Fracturing Fluid Damage Evaluation and Microscopic Damage Mechanism Study for Expansion Tight oil Test Area of Long 26

-

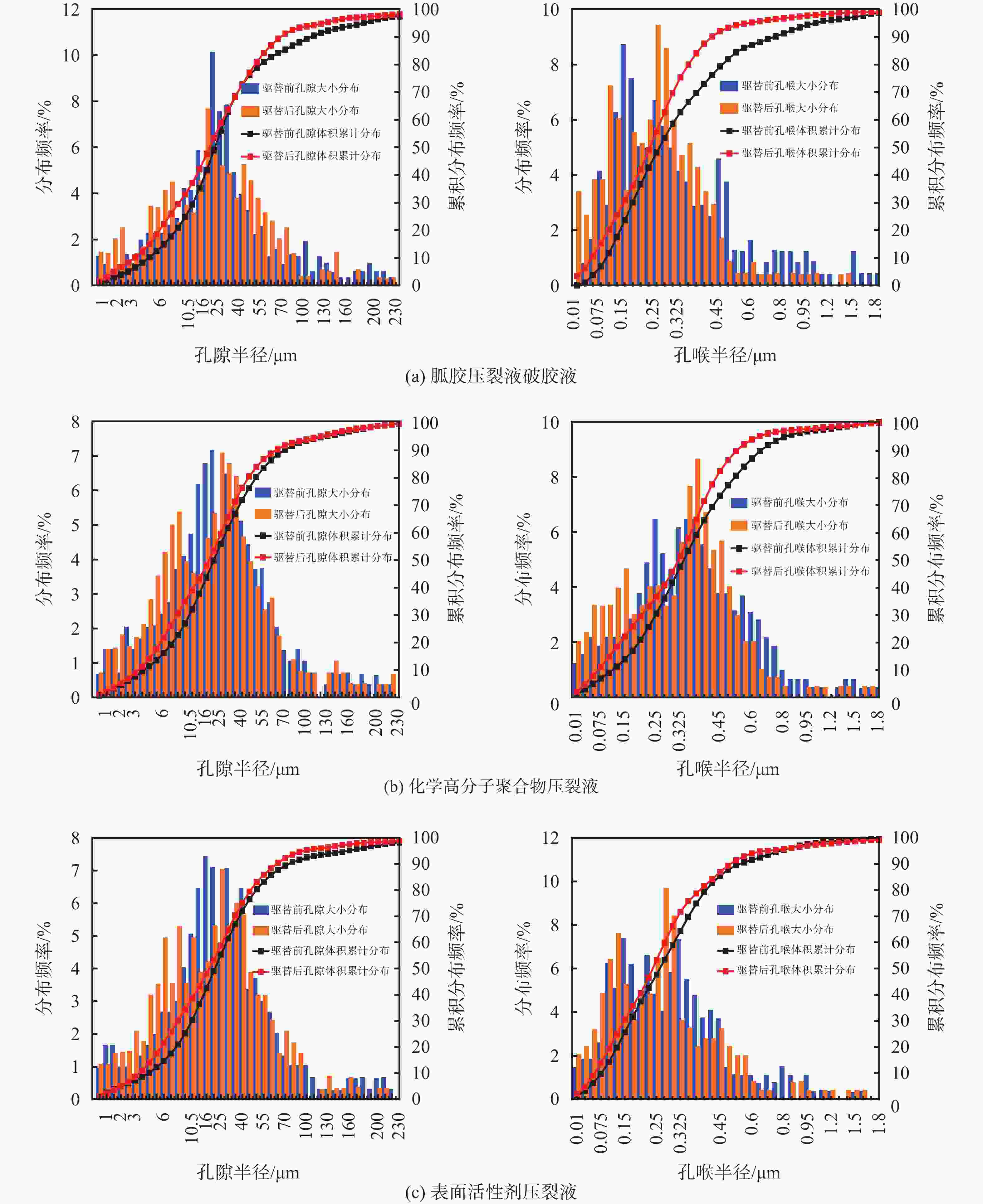

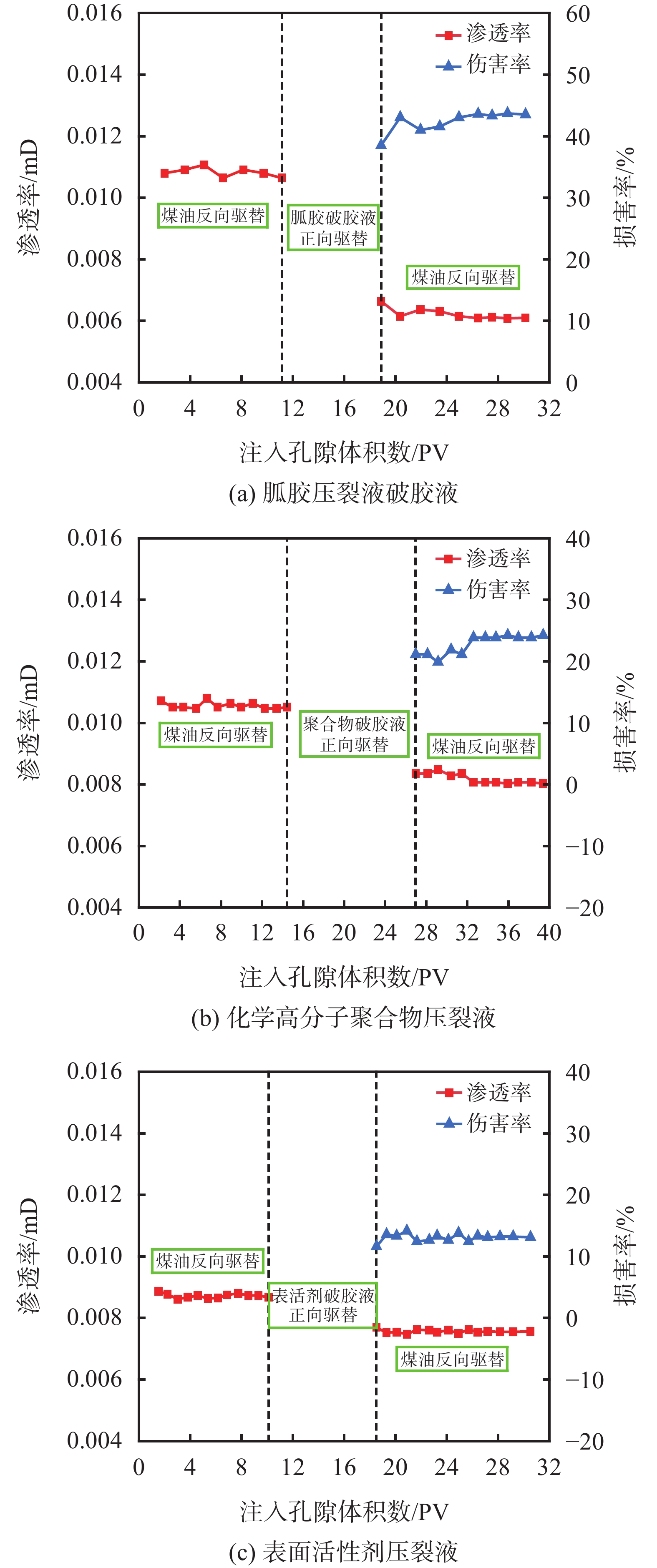

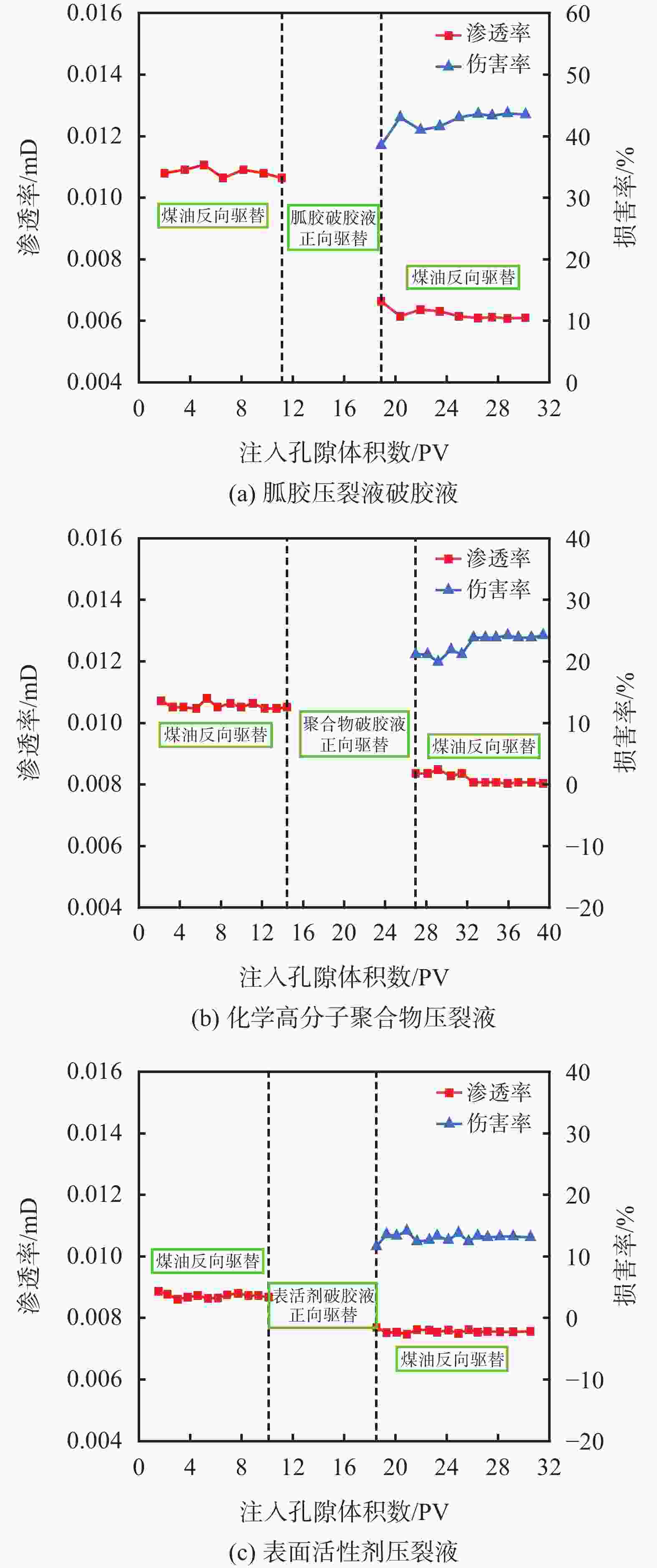

摘要: 大庆龙26外扩试验区为典型致密储层,对压裂液损害更为敏感。依据SY/T 5107—2005《水基压裂液性能评价方法》在储层温度(90 ℃)下采用岩心流动装置进行了胍胶、化学高分子聚合物和表面活性剂压裂液破胶液的岩心驱替实验;结合CT扫描评价了3种压裂液破胶液残渣、残胶在岩心中的分布和对孔隙孔喉的损害程度。岩心驱替实验结果表明,胍胶、化学高分子聚合物和表面活性剂3种压裂液破胶液对岩心损害率分别为43.5%、24.3%和13.1%。CT扫描结果显示,胍胶和化学高分子聚合物压裂液破胶液残留物分别集中于岩心前1/10~2/5段和前1/2段,表面活性剂压裂液破胶液残渣含量少,但能侵入岩心各处;胍胶、化学高分子聚合物和表面活性剂压裂液破胶液对储层岩心孔隙和孔喉的损害率分别为15.41%和9.01%,6.43%和3.14%,8.94%和6.27%。分析认为,3种压裂液破胶液对储层岩心均以液相损害为主,固相损害次之。Abstract: Extension area of long 26 in Daqing oilfield is typical tight reservoir, which is more sensitive to fracturing fluid damage. According to ‘SY/T 5107-2005 Recommended practices on measuring the properties of water-based fracturing fluid’, the core displacement experiments of guar gum, high molecular polymer and surfactant fracturing gel-breaking fluids were conducted at reservoir temperature (90 ℃) with core flow meter, and the distribution of residue and residual gum of the three fracturing gel-breaking fluids in the cores and their damage degree to pore throats were evaluated with CT scanning. The results of core displacement experiments indicated that the core damage rates of guar gum, high molecular polymer and surfactant fracturing gel-breaking fluids were 43.5%, 24.3% and 13.1% respectively. The results of CT scanning showed that residues of guar gum and high molecular polymer fracturing gel-breaking fluids were concentrated in the first 1/10~2/5 and 1/2 sections of the core respectively, and the residues of surfactant fracturing gel-breaking fluid were less but penetrated into the core. The pore and the pore throat damage rates on cores of guar gum , high molecular polymer and surfactant fracturing gel-breaking fluids were 15.41% and 9.01%, 6.43% and 3.14%, 8.94% and 6.27% respectively. The analysis showed that the three kinds of fracturing gel-breaking fluids on reservoir cores were mainly liquid damage, followed by solid damage.

-

表 1 龙26外扩区储层岩心矿物组成及黏土矿物含量

岩心编号 全岩矿物含量/% 黏土矿物相对含量/% 石英 钾长石 斜长石 方解石 黏土总量 伊利石 高岭石 绿泥石 伊蒙混层 蒙脱石 #18-3 25.0 7.5 45.8 16.0 15.6 14 2 18 66 12 #21-4 30.7 10.0 38.8 20.7 11 3 15 71 15 -

[1] 卢拥军. 压裂液对储层的伤害及其保护技术[J]. 钻井液与完井液,1995(5):39-46.LU Yongjun. Reservoir damage due to fracturing fluids and its protection[J]. Drilling Fluid & Completion Fluid, 1995(5):39-46. [2] 张海龙,崔福林,徐影. 压裂液伤害及油层保护研究[J]. 石油天然气学报(江汉石油学院学报),2005(S1):221-223.ZHANG Hailong, CUI Fulin, XU Ying. Damage caused by fracturing fluid and reservoir protection[J]. Journal of Oil and Gas Technology(J. JPI) , 2005(S1):221-223. [3] 孟祥燕,冉蜀勇,赵金洲,等. 强水敏低渗砂砾岩油藏压裂技术应用研究[J]. 钻采工艺,2007(4):53-55. doi: 10.3969/j.issn.1006-768X.2007.04.017MENG Xiangyan, RAN Shuyong, ZHAO Jinzhou, et al. Applied research of fracturing technology for strong water-sensitive and low permeability glutinite reservoir[J]. Drilling & Production Technology, 2007(4):53-55. doi: 10.3969/j.issn.1006-768X.2007.04.017 [4] 钟安海. 压裂液体系对岩心渗流能力的影响[J]. 钻井液与完井液,2011,28(3):69-71,96-97. doi: 10.3969/j.issn.1001-5620.2011.03.021ZHONG Anhai. Study on effect of fracturing fluid to seepage ability of core[J]. Drilling Fluid & Completion Fluid, 2011, 28(3):69-71,96-97. doi: 10.3969/j.issn.1001-5620.2011.03.021 [5] 韩金轩,杨兆中,李小刚,等. 柿庄北深煤层压裂伤害机理及低伤害压裂液评价[J]. 科学技术与工程,2014,14(21):219-223. doi: 10.3969/j.issn.1671-1815.2014.21.040HAN Jinxuan, YANG Zhaozhong, LI Xiaogang, et al. Fracturing damage mechanisms of deep coal seams and assessments of low damage fracturing fluids: the deep coal seam in the north of shizhuang on the Qinshui Basin[J]. Science Technology and Engineering, 2014, 14(21):219-223. doi: 10.3969/j.issn.1671-1815.2014.21.040 [6] 张华丽,周继东,杲春,等. 胍胶压裂液伤害性研究[J]. 科学技术与工程,2013,13(23):6866-6871. doi: 10.3969/j.issn.1671-1815.2013.23.039ZHANG Huali, ZHOU Jidong, GAO Chun, et al. The Damage of guar gum fracturing fluid[J]. Science Technology and Engineering, 2013, 13(23):6866-6871. doi: 10.3969/j.issn.1671-1815.2013.23.039 [7] 陈馥,李钦. 压裂液伤害性研究[J]. 天然气工业,2006(1):109-111,168. doi: 10.3321/j.issn:1000-0976.2006.01.033CHEN Fu, LI Qin. A study of formation damage of fracturing fluid[J]. Natural Gas Industry, 2006(1):109-111,168. doi: 10.3321/j.issn:1000-0976.2006.01.033 [8] 王所良,汪小宇,王玉功. 低伤害合成聚合物压裂液体系研究与应用[J]. 石油化工应用,2014,33(11):19-23. doi: 10.3969/j.issn.1673-5285.2014.11.005WANG Suoliang, WANG Xiaoyu, WANG Yugong. The development and application of low damage polymer base fracturing fluid system[J]. Petrochemical Industry Application, 2014, 33(11):19-23. doi: 10.3969/j.issn.1673-5285.2014.11.005 [9] 蒋其辉,蒋官澄,刘冲,等. 超分子压裂液体系的研制及评价[J]. 钻井液与完井液,2015,32(5):73-77.JIANG Qihui, JIANG Guancheng, LIU Chong, et al. Development and evaluation of supramolecular fracturing fluid[J]. Drilling Fluid & Completion Fluid, 2015, 32(5):73-77. [10] 刘彝,刘京,颜菲,等. 缔合非交联压裂液储层伤害特征[J]. 海洋石油,2018,38(4):57-61. doi: 10.3969/j.issn.1008-2336.2018.04.057LIU Yi, LIU Jing, YAN Fei, et al. The characteristics about the damage of associated non cross-linking fracturing fluid to reservoirs[J]. Offshore Oil, 2018, 38(4):57-61. doi: 10.3969/j.issn.1008-2336.2018.04.057 [11] 刘新全,易明新,赵金钰,等. 黏弹性表面活性剂(VES)压裂液[J]. 油田化学,2001(3):273-277. doi: 10.3969/j.issn.1000-4092.2001.03.026LIU Xinquan, YI Mingxin, ZHAO Jinyu, et al. Viscoelastic surfactant based fracturing fluids[J]. Oilfield Chemistry, 2001(3):273-277. doi: 10.3969/j.issn.1000-4092.2001.03.026 [12] 张荣明,林士英,李柏林. 黏弹性表面活性剂压裂液的研究应用现状分析[J]. 石油地质与工程,2006(3):73-75,110. doi: 10.3969/j.issn.1673-8217.2006.03.029ZHANG Rongming, LIN Shiying, LI Bolin. Present situation analysis and application on viscoelastic surfactant fracturing fluids[J]. Petroleum Geology and Engineering, 2006(3):73-75,110. doi: 10.3969/j.issn.1673-8217.2006.03.029 [13] 苑光宇,侯吉瑞,罗焕,等. 清洁压裂液的研究与应用现状及未来发展趋势[J]. 日用化学工业,2012,42(4):288-292,297.YUAN Guangyu, HOU Jirui, LUO Huan et al. Current situation and development trend with respect to research and application of clean fracturing fluid[J]. China Surfactant Detergent & Cosmetics, 2012, 42(4):288-292,297. [14] 牟善波,张士诚,付道明,等. 新型表活剂压裂液的实验特性及其在水锁气层中的应用[J]. 天然气工业,2009,29(12):65-67,145-146. doi: 10.3787/j.issn.1000-0976.2009.12.021MOU Shanbo, ZHANG Shicheng, FU Daoming, et al. An experimental study on the behaviors of new surfactant fracture fluid and its application in water lock gas reservoirs[J]. Natural Gas Industry, 2009, 29(12):65-67,145-146. doi: 10.3787/j.issn.1000-0976.2009.12.021 [15] 陈馥,刘彝,王大勇. 阳离子表面活性剂基压裂液的地层伤害性研究[J]. 钻井液与完井液,2007(6):62-65,92. doi: 10.3969/j.issn.1001-5620.2007.06.017CHEN Fu, LIU Yi, WANG Dayong. Studies in formation damages caused by cationic surfactant base fracturing fluids[J]. Drilling Fluid & Completion Fluid, 2007(6):62-65,92. doi: 10.3969/j.issn.1001-5620.2007.06.017 [16] 刘玉婷,崔丽,程芳,等. 压裂液伤害的计算机断层扫描技术[J]. 无损检测,2019,41(1):18-22. doi: 10.11973/wsjc201901005LIU Yuting, CUI Li, CHENG Fang, et al. Computed tomography technology for fracturing fluid damage[J]. Nondestructive Testing, 2019, 41(1):18-22. doi: 10.11973/wsjc201901005 [17] 王贤君,王磊,张明慧,等. 致密储层压裂液伤害的数字化评价方法——以P59井为例[J]. 石油地质与工程,2020,34(4):115-118. doi: 10.3969/j.issn.1673-8217.2020.04.023WANG Xianjun, WANG Lei, ZHANG Minghui, et al. Digital evaluation method of fracturing fluid damage in tight oil reservoirs-by taking P59 well as an example[J]. Petroleum Geology and Engineering, 2020, 34(4):115-118. doi: 10.3969/j.issn.1673-8217.2020.04.023 [18] 刘薇,卢双舫,王民,等. 致密砂岩储集空间全孔喉直径表征及其意义——以松辽盆地龙虎泡油田龙26外扩区为例[J]. 东北石油大学学报,2018,42(6):41-51. doi: 10.3969/j.issn.2095-4107.2018.06.005LIU Wei, LU Shuangfang, WANG Min, et al. Overall pore characterization of tight sandstone reservoir space and its significance: a case study of extension area of long 26 in Longhupao oilfield, Songliao basin[J]. Journal of Northeast Petroleum University, 2018, 42(6):41-51. doi: 10.3969/j.issn.2095-4107.2018.06.005 [19] 肖丹凤,韩露,孙建国,等. 聚合物压裂液在大庆低渗透储层的应用[J]. 油田化学,2009,26(2):131-134.XIAO Danfeng, HAN Lu, SUN Jianguo, et al. Application of polymer gelling fracturing fluid in low permeability reservoir in Daqing oilfield[J]. Oilfield Chemistry, 2009, 26(2):131-134. [20] 柳娜,南珺祥,刘伟. 鄂尔多斯盆地中部长6和长8储层特征及酸敏机理[J]. 石油学报,2008(4):588-591. doi: 10.3321/j.issn:0253-2697.2008.04.021LIU Na, NAN Junxiang, LIU Wei. Reservoir characteristics and acid sensitivity mechanism of Chang 6 and Chang 8 reservoirs in the central of Ordos Basin[J]. Acta Petrolei Sinica, 2008(4):588-591. doi: 10.3321/j.issn:0253-2697.2008.04.021 [21] 李勇,陈国明. 埕岛油田馆陶组黏土矿物分析与储层伤害研究[J]. 油田化学,2006(4):369-374. doi: 10.3969/j.issn.1000-4092.2006.04.020LI Yong, CHEN Guoming. Clay Minerals analysis and formation damage estimation for guantao formation of chengdao oil field[J]. Oilfield Chemistry, 2006(4):369-374. doi: 10.3969/j.issn.1000-4092.2006.04.020 [22] 中国石油勘探开发研究院廊坊分院压裂酸化技术服务中心. SYT 5107-2005水基压裂液性能评价方法[S]. 北京: 石油工业出版社, 2005.Langfang branch of petrochina research institute of petroleum exploration and development of fracturing and acidzing technology service center. SY/T 5107-2005 Recommended practices on measuring the properties of water-based fracturing fluid[S]. Beijing: Petroleum Industry Press, 2005. [23] 徐林静,张士诚,马新仿. 胍胶压裂液对储集层渗透率的伤害特征[J]. 新疆石油地质,2016,37(4):456-459.XU Linjing, ZHANG Shicheng, MA Xinfang. Characteristics of damage of guar fracturing fluid to reservoir permeability[J]. Xinjiang Petroleum Geology, 2016, 37(4):456-459. [24] 谢朝阳,李国,王鑫,等. 大庆油田注聚井解堵增注技术[J]. 大庆石油地质与开发,2003(6):57-59, 74. doi: 10.3969/j.issn.1000-3754.2003.06.021XIE Chaoyang, LI Guo, WANG Xin, et al. The shutoff removing and injection increasing technique of polymer injection well in Daqing Oilfield[J]. Petroleum Geology & Oilfield Development in Daqing, 2003(6):57-59, 74. doi: 10.3969/j.issn.1000-3754.2003.06.021 [25] 马莉,王彦玲,蒋官澄,等. 十六烷基三甲基溴化铵和FC911对砂岩表面润湿性的影响[J]. 油田化学,2011,28(4):419-422.MA Li, WANG Yanling, JIANG Guancheng, et al. Effects of CTAB and FC911 on wettability of sandstone surface[J]. Oilfield Chemistry, 2011, 28(4):419-422. [26] 屈乐,孙卫,杜环虹,等. 基于CT扫描的三维数字岩心孔隙结构表征方法及应用——以莫北油田116井区三工河组为例[J]. 现代地质,2014,28(1):190-196. doi: 10.3969/j.issn.1000-8527.2014.01.020QU Le, SUN Wei, DU Huanhong, et al. Characterization technique of pore structure by 3D digital core based on CT scanning and its application: An example from Sangonghe formation of 116 well field in Mobei Oilfield[J]. Geoscience, 2014, 28(1):190-196. doi: 10.3969/j.issn.1000-8527.2014.01.020 -

下载:

下载: