Synthesis and Evaluation of a High Strength Curable Resin LCM PMMM

-

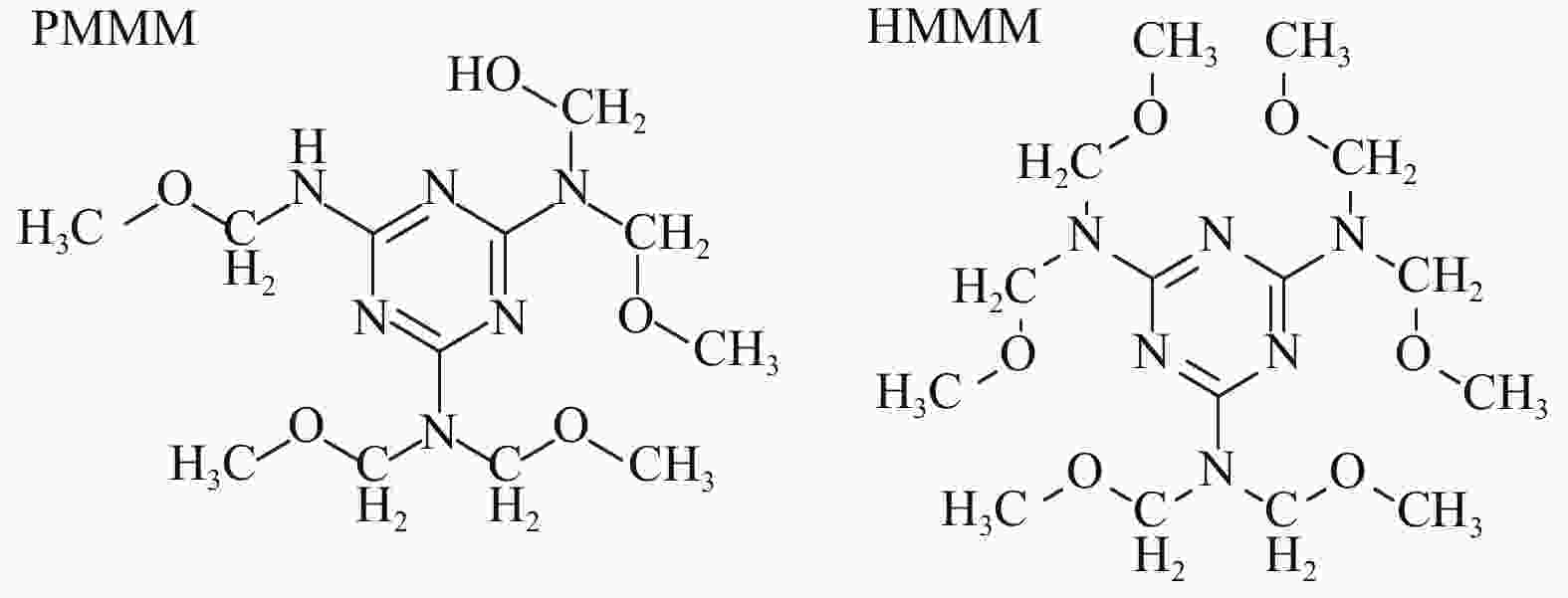

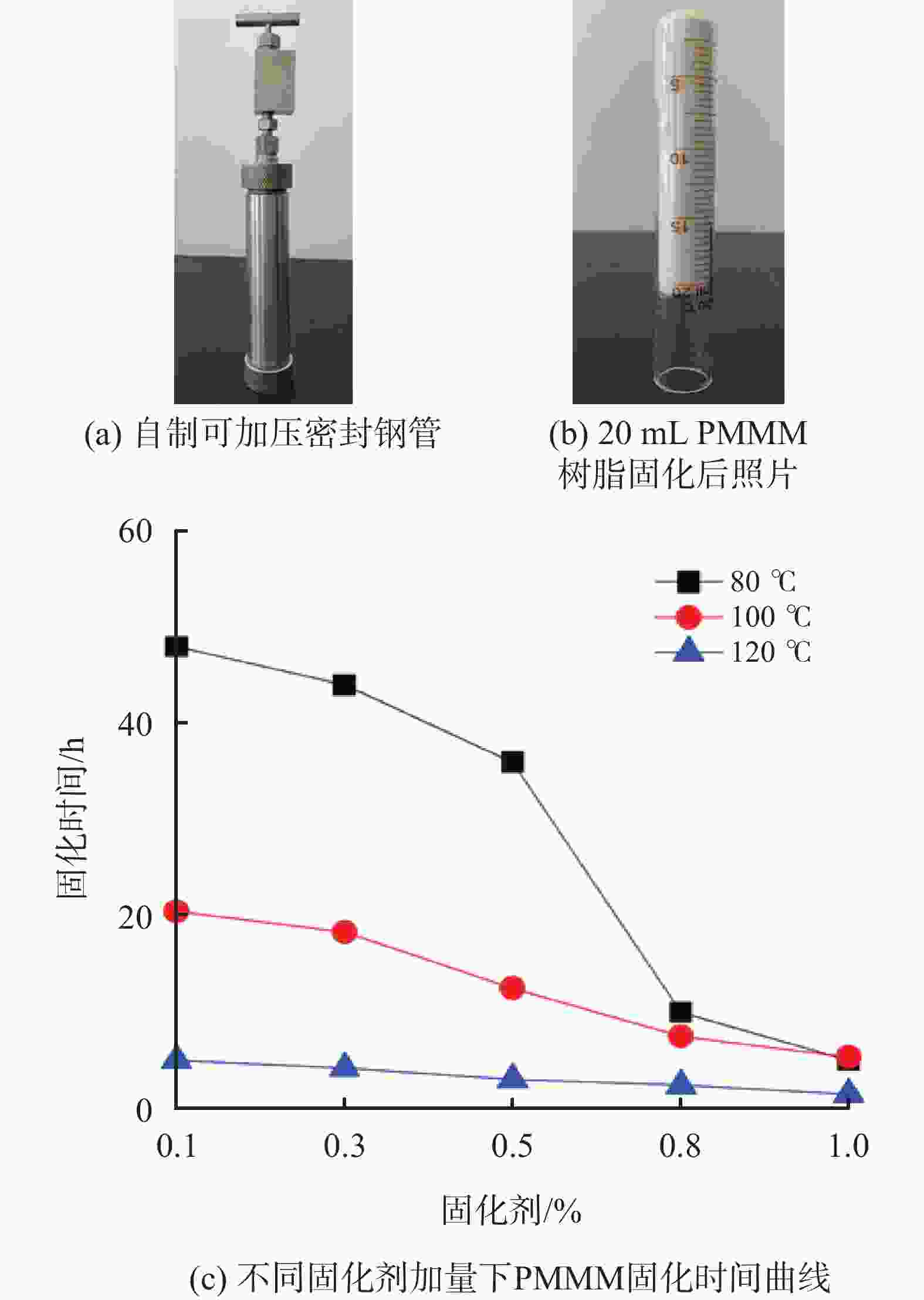

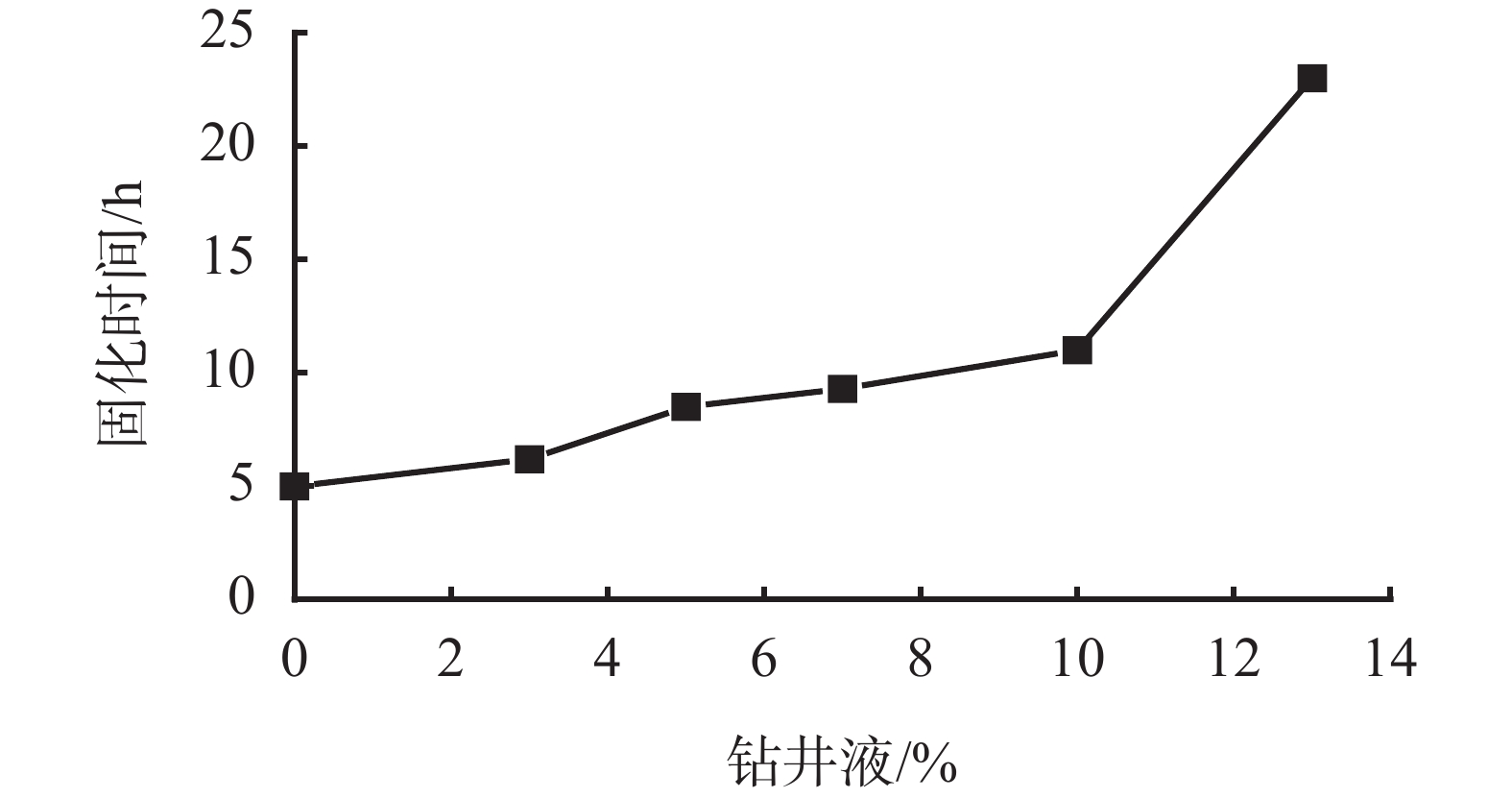

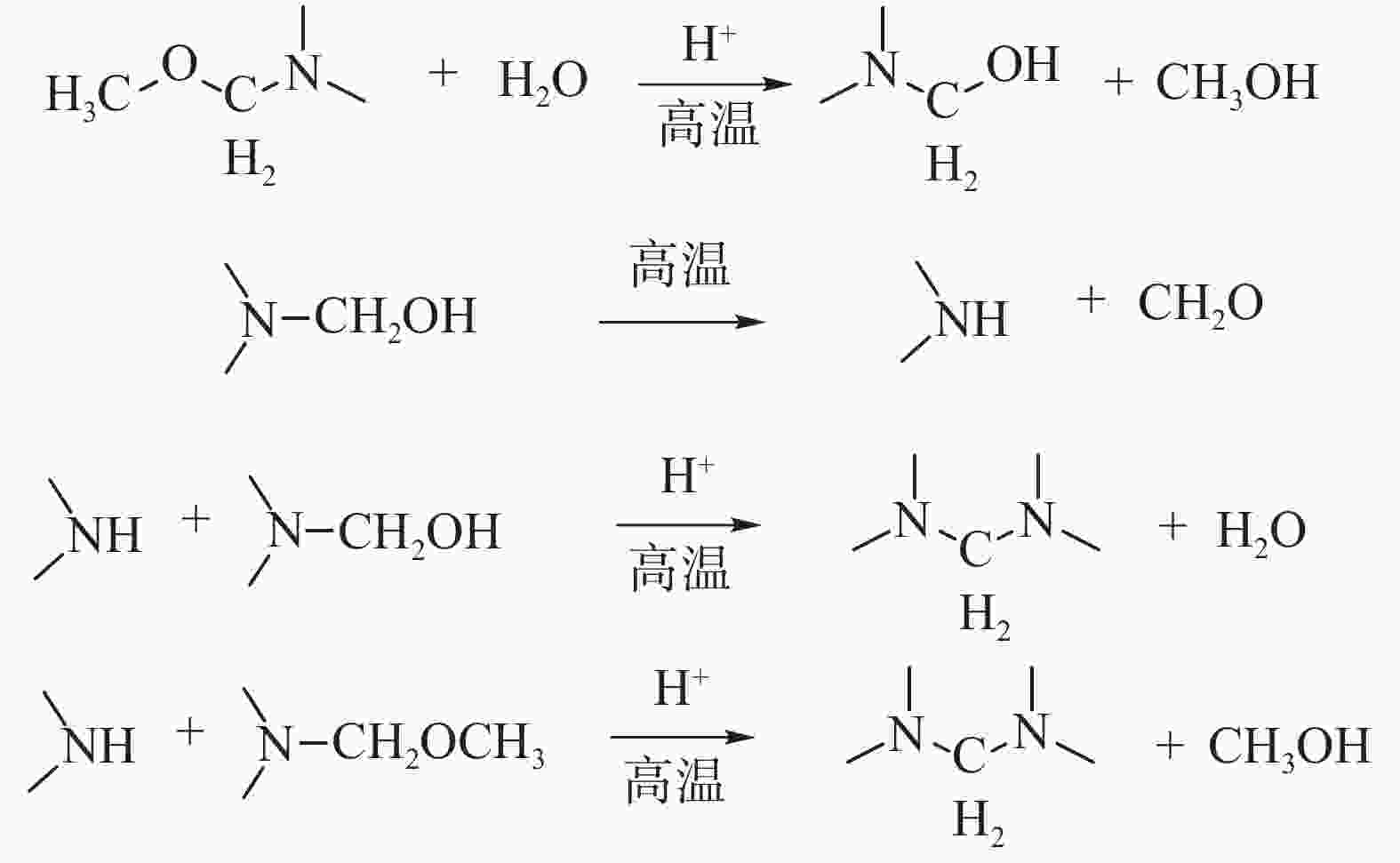

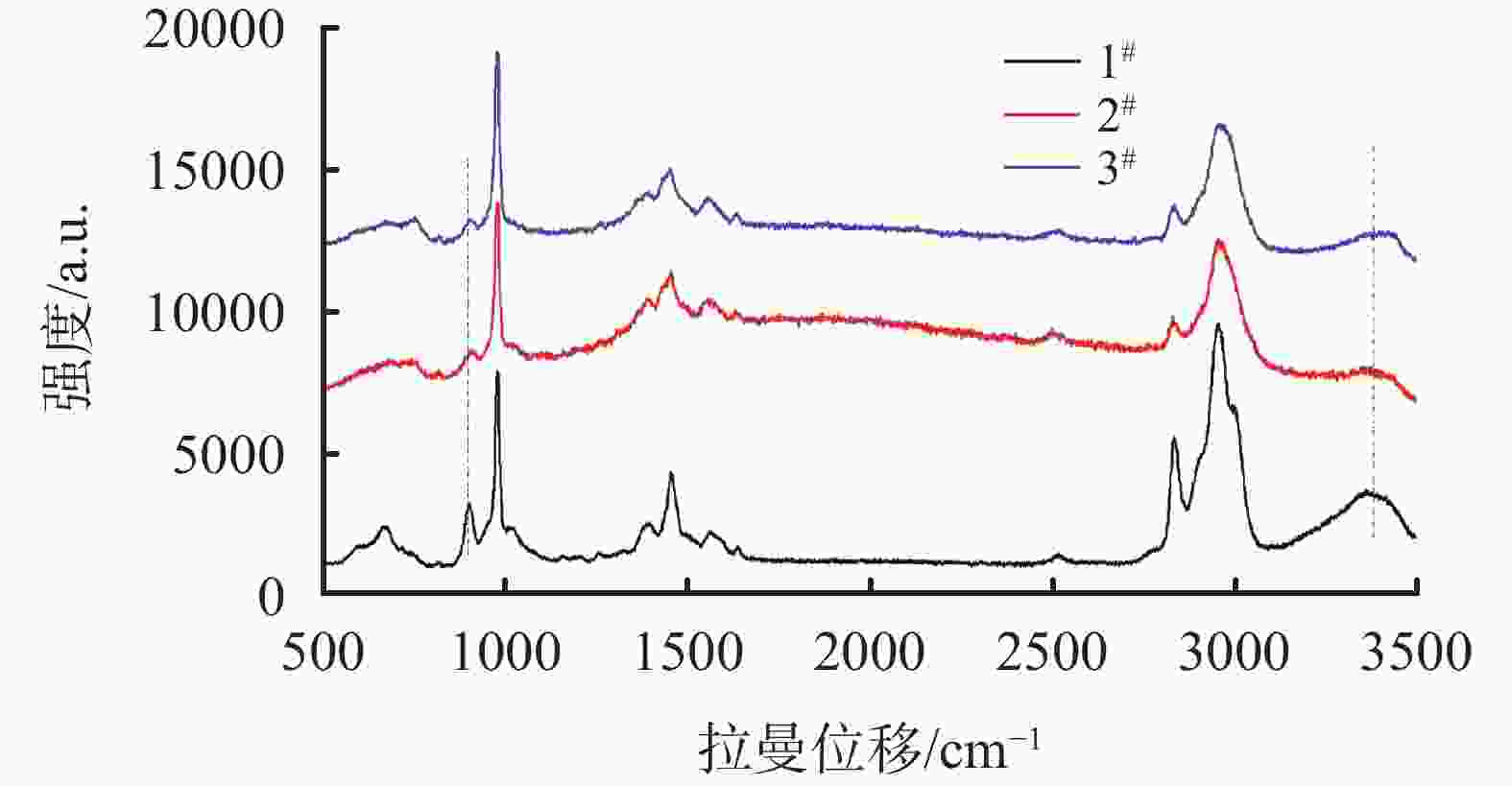

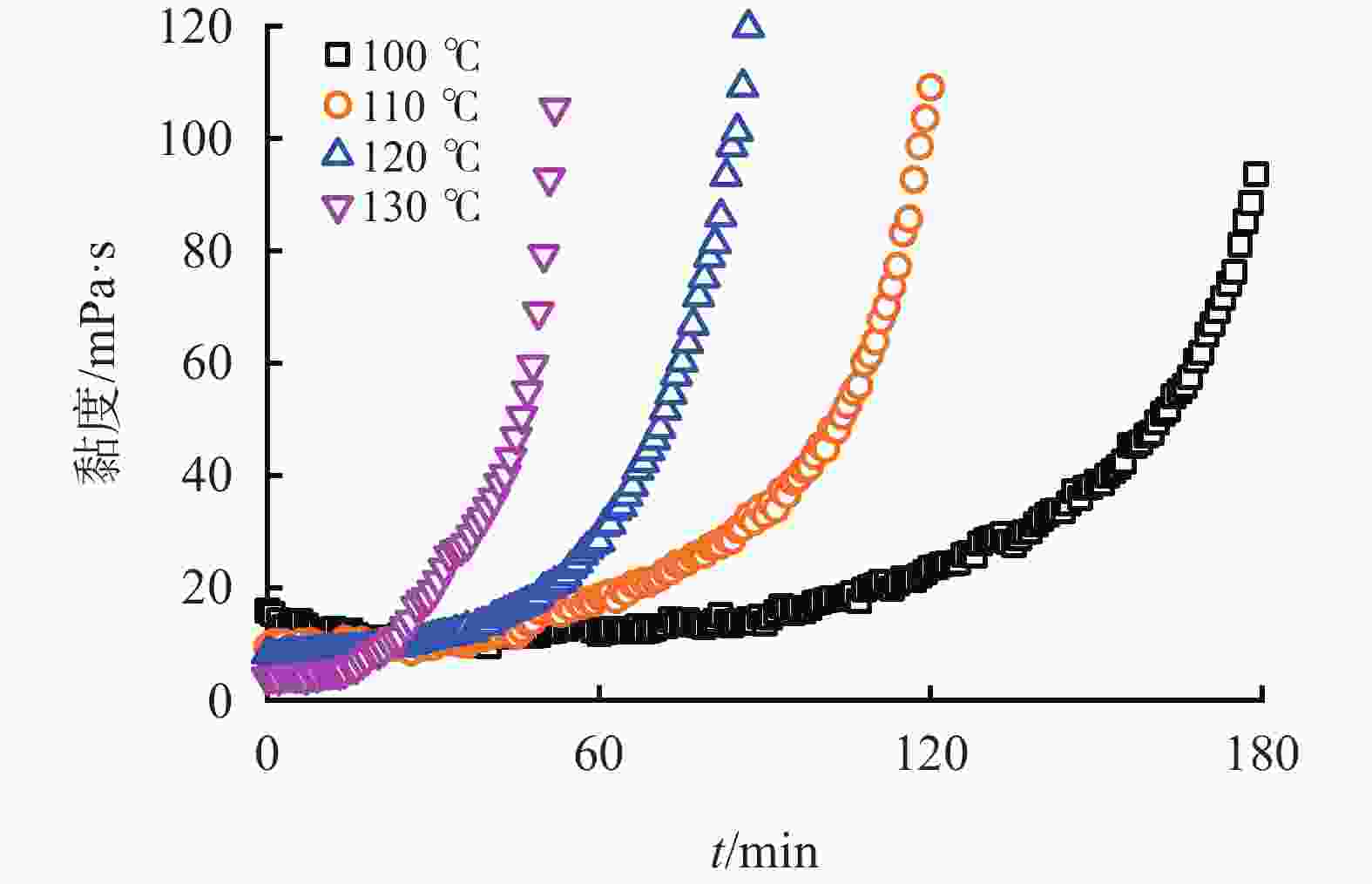

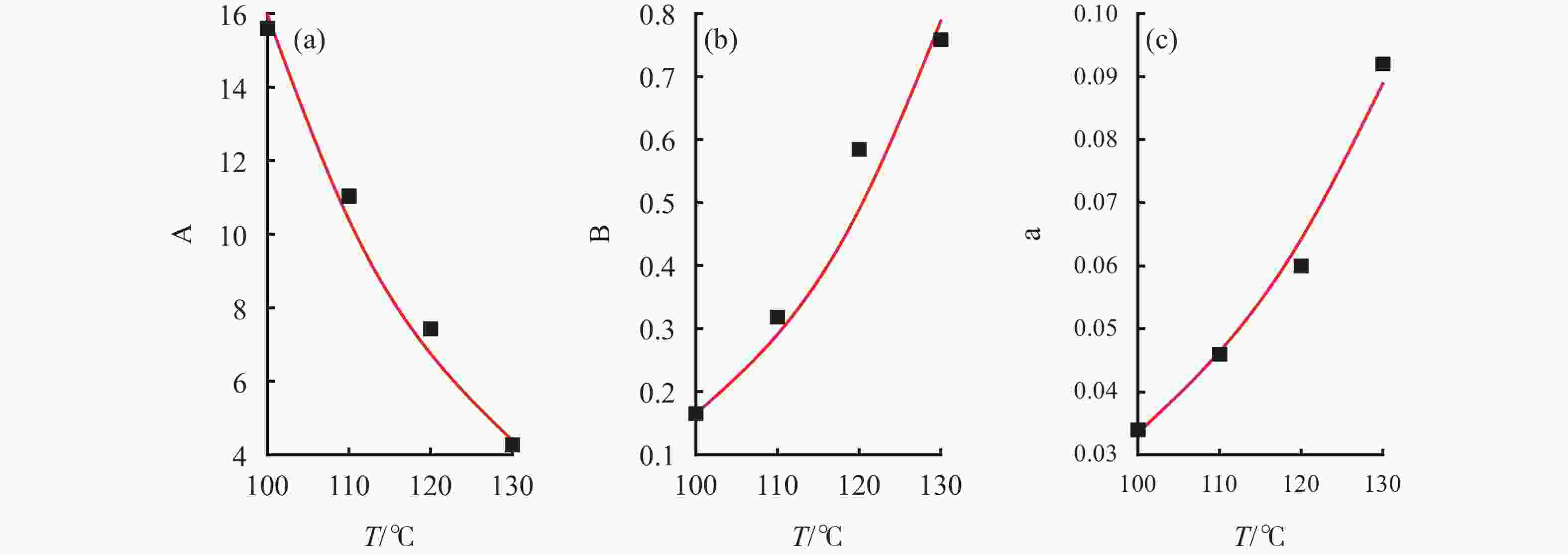

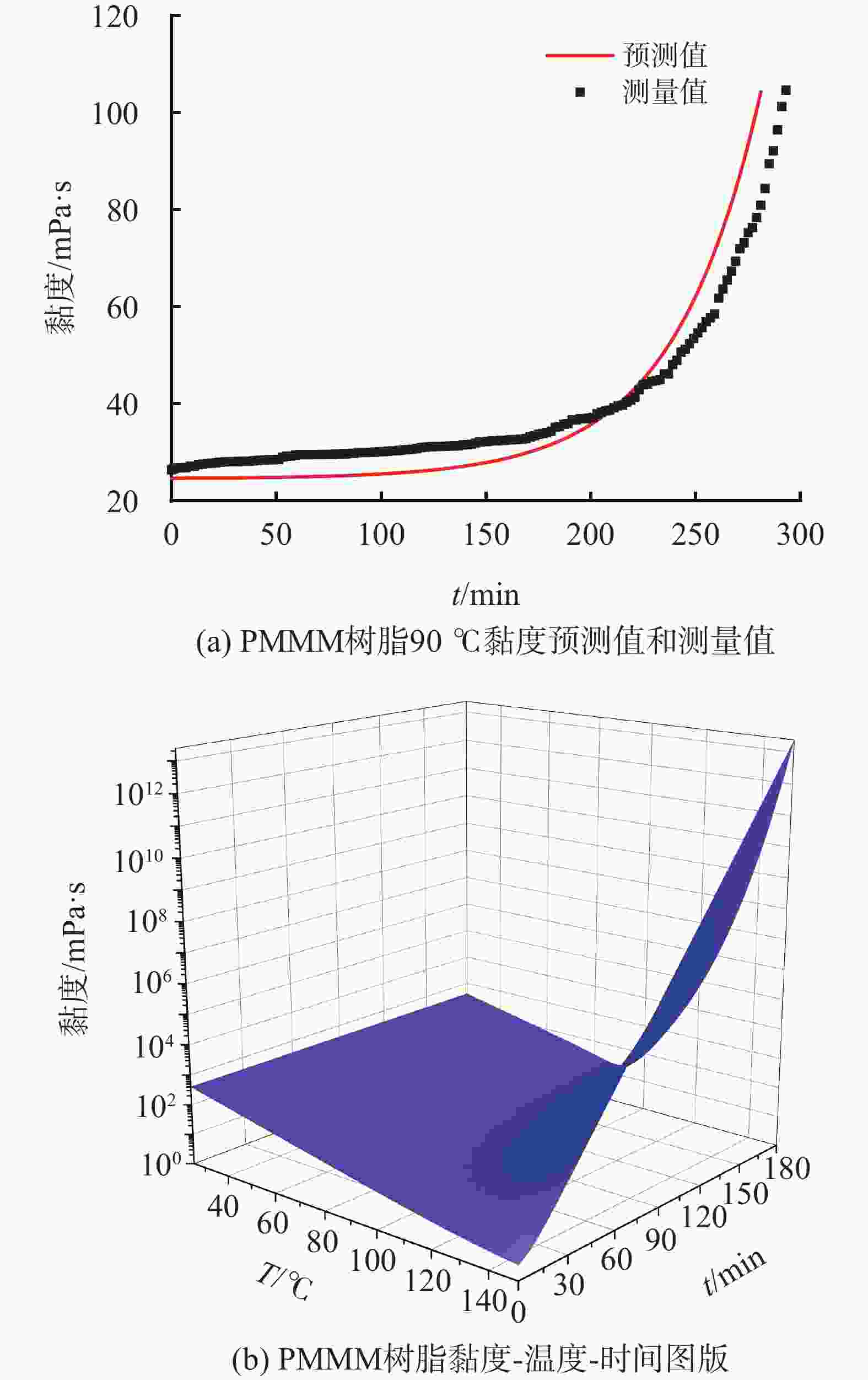

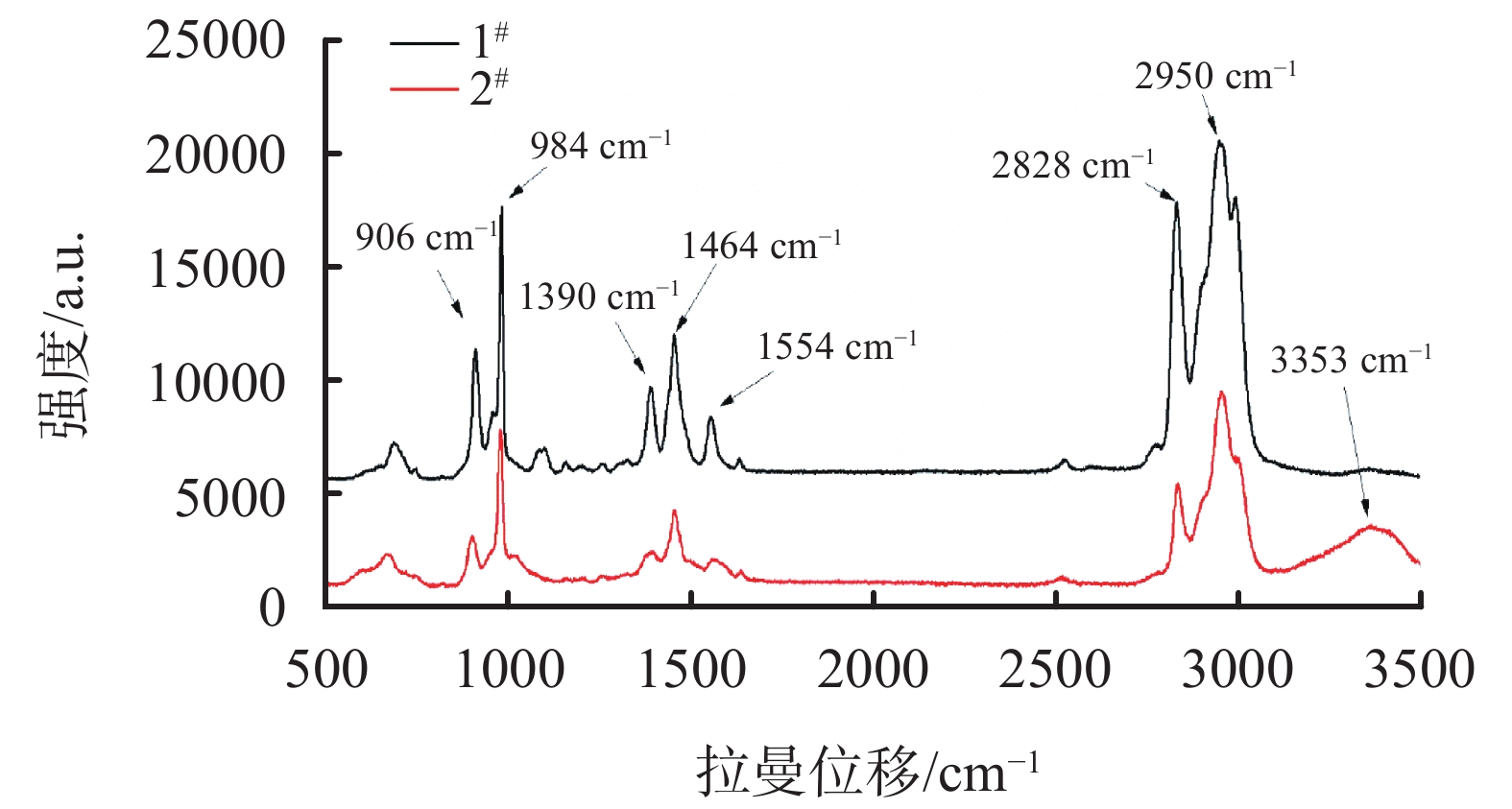

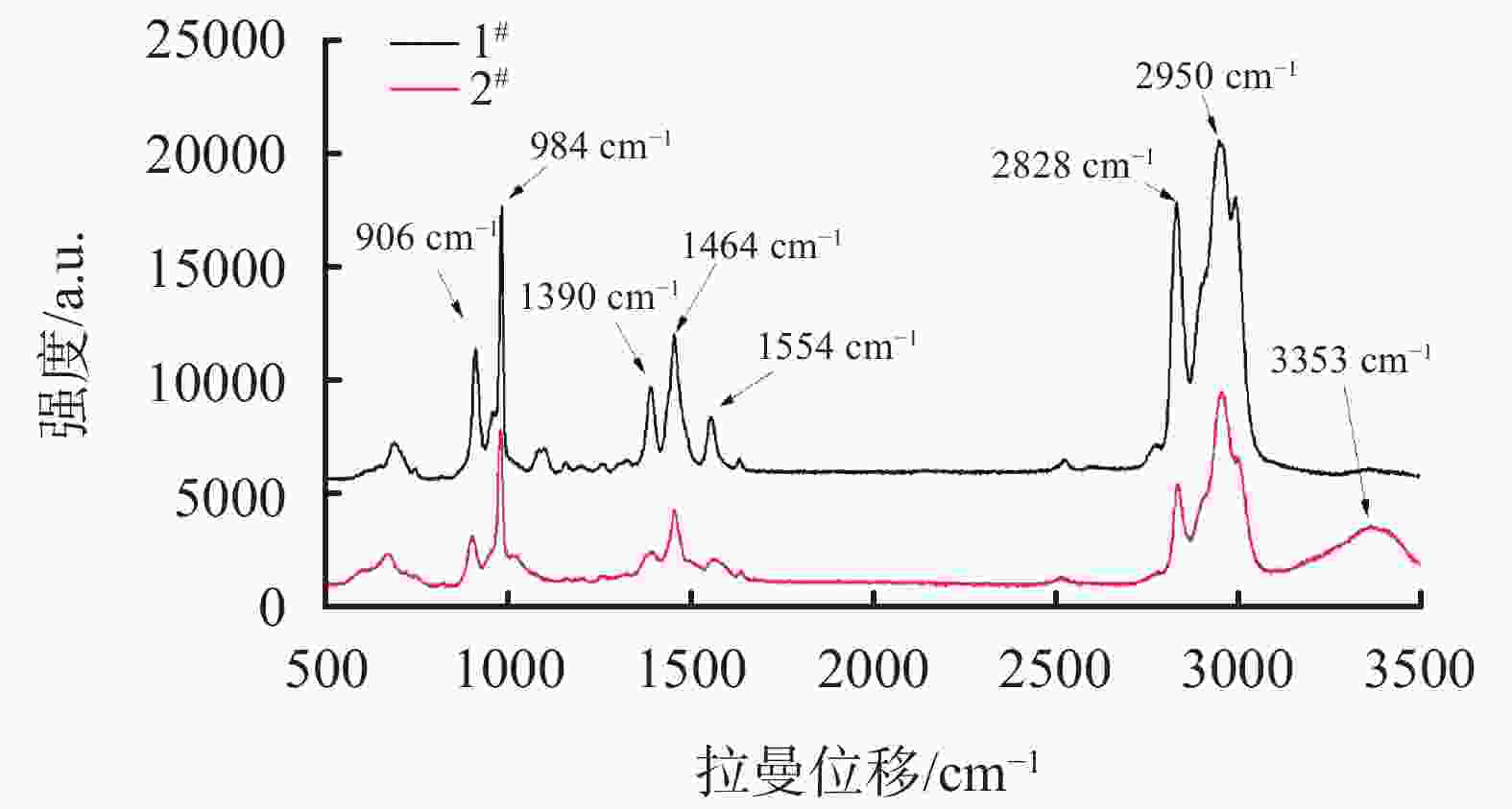

摘要: 裂缝性地层恶性漏失是油气钻井工程重大技术难题之一,可固化树脂和井下交联聚合物是常用堵漏材料,但存在井下交联可控性差、固化强度低等问题。研制了一种部分醚化改性氨基树脂PMMM,利用拉曼光谱分析了其分子结构,并揭示了固化机理。PMMM固化时间随着固化剂加量增加或温度升高而缩短,在80~130 ℃温度下可做到1~10 h可控,固化后不收缩,最高抗10%水基钻井液污染。PMMM固化后抗压强度随着CaSO4纳米晶须增加先增加后降低,0.5%纳米晶须加量下,80 ℃养护24 h后PMMM抗压强度最高达56 MPa,高于常规水泥堵漏材料。基于100~130 ℃下黏度数据,利用修改的阿伦尼乌斯黏度方程,拟合得到PMMM黏度-温度-时间曲线方程,方程预测90 ℃下黏度变化规律与实测数据相吻合,基本反映了PMMM堵漏材料加热条件下的黏度变化规律。整体而言,PMMM树脂固化堵漏材料具备配方简单、固化条件可控、固化后强度高等优点,在裂缝性地层恶性井漏中具有一定应用前景。Abstract: Severe loss of borehole working fluids into fractured formations is one of the major technical problems encountered in oil and gas drilling engineering. Curable resin and downhole crosslinking polymers are common lost circulation materials (LCMs) used for controlling this kind of loss. However, these LCMs are difficult to control in downhole crosslinking reaction and the cured LCMs have low strengths. This paper describes PMMM, an amino resin modified through partial etherification. Using Raman spectroscopy, the molecular structure of PMMM was analyzed and the mechanism of curing of the resin revealed. The time for PMMM to cure is shortened with increase in the concentration of curing agent or time, and can be controlled in a range of 1-10 h at temperatures between 80 ℃ and 130 ℃. PMMM will not shrink after curing, and is resistant to the contamination by maximum 10% water based mud. The compressive strength of PMMM which is treated with nano CaSO4 whickers, first increases and then decreases with increase in the concentration of the CaSO4 whiskers. PMMM treated with 0.5% nano CaSO4 whiskers has a maximum compressive strength of 56 MPa after aging at 80 ℃ for 24 hours, which is higher than the same compressive strength of conventional cement LCMs. Using viscosity data gathered at temperatures between 100 ℃ and 130 ℃ and the revised Arrhenius viscosity equation, a viscosity-temperature-time equation was obtained through data fitting. Change of viscosity at 90 ℃ predicted with this equation coincides with the data measured, indicating that the fitted equation can basically be used to predict the viscosity change of PMMM when heated. All in all, the curable PMMM resin LCM has many advantages such as easy to formulate, curing condition controllable and high compressive strength after curing etc. PMMM LCMs can be a good choice in dealing with severe lost circulation.

-

表 1 PMMM黏度曲线参数拟合公式结果

参数 拟合公式 R2 A A = 1176.6e-0.043T 0.9898 B B =2×10-13×T5.9583 0.9615 a a = 0.0013e0.0325T 0.9865 -

[1] ALKINANI H H, AL-HAMEEDI A T, FLORI R E,et al. Updated classification of lost circulation treatments and materials with an integrated analysis and their applications[C]. SPE Western Regional Meeting, 2018. [2] KNUDSEN K, LEON G A, SANABRIA A E, et al. First application of thermal activated resin as unconventional LCM in the middle east[C]. Abu Dhabi International Petroleum Exhibition and Conference, 2015. [3] ABDULRAZZAQ W, ALBURAIKAN R, SAVARI S, et al. Chemical sealant loss circulation materials for fractured formations: right-angle viscosity development with high plugging efficiency[C]. SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, 2018. [4] CAUGHRON D E, RENFROW D K, BRUTON J R, et al. Unique crosslinking pill in tandem with fracture prediction model cures circulation losses in deepwater gulf of Mexico[C]. Proceedings of IADC/SPE Drilling Conference, 2002. [5] 黎凌,李巍,欧阳伟. 遇水快速膨胀胶凝堵漏技术在长宁页岩气区块的应用[J]. 钻井液与完井液,2019,36(2):181-188. doi: 10.3969/j.issn.1001-5620.2019.02.009LI Ling, LI Wei, OU Yangwei. Application of a fast-swelling gel lost circulation material in shale gas drilling in block Changning[J]. Drilling Fluid & Completion Fluid, 2019, 36(2):181-188. doi: 10.3969/j.issn.1001-5620.2019.02.009 [6] 李辉,刘华康,何仲,等. 塔河油田碳酸盐岩储层恶性漏失空间堵漏凝胶技术[J]. 钻井液与完井液,2019,36(1):25-28. doi: 10.3969/j.issn.1001-5620.2019.01.005LI Hui, LIU Huakang, HE Zhong, et al. Use gel to control severe mud losses in carbonate reservoir formations in Tahe oilfield[J]. Drilling Fluid & Completion Fluid, 2019, 36(1):25-28. doi: 10.3969/j.issn.1001-5620.2019.01.005 [7] 于培志. 聚合物增韧脲醛树脂封堵剂的研究与应用[J]. 油田化学,2002(1):36-38,42. doi: 10.3969/j.issn.1000-4092.2002.01.011YU Peizhi. Polymer-toughened urea-formaldehyde resin aqueous gelling fluid as water plugging agent: preparation and uses[J]. Oilfield Chemistry, 2002(1):36-38,42. doi: 10.3969/j.issn.1000-4092.2002.01.011 [8] 谢志鹏,张会旗,原续波,等. 环氧树脂增韧改性的研究进展[J]. 高分子通报,2018(11):1-16.XIE Zhipeng, ZHANG Huiqi, YUAN Xubo, et al. Progress on the research of toughening modified epoxy resin[J]. Polymer Bulletin, 2018(11):1-16. [9] 王鑫,王德志,刘立柱,等. 纳米核壳橡胶的合成及其对EP的增韧改性[J]. 工程塑料应用,2016,44(8):106-110. doi: 10.3969/j.issn.1001-3539.2016.08.023WANG Xin, WANG Dezhi, LIU Lizhu, et al. Synthesis of nano core-shell rubber and its toughening modification for epoxy resin[J]. Engineering Plastics Application, 2016, 44(8):106-110. doi: 10.3969/j.issn.1001-3539.2016.08.023 [10] 孙文奎,周松,马俊辉,等. EVA-g-MAH对CaSO4晶须/尼龙6复合材料性能的影响[J]. 复合材料学报,2017,34(8):1645-1652.SUN Wenkui, ZHOU Song, MA Junhui, et al. Effects of EVA-g-MAH on the properties of CaSO4 whiskers/nylon 6 composites[J]. Acta Materiae Compositae Sinica, 2017, 34(8):1645-1652. [11] 胡红兵,林强,胡文祥. 环氧树脂流变学的研究进展[J]. 武汉工程大学学报,2021,43(3):248-255.HU Hongbing, LIN Qiang, HU Wenxiang. Progress in rheology of epoxy[J]. Journal of Wuhan Institute of Technology, 2021, 43(3):248-255. [12] 高堂铃,付刚,王先杰,等. RTM用低黏度树脂体系的工艺窗口预测[J]. 哈尔滨工业大学学报,2021,53(2):162-167. doi: 10.11918/202008011GAO Tangling, FU Gang, WANG Xianjie, et al. Prediction of processing windows for low viscosity epoxy resin system used in RTM[J]. Journal of Harbin Institute of Technology, 2021, 53(2):162-167. doi: 10.11918/202008011 -

下载:

下载: