Preparation of and Study on Sulfonated Humic Acid/Guar Gum Fracturing Fluid

-

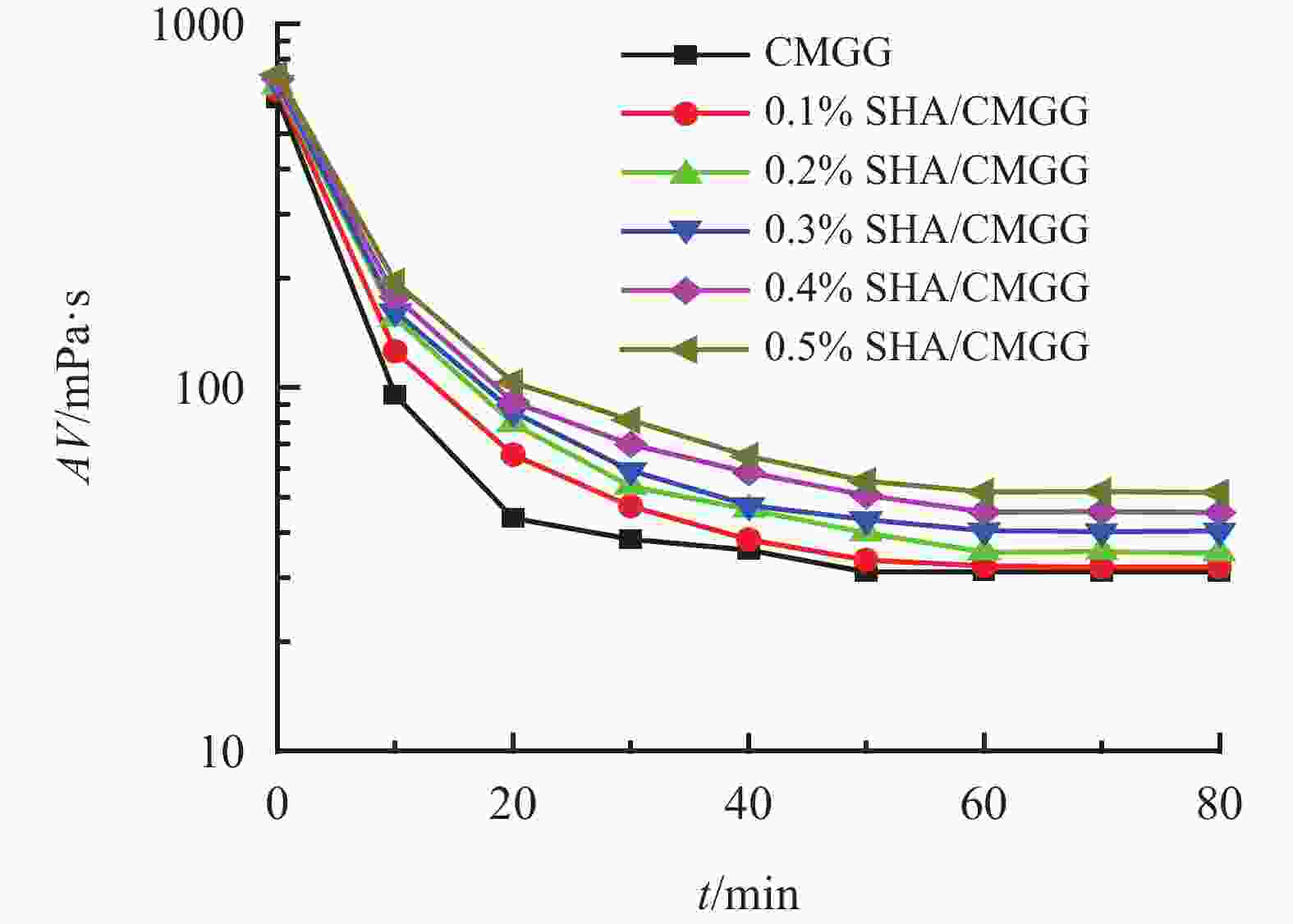

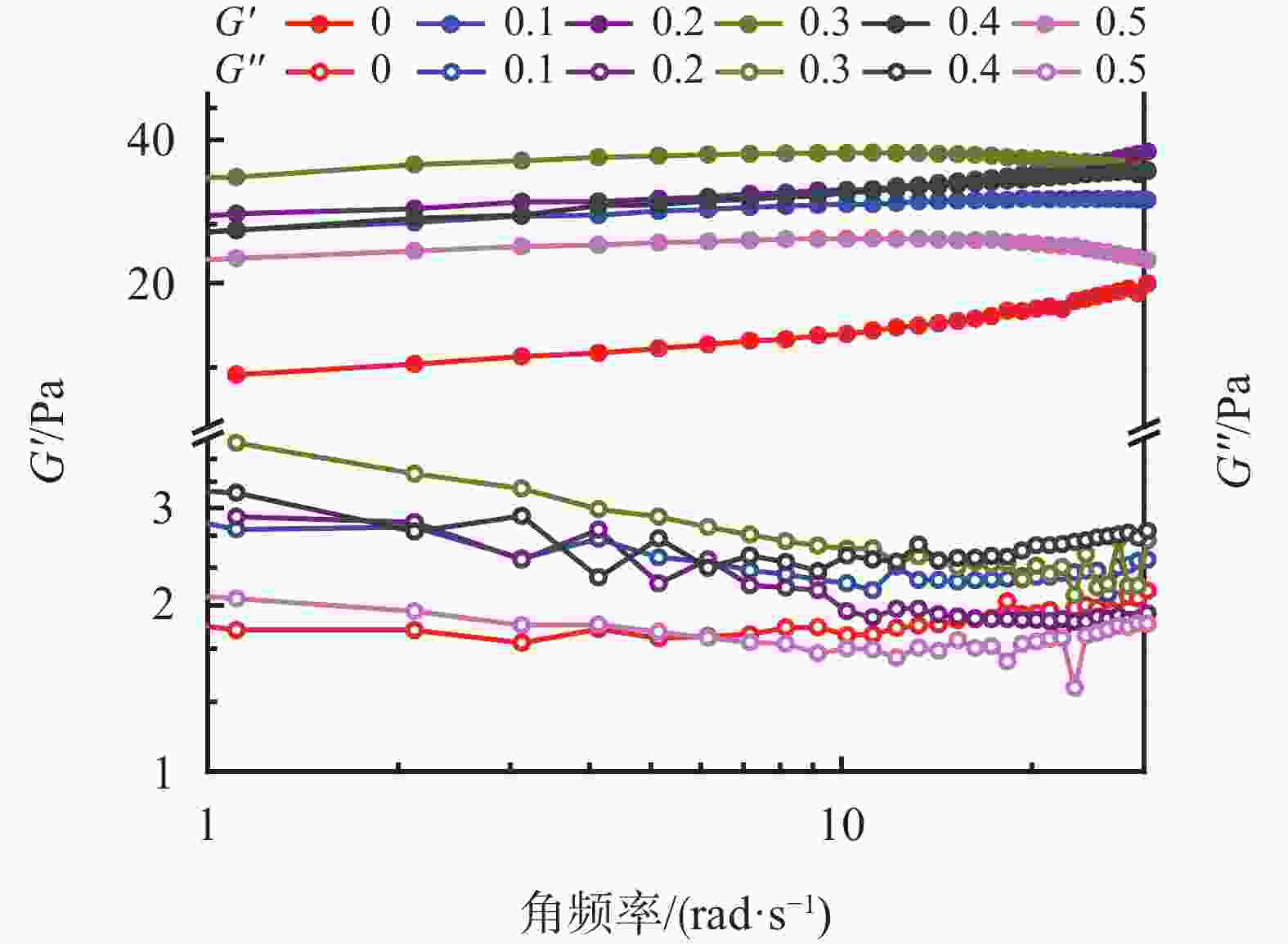

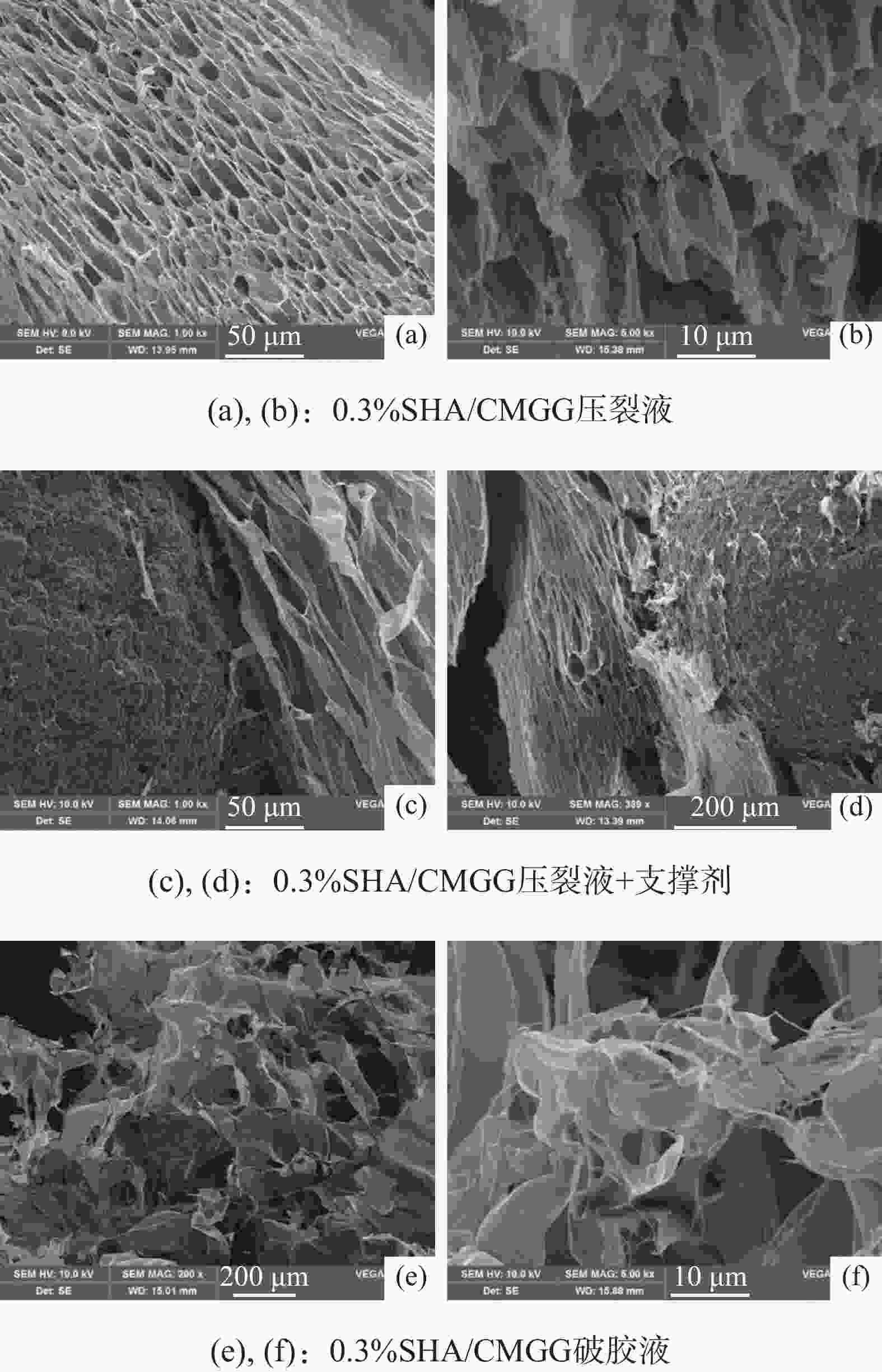

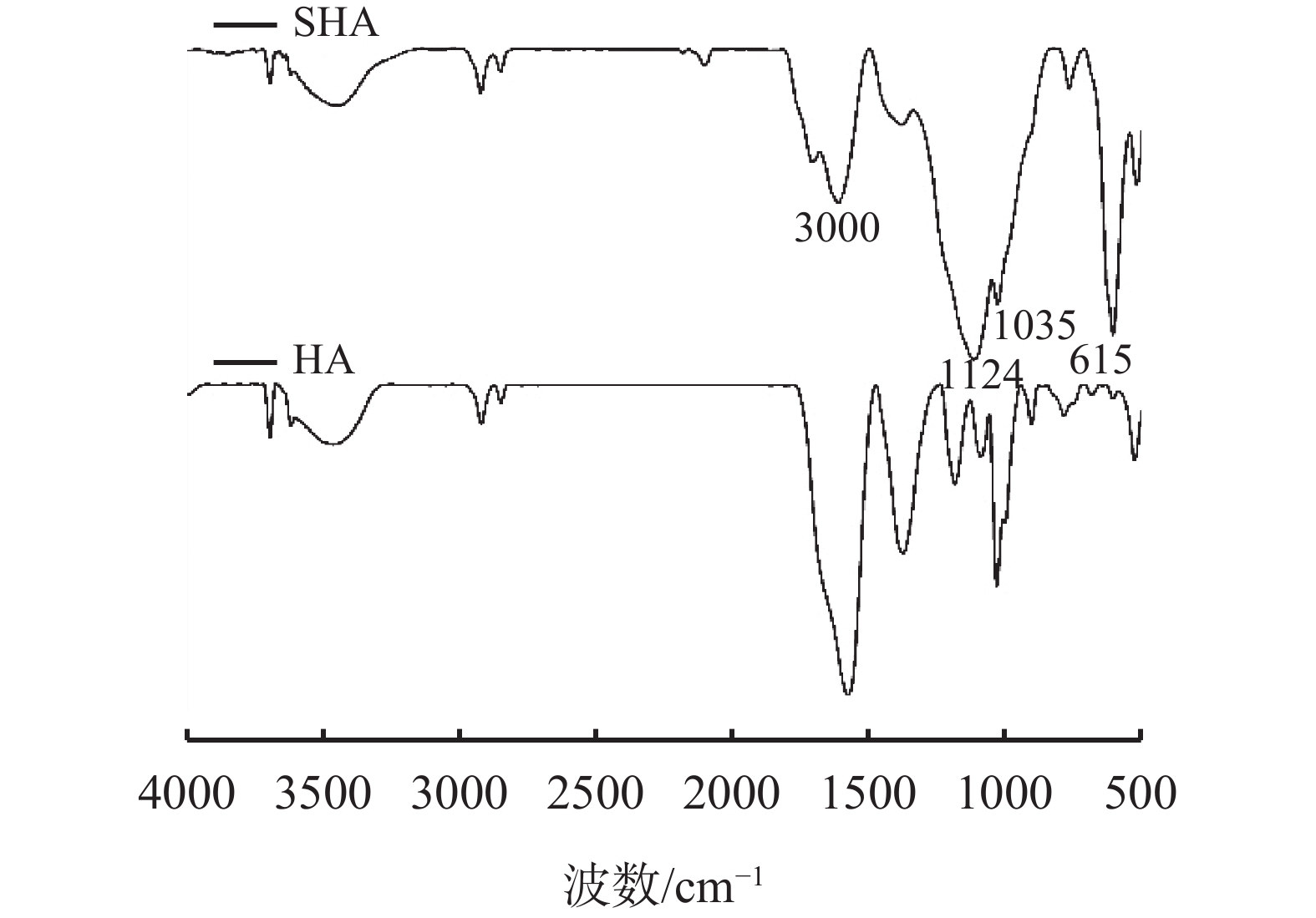

摘要: 采用亚硫酸钠对腐植酸进行磺化改性,磺化腐植酸(SHA)与羧甲基胍胶(CMGG)混合后,加入有机锆交联形成新型耐温耐盐型压裂液凝胶(SHA/CMGG),并研究了压裂液的应用性能。结果表明,SHA/CMGG凝胶比CMGG凝胶具有更好的黏弹性和悬砂能力,其中添加量0.3%SHA/CMGG压裂液性能最好,平均沉降速度为0.32 mm/min。由于磺酸根的引入,SHA/CMGG表现了优异的耐盐性,1%外加盐浓度下表观黏度下降率为50%。同时0.3%SHA/CMGG压裂液表现出良好的耐温耐剪切性能,在140 ℃和170 s−1剪切下,黏度为120 mPa·s,可保持60 min基本不变。破胶后,SHA/CMGG破胶液的黏度和岩心伤害性均变大,但增加量并不显著。通过SEM观察了压裂液作用过程的微观结构变化,SHA/CMGG凝胶具有致密的网状结构,对支撑剂的悬浮起着重要作用。Abstract: Humic acid is sulfonated with sodium sulfite to produce sulfonated humic acid (SHA) which is mixed with carboxy methyl guar gum (CMGG) to form a new high temperature salt-resistant gel (SHA/CMGG) for use in fracturing fluids by crosslinking the mixture of SHA and CMGG with organic zirconium. Studies on the operational performance of fracturing fluids treated with the SHA/CMGG gel showed that the SHA/CMGG gel has better viscoelasticity and sand suspension capacity than the CMGG gel; a fracturing fluid treated with 0.3% SHA/CMGG has the best performance, the average settling velocity of sands in the fracturing fluid is 0.32 mm/min. The introduction of sulfonate ions into the humic acid molecules renders SHA/CMGG excellent salt resistance, the apparent viscosity of the SHA/CMGG treated fracturing fluid is decreased by 50% when contaminated with 1% salt. The fracturing fluid containing 0.3% SHA/CMGG has excellent high temperature and shear resistance, its viscosity, after shearing at 140 ℃ and 170 s−1, is 120 mPa·s and remains almost unchanged for 60 min. After gel breaking, the viscosity of the SHA/CMGG treated fracturing fluid and the permeability damage of cores are all increased, only with small magnitudes. Observation of the change of the microstructure of the fracturing fluid under SEM showed that SHA/CMGG gel has dense network structure which is important to the suspension of proppants in the fracturing fluid.

-

Key words:

- Sulfonated humic acid /

- Guar gum /

- Fracturing /

- Viscoelasticity

-

表 1 压裂液悬砂性能测试结果

压裂液 沉降速度/mm·min−1 CMGG 1.12 0.1%SHA/CMGG 0.96 0.2%SHA/CMGG 0.57 0.3%SHA/CMGG 0.32 0.4%SHA/CMGG 0.53 0.5%SHA/CMGG 0.79 表 2 破胶液黏度和岩心伤害实验结果

样品 η /

mPa·sK0/

mDKd/

mDKd/K0 /

%CMGG 4.25 3.192 2.802 12.23 0.1%SHA/CMGG 4.31 3.192 2.767 13.31 0.2%SHA/CMGG 4.59 3.192 2.749 13.89 0.3%SHA/CMGG 4.78 3.192 2.731 14.43 0.4%SHA/CMGG 5.22 3.192 2.727 14.56 0.5%SHA/CMGG 6.07 3.192 2.719 14.83 -

[1] 董景锋,汪志臣,怡宝安,等. 低浓度胍胶压裂液体系的研究与应用[J]. 油田化学,2017,34(1):43-47.DONG Jingfeng, WANG Zhichen, YI Baoan, et al. Development and application of guar gum fracturing fluid with low concentration[J]. Oilfield Chemistry, 2017, 34(1):43-47. [2] 赖小娟,宫米娜,崔争攀,等. 低渗透油气储层压裂液的研究进展[J]. 精细石油化工,2015,32(4):77-80. doi: 10.3969/j.issn.1003-9384.2015.04.018LAI Xiaojuan, GONG Mina, CUI Zhengpan, et al. Research progress of fracturing fluid for low permeability reservoir[J]. Speciality Petrochemicals, 2015, 32(4):77-80. doi: 10.3969/j.issn.1003-9384.2015.04.018 [3] 王宝峰,陈作,吴春方,等. 深层致密砂岩气藏中高温压裂液开发及应用[J]. 精细石油化工,2019,36(1):10-14. doi: 10.3969/j.issn.1003-9384.2019.01.003WANG Baofeng, CHEN Zuo, WU Chunfang, et al. The development and application of high temperature fracturing fluid in deep tight sandstone gas reservoir[J]. Speciality Petrochemicals, 2019, 36(1):10-14. doi: 10.3969/j.issn.1003-9384.2019.01.003 [4] 王牧群,邬国栋,姚旭洋,等. 快速水合瓜胶压裂液的研究与应用[J]. 钻井液与完井液,2020,37(6):789-793.WANG Muqun, WU Guodong, YAO Xuyang, et al. Research and application of FHG fracturing fluid[J]. Drilling Fluid & Completion Fluid, 2020, 37(6):789-793. [5] 刘银仓,谢娟,孙春佳,等. 羧甲基羟丙基胍胶酸性压裂液体系的制备及性能[J]. 油田化学,2019,36(1):43-47,37.LIU Yincang, XIE Juan, SUN Chunjia, et al. Preparation and properties of CMHPG acid fracturing fluid system[J]. Oilfield Chemistry, 2019, 36(1):43-47,37. [6] 吴江. 腐植酸的化学改性及其对煤粒的分散性能研究[D]. 西安: 陕西科技大学, 2019.WU Jiang. Chemical modification of humic ccid and its dispersion property to coal particles[D]. Xi'an: Shaanxi University of Science and Technology, 2019. [7] 张乔良,张贵才,葛际江. 腐植酸在油田中的应用[J]. 钻井液与完井液,2004(3):55-57,67-68.ZHANG Qiaoliang, ZHANG Guicai, GE Jijiang. Humic acid and its application in oilfield[J]. Drilling Fluid & Completion Fluid, 2004(3):55-57,67-68. [8] 郑易安,王文波,王爱勤. 腐植酸高吸水性树脂研究进展[J]. 高分子通报,2011(8):38-47.ZHENG Yian, WANG Wenbo, WANG Aiqin. Progress in superabsorbent with humic acid[J]. Chinese Polymer Bulletin, 2011(8):38-47. [9] 吴红运,高丽娟,杨小莹,等. 褐煤腐植酸磺化改性工艺及表征[J]. 洁净煤技术,2014,20(6):42-45.WU Hongyun, GAO Lijuan, YANG Xiaoying, et al. Sulfonation and characterization of lignite humic acid[J]. Clean Coal Technology, 2014, 20(6):42-45. [10] ZHANG K, ZHANG G, LI Z, et al. Laboratory evaluation of a low pH and low polymer concentration zirconium-CMHPG gel system for hydraulic fracturing[J]. Energy & Fuels, 2019, 33(10):9720-9735. [11] 宋洁,齐钟昱,杨通,等. 磺化腐植酸有机保水剂的制备及应用[J]. 现代化工,2020,40(5):128-132.SONG Jie, QI Zhongyu, YANG Tong, et al. Preparation and application of sulfonated humic acid-based organic water retaining agent[J]. Modern Chemical Industry, 2020, 40(5):128-132. [12] 张光华,贾宇荣,李俊国,等. 磺化腐植酸-甲醛-磺化丙酮聚合物合成及性能研究[J]. 陕西科技大学学报,2014,32(5):63-67. doi: 10.3969/j.issn.1000-5811.2014.05.013ZHANG Guanghua, JIA Yurong, LI Junguo, et al. Synthesis and properties of sulfonated humic acid-formaldehyde-sulfonated acetone polymer[J]. Journal of Shaanxi University of Science and Technology, 2014, 32(5):63-67. doi: 10.3969/j.issn.1000-5811.2014.05.013 [13] 马国艳,沈一丁,王小荣,等. 压裂用疏水缔合聚合物溶液性质及减阻性能[J]. 精细化工,2016,33(10):1159-1164.MA Guoyan, SHEN Yiding, WANG Xiaorong, et al. Solution properties and drag reduction of hydrophobically associating polymer for fracturing fluids[J]. Fine Chemicals, 2016, 33(10):1159-1164. [14] 何春明,才博,卢拥军,等. 瓜胶压裂液携砂微观机理研究[J]. 油田化学,2015,32(1):34-38.HE Chunming, CAI Bo, LU Yongjun, et al. Microscopic mechanism of proppant carrying capacity of fracturing fluid[J]. Oilfield Chemistry, 2015, 32(1):34-38. [15] 张艺耀. 瓜胶压裂液结构及黏弹性与携砂性能的关系研究[D]. 成都: 西南石油大学, 2014.ZHANG Yiyao. Study on the relationship between structure viscoelasticity and sand-carrying performance of cucurbit gum fracturing fluid[D]. Chengdu: Southwest Petroleum University, 2014. -

下载:

下载: