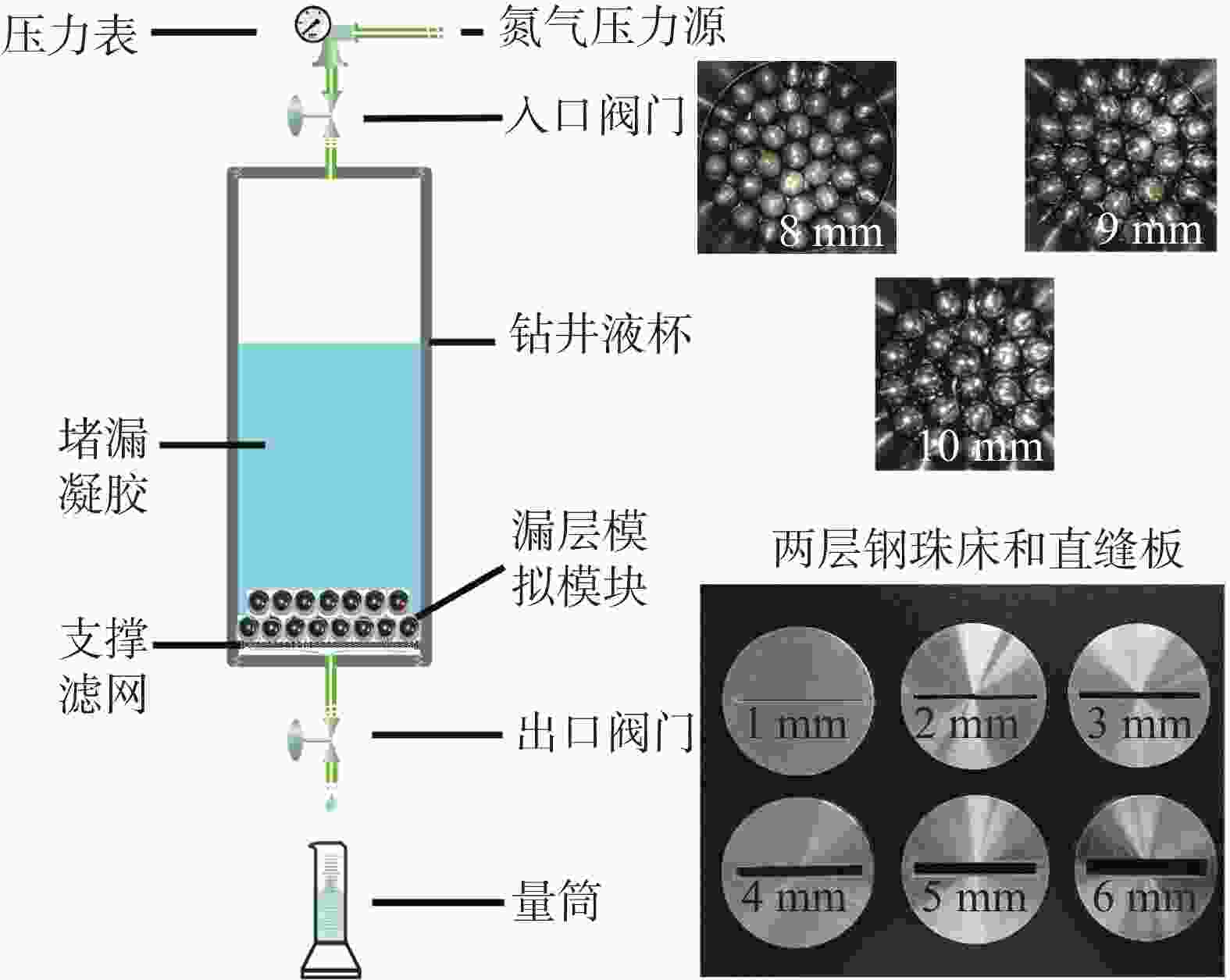

摘要: 长7页岩油储层致密但流体流动性好,砂岩储层存在微米级孔隙,加上存在断层构造,导致钻进过程中渗透性漏失、裂缝性漏失甚至失返性漏失频发,常规堵漏材料无法满足钻井施工要求,造成非生产时间和成本大幅度增加,严重制约了勘探开发进程。借助超分子化学理论,通过合成优化配方,研发出了新型超分子聚合物防漏堵漏材料,并对其微观结构、剪切稀释性和恶性漏失承压堵漏能力进行了表征与测试。研究结果表明,超分子聚合物堵漏材料不仅具有优异的剪切稀释性和黏附能力,而且对两层钢珠床(钢珠直径8~10 mm)模拟的大孔隙性漏失和直缝板(缝宽2~6 mm)模拟的裂缝性漏失均具有较强的承压堵漏效果,承压达6 MPa。在长7页岩油区块典型恶性漏失井应用表明,超分子聚合物堵漏技术可以有效提高裂缝性漏层的承压能力,减少漏失量并降低综合堵漏成本,助力长7页岩油勘探开发,值得进一步研究和推广。Abstract: The Chang 7 shale oil reservoir is tight but has good fluid fluidity, which has micron-scale pores and fracture structure, leading to frequent permeable loss, fractured loss and total loss during the drilling process. Conventional plugging materials cannot meet the drilling construction requirements, resulting in a significant increase in non-production time and costs, and severely restricting the exploration and development process. Based on the theory of supramolecular chemistry, this research developed a new type of supramolecular polymer plugging material through synthesis formula optimization, and characterized and tested its microstructure, shear thinning and loss mitigation and pressure-bearing plugging ability. The research results show that the supramolecular gel plugging material not only has excellent shear thinning properties and adherence abilities, but also has a strong pressure-bearing plugging effect in large pore loss zones simulated by two-layer steel ball beds (the steel ball diameters are 8 mm ~ 10 mm) and fractured loss zones simulated by longitudinal slotted plate (the fracture widths are 2 mm~6 mm), with a pressure-bearing capacity up to 6MPa. Its application of typical total loss well in Chang 7 shale oil block shows that supramolecular gel plugging technology can effectively improve the pressure-bearing capacity of fractured loss zones reducing loss volume and comprehensive plugging costs, and helps Chang 7 shale oil exploration and development. Thus, it is worthy of further research and promotion.

-

Key words:

- Lost circulation /

- Fractured loss /

- Supramolecular polymer /

- Chang 7 shale oil

-

表 1 超分子聚合物合成方案设计

序号 AM∶WS-1 t/h 引发剂/% SDS/% T/℃ 1 99∶1 2 0.2 1 40 2 99∶5 3 0.3 2 50 3 90∶10 4 0.4 3 60 4 88∶12 5 0.5 4 70 5 99∶5 3 0.3 2 50 6 99∶5 4 0.2 1 40 7 99∶5 5 0.5 4 70 8 99∶5 2 0.4 3 60 9 90∶10 4 0.5 3 60 10 90∶10 2 0.2 4 70 11 90∶10 5 0.4 1 40 12 90∶10 3 0.3 2 50 13 88∶12 5 0.4 4 70 14 88∶12 4 0.5 3 40 15 88∶12 2 0.3 2 50 16 88∶12 3 0.2 1 60 表 2 不同配方条件下0.2%~0.5%超分子聚合物溶液剪切稀释测试结果

序号 超分子聚合物/

%高剪切速率

下的黏度/

mPa·s低剪切速率

下的黏度/

mPa·s1 0.5 78 8120 2 0.5 55 12510 3 0.5 46 78080 4 0.5 89 42015 5 0.3 68 7954 6 0.2 45 15420 7 0.5 50 100871 8 0.5 87 45792 9 0.5 68 10541 10 0.5 62 51234 11 0.5 49 112540 12 0.5 95 41258 13 0.5 88 9974 14 0.5 51 77589 15 0.5 42 78564 16 0.5 91 22543 表 3 不同浓度超分子聚合物堵漏剂漏失量随压力的变化

P/

MPa不同超分子聚合物浓度(%)下的漏失量/mL 10 15 20 0 0 0 0 1 63 48 0 2 全漏失 全漏失 0 3 0 4 1 5 24 6 全漏失 -

[1] 徐同台, 刘玉杰, 申威. 钻井工程防漏堵漏技术[M]. 北京: 石油工业出版社, 1997.XU Tongtai, LIU Yujie, SHEN Wei. Loss prevention and plugging technology for drilling engineering[M]. Beijing: Petroleum Industry Press, 1997. [2] 杨勇,罗鸣,韩成,等. 国内外大裂缝、溶洞性复杂地层堵漏技术进展[J]. 化学工程与装备,2018(8):282-284.YANG Yong, LUO Ming, HAN Cheng, et al. Progress in plugging technology for large fractures and complex cavernous formations at home and abroad[J]. Chemical Engineering & Equipment, 2018(8):282-284. [3] 温峥,杨双春,潘一,等. 堵漏技术的研究进展[J]. 油田化学,2016,33(1):186-190.WEN Zheng, YANG Shuangchun, Pan Yi, et al. Research progress of plugging technology[J]. Oilfield Chemistry, 2016, 33(1):186-190. [4] 王中华. 复杂漏失地层堵漏技术现状及发展方向[J]. 中外能源,2014(1):39-48. doi: 10.3969/j.issn.1673-579X.2014.01.007WANG Zhonghua. The status and development direction of plugging technology for complex formation lost circulation[J]. Sino-global Energy, 2014(1):39-48. doi: 10.3969/j.issn.1673-579X.2014.01.007 [5] 康玉柱. 中国非常规油气勘探重大进展和资源潜力[J]. 石油科技论坛,2018,37(4):1-7. doi: 10.3969/j.issn.1002-302x.2018.04.001KANG Yuzhu. Significant Exploration Progress and Resource Potential of Unconventional Oil and Gas in China[J]. Petroleum Science and Technology Forum, 2018, 37(4):1-7. doi: 10.3969/j.issn.1002-302x.2018.04.001 [6] WHITE R J. Lost-circulation materials and their evaluation[C]. //Drilling and Production Practice, American Petroleum Institute, 1956. [7] ALSABA M, NYGAARD R, HARELAND G, et al. Review of lost circulation materials and treatments with an updated classification[C]. //AADE Fluids Technical Conference and Exhibition, American Association of Drilling Engineers, 2014 : 1-9. [8] ABRAMS A. Mud design to minimize rock impairment due to particle invasion[J]. Journal of petroleum technology, 1977, 29(5):586-592. doi: 10.2118/5713-PA [9] DICK M A, HEINZ T J, SVOBODA C F, et al. Optimizing the Selection of Bridging Particles for Reservoir Drilling Fluids[C]. //SPE International Symposium on Formation Damage Control, Society of Petroleum Engineers, 2000: 8. [10] VICKERS S, COWIE M, JONES T, et al. A new methodology that surpasses current bridging theories to efficiently seal a varied pore throat distribution as found in natural reservoir formations[J]. Wiertnictwo, Nafta, Gaz, 2006, 23(1):501-515. [11] ARSHAD U, JAIN B, RAMZAN M, et al. Engineered Solution to Reduce the Impact of Lost Circulation During Drilling and Cementing in Rumaila Field, Iraq[C].//International Petroleum Technology Conference, International Petroleum Technology Conference, 2015: 17. [12] 张新民,聂勋勇,王平全,等. 特种凝胶在钻井堵漏中的应用[J]. 钻井液与完井液,2007(5):83-84+94. doi: 10.3969/j.issn.1001-5620.2007.05.028ZHANG Xinmin, NIE Xunyong, WANG Pingquan, et al. A special gel for mud loss control[J]. Drilling Fluid & Completion, 2007(5):83-84+94. doi: 10.3969/j.issn.1001-5620.2007.05.028 [13] 王平全,聂勋勇,张新民,等. 特种凝胶在处理“井漏井喷”中的应用[J]. 天然气工业,2008(6):81-82+85+150-151. doi: 10.3787/j.issn.1000-0976.2008.06.021WANG Pingquan, NIE Xunyong, ZHANG Xinmin, et al. Application of a special gel to controlling blowout and lost circulation[J]. Natural Gas Industry, 2008(6):81-82+85+150-151. doi: 10.3787/j.issn.1000-0976.2008.06.021 [14] 王平全,李再钧,聂勋勇,等. 用于钻井堵漏和封堵的特种凝胶抗冲稀性能[J]. 石油学报,2012,33(4):697-701.WANG Pingquan, LI Zaijun, NIU xunyong, et al. Anti-dilution properties of a special gel applied to loss circulation control in drilling[J]. Acta Petrolei Sinica, 2012, 33(4):697-701. [15] 周厚培. 聚合物凝胶堵漏工艺[J]. 油田化学,1987(3):161-169.ZHOU Houpei. Technology of polymer gelling plugging in case of circulation losses[J]. Oilfield Chemistry, 1987(3):161-169. [16] 张希文,李爽,张洁,等. 钻井液堵漏材料及防漏堵漏技术研究进展[J]. 钻井液与完井液,2009,26(6):74-76. doi: 10.3969/j.issn.1001-5620.2009.06.022ZHANG Xiwen, LI Shuang, ZHANG Jie, et al. Research progress on lost circulation materials and lost circulation control technology[J]. Drilling Fluid & Completion, 2009, 26(6):74-76. doi: 10.3969/j.issn.1001-5620.2009.06.022 [17] 沈家骢,孙俊奇. 超分子科学研究进展[J]. 中国科学院院刊,2004(6):420-424. doi: 10.3969/j.issn.1000-3045.2004.06.006SHEN Jiacong, SUN Junqi. Research development of supramolar science[J]. Bulletin of Chinese Academy of Sciences, 2004(6):420-424. doi: 10.3969/j.issn.1000-3045.2004.06.006 [18] 李旋,蒋瑶,谢千秋,等. 超分子水凝胶材料研究进展[J]. 应用化工,2019,48(5):1140-1145. doi: 10.3969/j.issn.1671-3206.2019.05.036LI Xuan, Jiang Yao, XIE Qianqiu, et al. Progress in supramolecular hydrogel materials[J]. Applied Chemical Industry, 2019, 48(5):1140-1145. doi: 10.3969/j.issn.1671-3206.2019.05.036 [19] 张政. 超分子自愈合水凝胶的制备及性能研究[D]. 宁波: 宁波大学, 2018.ZHANG Zheng. Preparation and performance study of supramolecular self-healing hydrogel[D]. Ningbo: Ningbo University, 2018. [20] 王勇,蒋官澄,杜庆福,等. 超分子化学堵漏技术研究与应用[J]. 钻井液与完井液,2018,35(3):48-53. doi: 10.3969/j.issn.1001-5620.2018.03.008WANG Yong, JIANG Guancheng, DU Qingfu, et al. Study and application of supramolecule chemical LCM technology[J]. Drilling Fluid & Completion Fluid, 2018, 35(3):48-53. doi: 10.3969/j.issn.1001-5620.2018.03.008 [21] 方俊伟,吕忠楷,何仲,等. 化学凝胶堵剂承压堵漏技术在顺北3井的应用[J]. 钻井液与完井液,2017,34(6):13-17. doi: 10.3969/j.issn.1001-5620.2017.06.003FANG Junwei, LYU Zhongkai, HE Zhong, et al. Application of chemical gel LCM on well Shunbei-3[J]. Drilling Fluid & Completion Fuild, 2017, 34(6):13-17. doi: 10.3969/j.issn.1001-5620.2017.06.003 [22] 王骁男,张栋俊,吕忠楷,等. 智能凝胶塞在晋中3井的应用[J]. 钻采工艺,2018,41(5):110-112. doi: 10.3969/J.ISSN.1006-768X.2018.05.33WANG Xiaonan, ZHANG Dongjun, LYU Zhongkai, et al. Application of smart gel plug in jinzhong 3 well[J]. Drilling & Production Technology, 2018, 41(5):110-112. doi: 10.3969/J.ISSN.1006-768X.2018.05.33 [23] 胡祖彪,张建卿,王清臣,等. 长庆油田华H50-7井超长水平段钻井液技术[J]. 石油钻探技术,2020,48(4):28-36.HU Zubiao, ZHANG Jianqing, WANG Qingchen, et al. Drilling fluid technology for ultra-long horizontal section of well Hua H50-7 in the Changqing Oilfield[J]. Petroleum Drilling Techniques, 2020, 48(4):28-36. [24] 王平全,朱涛. 一种评价特种凝胶ZND启动压力的新仪器[J]. 钻井液与完井液,2015,32(1):57-59.WANG Pingquan, ZHU Tao. A novel instrument for evaluation start-up pressure of special gel ZND[J]. Drilling Fluid & Completion Fuild, 2015, 32(1):57-59. [25] 李文博,李公让. 可控化聚合物凝胶堵漏材料的研究进展[J]. 钻井液与完井液,2021,38(2):133-141.LI Wenbo,LI Gongrang. Research progress of controllable polymer gel lost circulation materials[J]. Drilling Fluid & Completion Fuild, 2021, 38(2):133-141. [26] 许婧,王在明,张艺馨,等. 自固结堵漏技术在冀东油田G21X3井的应用[J]. 钻井液与完井液,2021,38(1):89-92.XU Jing, WANG Zaiming, ZHANG Yixin, et al. Application of a Self-Solidifying Lost Circulation Material in Well G21X3 in Jidong Oilfield[J]. Drilling Fluid & Completion Fluid, 2021, 38(1):89-92. -

下载:

下载: