Preparation of Gel Microspheres for Water Based Drilling Fluids and Its Application in Lost Circulation Control

-

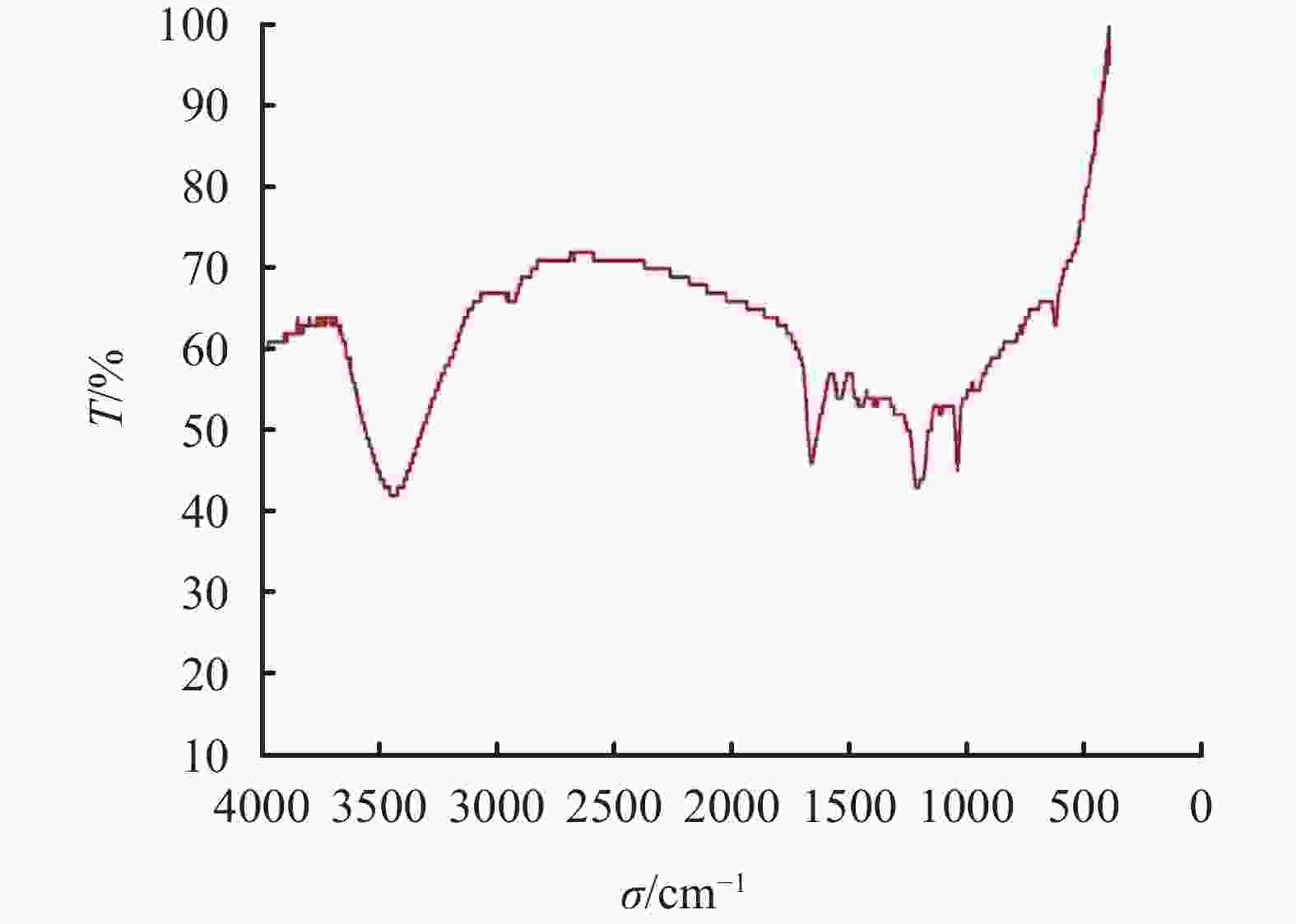

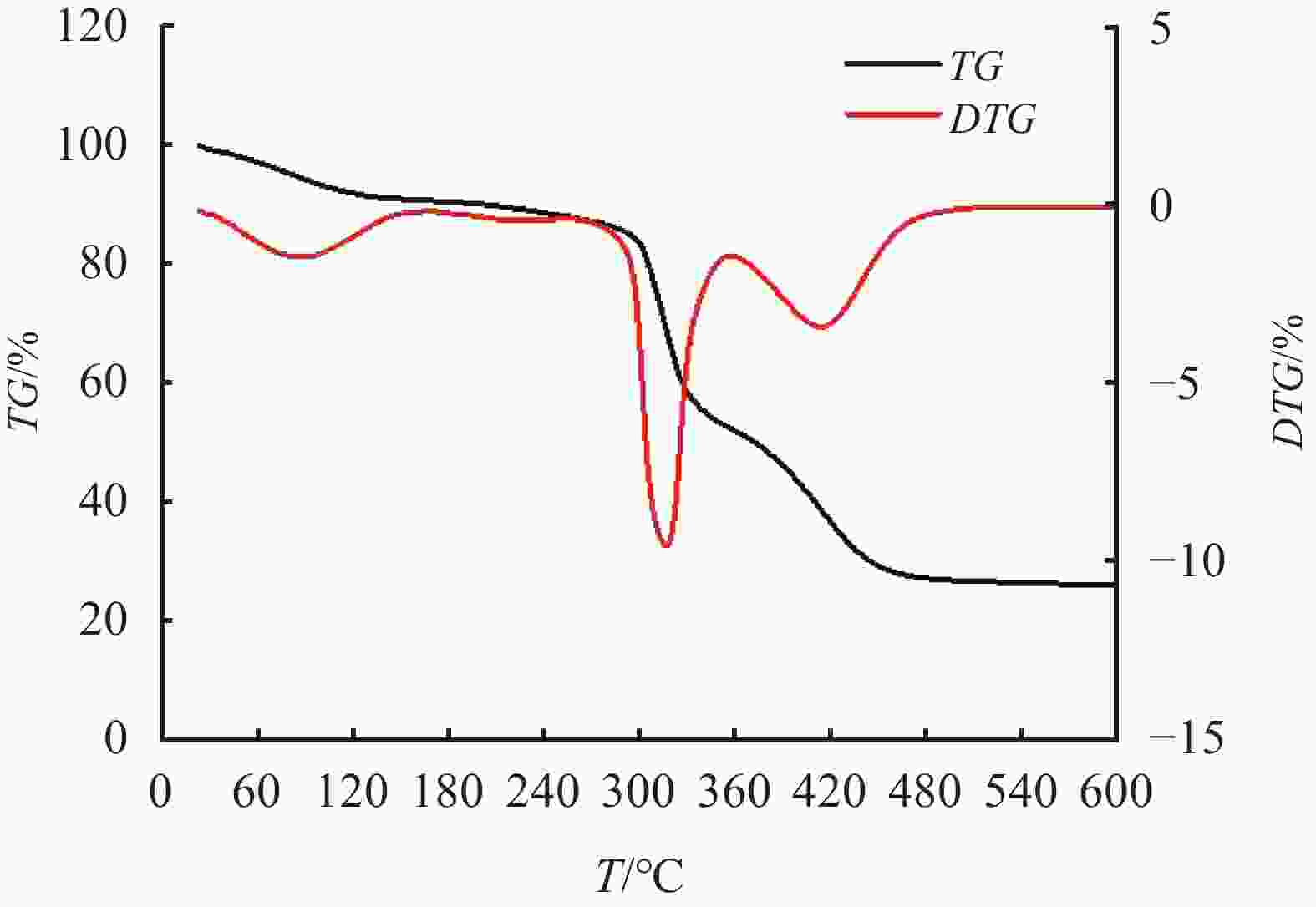

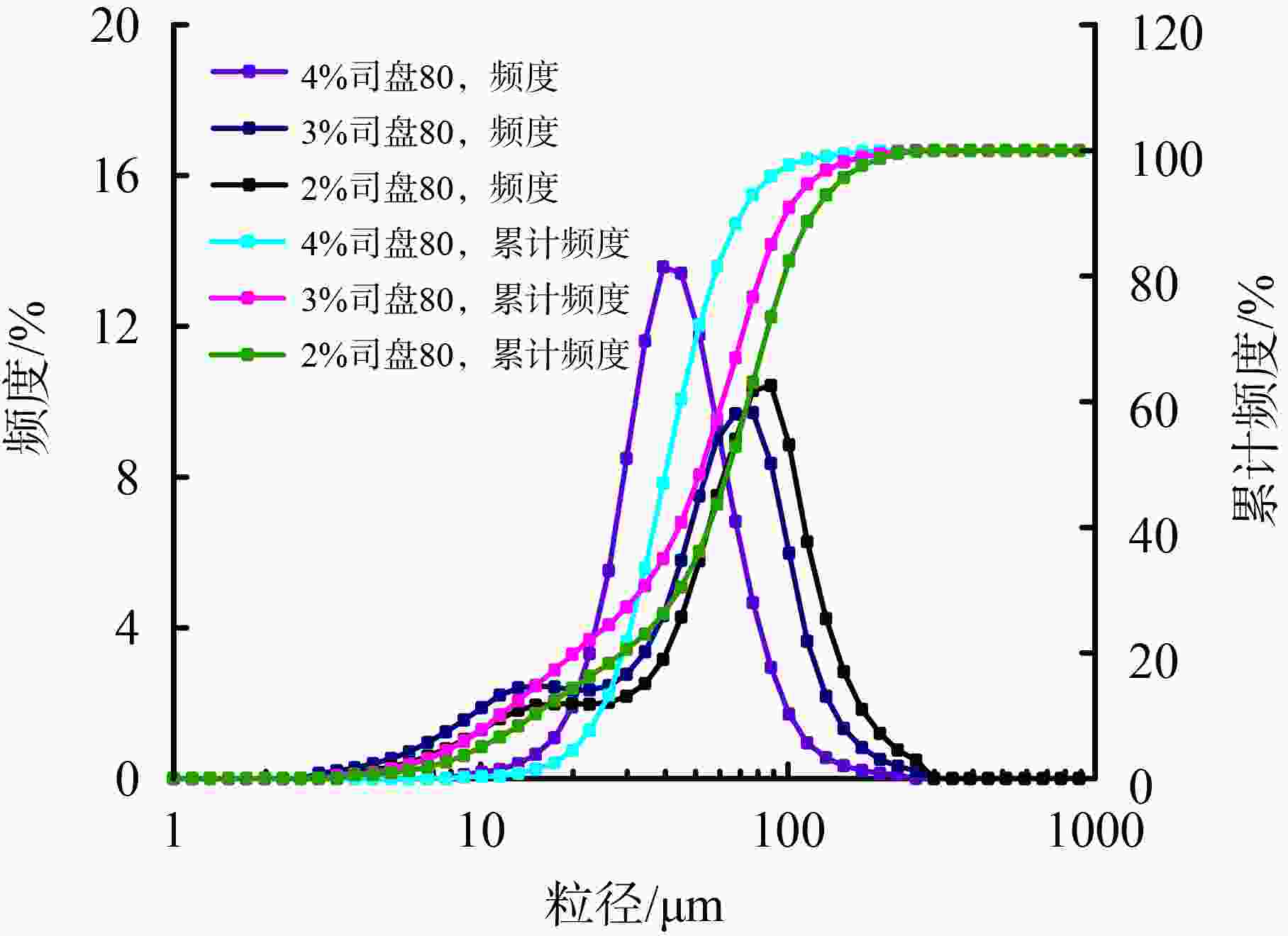

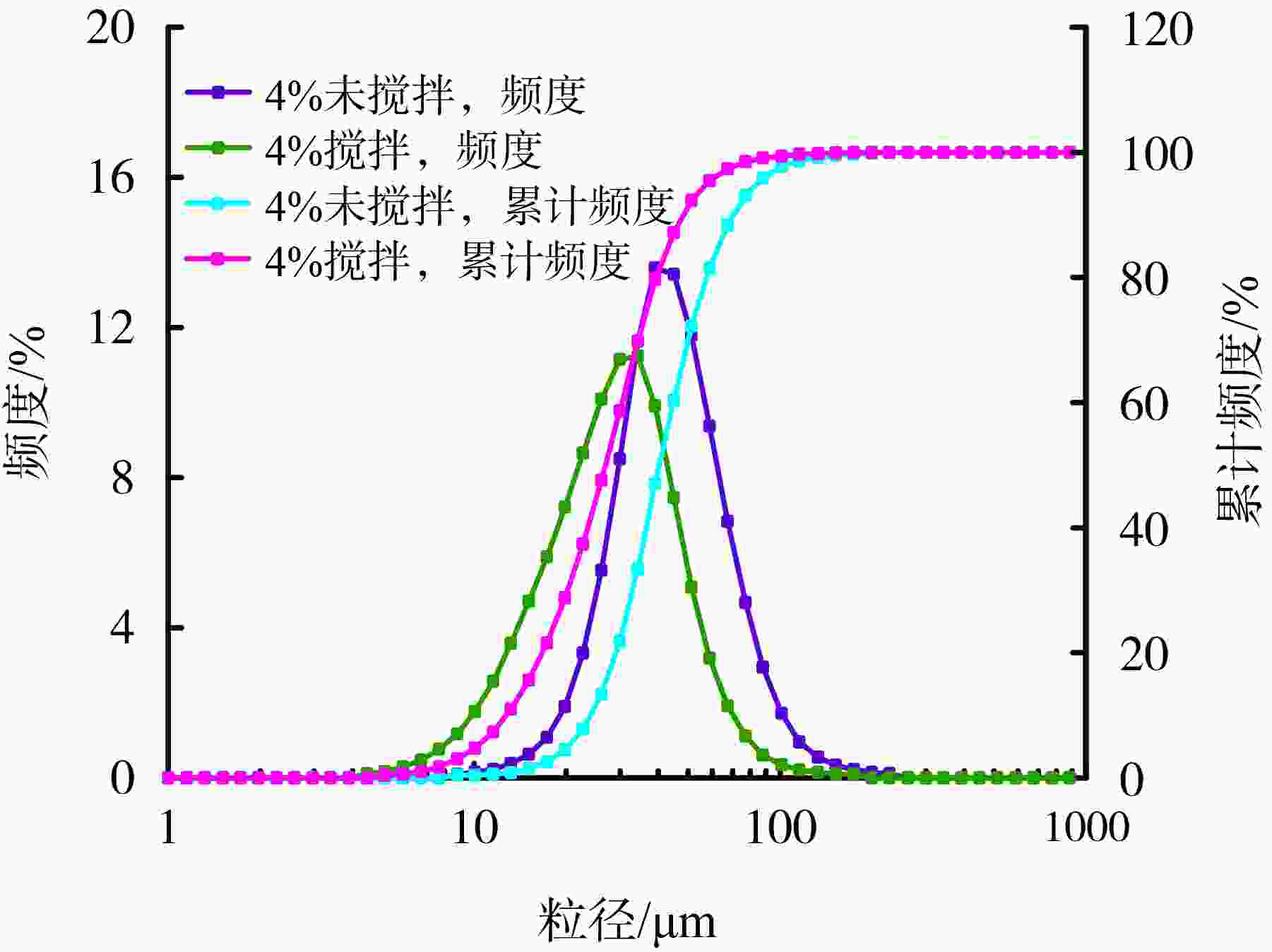

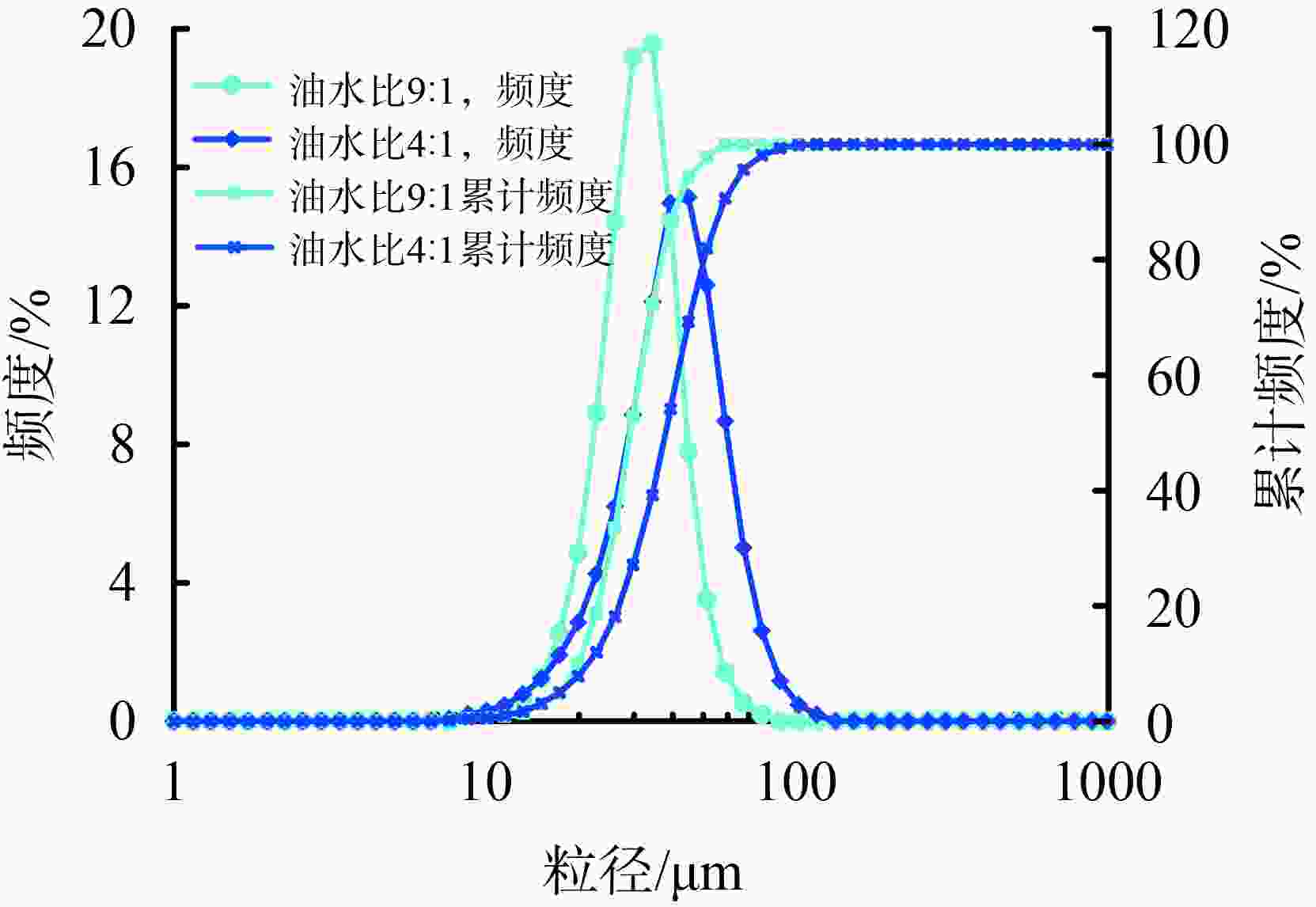

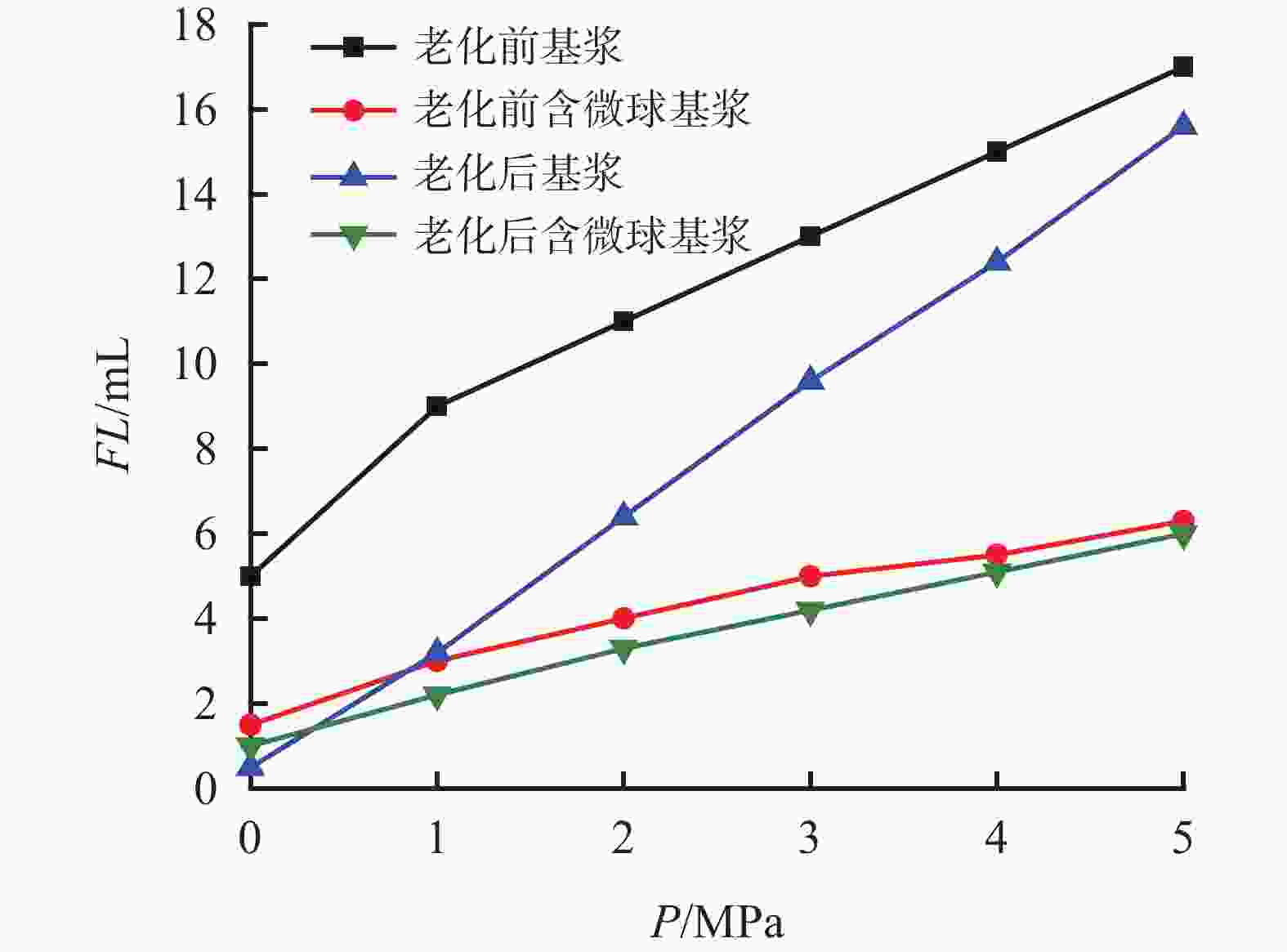

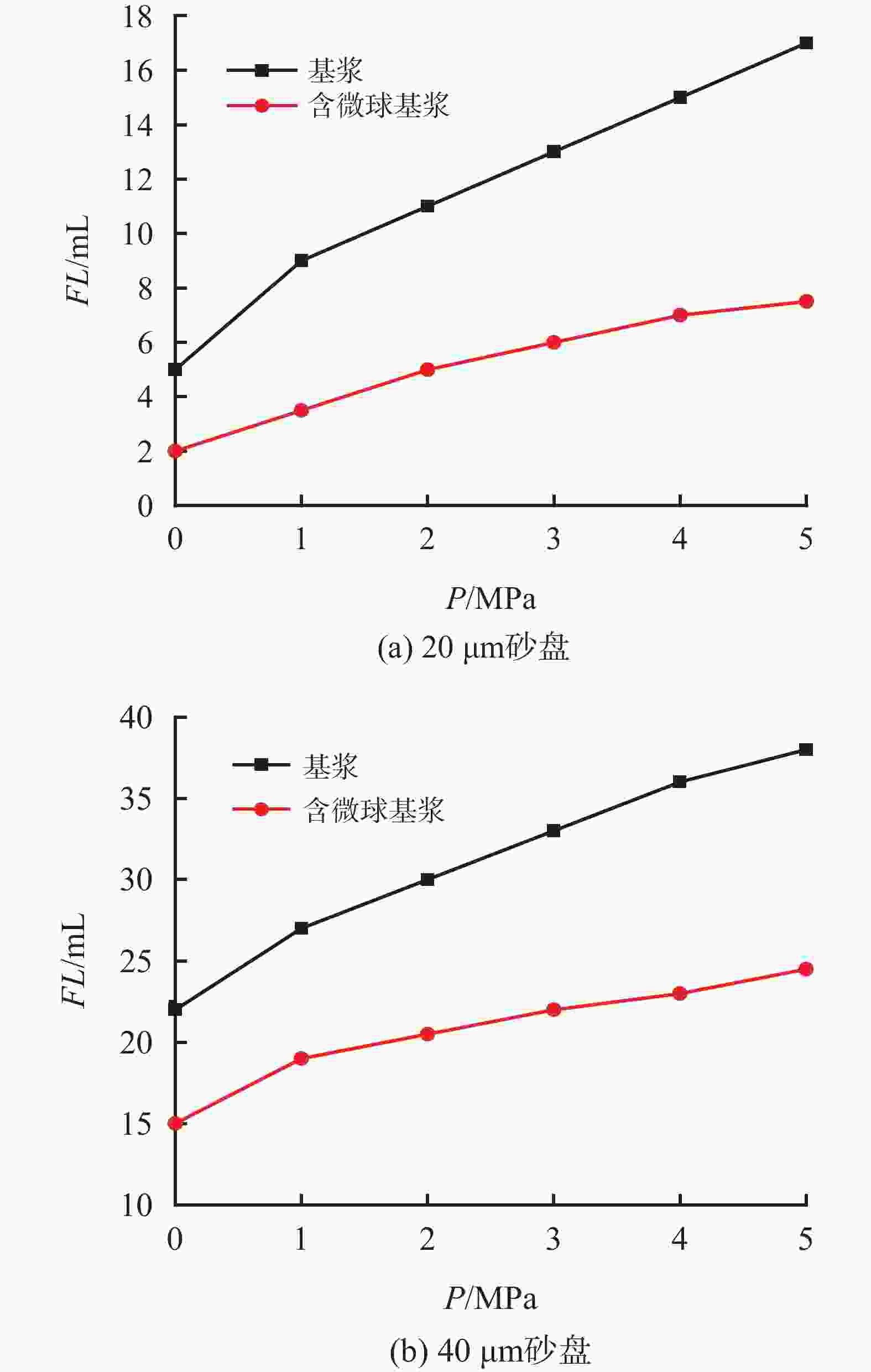

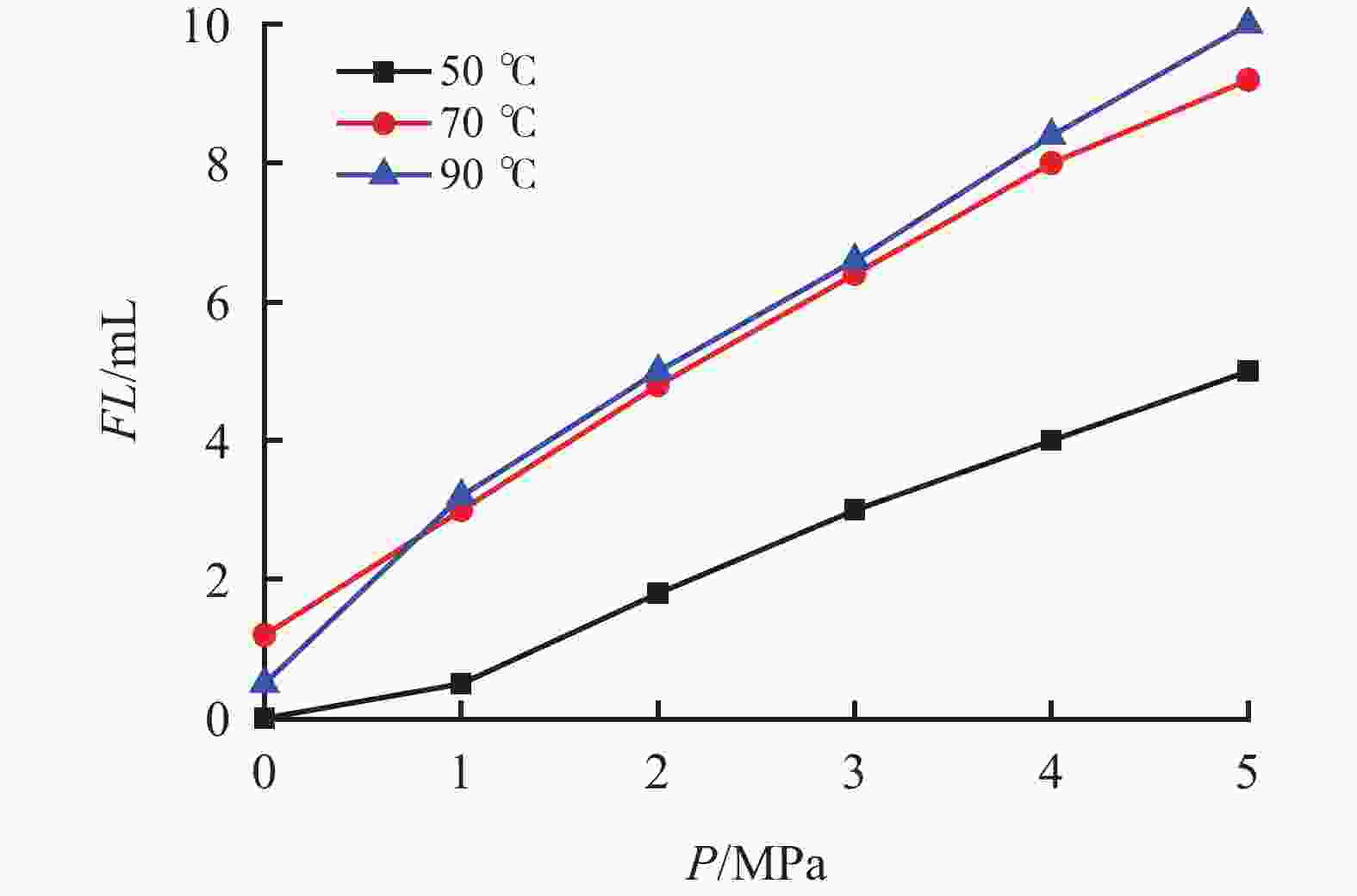

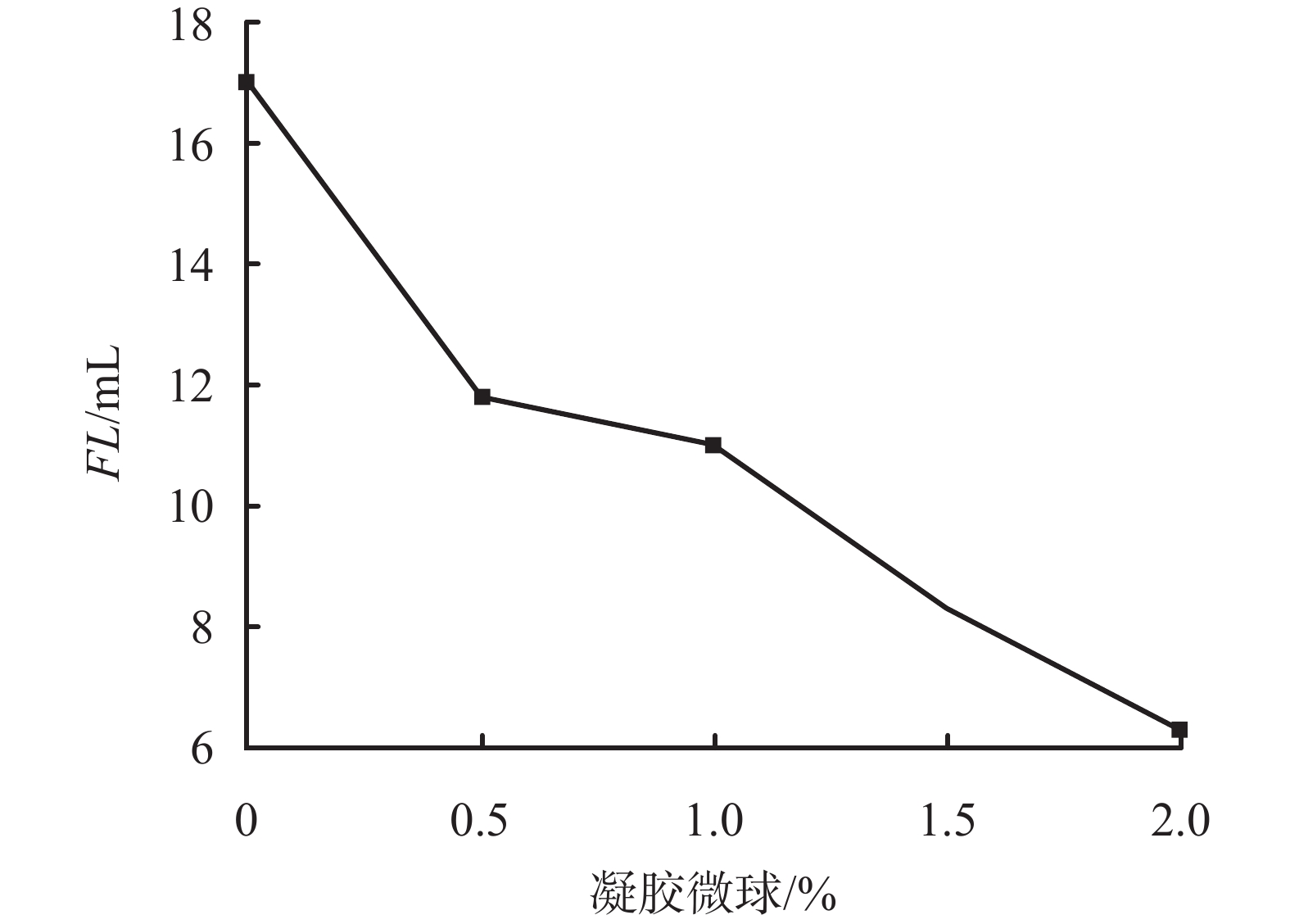

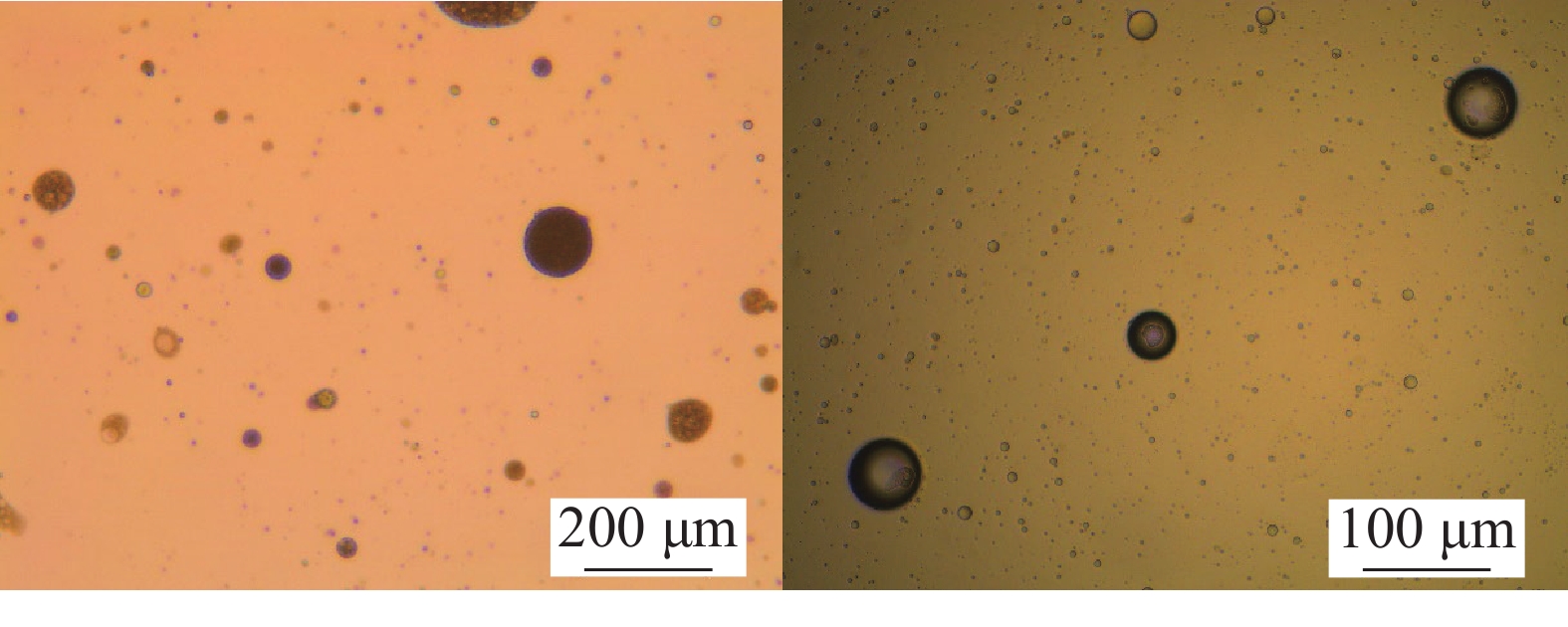

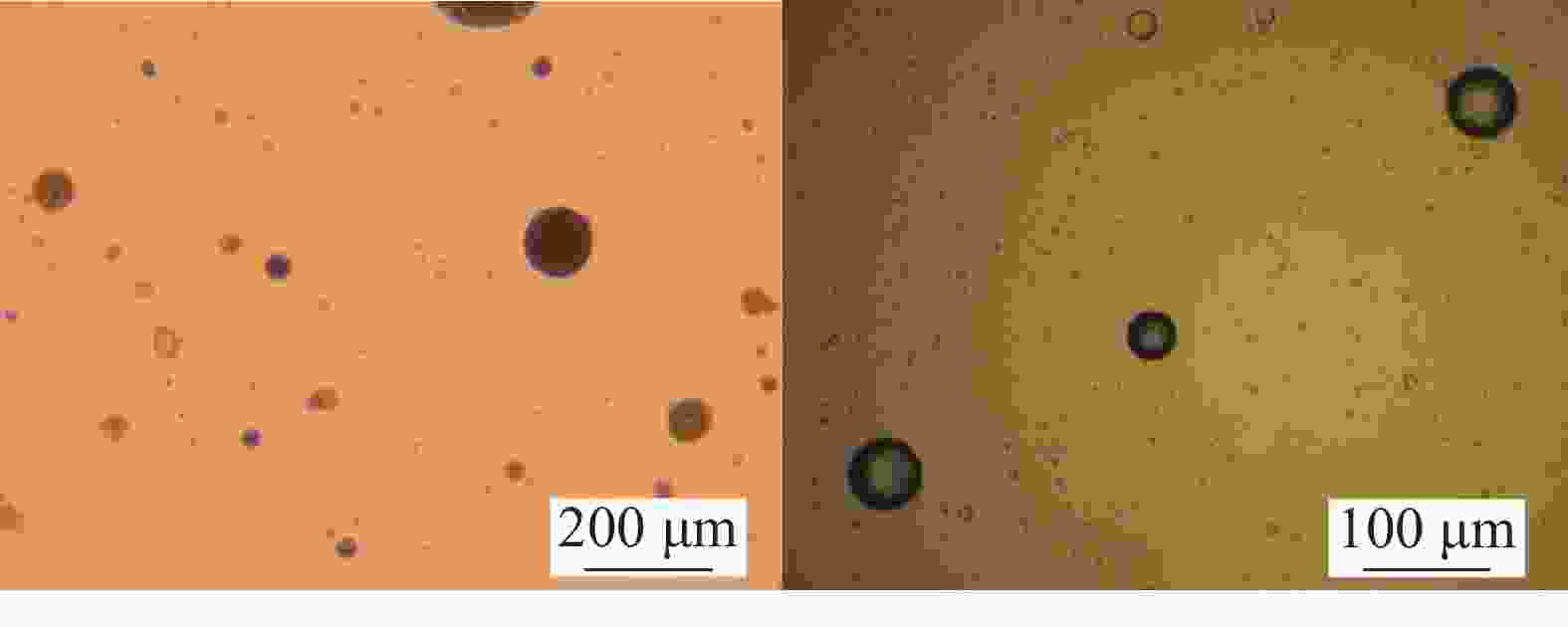

摘要: 采用反相乳液聚合法,合成了水基钻井液用凝胶微球。采用电子显微镜、红外光谱、热重分析、粒径分析,对合成的凝胶微球的组成、形貌及热稳定性进行了表征。结果显示制备出的凝胶微球呈现微米级球形结构,尺寸在4.5~68 μm范围内,初始热分解温度为150 ℃。同时考察了乳化剂加量、搅拌、油水比对凝胶微球粒径的影响,评价了凝胶微球的堵漏性能。结果表明,反应条件对凝胶微球尺寸有较大影响,随着乳化剂加量的增大,凝胶微球的平均粒径减小;适当搅拌会促进乳状液的稳定,合成得到的凝胶微球的粒径较小;增大油水比会导致凝胶微球的平均粒径减小。通过堵漏实验可知,凝胶微球有良好的封堵效果,其中乳化剂加量为4%,油水比为7∶3,不搅拌条件下制备的凝胶微球平均粒径为45.1 μm,是封堵效果最好的凝胶微球。Abstract: A gel microsphere lost circulation material (LCM) has been synthesized through inverse emulsion polymerization. The composition, morphology and thermal stability of the gel microspheres were characterized using electron microscope, IR spectroscopy, thermogravimetric analysis and particle size analysis. It was found in these studies that the gel microspheres are in a micron spherical structure, with their particle sizes ranging from 4.5 μm to 68 μm. The initial thermal decomposition temperature of the gel microspheres is 150 ℃. The effects of the amount of emulsifier added into the reaction, mixing of the reactants and oil/water ratio on the particle size of the gel microspheres were examined and the performance of the gel microspheres evaluated. The results of the examination showed that the reaction conditions have a great influence on the sizes of the gel microspheres; as the amount of emulsifier increases, the average diameter of the gel microspheres decreases. Proper stirring promotes the stability of the emulsion, thereby reducing the particle sizes of the gel microspheres. An increase in oil/water ratio decreases the average particle size of the gel microspheres. The LCM evaluation test results showed that the gel microspheres have a good lost circulation control effect; gel microspheres, which are produced at 4% emulsifier, oil/water ratio of 7∶3 and without stirring have average particle size of 45.1 μm, and are the best LCM.

-

Key words:

- Gel microsphere /

- Water based drilling fluid /

- Lost circulation material

-

表 1 含不同粒径凝胶微球乳液基浆老化前后的流变性

平均

粒径/μm实验

条件φ600 φ300 PV/

mPa·sYP/

PaFLAPI/

mL29.6 老化前 20 12 8 2.0 16.0 120 ℃、16 h 24 14 10 2.0 20.4 30.2 老化前 30 23 7 8.0 19.6 120 ℃、16 h 62 42 20 11.0 18.4 39.3 老化前 26 17 9 4.0 19.2 120 ℃、16 h 45 28 17 5.5 20.0 45.1 老化前 39 31 8 11.5 18.4 120 ℃、16 h 59 40 19 10.5 18.0 55.5 老化前 36 31 5 13.0 17.2 120 ℃、16 h 51 35 16 9.5 16.8 68.2 老化前 34 25 9 8.0 17.2 120 ℃、16 h 55 46 9 18.5 16.0 -

[1] 商洪义. 井壁失稳的原因及预防措施探讨[J]. 西部探矿工程,2019,31(7):28-29. doi: 10.3969/j.issn.1004-5716.2019.07.010SHANG Hongyi. Probe into the causes of well wall instability and preventive measures[J]. West-China Exploration Engineering, 2019, 31(7):28-29. doi: 10.3969/j.issn.1004-5716.2019.07.010 [2] 柳新风. 钻井工程设计风险评价研究[D]. 成都: 西南石油大学, 2014.LIU Xinfeng. Study on risk assessment of drilling engineering design[D]. Chengdu: Southwest Petroleum University, 2014. [3] 郭永宾, 颜帮川, 黄熠, 等. 高温成胶可降解聚合物凝胶堵漏剂的研制与评价[J]. 钻井液与完井液, 2019, 36(3): 293-297.GUO Yongbin, YAN Bangchuan, HUANG Yi, et al. Development and evaluation of high temperature gel forming degradable polymer gel plugging agent[J]. Drilling Fluid & Completion Fluid, 2019, 36(3): 293-297. [4] 吕开河, 章超, 黄贤斌, 等. 一种水基钻井液用抗高温承压封堵剂及其制备方法与应用: 中国, CN112812245A[P]. 2021-05-18.LYU Kaihe, ZHANG Chao, HUANG Xianbin, et al. A high temperature resistant pressure sealing agent for water-based drilling fluid and its preparation method and Application: China, CN112812245A[P]. 2021-05-18. [5] 穆海朋. 钻井中封堵漏层和水层的理论研究及新型堵剂的研制[D]. 中国石油大学, 2009.MU Haipeng. Theoretical study on plugging layer and water layer in drilling and development of new plugging agent[D]. China University of Petroleum, 2009. [6] 卢绍杰, 孙希明. 淀粉与DADMAC/AM接枝共聚反相胶乳[J]. 高分子材料科学与工程, 1999, 15(5): 52-55.LU Shaojie, SUN Ximing. Inverse latex of graft copolymerization of starch with DADMAC/am[J]. Polymer Materials Science & Engineering, 1999, 15(5): 52-55. [7] GE X, YE Q, XU X, et al. Studies of inverse emulsion copolymerization of (2-ethacryloyloxyethyl) trimethyl ammonium chloride and acrylamide[J]. Journal of Applied Polymer Science, 1998, 67(6):1005-1010. doi: 10.1002/(SICI)1097-4628(19980207)67:6<1005::AID-APP6>3.0.CO;2-M [8] 高青雨,石家华,王振卫. DMAEMA/SAMPS反相乳液聚合动力学[J]. 胶体与聚合物,2000,18(3):1-4. doi: 10.3969/j.issn.1009-1815.2000.03.001GAO Qingyu, SHI Jiahua, WANG Zhenwei. Kinetics of inverse emulsion polymerization of DMAEMA/SAMPS[J]. Chinese Journal of Colloid & Polymer, 2000, 18(3):1-4. doi: 10.3969/j.issn.1009-1815.2000.03.001 [9] NEFF R E , RYLES R G . Cross-linked cationic polymeric microparticles: US, US4968435 A[P]. 1992. [10] RYLES R G , HONIG D S , HARRIS E W , et al. Cross-linked anionic and amphoteric polymeric microparticles: EP, US5171808 A[P]. 1992. [11] 李震宇, 马莉. 丙烯酰胺类水凝胶微球调驱剂的研究进展[J]. 中国石油和化工标准与质量, 2011, 31(6): 20,19.LI Zhenyu, MA Li. Research progress of acrylamide hydrogel microsphere profile control and flooding agent[J]. China Petroleum and Chemical Standard and Quality, 2011, 31(6): 20, 19. [12] CHANG K T , FRAMPTON H , MORGAN J C . Method of recovering hydrocarbon fluids from a subterranean reservoir: US, US20030155122 A1[P]. 2004. [13] H FRAMPTON, J C MORGAN, S K CHEUNG, et al. Development of a novel waterflood conformance control system[C]. SPE 89391, 2004. [14] 赵怀珍,吴肇亮. 水溶性交联聚合物微球的制备及性能[J]. 精细化工,2005,22(1):62-65. doi: 10.3321/j.issn:1003-5214.2005.01.019ZHAO Huaizhen, WU Zhaoliang. Preparation and properties of water soluble crosslinked polymer microspheres[J]. Fine Chemicals, 2005, 22(1):62-65. doi: 10.3321/j.issn:1003-5214.2005.01.019 [15] 韩秀贞,李明远. 交联聚合物微球体系水化性能分析[J]. 油田化学,2006,23(2):162-165.HAN Xiuzhen, LI Mingyuan. Analysis of hydration properties of crosslinked polymer microspheres[J]. Oilfield Chemistry, 2006, 23(2):162-165. [16] 宗华,林梅钦. 交联聚合物微球体系封堵特性影响因素研究[J]. 应用化学,2007,36(7):693-695.ZONG Hua, LIN Meiqin. Study on Influencing Factors of plugging characteristics of crosslinked polymer microspheres[J]. Chinese Journal of Applied Chemistry, 2007, 36(7):693-695. [17] SYDANSK R D. A newly developed chromium(III) gel technology[J]. SPE Reservoir Engineering, 1990, 5(3): 346-352. [18] SERIGHT, R. S. Gel placement in fractured systems[J]. SPE Production & Facilities, 1995, 10(4): 241-248. [19] 项营,王玺,蒋官澄,等. 反相乳液聚合法合成凝胶微球及其封堵性能评价[J]. 钻井液与完井液,2020,37(3):275-281. doi: 10.3969/j.issn.1001-5620.2020.03.002XIANG Ying, WANG Xi, JIANG Guancheng, et al. Synthesis of gel microspheres by inverse emulsion polymerization and evaluation of their plugging properties[J]. Drilling Fluid & Completion Fluid, 2020, 37(3):275-281. doi: 10.3969/j.issn.1001-5620.2020.03.002 [20] KHATER M , SHAHAB U , AL-RUBAIYEA J , et al. Isolation of a horizontal hole section in an openhole well using a nondamaging temporary gel plug to facilitate hydrocarbon production from the remaining lateral section-A case history from Kuwait[R].IADC/SPE 72291, 2001. [21] JIA H, PU W F, ZHAO J Z, et al. Experimental investigation of the novel phenol formaldehyde cross-linking HPAM gel system: Based on the secondary cross-linking method of organic cross-linkers and its gelation performance study after flowing through porous media[J]. Energy & Fuels, 2011, 25(2):727-736. [22] ZHAO J Z, JIA H, PU W F, et al. Influences of fracture aperture on the water-shutoff performance of polyethyleneimine cross-linking partially hydrolyzed polyacrylamide gels in hydraulic fractured reservoirs[J]. Energy & Fuels, 2011, 25(6):2616-2624. [23] JIA H, ZHAO J Z, JIN F Y, et al. New insights into the gelation behavior of polyethyleneimine cross-linking partially hydrolyzed polyacrylamide gels[J]. Industrial & Engineering Chemistry Research, 2012, 51(38):12155-12166. [24] YADAV U S, V MAHTO. Investigating the effect of several parameters on the gelation behavior of partially hydrolyzed polyacrylamide-hexamine-hydroquinone gels[J]. Industrial & Engineering Chemistry Research, 2013, 52(28):9532-9537. [25] IMQAM A, BAI B. Optimizing the strength and size of preformed particle gels for better conformance control treatment[J]. Fuel, 2015, 148:178-185. doi: 10.1016/j.fuel.2015.01.022 -

下载:

下载: