Study on Optimization of High Temperature Cement Slurry with Elasticity and Toughness

-

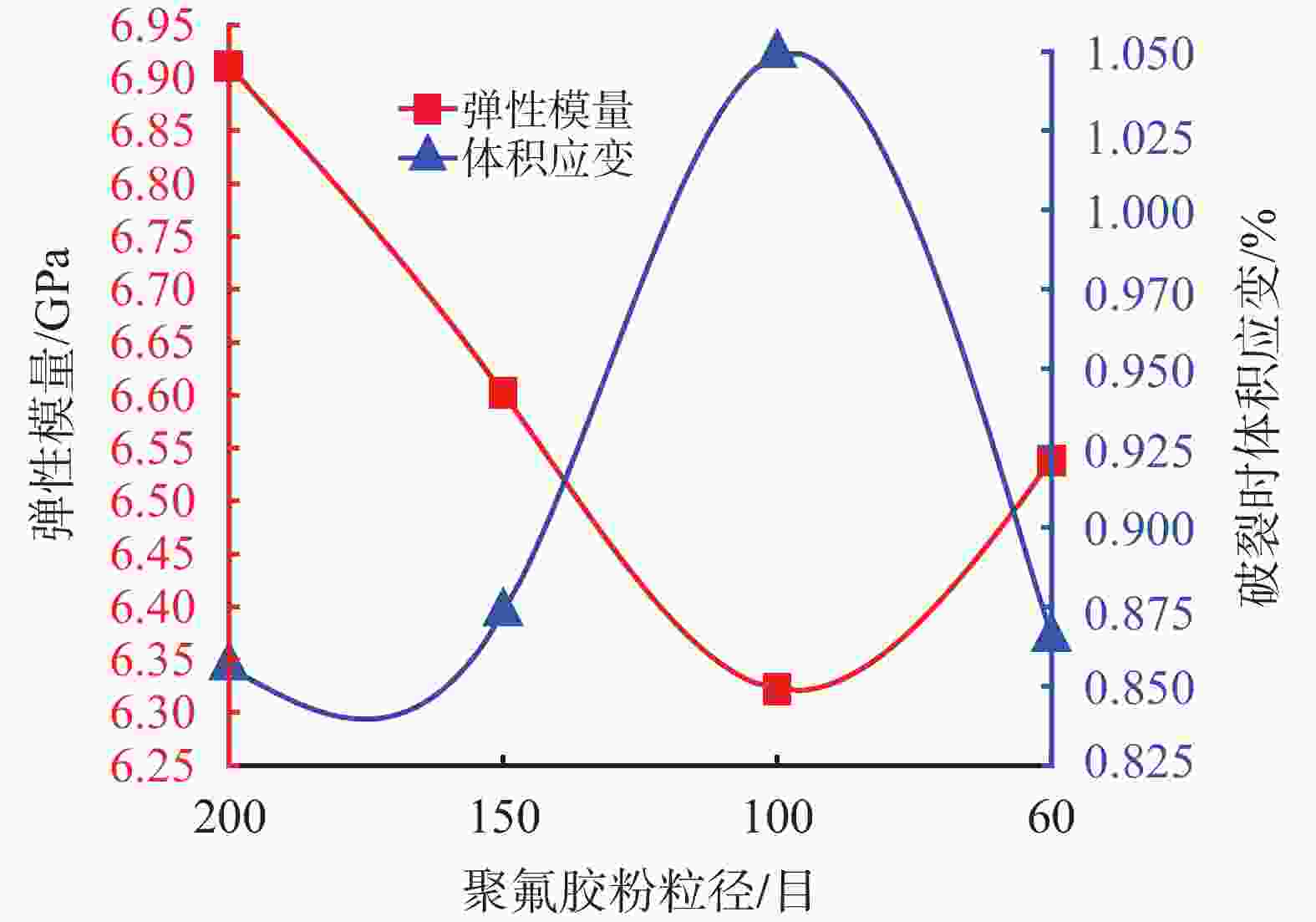

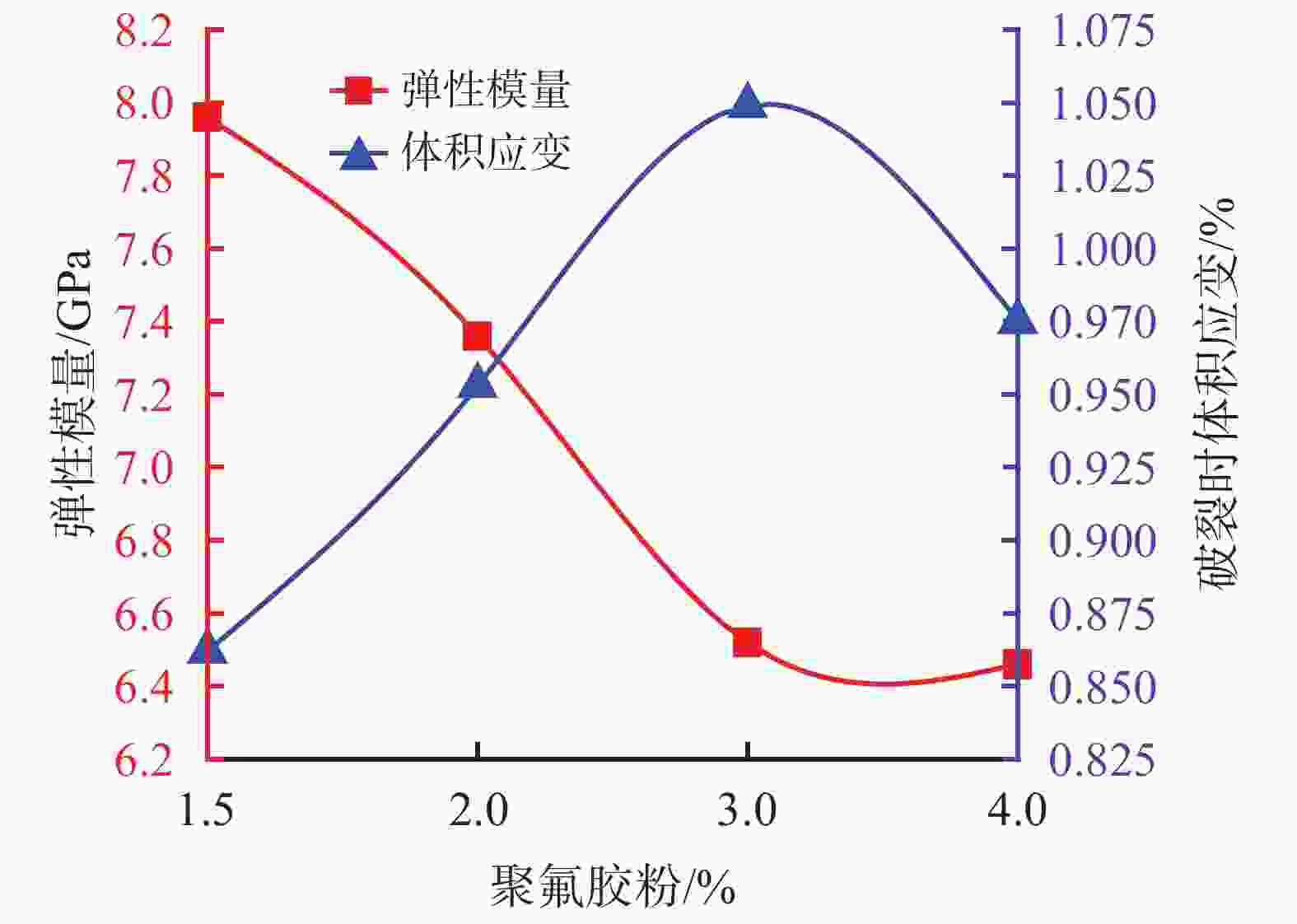

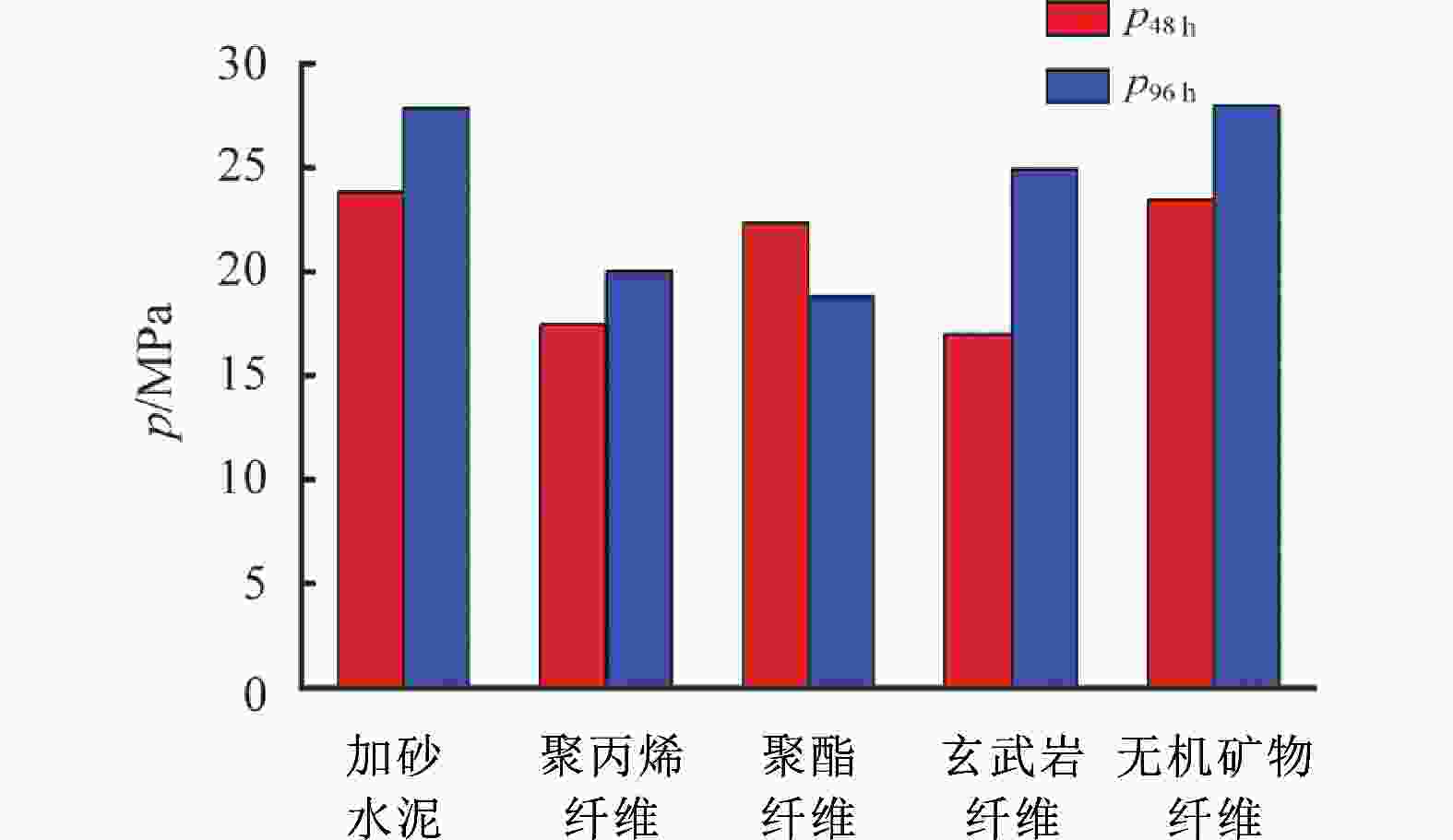

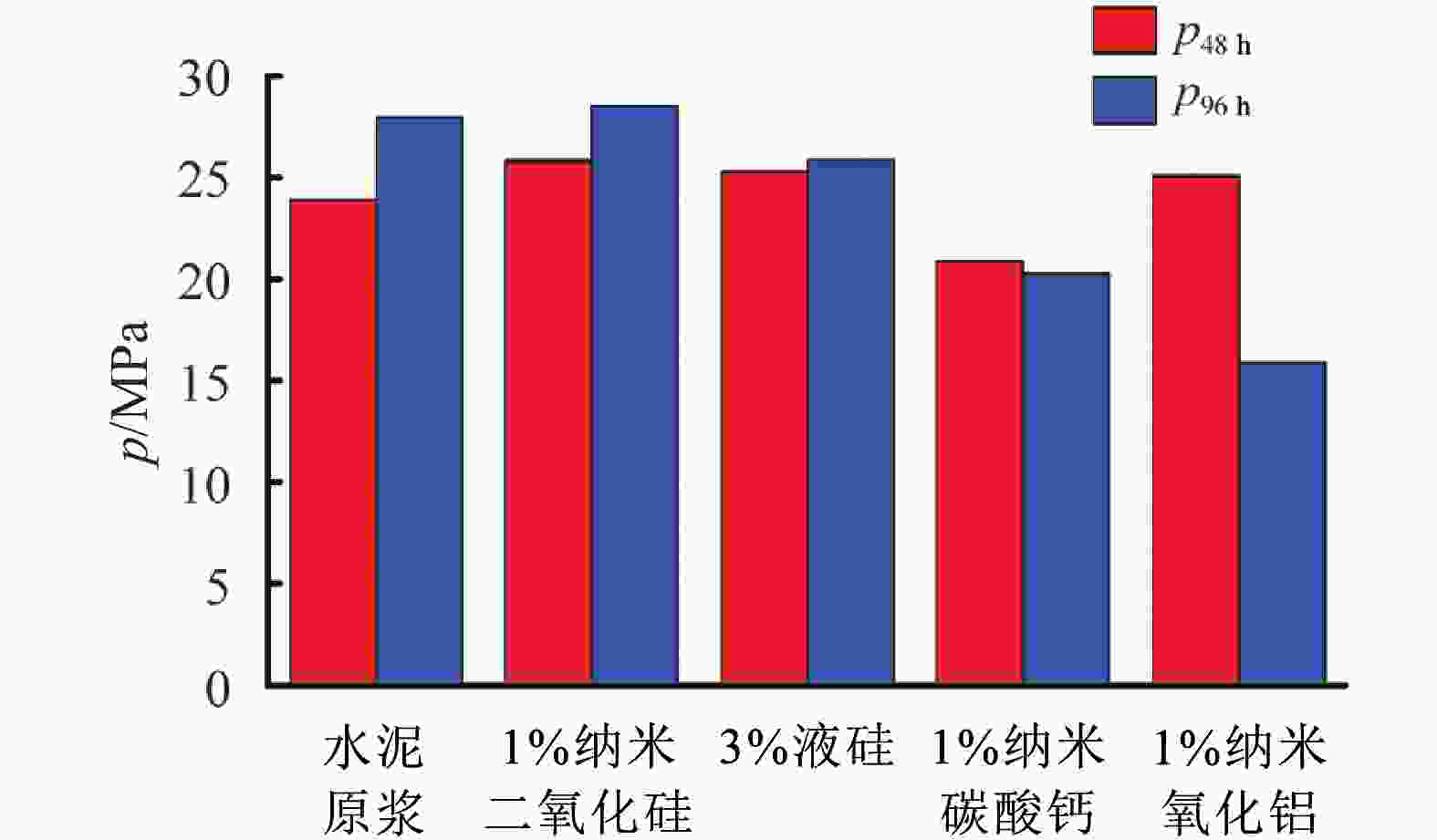

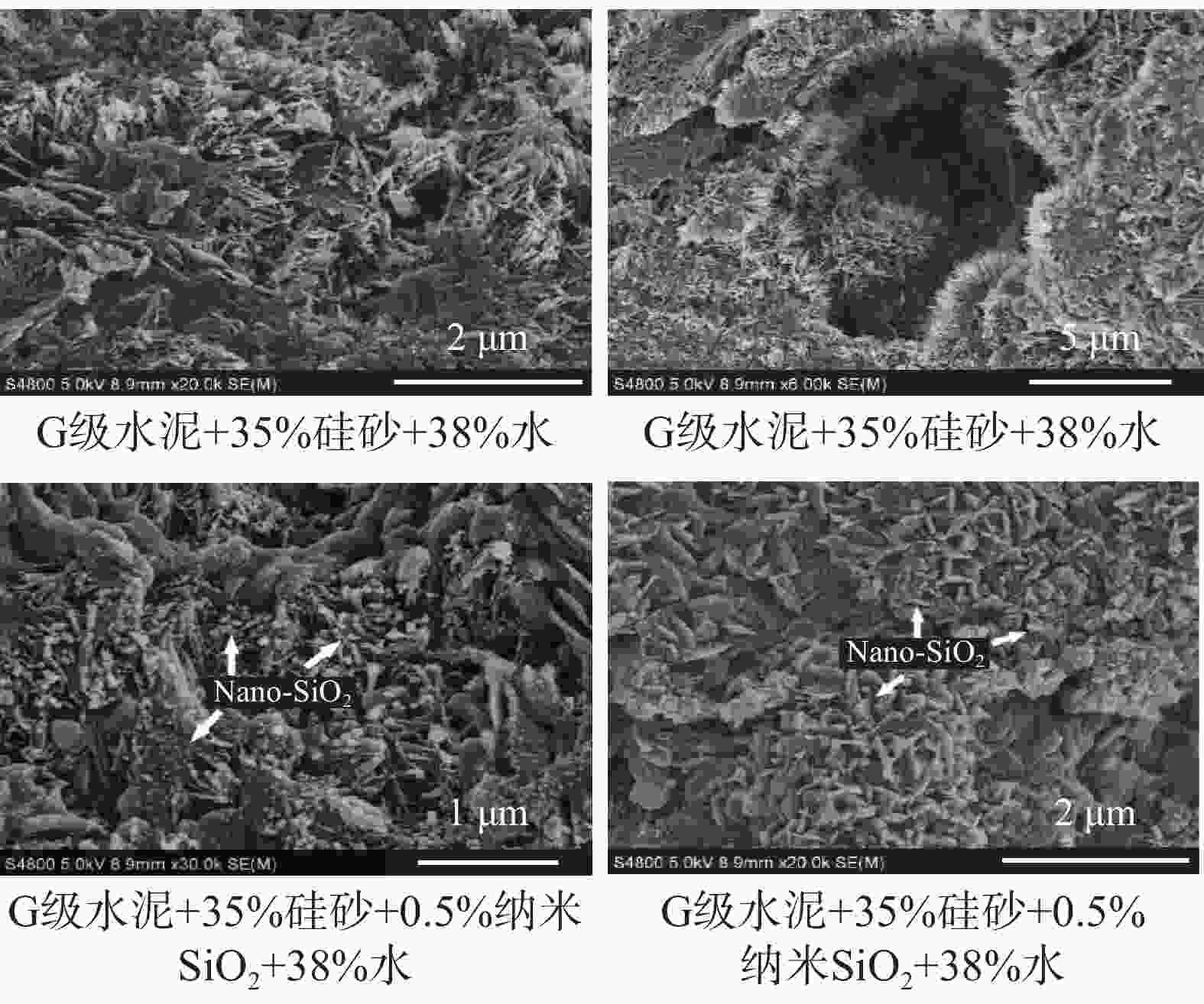

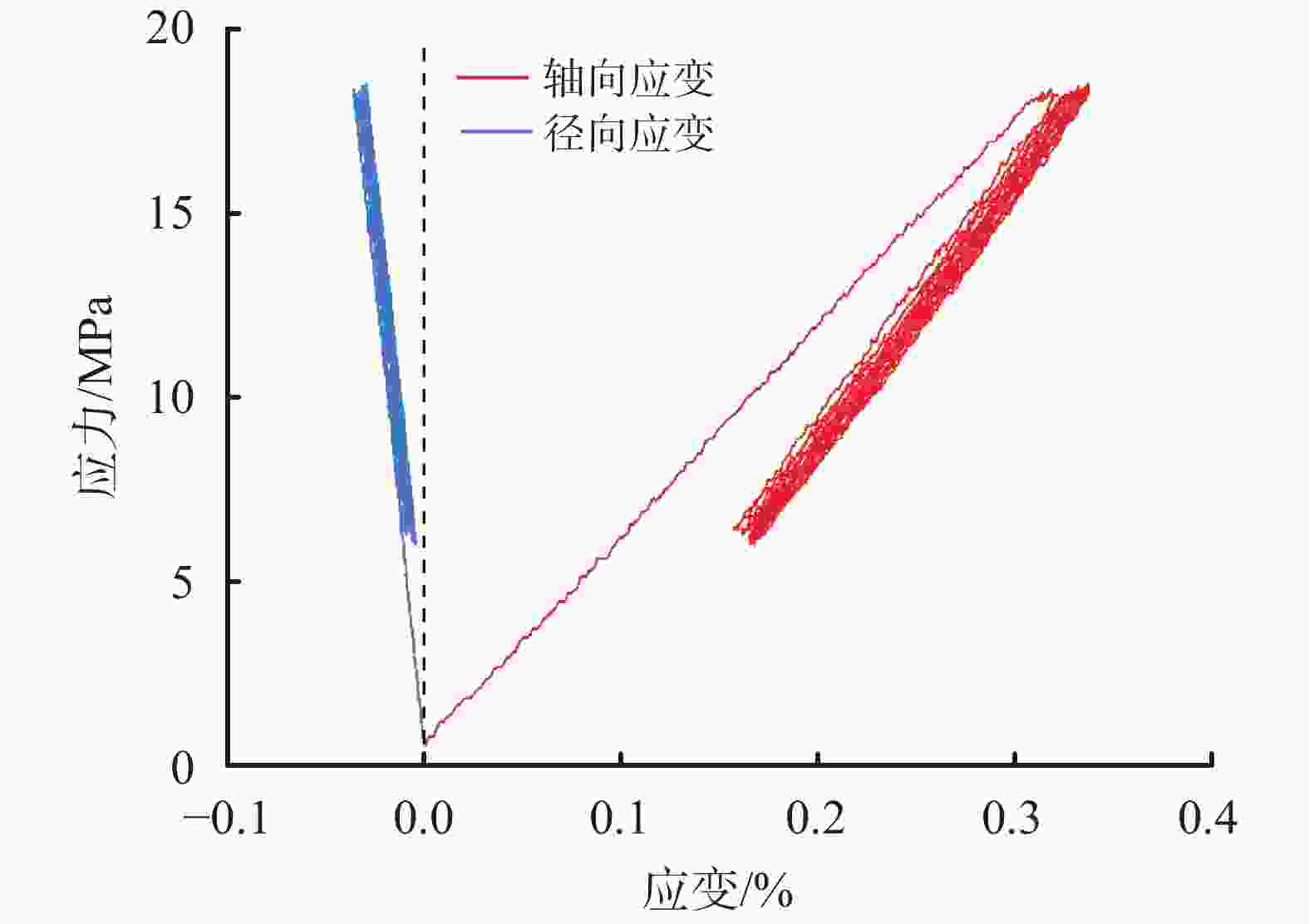

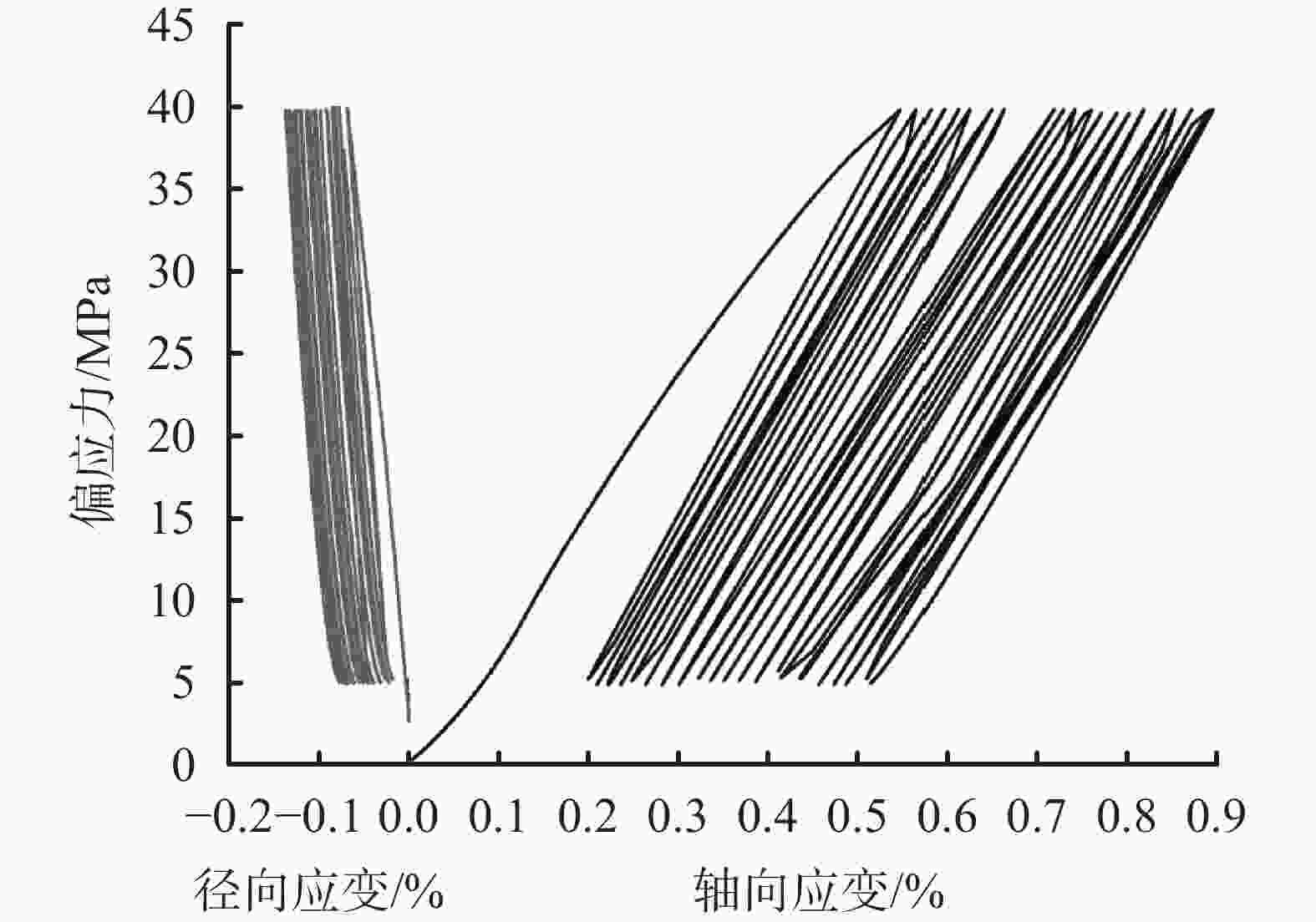

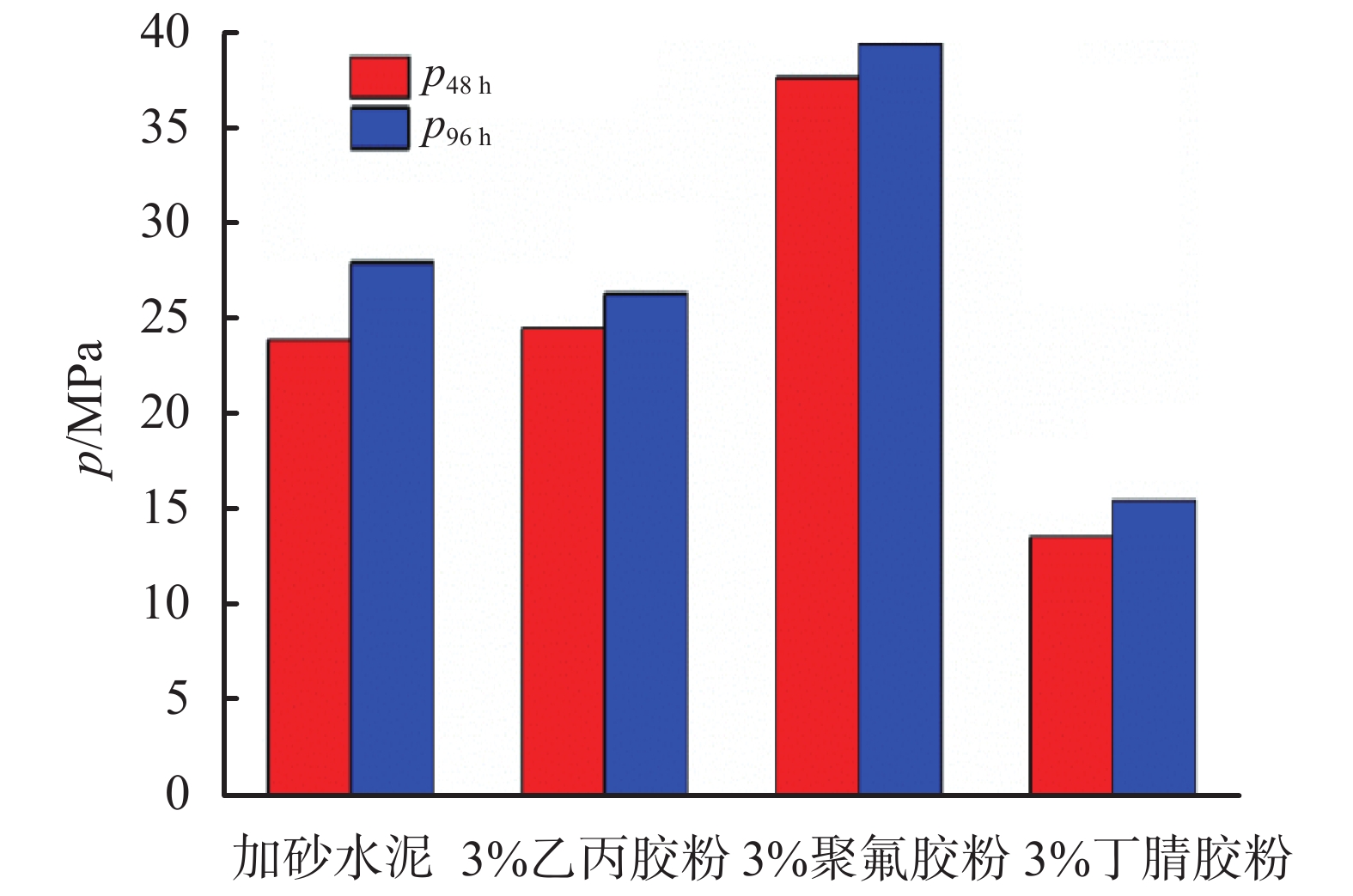

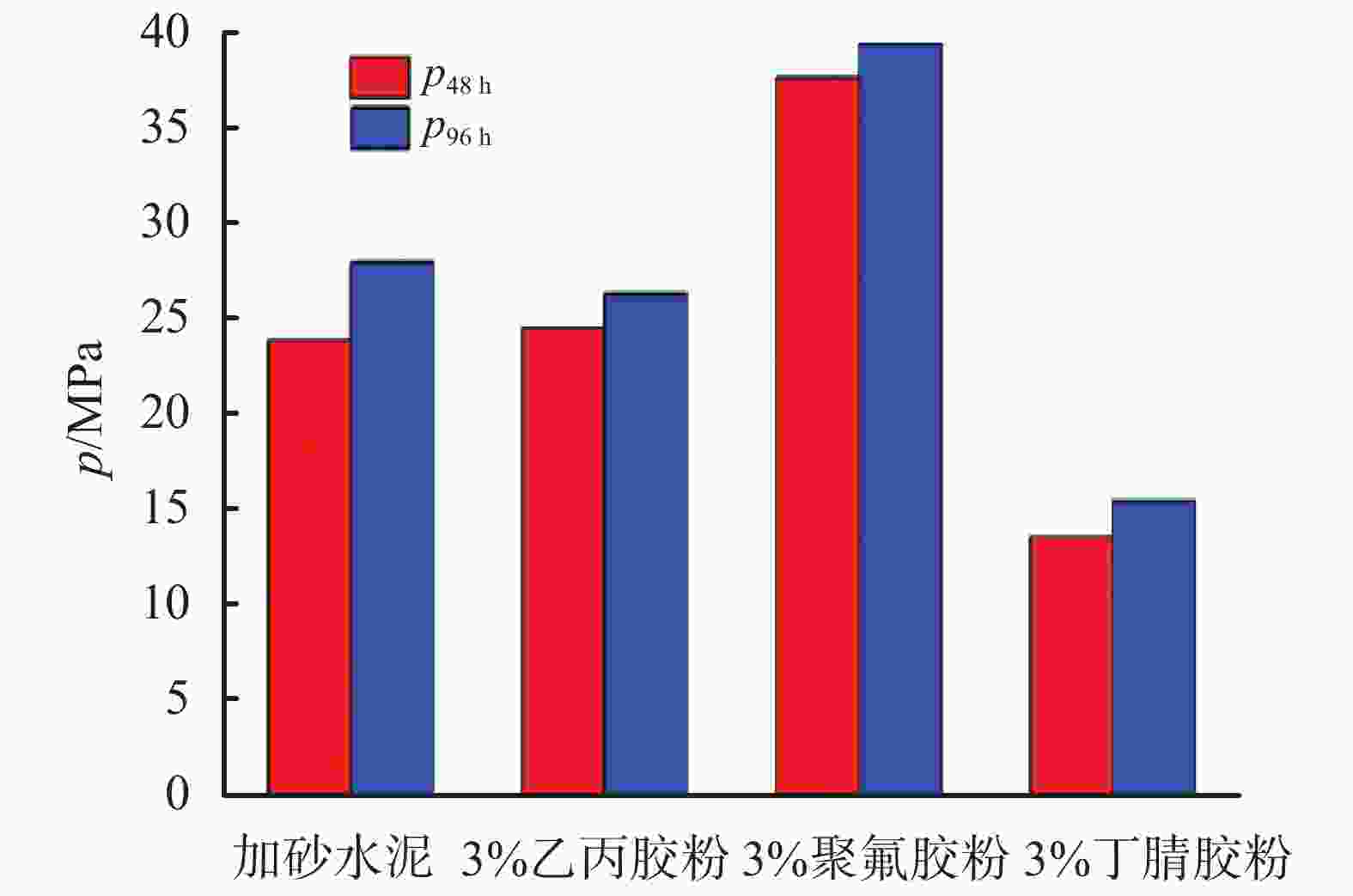

摘要: 在顺北区块和塔中北坡勘探开发过程中,面临着传统水泥石硬脆性明显,在压裂施工中易出现环空微间隙,破坏水泥环完整性的问题。通过理论分析及实验研究,研发了水泥石弹韧性改性新方法,由传统技术的材料高性能发展为结构高性能,通过亲水改性的聚氟胶粉改善水泥石的弹性,有机、无机纤维协同作用增加水泥石的韧性,纳米二氧化硅改善水泥石微观结构增加强度,研发了抗高温弹韧剂,其耐温大于150 ℃,能降低水泥石弹性模量达37.13%,同时保持水泥石具有较高强度,并且具有较好的经济性。以高温弹韧剂为关键,通过评价配套的高温固井外加剂,开发出一套性能良好的高温弹韧性水泥浆体系,体系流变性良好、稠化时间合理、API失水量为45 mL,水泥石弹性模量为6.089 GPa、抗压强度大于30 MPa,满足固井施工要求,为高温高强高韧性水泥浆体系的推广应用奠定了基础。Abstract: In the oil and gas development in the Shunbei block and the Beipo (north slope) block in the middle of Tarim basin, the set cement of conventional cement slurries is found to be hard and brittle, therefore micro gaps are easily to form during fracturing operation, damaging the integrity of the cement sheath. A new method for improving the elasticity and toughness of set cement has been developed through theoretical analysis and laboratory experiment, converting the high performance materials in conventional technology into high performance structure. The elasticity of set cement is improved using a hydrophilically modified poly-fluorine rubber powder, the toughness of the set cement is enhanced through the synergy of organic and inorganic fibers, and the strength of the set cement is increased by improving the microstructure of the set cement with nano-silica. A high temperature elasticity and toughness enhancer was developed. As a cost-effective additive, it works properly at high temperatures up to 150 ℃, it is able to reduce the elastic modulus of set cement by 37.13% and helps the set cement to maintain a higher strength at the same time. Using this high temperature elasticity and toughness enhancer as the key additive, a cement slurry with high temperature elasticity and toughness was formulated with other additives selected through careful evaluation. The cement slurry has good rheology and proper thickening time. The API filter loss of the cement slurry is 45 mL, the elastic modulus and the compressive strength of the set cement are 6.089 GPa and 30 MPa respectively, satisfying the needs of oil and gas well cementing. The development of this cement slurry has set a foundation for the popularization of high temperature high strength high toughness cement slurries.

-

表 1 不同配方水泥石的三轴数据汇总

配方 弹性模量/

MPa泊松比 体积模量/

MPap/

MPa破裂时体积

应变/%1# 10 783.654 0.094 4426.787 46.723 0.591 2# 6993.985 0.127 3125.105 36.792 0.871 3# 6855.029 0.116 2975.273 41.397 0.847 4# 6779.752 0.075 2658.726 46.268 1.232 5# 6940.275 0.101 3865.372 45.490 0.965 6# 6952.897 0.116 3919.156 34.973 1.206 表 2 水泥石在不同温度、压力下的抗压强度

实验条件 p/MPa 24 h 72 h 7 d 110 ℃/20 MPa 20.34 24.90 25.50 130 ℃/20 MPa 23.50 29.65 30.10 150 ℃/20 MPa 24.50 30.86 30.97 -

[1] 杨广国,陶谦,高元,等. 高温高压气井复合型水泥浆体系研究与应用[J]. 科学技术与工程,2016,16(20):151-155.YANG Guangguo, TAO Qian, GAO Yuan, et al. Research and application of high temperature high pressure gas well complex cement slurry[J]. Science Technology and Engineering, 2016, 16(20):151-155. [2] 王文斌,马海忠,魏周胜,等. 抗冲击韧性水泥浆体系室内研究[J]. 钻井液与完井液,2004,21(1):36-39.WANG Wenbin, MA Haizhong, WEI Zhousheng, et al. Laboratory study on impact resistance toughness cement slurry system.[J]. Drilling Fluid & Completion Fluid, 2004, 21(1):36-39. [3] 李为民,许金余. 玄武岩纤维对混凝土的增强和增韧效应[J]. 硅酸盐学报,2008,36(4):476-481.LI Weimin, XU Jinyu. Strengthening and toughening in basalt fiber-reinforced concrete[J]. Journal of the Chinese Ceramic Society, 2008, 36(4):476-481. [4] 步玉环,王瑞和,程荣超. 油气固井纤维水泥浆性能研究[J]. 石油钻采工艺,2005,27(2):25-27.BU Yuhuan, WANG Ruihe, CHENG Rongchao. Performance of fiber cement slurry for well cementation[J]. Oil Drilling & Production Technology, 2005, 27(2):25-27. [5] 李早元,郭小阳. 橡胶粉对油井水泥石力学性能的影响[J]. 石油钻探技术,2008,36(6):52-55.LI Zaoyuan, GUO Xiaoyang. Effects of rubber powder on dynamics properties of oil cement stone[J]. Petroleum Drilling Techniques, 2008, 36(6):52-55. [6] 刘慧婷,刘硕琼,张华,等. 纳米硅溶胶DRN-1L在固井水泥浆中的研究与应用[J]. 硅酸盐通报,2016(11):3536-3540.LIU Huiting, LIU Shuoqiong, ZHANG Hua, et al. Research and application of nano silica sol DRN-1L in cement slurry[J]. Bulletin of the Chinese Ceramic Society, 2016(11):3536-3540. [7] 李明,刘萌,杨元意,等. 碳酸钙晶须与碳纤维混杂增强油井水泥石力学性能[J]. 石油勘探与开发,2015,42(1):94-100.LI Ming, LIU Meng, YANG Yuanyi, et al. Mechanical properties of oil well cement stone reinforced with hybrid fiber of calcium carbonate whisker and carbon fiber[J]. Petroleum Exploration and Development, 2015, 42(1):94-100. [8] 华苏东,姚晓. 复合纤维提高油井水泥石韧性的研究[J]. 钻井液与完井液,2007,24(4):40-42.HUA Sudong, YAO Xiao. Composite fiber improves the toughness of oil-well set cement[J]. Drilling Fluid & Completion Fluid, 2007, 24(4):40-42. [9] 步玉环,王瑞和,程荣超,等. 油气固井纤维水泥浆性能研究[J]. 石油科学(英文版),2005,2(2):88-91.BU Yuhuan, WANG Ruihe, CHENG Rongchao, et al. Performance of fiber cement slurry in the oil and gas well cementation[J]. Petroleum Science, 2005, 2(2):88-91. [10] TANG M, LI J Q, LIU H L, et al. Basalt fiber reinforce cement-based composite materials[J]. Advanced Materials Research, 2012, 1495(751):1837-1842. [11] JESUS MARTIN-DEL-RIO JUAN, MARQUEZ-MARTINEZ GONZALO, ROMERO MACIAS EMILIO, et al. Comparing mechanical behavior of API H-class cement reinforced with carbon, mineral or polypropylene fiber additions[J]. Arabian Journal for Science and Engineering, 2019, 44(6):6119-6125. -

下载:

下载: